What Common Mistakes Shorten a Tractor’s Lifespan? A Manufacturer’s Field Guide

Last month in northern Kenya, I watched a nearly new 75HP tractor with less than 2,000 hours limp off a maize field—main bearings shot, radiator caked in dust, and hydraulic oil1 like black coffee. The operator was stunned: “But it’s not even old yet!” That’s a story I hear too often.

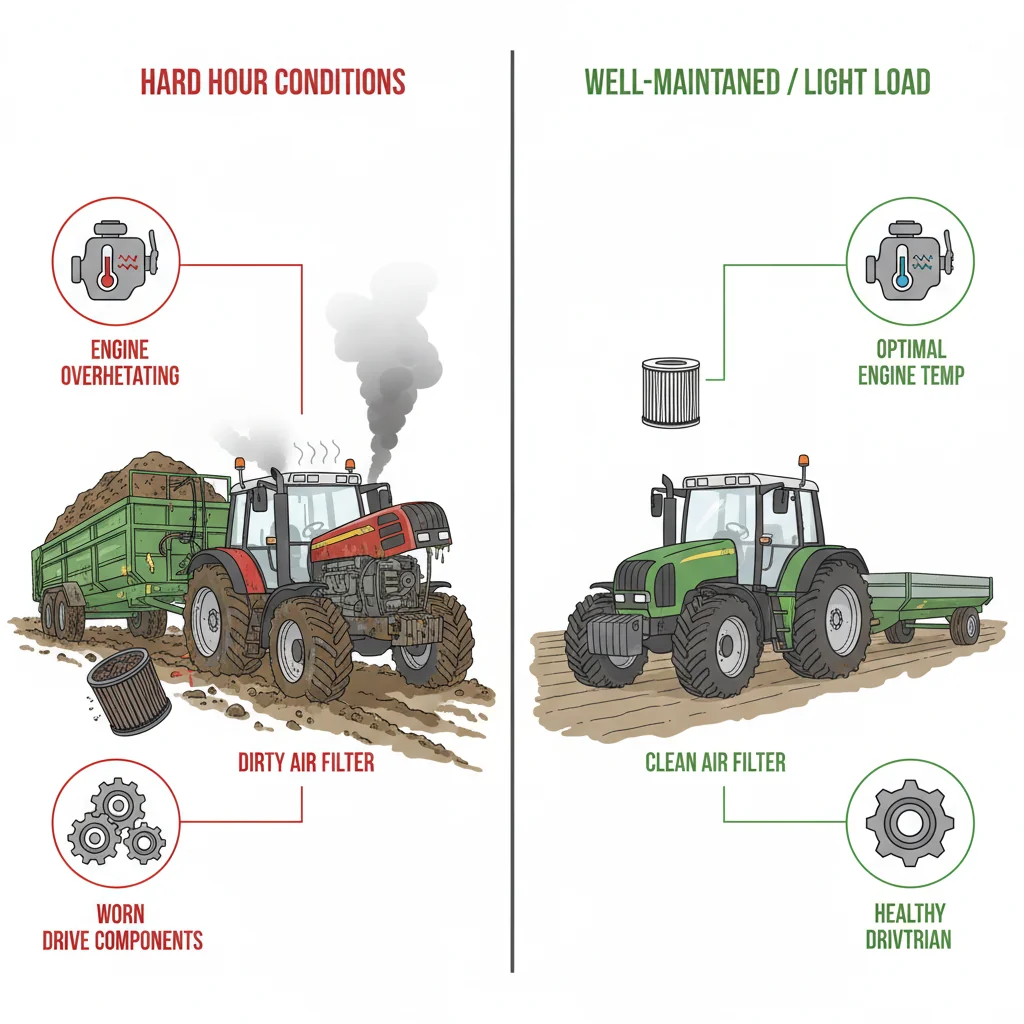

Tractor lifespan is primarily determined by engine hours2 accumulated under proper operating conditions, not by calendar years alone. The most common causes of premature wear are hard hours3, such as overloading, insufficient lubrication, and repeated exposure to dust or water. Skipping hour-based maintenance intervals4, using non-approved oils or filters, and ignoring low fluid levels or minor leaks accelerate mechanical failure.

What Are Tractor “Hard Hours” and Why Do?

Tractor lifespan is defined by engine hours, not calendar years. “Hard hours”—operating under overload, overheating, poor lubrication, or dirty conditions—rapidly accelerate wear. Two machines with identical hours can differ drastically in condition based on usage quality. Minimizing hard hours through proper maintenance and operation is critical for maximizing tractor longevity.

Most people don't realize that a tractor’s engine hours only tell part of the story. What really matters is how those hours were spent. I’ve seen two 90HP 4WD tractors in Kazakhstan, each showing just over 5,000 hours. One ran mostly on flat wheat fields, well maintained, never overloaded. The other pulled heavy trailers up steep, rocky slopes and often worked with low oil—plus the air filters were always clogged with dust. Same hours, but the second tractor’s engine needed a complete rebuild while the first was still running strong.

Let me share something important about “hard hours.” These are the hours when a tractor works under harsh conditions—overloading, running at high RPMs for long stretches, or operating with dirty oil and clogged filters. Even simple things like cold starts in winter, then immediately pushing the tractor to full load, will count as hard hours. I’ve seen it in Peru: one customer started his 75HP unit every morning and went straight to plowing heavy clay without warming up. After just three seasons, the engine lost compression and the hydraulic pump failed. That’s a short service life.

To be honest, avoiding hard hours is the best way to extend tractor life. Warm up the engine, check oil and coolant levels, and clean the air filters, especially in dusty regions. Never run implements beyond the rated three-point hitch or PTO limits—if your plow needs more than 2,400 kg lift, upgrade your tractor or lighten the load. I always suggest treating every start as an investment in longer service.

Frequent operation of a tractor with clogged air filters causes abrasive dust to enter the engine, leading to significantly faster internal wear even if total engine hours are not high.True

A clogged air filter allows fine dust particles to bypass filtration, contaminating the engine oil and causing accelerated wear of cylinder walls, pistons, and rings. This kind of 'hard hour' use degrades engine life much faster than operating in clean conditions.

A tractor that is regularly overloaded on flat fields will experience less wear than one that operates within its rated capacity on hilly terrain.False

Overloading a tractor, even on flat terrain, puts excessive stress on the engine, transmission, and driveline components, resulting in increased wear and risk of failure. Properly rated loads on hilly terrain are challenging, but consistent overloading on any terrain is more damaging in the long run.

Key takeaway: Tractor longevity depends more on the quality of operating hours—avoiding overload, overheating, and poor maintenance—than on age or total hours alone. Focusing on reducing 'hard hours' is the most effective way to extend a tractor’s service life and reduce major repairs.

Does Skipping Hour-Based Service Harm Tractors?

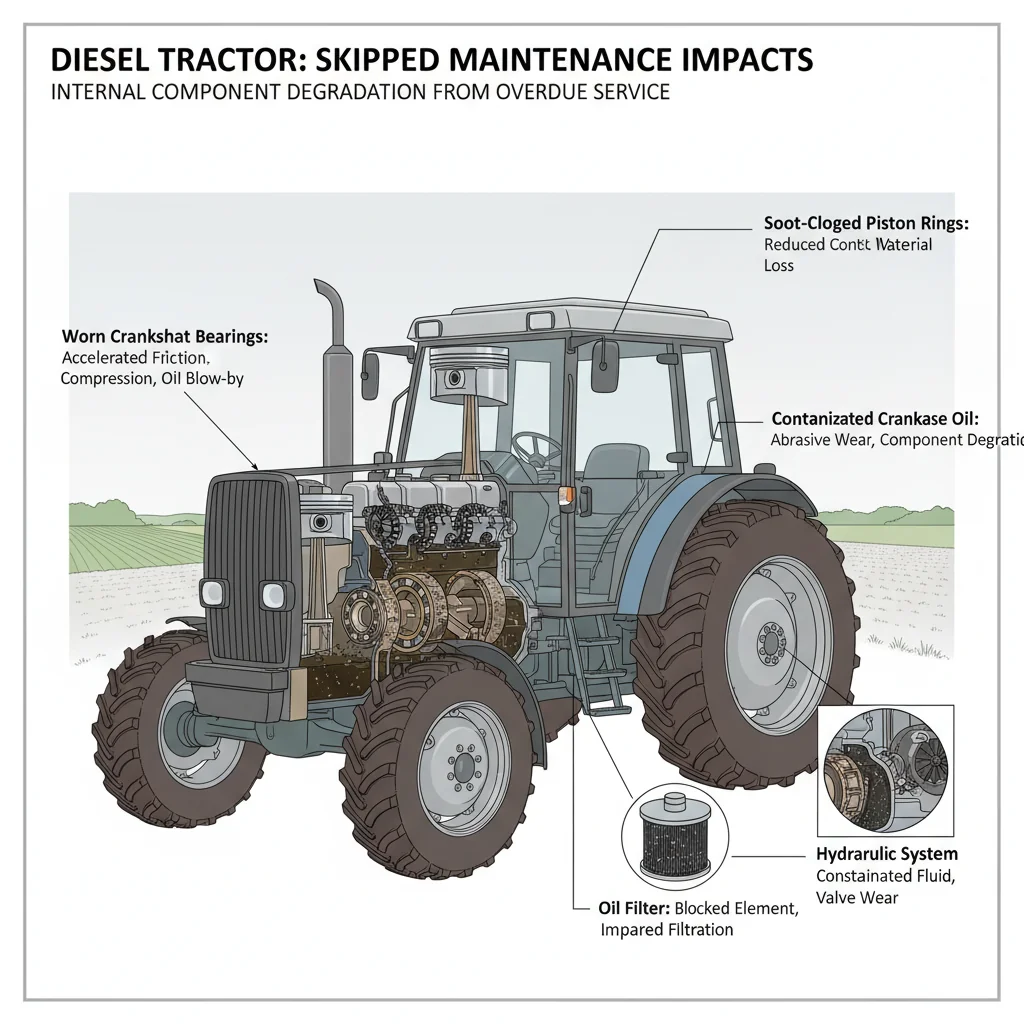

Neglecting hour-based maintenance intervals dramatically shortens tractor lifespan. Diesel engines accumulate soot and fuel contaminants based on running hours, not calendar time. Exceeding recommended oil and system service intervals by 1.5–2× accelerates wear on bearings, turbochargers, and hydraulics—often leading to costly failures far earlier than expected.

The biggest mistake I see is farmers using the calendar instead of the hour meter for service. On a recent visit to a cooperative in Bolivia, I found several 80HP tractors with over 600 hours since their last oil change—more than double the recommended interval. The engines all sounded fine, but when we drained the oil, it was pitch black and thick with soot. I’ve seen this cause bearing wear and even turbocharger failure long before the tractors reach 4,000 hours. Diesel engines don’t care about months—they wear down by running hours.

Here’s what matters most when it comes to maintenance: oil and filters need freshening after about 250–300 hours, not just once a year. This isn’t just about the engine. Contaminated oil moves through the hydraulic system, damaging pumps and making controls sluggish. In Kazakhstan, one customer ignored hour-based service on a 120HP unit. The result? Hydraulic lift problems5 during peak harvest because the filter was clogged. They lost two days waiting for a replacement pump, plus the cost of emergency repairs.

To be honest, I always suggest keeping a simple logbook—just a notebook or a phone app in the cab. Record engine hours and what service you’ve done. Build three habits: daily walk-around checks, a quick grease and clean every 50 hours, and stick to the factory intervals for oil, filters, and hydraulics. That’s what separates a 10,000-hour workhorse from a 3,000-hour “worn-out” tractor. A little discipline saves thousands in repairs and keeps your equipment working when you need it most.

Relying solely on the calendar for tractor servicing can lead to accelerated engine wear, because engine oil degrades more from cumulative run hours than from simply sitting idle.True

Tractor engines accumulate contaminants and experience lubrication breakdown based on operating hours, not elapsed time. This means oil and filters may be far past their effective lifespan if servicing is based only on months or years, especially during high-use periods.

As long as the engine sounds normal and there are no warning lights, skipping hour-based service intervals will not cause any significant harm to the tractor.False

Many forms of internal engine damage, such as bearing wear and oil sludge buildup, develop silently and do not trigger alarms or cause immediate noise. Regular hour-based servicing is essential to prevent unseen wear that shortens engine life.

Key takeaway: Always follow hour-based maintenance schedules for engine oil, filters, and hydraulic systems6—not just annual or seasonal checks. Ignoring the hour meter leads to premature wear, expensive repairs, and can halve a tractor’s working life. Simple recordkeeping and routine adherence are vital for maximizing equipment value.

Are Cheap Oils and Filters Damaging?

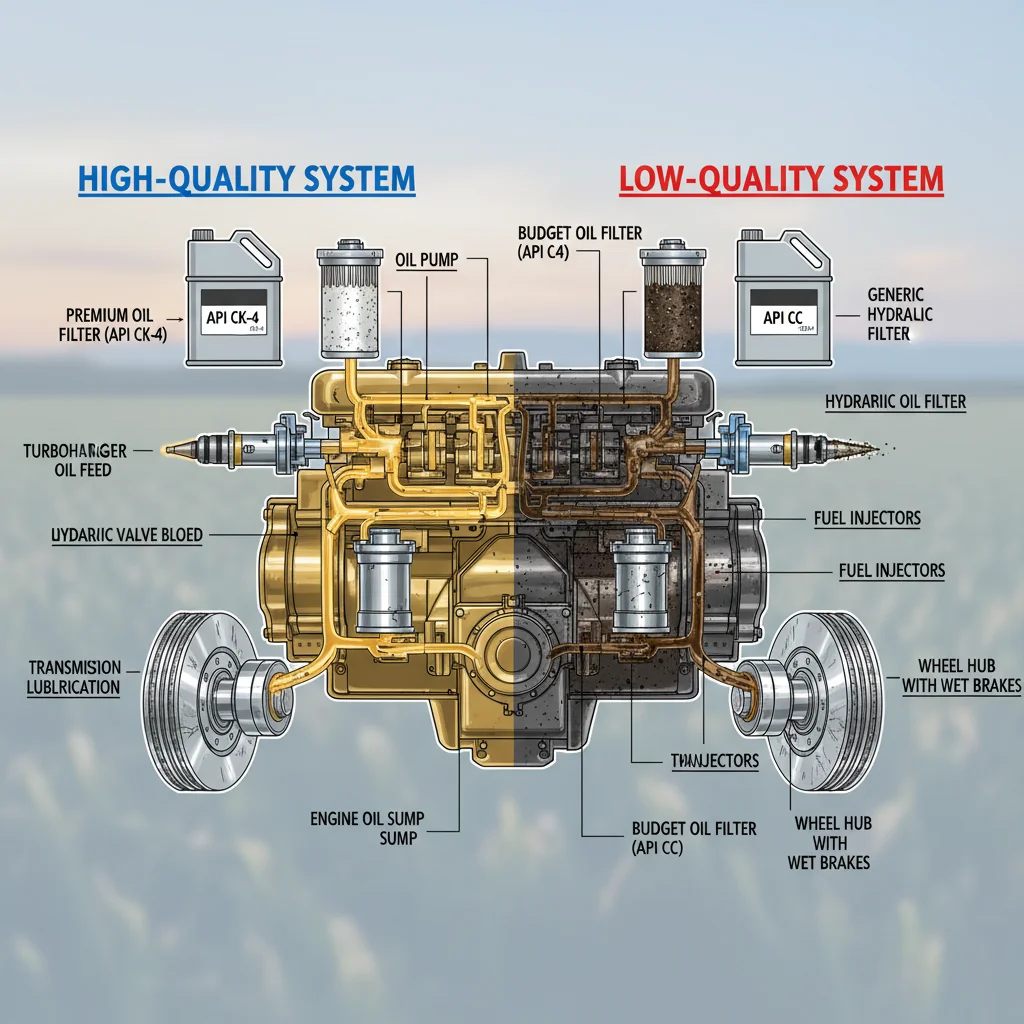

Using low-cost or incorrect engine oil and filters can severely reduce tractor lifespan. Modern diesel engines and hydraulic systems require oils with specific ratings (such as API CI-4/CK-47) and correct viscosities. Inferior oils or filters allow contaminants to damage injectors, pumps, and wet brakes, resulting in costly repairs far exceeding any initial savings.

Let me share something important about tractor maintenance that comes up again and again, especially in places like Bolivia and Kazakhstan. Choosing the cheapest oil or filter might look like a smart way to save a few dollars. But in reality, modern diesel engines and hydraulic systems aren’t built for shortcuts. I’ve seen a 90HP 4WD tractor in rural Peru start having injector issues just 600 hours after a cheap, off-brand oil was used. The repair bill for new injectors and a high-pressure pump was over $2,500—far more than any savings from budget fluids.

Here’s the thing—engine and hydraulic oils need specific ratings, like API CI-4 or CK-4, and the right viscosity for your climate. If you use a 15W-40 oil in a cold region, the engine might run dry for the first few minutes each morning. Too thin oil in tropical heat? Bearings and turbochargers can wear out early. I always suggest checking your manual for the recommended oil type; it’s usually written right next to the dipstick or filter housing. For hydraulic systems, generic “universal” oil often doesn’t meet the specs for wet brakes and clutches. I’ve heard from several Kenyan contractors who ended up with noisy brakes and early clutch failures after using supermarket-grade oils. The cost to fix? Sometimes $1,000 just for brake parts.

Low-quality filters are another hidden risk. They might cost $10 less, but if they let abrasive dust or water into your fuel or oil system, the damage can be severe and fast. I recommend always choosing filters that meet or exceed the tractor manufacturer’s specifications. It’s a small investment that protects your biggest asset in the field.

Using low-quality oil filters in modern tractor engines can lead to premature injector wear due to insufficient filtration of fine contaminants.True

Modern diesel engines rely on high-pressure fuel systems with very tight tolerances. Cheap filters often fail to capture micro-particles, allowing abrasive materials to circulate and accelerate wear, especially in components like injectors.

All oils labeled as 'universal tractor oil' provide the same level of protection for both hydraulic and engine systems, regardless of brand.False

Universal tractor oils can vary greatly in their additive packages and base oil quality. Some off-brand or cheap oils might not meet the required specifications for modern engines or hydraulic systems, leading to inadequate protection and increased risk of component failure.

Key takeaway: Always use oils and filters that meet or exceed manufacturer specifications. Cutting costs with generic lubricants or low-quality filters may lead to premature engine, hydraulic, or brake failure, resulting in expensive repairs and reduced tractor reliability—especially in demanding climates and field conditions.

What Happens If Tractor Fluids Run Low?

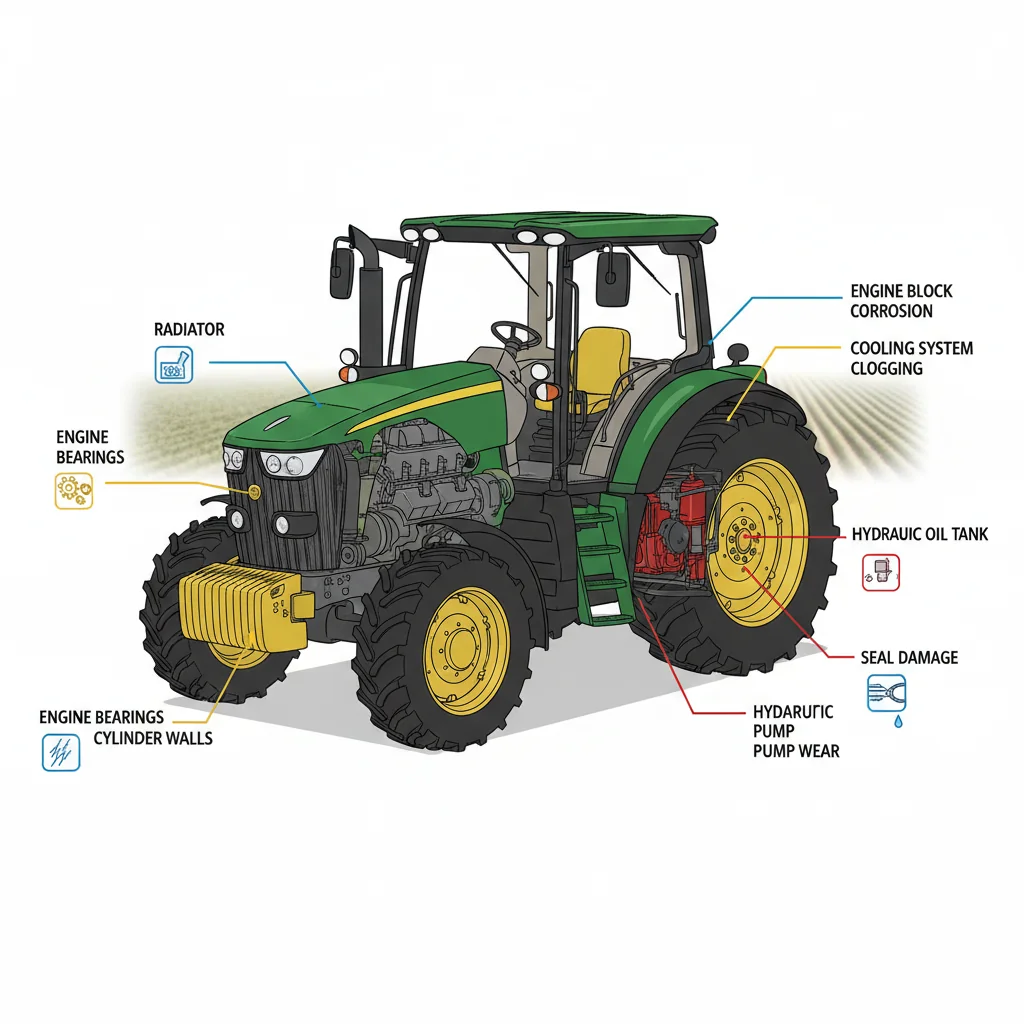

Running a tractor with low or contaminated fluids—such as engine oil, coolant, or hydraulic oil—rapidly increases component wear. Insufficient engine oil exposes bearings and cylinder walls, while dirty or low hydraulic fluid leads to pump cavitation and seal failure. Regular fluid checks and prompt leak repairs are essential for maintaining tractor longevity.

I've worked with customers in Kenya and Peru who underestimated the damage that low or dirty fluids can cause. One farmer in Nakuru, Kenya called me after his 85HP tractor’s engine seized during plowing season. He’d been topping off with just any oil he found locally, not realizing he’d run the engine for weeks with both low and contaminated oil. The result? Scored cylinder walls and destroyed bearings. Repairs took over two weeks and cost nearly as much as a year’s worth of preventive maintenance.

The reality is, even a small hydraulic oil leak—just a drip under the pump or a damp hose—gets ignored far too often. I saw this last year in Bolivia: a distributor lost two hydraulic pumps on 75HP units because operators kept running with low fluid. The pumps started to cavitate, making a whining noise and losing pressure. By the time they stopped to investigate, the damage was done. Replacing a hydraulic pump is not cheap, and waiting for parts in remote regions can mean weeks of downtime.

From my experience, a quick daily check makes all the difference. Before starting up, I always suggest checking the engine oil8 dipstick, coolant level, and scanning under the tractor for wet spots or puddles. Look at your hydraulic hoses and cylinders—if you see any sign of oil, fix it before it becomes a bigger problem. Topping off with the right fluid and replacing worn hoses early is far less expensive than losing a season’s work to a major failure.

Running a tractor engine with low hydraulic fluid can cause the hydraulic pump to overheat and fail, even if the engine oil is at the correct level.True

Hydraulic pumps rely on fluid both for pressure generation and cooling; operating with low fluid can cause excessive heat buildup and rapid wear, leading to pump failure regardless of the engine oil condition.

Using clean engine oil from any automotive shop is always suitable for tractor engines, as all oils provide the same level of protection.False

Tractor engines often require oils with specific additives and viscosity suited for heavy-duty, high-temperature agricultural use; automotive oils may lack the necessary properties, leading to inadequate lubrication and increased engine wear.

Key takeaway: Ignoring low or dirty fluids in tractors accelerates wear on critical components and can lead to catastrophic failures, such as engine overheating or hydraulic pump damage. Consistent fluid checks and proactive leak repairs are simple, cost-effective steps that significantly extend a tractor’s service life.

How Does Cooling System Neglect Harm Tractors?

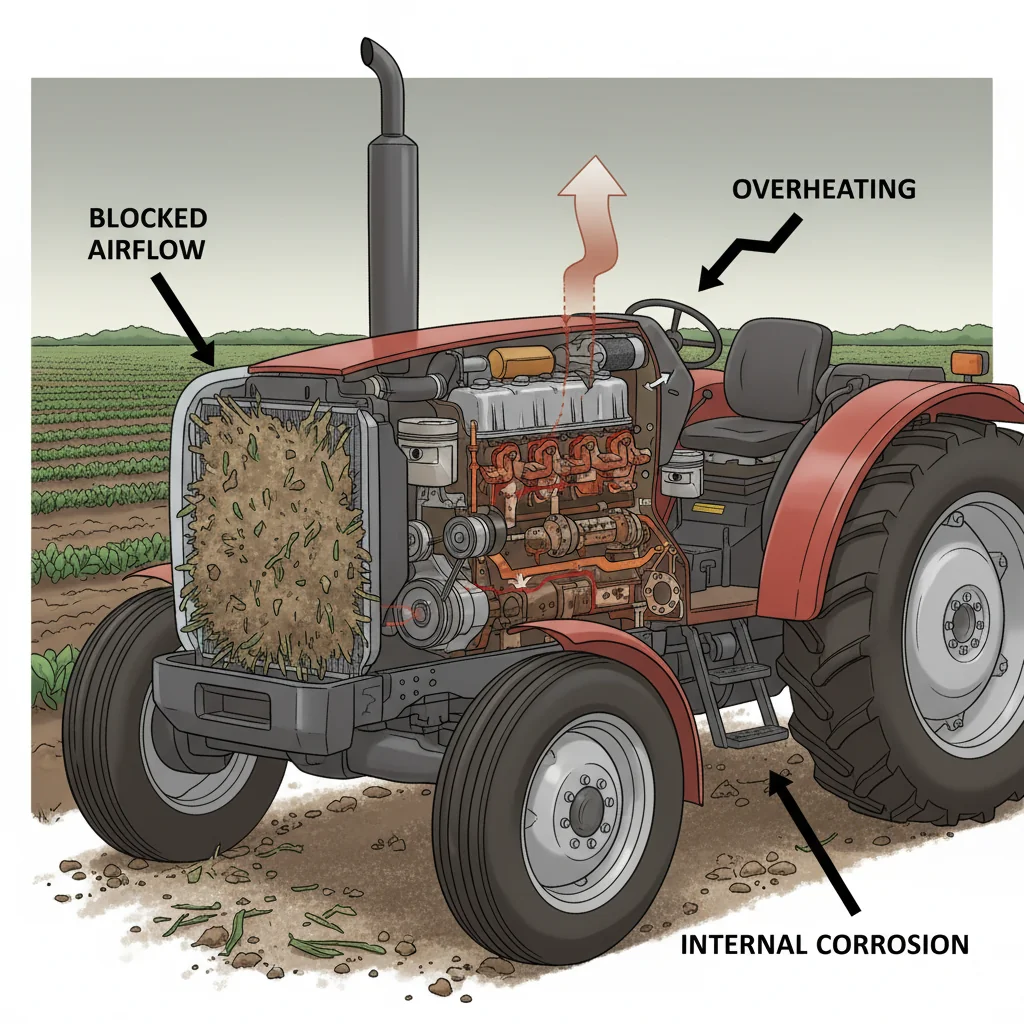

Neglecting the tractor’s cooling system—such as allowing radiator fins9 and air intakes to clog with dust or debris—causes overheating, which rapidly shortens engine lifespan. Using plain water instead of a 50:50 antifreeze and demineralized water mix10 also promotes internal corrosion, leading to costly repairs and reduced reliability.

Here’s what matters most when looking at tractor engine reliability: cooling system neglect quietly destroys more engines than any other maintenance mistake I see. Just last year, I had a customer in Bolivia with a fleet of 80HP tractors—solid workhorses, but they kept blowing head gaskets during maize harvest. When I visited, the radiator fins were packed tight with dust and husks, and the air intake screens hadn’t been cleaned in weeks. The temperature gauge had nudged into the red several times, but the operators “just finished the row.” That small delay resulted in warped cylinder heads and a repair bill that wiped out their fuel savings for the season.

From my experience, this mistake isn’t limited to big farms or one country. I’ve seen smaller growers in Nigeria and Kazakhstan run into the same issues, especially during dry seasons or when working with chaffy crops. Many think topping up with plain water is fine, but hard well water leads to scale buildup inside the radiator, and without proper antifreeze, internal rust eats away at pumps and liners. I always suggest using a 50:50 mix of antifreeze and demineralized water, changed every two to three years. It’s a small expense compared to an engine rebuild.

The reality is, cleaning radiator screens and checking coolant should be part of your daily routine—especially in dusty conditions. Watch the temperature gauge closely. If it climbs, stop immediately and clear the blockage. Taking a few minutes now saves thousands later. Most tractor engines will last double the hours if you keep them cool and corrosion-free.

Chronic neglect of a tractor’s cooling system often leads to warped cylinder heads and premature engine failure, because sustained overheating alters metal tolerances and gasket integrity.True

Overheating from a clogged or poorly maintained cooling system causes expansion and warping of engine components, especially the cylinder head, which disrupts sealing surfaces and leads to gasket failure and ultimately major engine damage.

If a tractor’s cooling system is neglected, simply topping off coolant fluid occasionally is enough to prevent engine damage during heavy workloads.False

Merely adding coolant does not address underlying issues such as blocked radiator fins, dirty air intake screens, or deteriorated hoses; these problems will still cause overheating and engine damage even if fluid levels appear normal.

Key takeaway: Regular cleaning of radiators and screens, maintaining proper coolant mixtures, and immediate response to rising temperature gauges are essential to prevent engine damage. Overheating from cooling system neglect is a leading cause of premature engine failure in conventional farm tractors.

What Happens If Tractor Grease Points Are Ignored?

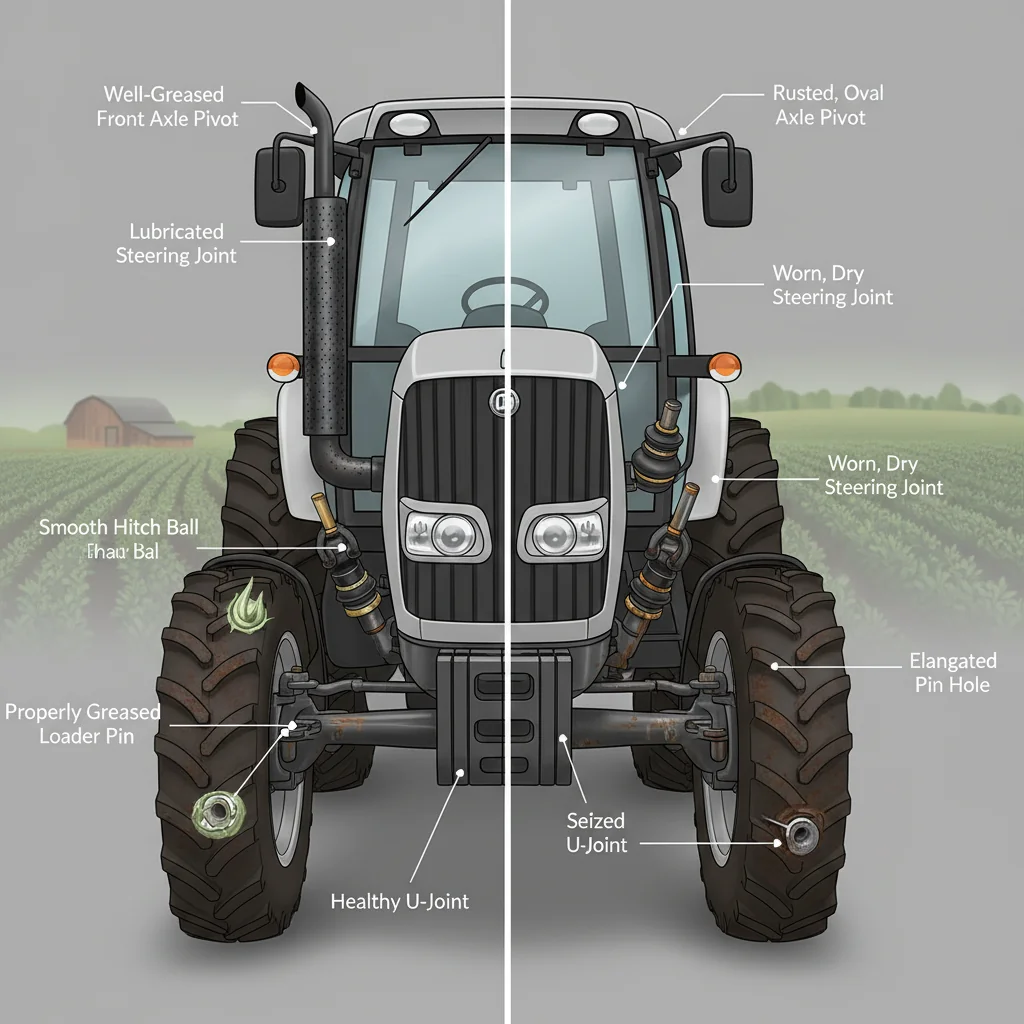

Neglecting tractor grease points—such as front axle pivots, steering joints, U-joints, hitch balls, and loader pins11—leads to accelerated wear, increased friction, and the formation of oval holes or rust. This lack of lubrication often results in costly repairs, with minor maintenance failures escalating into significant component damage over time.

I've worked with customers in Bolivia and Kenya who learned the hard way what happens when grease points get ignored. On a 75HP 4WD tractor, one farmer in Cochabamba skipped routine greasing for a full planting season—by harvest, the front axle pivots were so worn that the holes had turned oval and started to clunk. What should have been a simple, five-minute greasing job every week became a $600 axle rebuild. I see similar problems with loader pins and U-joints. When these parts run dry, metal grinds on metal. You’ll hear squeaks at first, then notice loose steering, and eventually face seized joints or snapped pins.

To be honest, this kind of failure never happens overnight. It’s a slow build-up—especially in muddy or wet conditions where water displaces old grease and brings rust. In Tanzania, I visited a farm running several 90HP units. They worked through the rainy season without greasing the three-point hitch balls. After three months, rust locked up the balls, and it cost them at least two working days to free everything up and replace the worst joints. That’s lost time and a bill of several hundred dollars, all because a $3 grease nipple was neglected.

Here’s what matters most: regular greasing—every 50 to 100 hours, or more often in heavy rain or dust—prevents these headaches. Keep a dedicated grease gun in the tractor shed. Wipe each fitting before you pump in fresh grease. I always suggest making a simple chart of all grease points; this habit will save you from expensive repairs, especially when spare parts take weeks to arrive.

Neglecting tractor grease points can cause bushings and pins to wear into oval shapes, leading to imprecise steering and expensive repairs.True

Without regular greasing, metal-on-metal contact increases friction and wear, causing originally round holes and bushings to deform into oval shapes. This results in sloppy connections and can compromise steering accuracy or loader performance, often requiring costly replacement or machining.

If tractor grease points are ignored, the only consequence is that the machine will become slightly noisier, but its components will remain structurally sound.False

Ignoring grease points does more than increase noise; it leads to accelerated wear, deformation, and sometimes catastrophic failure of key components like pivots, U-joints, and pins. Structural integrity is compromised over time, not just operational comfort.

Key takeaway: Regularly greasing all critical tractor lubrication points, especially every 50–100 hours, prevents expensive component failures. Ignoring these areas can turn a low-cost maintenance task into major repair costs and extended downtime, particularly in harsh or wet field conditions.

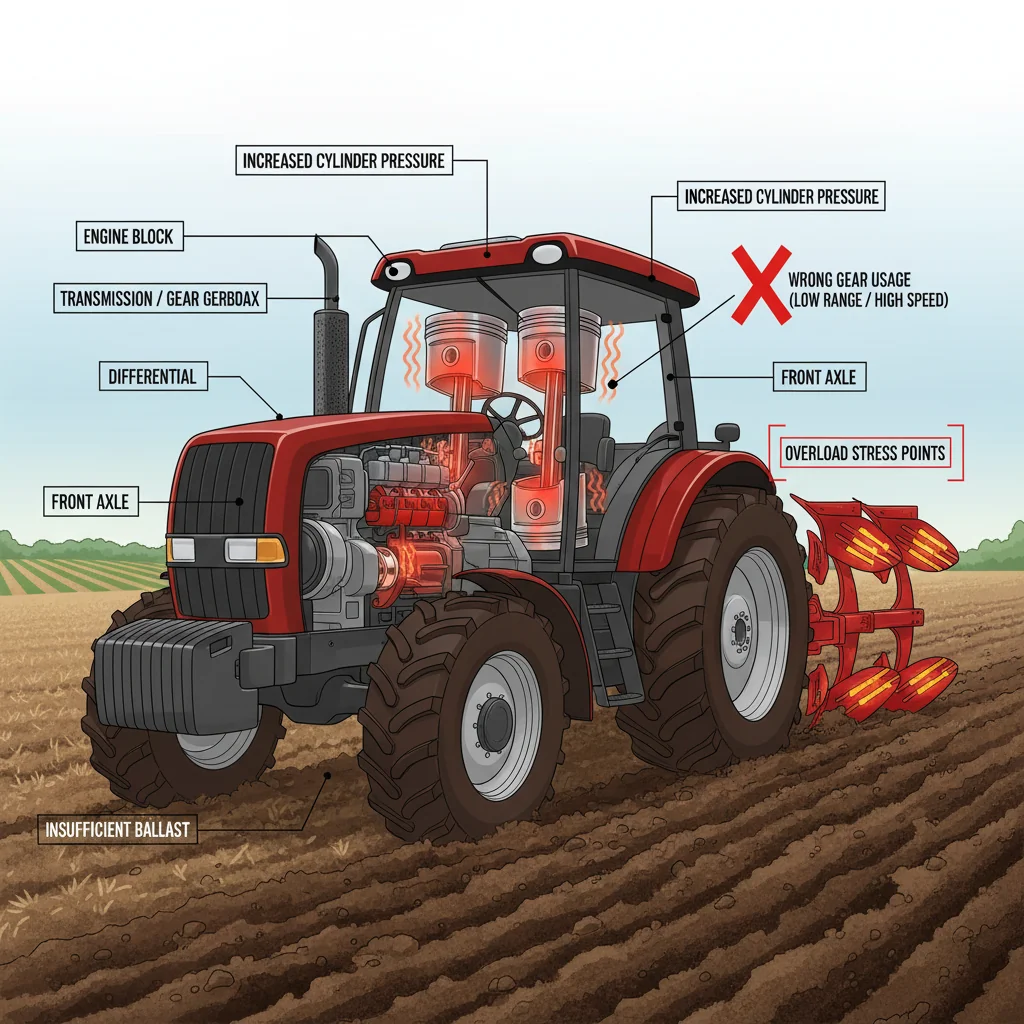

Does Overloading Damage Tractor Engines?

Consistently operating a tractor beyond its rated limits—such as using oversized implements, incorrect gears, or insufficient ballast12—raises engine stress and overloads the drivetrain. Prolonged lugging13 at low RPM under heavy load increases cylinder pressures, accelerating wear on bearings and crankshafts. Correct gear selection and proper implement matching14 are essential to prevent premature mechanical failure.

Last month, a contractor in northern Kazakhstan sent me photos of a 95HP tractor that had snapped a connecting rod during deep tillage. He’d paired it with a heavy 4m disc harrow—well beyond what the PTO and drawbar were rated for. The engine was constantly lugging in too high a gear, with RPM dropping below 1,600 for hours at a stretch. That’s a recipe for disaster. When a diesel engine is forced to work under heavy load at low RPM, cylinder pressures spike, and the crankshaft, bearings, and pistons take a real beating. In this case, repairs cost almost as much as a used 60HP tractor.

From my experience, this problem isn’t limited to one country. I’ve seen similar failures in Peru and Nigeria—especially when people add larger implements after upgrading just the tractor. Pulling a 3-bottom plough with a machine designed for 2 can overload the entire drivetrain. You’ll notice symptoms like stalling in tough soil, overheating, or front tires lifting off the ground when running a loader without enough rear ballast. These are all red flags.

The reality is, a tractor should handle long, demanding jobs at roughly 65–80% of its rated power—not at the very edge. I always recommend checking the implement size against your tractor’s PTO and three-point hitch capacity. Run the engine within its torque band (typically 1,700–2,100 RPM for most models). If you constantly wish you had “more tractor,” it’s time to reconsider your setup before something breaks.

Repeatedly operating a tractor engine under heavy load at low RPM can lead to excessive cylinder pressures, increasing the risk of catastrophic failures like connecting rod breakage.True

Running a diesel engine under heavy load at low RPM raises cylinder pressures because the engine struggles to burn fuel efficiently, placing extra stress on internal components such as the crankshaft, bearings, and connecting rods. This accelerates wear and increases the likelihood of mechanical failure.

Using a tractor with an implement rated above its drawbar capacity will only reduce fuel efficiency, but it will not contribute to mechanical engine damage.False

Overloading a tractor does more than just lower fuel efficiency; it can cause serious mechanical damage. Exceeding drawbar or PTO ratings forces the engine and drivetrain components to operate beyond their design limits, leading to failures such as broken connecting rods, worn bearings, and even cracked blocks.

Key takeaway: Overloading tractors and improper gear use are leading causes of reduced tractor lifespan. Matching implement size to tractor power, maintaining engine RPM within the optimal torque band, and avoiding continuous operation at full throttle help protect drivetrain components and extend equipment service life.

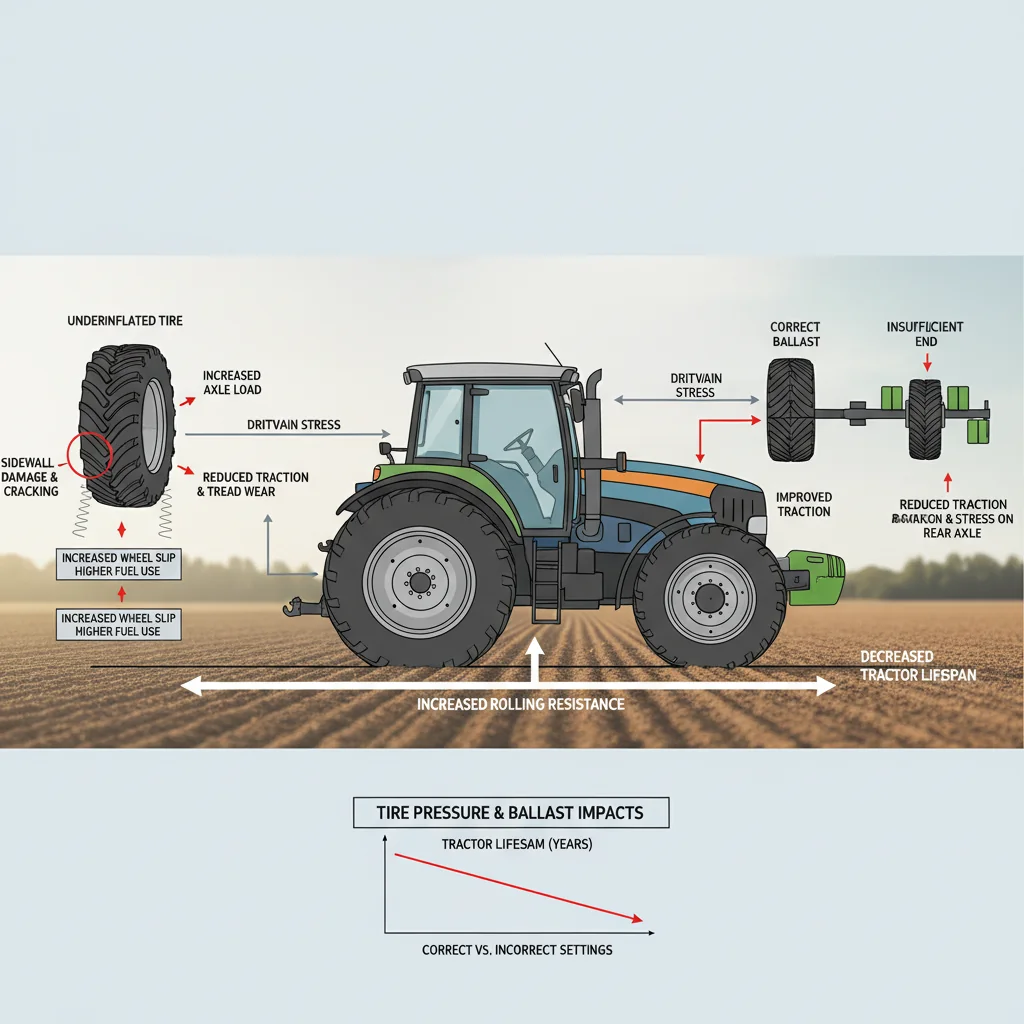

How Do Tire Pressure and Ballast Affect Lifespan?

Ignoring proper tire pressure, ballast, and wheel slip15 significantly shortens tractor lifespan. Underinflated or uneven tires raise rolling resistance and fuel use, causing sidewall damage. Overinflation leads to excessive wheel slip, wasted power, and drivetrain stress. Insufficient ballast during loader work overloads the front axle, risking cracks and failures. Routine tire checks and balanced ballast extend service life by 20–30%.

Here’s what matters most when looking at tractor lifespan: tire pressure, wheel slip, and ballast aren’t minor details—they’re the foundation. I’ve seen far too many farms in Brazil run 90HP 4WD tractors with underinflated rear tires. The result? Rolling resistance shoots up, fuel use climbs, and after just one season, the sidewalls start cracking. Those tires were supposed to last four years, but they barely made it past two. That’s not just a tire problem—it stresses the axles and the differential over time.

Too much pressure is just as risky. A customer in Kazakhstan once set his tires at max pressure from the chart, thinking it’d save him trouble. Instead, he noticed wheel slip jumping above 18% during heavy tillage. When you see that much slip, most of your engine power is turning into heat and soil disturbance, not actual work. His fuel bills went up, and within a year, the transmission started whining—a classic sign of overworked gears.

Insufficient ballast is another silent killer. On loader jobs in Kenya, I’ve watched 75HP tractors with no rear weights develop cracks near the front axle mounts after a season of moving heavy silage. The front axle simply can’t handle all that weight alone. Proper ballast—whether wheel weights, liquid in the rear tires, or a simple box on the three-point hitch—keeps the tractor balanced and spreads the load.

I always suggest checking tire pressures weekly, especially before big jobs. Use the manufacturer’s load-pressure chart as your guide. Small adjustments here can add years to your tractor’s service life and save real money.

Consistently running tractor tires at lower-than-recommended pressure increases rolling resistance and accelerates both tire and axle wear, reducing overall machine lifespan.True

Underinflated tires flex excessively, leading to heat buildup in the sidewalls and premature cracking. The increased resistance also places additional stress on drivetrain components like axles and differentials, shortening their service life.

Adding more ballast to a tractor always extends tire life by improving traction and reducing slip.False

Excessive ballast increases the load on tires, causing higher soil compaction and greater tire stress. Over-ballasting can actually accelerate tire wear and damage, particularly if tire pressure is not adjusted to match the increased weight.

Key takeaway: Maintaining correct tire pressure, monitoring wheel slip, and using appropriate ballast are essential for reducing drivetrain stress, fuel costs, and premature component wear. Consistent attention to these factors can extend a tractor’s operational life by up to 30% and prevent costly repairs.

What Early Warning Signs Signal Tractor Issues?

Ignoring warning signs—such as unusual noises, new vibrations, warning lights, hard starting, minor fluid leaks, or a burnt smell—can escalate minor faults into major repairs. Early attention to changes like a flickering charge light16, hydraulic weep, or frayed belt helps prevent costly breakdowns and extends tractor service life.

I've worked with customers who made the mistake of ignoring early warning signs, thinking they could finish “just one more job” before checking on a strange noise or flickering light. In Peru, a cooperative running 75HP 4WD tractors once called me after a simple hydraulic leak17 turned into a full failure—what started as a small drip at the pump became a ruptured hose that caused two days of downtime. The cost to fix the pump and replace lost fluid was ten times higher than just swapping the hose during a routine check.

Operators often tell me, “It still runs, so I’ll look at it later.” But a new vibration, hard starting, or even a burnt smell means something is already going wrong. I’ve seen a frayed fan belt snap in the field, overheating the engine and creating a much bigger problem. A flickering charge light isn’t just an annoyance—it’s usually the first clue that your alternator or wiring is about to fail, which can stop the tractor right in the middle of planting season.

I always suggest training every operator to do a quick walk-around both before and after work. Listen for unusual ticks, knocks, or whining from the transmission. Check for small oil or coolant leaks, and never ignore changes in smoke color or brake feel. Tightening a loose fastener or replacing a $20 belt early can save thousands in repairs and, more importantly, keep your tractor working when you need it most. That’s how you avoid costly surprises at the worst possible time.

Ignoring a persistent hydraulic fluid drip can cause contamination of the entire hydraulic system, potentially damaging sensitive components like control valves and cylinders.True

Hydraulic systems are sealed to prevent both fluid loss and contamination. Even a small leak can allow dirt and moisture to enter, which can damage internal parts and accelerate wear in pumps, valves, and actuators.

A flickering warning light on the dashboard usually means the sensor is faulty, not that there is an actual problem with the tractor.False

Warning lights are triggered by sensors designed to detect abnormal conditions such as low oil pressure or overheating. Ignoring a flickering warning light risks missing an early indicator of a real mechanical or electrical issue.

Key takeaway: Promptly addressing small warning signs like abnormal sounds, leaks, or indicator lights prevents minor faults from developing into expensive failures. Training operators to perform daily checks and respond quickly to changes is essential for maximizing tractor lifespan and minimizing downtime in critical farming seasons.

How Does Improper Storage Damage Tractors?

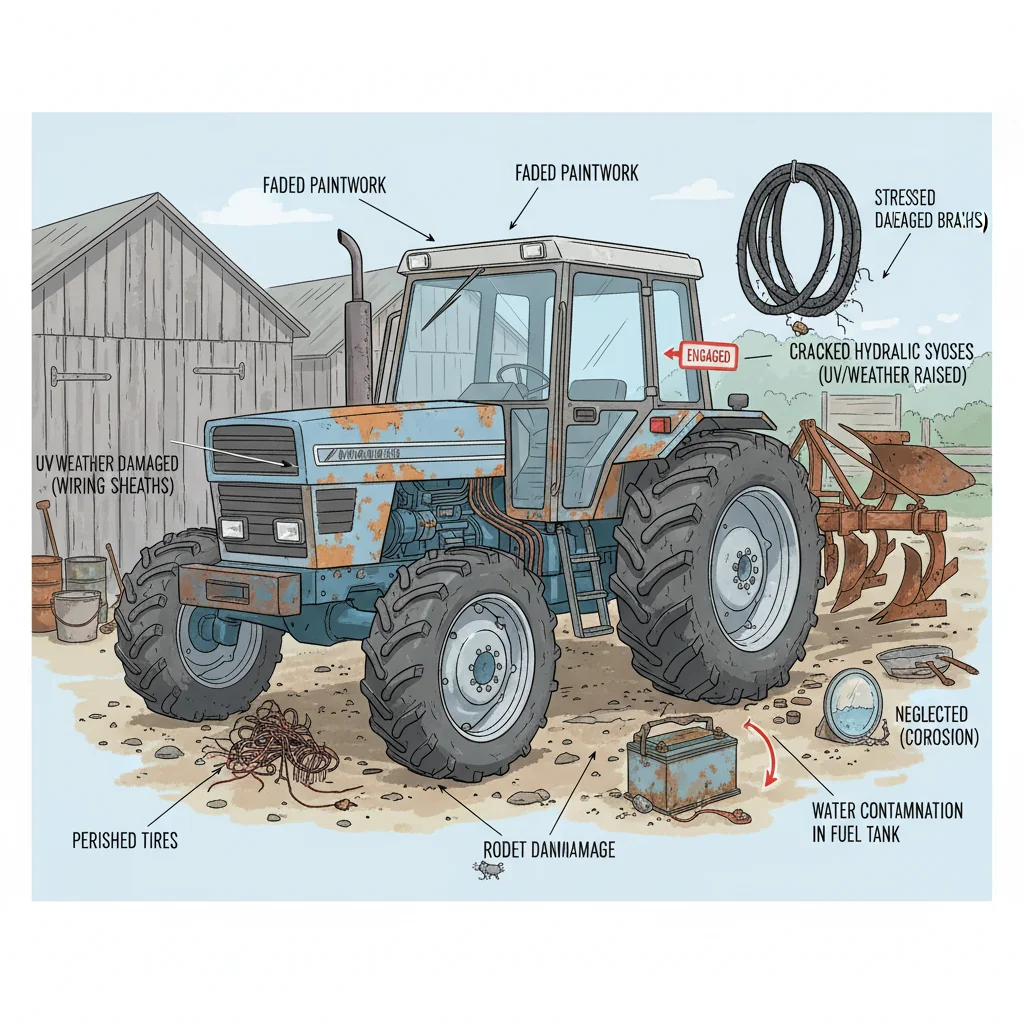

Improper tractor storage accelerates wear on critical components. Exposure to weather causes paint fading, cracked hoses, and perished tires, while UV and rain damage wiring. Raised implements stress hydraulics, and engaged handbrakes risk seized cables. Poor fuel and battery management lead to condensation, electrical issues, and rodent damage in wiring.

To be honest, I see tractors age faster from bad storage than from hard work in the field. Parking a machine outside—sun, rain, dust—will break down paint, rubber, and wiring faster than plowing a hundred hectares. In Brazil, I visited a farm where a 75HP tractor sat through two rainy seasons uncovered. The hoses turned brittle, tires developed deep cracks, and the wiring gave endless trouble. By year three, the owner faced leaks and electrical faults that cost more than a regular service.

Leaving implements raised is another common mistake, especially during the off-season. I’ve seen this in Kazakhstan, where cold winters and months of downtime are normal. Raised ploughs or harrows keep the hydraulic system under constant pressure. Over time, seals harden and start leaking—sometimes the hitch “slumps” overnight, dropping implements without warning. It’s not just messy; repairs to the hydraulic pump or cylinder can run over $400, not counting lost time.

Fuel and batteries cause their own problems if ignored. Half-empty tanks suck in moisture, leading to water in the diesel—last year, a customer in Kenya had to drain his tank and replace two injectors because of rust. Batteries left connected will discharge, especially in hot or humid climates. I always suggest removing the battery and charging it every few weeks, or at least disconnecting the terminals. Rodents are another headache—if a tractor sits untouched, wiring and cab insulation become prime nesting spots.

Simple steps like washing, greasing, and prepping your machine before storage save money and stress later. I recommend making this part of your end-of-season routine. It’s the best way to avoid “mystery” breakdowns when you need your tractor most.

Tractors stored outdoors without protection often develop electrical issues because moisture infiltrates connectors and wiring harnesses, accelerating corrosion and short circuits.True

Moisture from rain and humidity can penetrate electrical components when tractors are left uncovered, causing metal parts to corrode and leading to unreliable electrical performance—a problem worsened by repeated wet-dry cycles.

Keeping a tractor's fuel tank nearly empty during long-term storage helps prevent condensation and internal rust.False

A nearly empty fuel tank actually increases the risk of condensation forming on the tank walls, leading to water accumulation and rust; it is best practice to store tractors with a full fuel tank to minimize air space and moisture buildup.

Key takeaway: Incorrect storage practices—such as parking tractors outdoors, leaving implements raised, neglecting batteries, and allowing fuel tanks to sit half full—directly cause preventable mechanical and electrical failures. Proper off-season preparation extends service life, avoids costly repairs, and ensures reliable operation when the tractor is needed most.

What Operator Errors Damage Tractor Lifespan?

Rough operation, such as shifting from forward to reverse without stopping, overloading axles with raised heavy implements18, aggressive tire spinning, and bypassing safety switches, accelerates tractor wear. These actions damage clutches, torque converters, axles, and the drivetrain. Proper operator training and adherence to safe techniques are essential for maximizing equipment longevity.

I've seen too many tractors in Brazil and Kenya suffer early failure because of how they're driven, not how they're built. One customer in Mato Grosso bought four 80HP units for sugarcane work. By the second season, two already needed clutch overhauls—both had operators who would slam between forward and reverse without letting the tractor stop first. That single habit can destroy clutches and transmission synchros in less than a year, especially on loader work. The reality is, mechanical parts like clutches and torque converters are designed for smooth transitions, not shock loads every hour.

Another common mistake is hauling heavy implements with the hitch raised high while traveling fast over rough tracks. I watched a crew in Kazakhstan move a 1,200 kg disc harrow this way—front axles developed cracks after just one harvest. The extra leverage from the raised implement puts huge force on the front axle and frame. Keeping heavy tools low and reducing speed over rough ground can prevent years of wear in a single season.

Aggressive tire spinning is another silent killer. If the tractor starts to bog, spinning the tires just chews up rubber and strains the final drives. It's much safer to back off, shift down, or engage the differential lock. And while it seems harmless, bypassing safety switches—like the seat or PTO neutral start—can lead to sudden shocks on the driveline or even damage from accidental engagement.

I always recommend that every operator, even family members, get a proper walk-through on safe driving and handling. One rough driver can cut a tractor’s useful life in half. A little training now saves a lot of repair later.

Repeatedly shifting between forward and reverse without allowing the tractor to come to a complete stop can significantly reduce the lifespan of the clutch and transmission synchronizers.True

This habit causes excessive wear on the clutch and synchronizers because these components are forced to absorb the shock and speed difference, which they are not designed for, especially during loader work or when under load.

Letting the engine idle at low RPM for extended periods is beneficial for engine longevity and prevents damage to internal components.False

Long-term idling at low RPM can actually lead to incomplete combustion, carbon buildup, and poor lubrication, which may increase wear on engine parts and reduce overall engine life.

Key takeaway: Poor operator habits—especially rough handling, ignoring safety features, and aggressive driving—can drastically reduce a tractor’s useful life. Standardizing safe procedures and ensuring all users are trained on correct techniques can prevent costly damage and extend equipment lifespan significantly.

Do Dull Implements Harm Tractor Components?

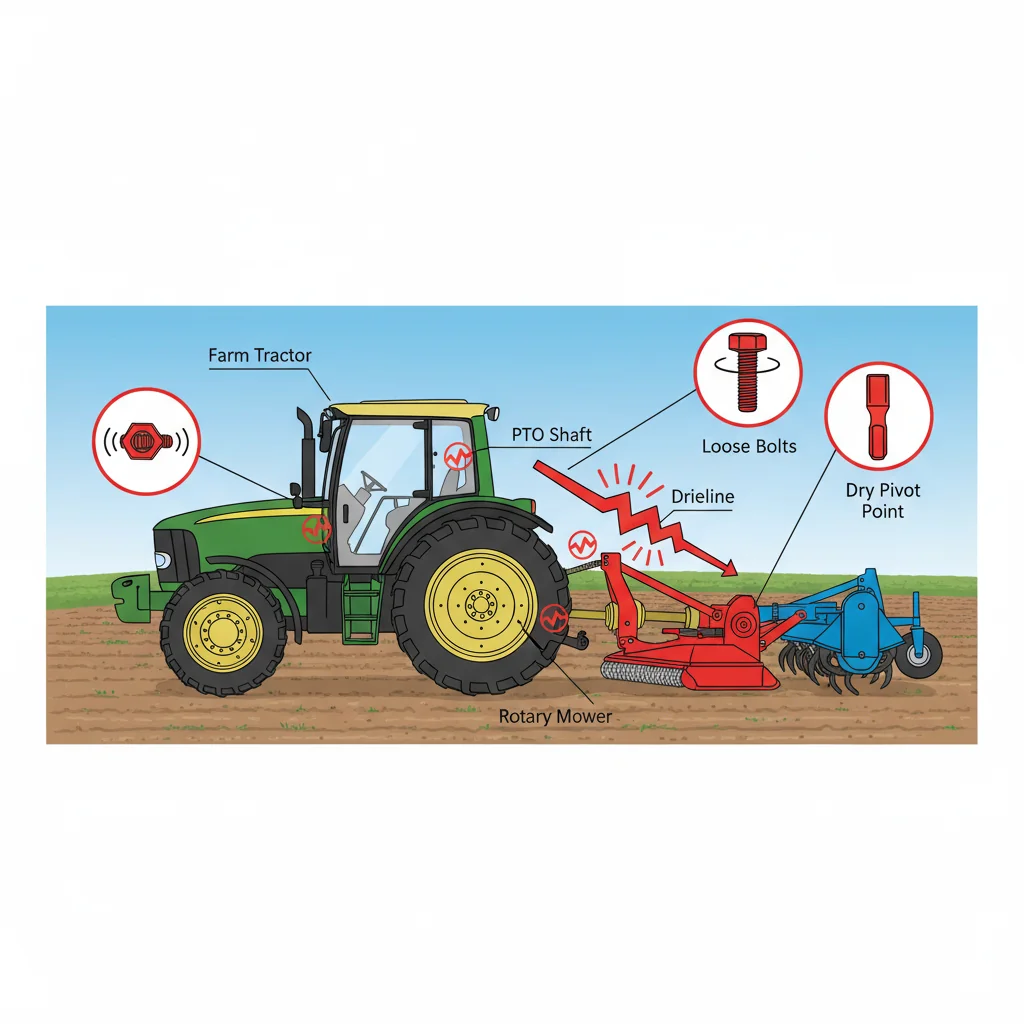

Dull or poorly maintained implements, such as mower blades or tiller tines, force tractors to operate under excessive load, straining the engine, PTO, and driveline. Loose bolts, worn pins, and dry pivot points cause shock loads and misalignment, risking damage to both implements and tractor hitch points. Regular maintenance significantly reduces mechanical stress and downtime.

Here's what matters most when you’re running conventional tractors in tough field conditions—implement care is not optional if you want to avoid engine and driveline headaches. I’ve seen farms in central Kazakhstan burn through PTO shafts in less than a season simply because rotary cutters were never sharpened. When mower blades are dull or tiller tines get rounded off, the tractor has to supply more torque just to do the same work. That extra load forces the engine and PTO to run hotter and harder, especially on models rated around 75HP or less. Over time, you’ll notice more fuel consumption and slower job completion. Farmers often blame the tractor, but the real problem is usually at the back.

I remember a customer in Peru who complained about constant vibration and broken hitch pins. His rotary tiller looked fine from a distance, but the mounting bolts were loose and the pivot points had run dry. Every bounce sent a shock load right through the three-point hitch and into the transmission housing. That’s a recipe for expensive downtime—he ended up needing new bushings and a PTO yoke. A little regular maintenance would have saved him at least two full working days during peak season.

So, I always suggest a simple routine: sharpen cutting blades two or three times per season (more if you’re in rocky soil), check and tighten all hardware, and grease every pivot point. Take five minutes to inspect the PTO shaft and guards before each job. Well-maintained implements keep your tractor running smoothly, save fuel, and extend the working life of both tractor and attachments.

Running a tractor with dull tiller tines can cause the PTO shaft to experience irregular torque spikes, increasing wear on universal joints and bearings.True

When tiller tines are dull, they require more force to penetrate and churn the soil. This leads to inconsistent resistance, causing the PTO shaft to transmit uneven loads. These torque spikes accelerate wear on the PTO's universal joints and bearings, which are designed for smoother, more consistent power delivery.

Using dull mower blades only affects the quality of the cut, but does not impact the tractor’s engine or driveline performance.False

Dull mower blades force the tractor to supply more power to achieve the same cutting action, increasing load on both the engine and driveline components such as the PTO. This additional stress can lead to overheating and premature wear, so implement sharpness is directly linked to tractor health, not just cut quality.

Key takeaway: Keeping tractor implements sharp, lubricated, and properly tightened minimizes extra stress on the engine, PTO, and driveline. Regular maintenance of blades, bolts, and pivot points improves fuel efficiency, extends equipment life, and helps avoid costly repairs to both tractor and attachments.

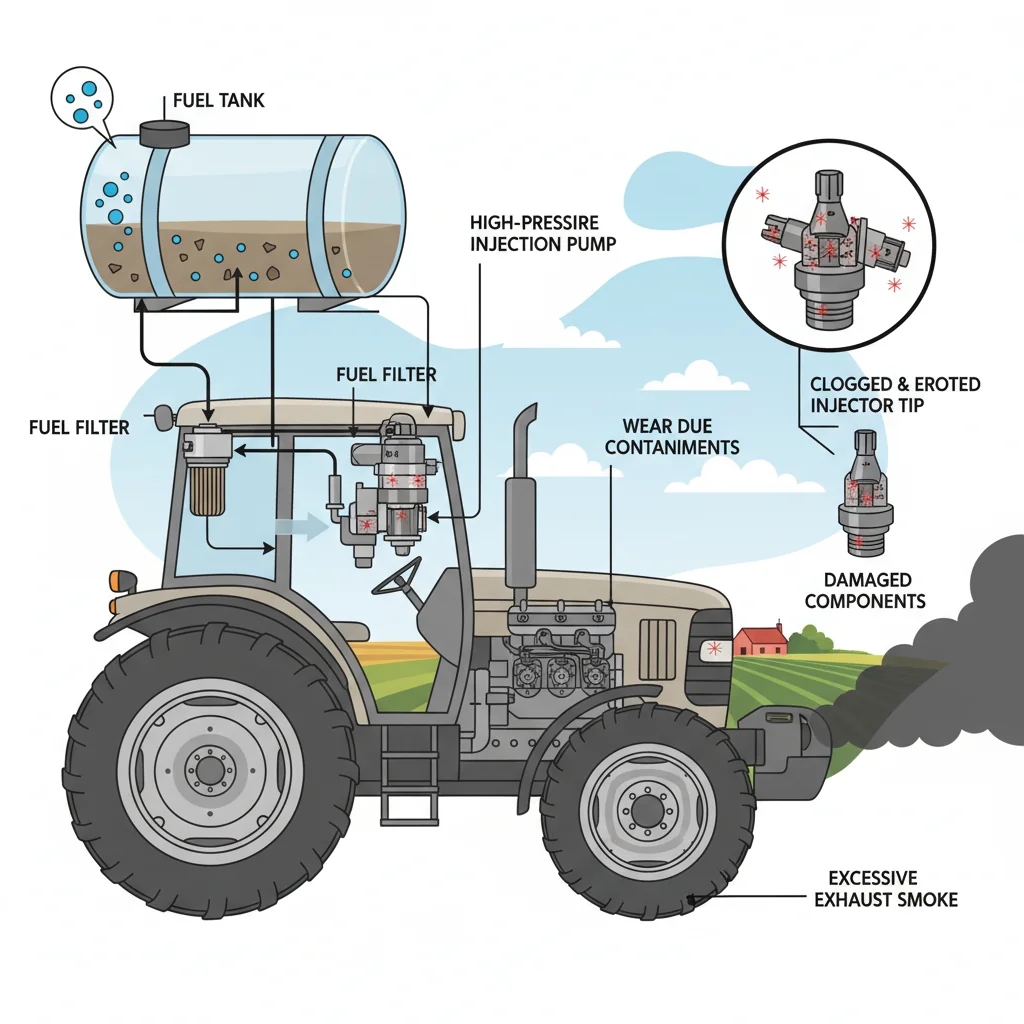

How Does Fuel Contamination Damage Tractors?

Dirty or water-contaminated diesel is a leading cause of premature engine failure in farm tractors. Particles over 10–20 microns and water from condensation or poor storage rapidly wear modern injectors and high-pressure pumps, causing hard starting, rough idle, power loss, and smoke. Proper filtration, clean storage, and timely filter changes are essential.

Here’s what matters most when talking about tractor reliability in real-world farming—clean diesel is not optional, especially in emerging markets. I’ve seen too many solid 80HP and 100HP units in Tanzania and Peru come into the shop with injector issues long before hitting 3,000 hours. Almost every time, the root cause is dirty or water-laden diesel—nothing fancy, just poor storage practices or skipping filter changes. Modern high-pressure common rail systems run with clearances under 5 microns. That means any particles above 10–20 microns, or water from condensation, start grinding away at your injectors and fuel pumps like sandpaper. The result? Hard starting in the morning, rough idle, black or white smoke, and a noticeable drop in pulling power—especially when running heavy implements like a 2,500 kg disc plow.

From my experience, a farmer in northern Kazakhstan struggled every winter because his diesel tanks weren’t kept full overnight. In that cold, condensation built up inside the tanks, letting water drip into the fuel. Within two years, his injectors were shot, and he faced a repair bill worth almost 15% of his tractor’s value. I always suggest using a proper transfer pump with a 5–10 micron water-separating filter, and draining your water separator at least weekly—daily if you’re working long hours or in humid conditions.

Don’t just rely on the original filter. Always source clean diesel from a trusted supplier, and keep your storage tanks sealed and above ground if possible. A little discipline with fuel handling saves money and keeps your tractor running strong for years.

Water contamination in diesel fuel can cause injector tip erosion in modern tractors, leading to poor spray patterns and reduced engine efficiency.True

Water in fuel creates microscopic jets of steam when exposed to high-pressure injection systems, which can pit and erode the injector tips, compromising atomization and combustion.

Using a finer fuel filter than recommended by the manufacturer always improves tractor reliability by keeping more contaminants out of the fuel system.False

Using filters with micron ratings finer than specified can restrict fuel flow, potentially causing fuel starvation and excessive strain on the pump, which can harm engine performance and reliability.

Key takeaway: Fuel cleanliness is critical for farm tractor longevity. Even minor water or particle contamination accelerates wear on precision diesel components, cutting injector life by half or more. Prevent engine damage by using quality filters, keeping tanks full, draining separators, and sourcing fuel carefully.

Conclusion

We’ve looked at the main habits that can shorten a tractor’s life—things like frequent overloading, running too hot, and skipping regular maintenance. From what I’ve seen in the field, many buyers get caught up in engine size or price, but the real cost comes later when hard hours and missed service lead to downtime or expensive repairs. Don’t let a “showroom hero, field zero” situation catch you off guard—focus on how the tractor will actually be used day to day. If you have questions about matching a machine to your conditions or want advice on parts support, feel free to reach out. Every farm’s different, and I’m happy to help you find what works in the future.

References

-

Expert explanation on pump cavitation and seal failure caused by low hydraulic oil, highlighting costly repairs and downtime. ↩

-

Explains why engine hours better reflect tractor usage and maintenance needs, helping farmers optimize equipment longevity. ↩

-

Detailed insights on how operating conditions accelerate tractor wear and strategies to minimize hard hours for longer engine life. ↩

-

Explains how adhering to hour-based service prevents premature engine wear and costly failures, backed by real-world examples. ↩

-

Details the impact of clogged filters on hydraulic systems and how it causes downtime and expensive repairs during critical periods. ↩

-

Expert insights on how using the right hydraulic oil prevents costly damage to wet brakes and clutches in agricultural tractors. ↩

-

Detailed explanation of API CI-4/CK-4 oil standards ensures proper protection and longevity of modern diesel tractor engines. ↩

-

Detailed insights on how low or contaminated engine oil causes bearing and cylinder wall damage, crucial for tractor longevity. ↩

-

Explore how dust-clogged radiator fins cause overheating and engine damage, with expert tips on maintenance to extend tractor lifespan. ↩

-

Learn why the correct antifreeze mix prevents corrosion and costly repairs, ensuring reliable tractor engine cooling and longevity. ↩

-

Details how lack of lubrication on loader pins causes metal wear and failure, leading to expensive downtime and repairs. ↩

-

Learn how insufficient ballast overloads the front axle, risking cracks and failures, and how proper ballast extends tractor service life by 20–30%. ↩

-

Explains how operating tractors at low RPM under heavy load causes engine damage, with expert insights on prevention. ↩

-

Details the importance of matching implements to tractor capacity to avoid overload and costly mechanical failures. ↩

-

Explore how excessive wheel slip wastes power, increases fuel use, and causes drivetrain stress, impacting tractor efficiency and durability. ↩

-

Expert explanation on flickering charge light as an early warning for alternator or wiring failure, preventing costly breakdowns. ↩

-

Detailed insights on how hydraulic leaks escalate repair costs and cause downtime, crucial for maintaining tractor efficiency. ↩

-

Understand the mechanical stress caused by hauling heavy implements raised high and how it leads to axle cracks and frame damage. ↩