How Utility Tractor Lifting Works: Field Guide to Avoid Costly Mistakes

Not long ago, I watched a team in northern Kazakhstan struggle to lift loaded seed pallets with a shiny new 85hp tractor—only to find the loader barely managed half the weight it promised. They were sure more horsepower was the answer, but the real story was hidden in the hydraulics and frame.

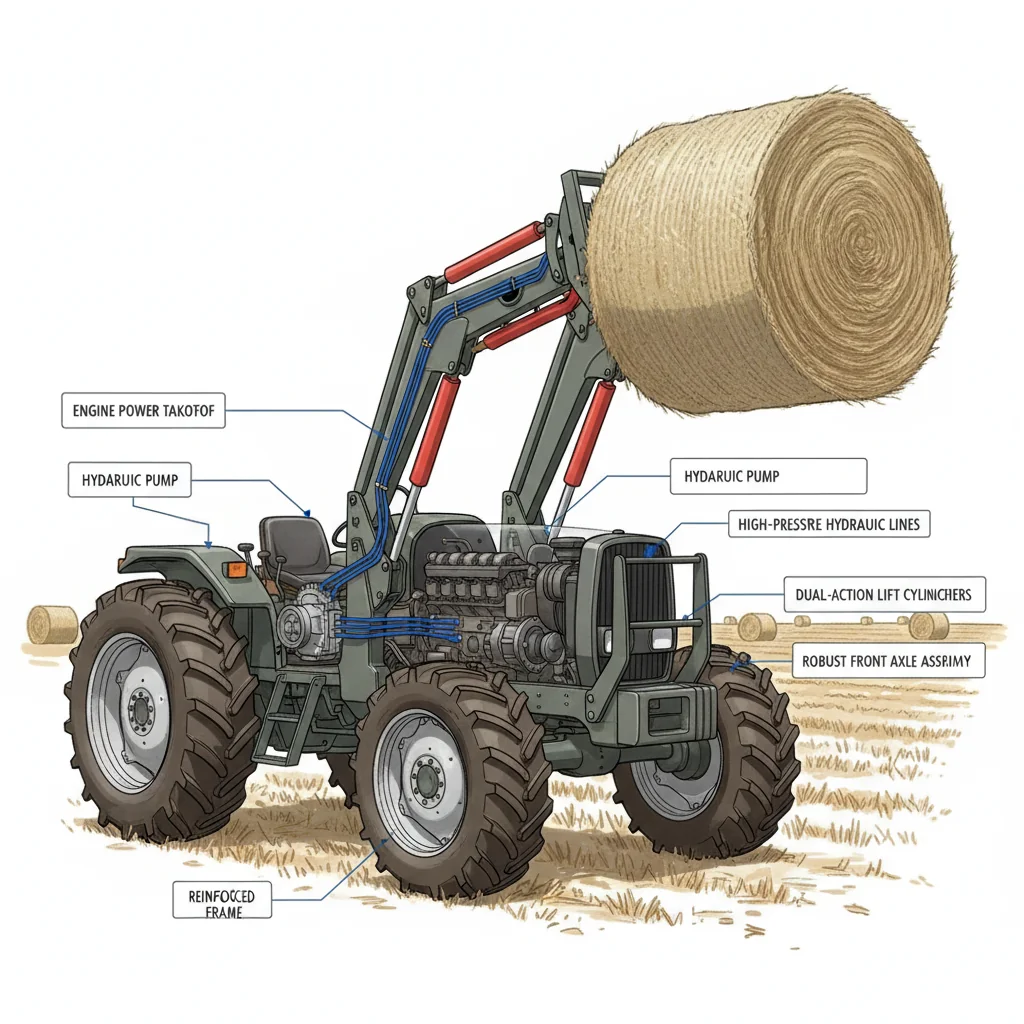

Utility tractor lifting capacity is determined primarily by hydraulic system pressure and flow, along with the structural integrity of the chassis, axles, and loader mounts. Hydraulic pumps, typically delivering 16–25 GPM at 180–220 bar, provide the force needed for loader and three-point hitch operation. Frame strength and operating weight control how much of that force can be safely used.

What lets utility tractors lift heavy loads?

Utility tractors lift heavy loads using hydraulic pressure1 and robust chassis design. The engine powers a pump that delivers high oil flow—typically 16–25 GPM at 180–220 bar—directly to loader and hitch cylinders. Chassis strength2, frame, and axle design determine safe lifting limits, not just engine horsepower.

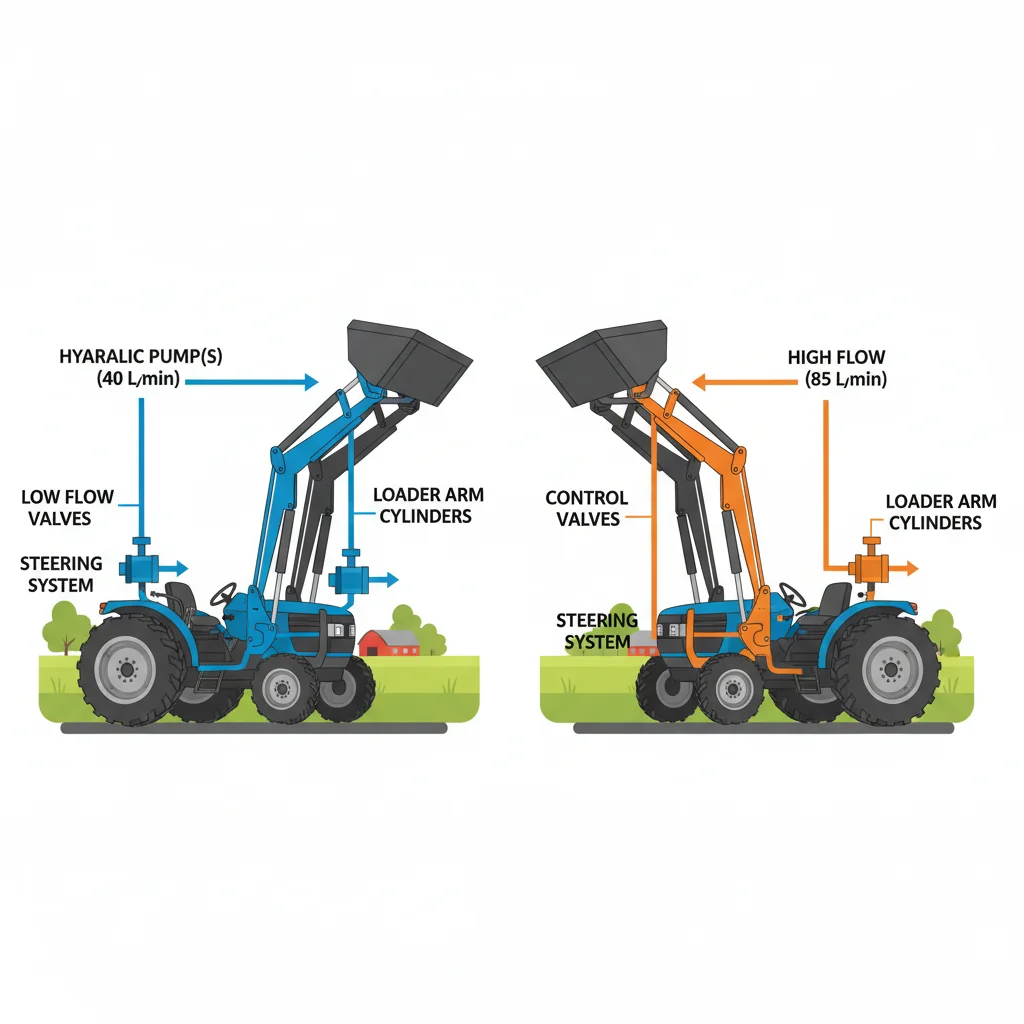

Most people think engine horsepower is what lets a utility tractor handle heavy loads, but that's only part of the story. The real work happens in the hydraulic system. The engine drives a pump that creates oil flow—often between 60 and 90 liters per minute on a 60 to 100 HP model—at pressures up to 220 bar. That oil pushes through the loader and three-point hitch cylinders, lifting everything from feed bags to mounted plows. But if the chassis isn't strong enough, all that hydraulic power is wasted.

Let me share something from Bolivia. I worked with a customer running a 75HP tractor on a sugarcane farm. He expected to use a large front loader for hauling bundles, but the front axle was too light. Even though the pump delivered enough flow, the axle twisted under repeated use. The lesson? The frame, front axle, and rear housing must be able to carry the load the hydraulics can lift. Tractor weight matters—a heavier, properly balanced machine will actually handle more real-world loader work than a lighter, higher-HP model.

I've seen buyers in Kenya focus only on horsepower, then end up disappointed when their tractors struggle with big implements. I always suggest checking the full hydraulic specs: pump flow, working pressure, and cylinder size. Compare the three-point hitch capacity at the ball ends and the loader’s lift at full height. The safest choice is a unit with a strong chassis and hydraulic system that matches your actual jobs. That’s what keeps your tractor working—not just the number on the engine cover.

A utility tractor’s ability to lift heavy loads depends more on the hydraulic system’s flow rate and pressure than on engine horsepower alone.True

The hydraulic system, powered by the engine, determines how much force can be applied to lift implements or loads. Even with a high-horsepower engine, if the hydraulic system’s flow rate or pressure is insufficient, lifting capacity will be limited.

Increasing a utility tractor’s engine horsepower will automatically allow it to lift heavier loads, regardless of its hydraulic system.False

Higher engine horsepower does not guarantee increased lifting capacity. The tractor’s hydraulic system and chassis strength are the primary factors in lifting, and without improvements to these, more horsepower alone will not enable heavier lifting.

Key takeaway: Hydraulic pressure and chassis strength, not just engine horsepower, enable utility tractors to lift heavy loads. Always compare hydraulic specs, cylinder dimensions, and tractor weight—not just hp ratings—when selecting a model for loader work or heavy implements.

How Do Loaders and 3-Point Hitches Differ?

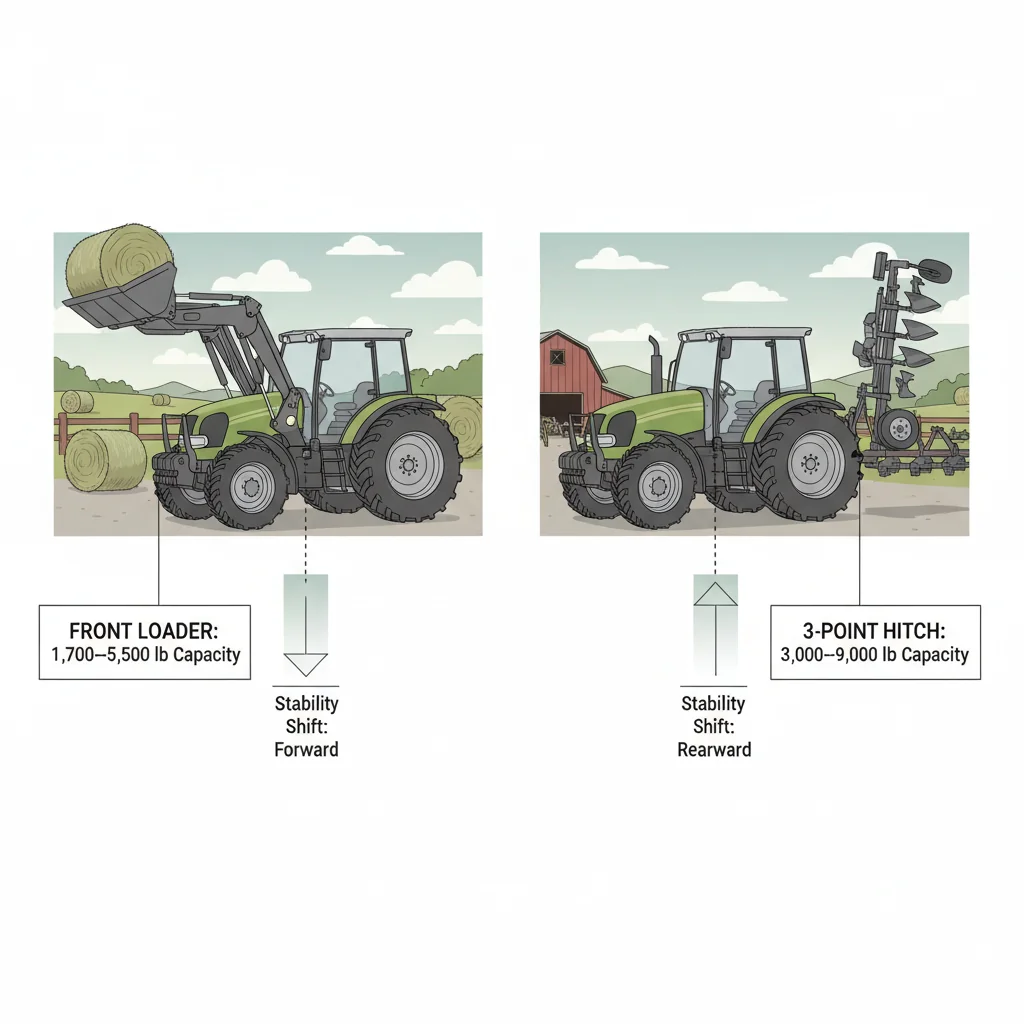

Utility tractors lift loads using either a front loader or a rear 3-point hitch3. The 3-point hitch, positioned inside the wheelbase4, offers greater stability and higher lift capacities (3,000–9,000 lb), ideal for heavy implements. Front loaders provide flexibility for bales or pallets but are less stable, with typical capacities of 1,700–5,500 lb.

Let me share something important about how loaders and 3-point hitches actually work in the field. Both systems lift and move loads, but where the weight sits and how the tractor handles it are completely different stories. The three-point hitch is bolted to the rear and sits inside the wheelbase—meaning the load is close to the tractor’s center of gravity. That’s why a typical 80HP utility tractor can safely lift around 3,500 to 7,000 pounds on the rear, especially with a solid ballast. I’ve seen farmers in Kazakhstan run heavy sprayers and large mowers this way, covering big fields without worrying about tipping.

Now, front loaders are a different animal. They mount up front, pushing the weight ahead of the front axle. This setup is great for grabbing bales or stacking pallets, but you sacrifice stability—especially on uneven ground. For example, in Brazil, one customer tried to move wet silage with a loader rated for about 2,500 pounds. On a slope, that same load felt twice as risky, and he nearly lost control. Loader capacities on utility tractors usually range from about 1,700 up to 5,500 pounds, but you have to keep the load low and move slowly to stay safe.

Here’s the real-world advice: match the attachment to your main job. Use the three-point hitch for heavy, mounted implements like plows, sprayers, or seeders—especially if you’re working long hours. Use the loader for flexible tasks, but always double-check the lift rating and consider extra rear ballast. That’s how you keep your operation efficient and safe.

A three-point hitch allows a tractor to safely lift heavier implements than a front loader of the same tractor, because the hitch’s load position is closer to the rear axle and within the wheelbase.True

This is true because positioning the load near the tractor’s center of gravity reduces leverage forces and improves stability, allowing for greater safe lifting capacity at the rear.

Front loaders and three-point hitches distribute weight in the same way, so both have similar effects on tractor stability and traction.False

This is false because front loaders place loads farther from the center of gravity and in front of the axle, which increases leverage and reduces stability, while a three-point hitch positions the load closer to the rear axle, enhancing balance and traction.

Key takeaway: The rear 3-point hitch on utility tractors provides greater stability and higher lift capacity for mounted implements, while front loaders excel at flexible loading tasks but with lower weight ratings and stability. Selection should match the intended task for safe, efficient operation.

How to Read Tractor Lift Capacity Specs?

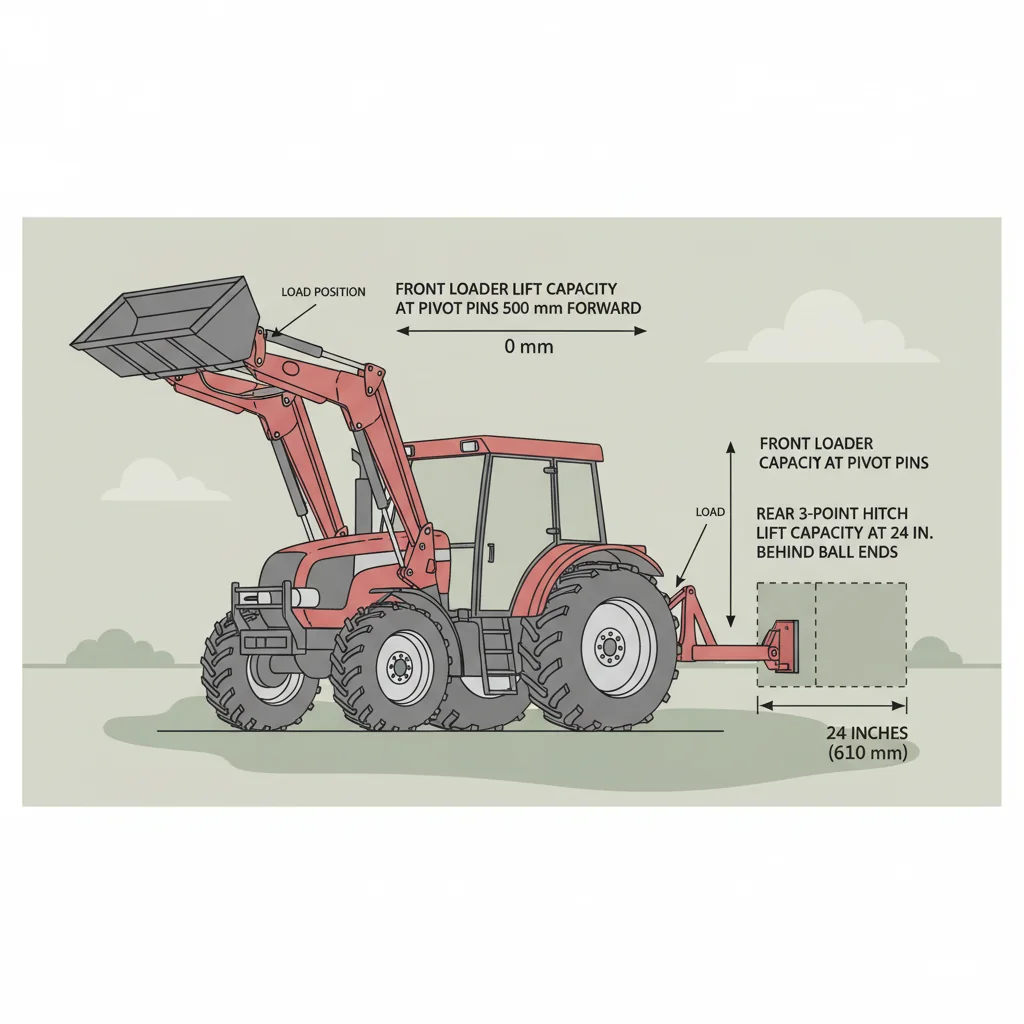

Tractor lift capacity specifications are often given at different points: at the loader’s pivot pin, 500 mm forward of the pin, or at full height. The highest number is usually at the pivot pin but real-world use aligns with 500 mm forward. Always confirm measurement points and derate brochure figures by 20–30%.

The biggest mistake I see is trusting the highest lift capacity number in a brochure without asking where it’s measured. For loaders, manufacturers often print the lift at the pivot pin—right where the loader arm meets the frame. Sure, that number looks impressive. But once you mount a hay bale or a bag of fertilizer out on pallet forks, you’re working 500 mm or more forward of that pin. In real field conditions, that same loader rated for 2,700 kg at the pin might only lift about 1,700 kg out at 500 mm forward. I’ve seen this catch farmers in Brazil off guard when they tried to stack big round bales—suddenly, the loader struggled to lift what they thought would be no problem.

Here’s what matters most when comparing tractors or loaders: always check the measurement point. “At the pin” is best for marketing, but “500 mm forward” is what you’ll actually use for most jobs. The same applies to three-point hitches. If you see a spec like “7,000 lb lift,” dig deeper. Ask if that’s at the hitch ball ends or 24 inches behind. In Kazakhstan, I once worked with a farm that bought 120HP tractors expecting to run heavy disc harrows, but the three-point linkage couldn’t actually lift those implements at working distance. They had to upgrade the hydraulic system—an expensive fix.

To be honest, I always suggest derating any brochure figure by 20 to 30 percent for real-world planning. This buffer saves you trouble, especially on bumpy fields or with continuous loader work. If you’re not sure, get the dealer to demonstrate with your actual implements before you buy.

Loader lift capacity ratings measured at the pivot pin will almost always overstate the loader's real-world lifting ability at the implement's working edge, especially when using pallet forks or a bucket.True

Lift capacity at the pivot pin does not account for the leverage effect as the load is moved forward from the tractor, which reduces effective lifting power at the tool’s furthest point.

If a tractor loader can lift a certain weight at the pivot pin, it will be able to lift the same weight at any point along the loader arms, including the tip of pallet forks.False

Lift capacity decreases as the load is positioned further from the pivot pin due to increased leverage, so the loader cannot lift the same weight at the implement’s tip as it can at the pivot point.

Key takeaway: Tractor lift capacity ratings vary depending on measurement points—pivot pin, 500 mm forward, or full height. The most relevant figure for field use is typically 500 mm forward of the pin. For practical operations, always reduce brochure lift numbers by 20–30% to avoid costly mistakes.

How to Match Tractor Lift Capacity?

To match utility tractor lift capacity to tasks, always use the heaviest regular load5 as a baseline, not the average. For loader work, select a tractor-loader with rated lift at full height, 500 mm forward, at least 30–40% above the heaviest load handled. Overloading risks costly downtime and equipment damage.

Here's what matters most when matching tractor lift capacity—don’t fall into the trap of planning around average loads. I’ve seen too many buyers in Brazil and Kazakhstan end up with damaged loaders because they sized their tractors for “typical” work, not their heaviest recurring job. For example, one customer in Mato Grosso thought a 1,500 kg loader rating was enough for their silage bales, but after a rainy season, those bales started hitting 1,900 kg. Their loader frame bent after only four months. That’s why I always say: choose your tractor-loader combo based on the heaviest regular load, then add a 30–40% margin.

Let’s break down what this means in practice. If you’re handling double-stacked fertilizer pallets weighing around 1,300 kg each, plus a 200 kg pallet and 100 kg fork, your real working load is 1,600 kg minimum. Look for a front loader with at least 2,100–2,200 kg rated lift—measured at full height and 500 mm forward, not just at the pins. This safety margin covers those “rainy season surprises” and keeps your hydraulics, frame, and axles from wearing out early.

On the three-point hitch, leverage can turn a 1,200 kg sprayer into a 1,700 kg effective load if it hangs far behind the arms. I’ve worked with farmers in Kenya who underestimated this and snapped lower links when lifting heavy tillers. I suggest always checking both the implement’s real weight and its balance point before buying. This approach avoids downtime and protects your investment.

A tractor’s maximum loader lift capacity is typically rated at the pivot pins and can be significantly lower at the bucket edge due to leverage and geometry.True

Loader lift capacity ratings are often measured at the pivot pins, which provide the most advantageous position for lifting. However, as you move the load outward to the bucket edge, the effective capacity decreases because of increased leverage and altered force distribution. This detail is crucial for accurately matching lift needs to actual working conditions.

If a tractor can lift a particular weight on dry ground, it will handle the same load safely in muddy or uneven conditions.False

Ground conditions like mud or uneven terrain can destabilize the tractor and loader, making it unsafe to lift maximum-rated loads. Stability and traction are compromised, increasing the risk of tipping or equipment damage, even if the loader is technically rated for that weight.

Key takeaway: Always size tractor lift capacity based on the heaviest recurring task, not the average. Ensure a 30–40% safety margin above your largest load, accounting for implement weight and leverage. This approach reduces the risk of costly mistakes and maintains equipment reliability.

How Do Weight and Axle Ratings Affect Lifting?

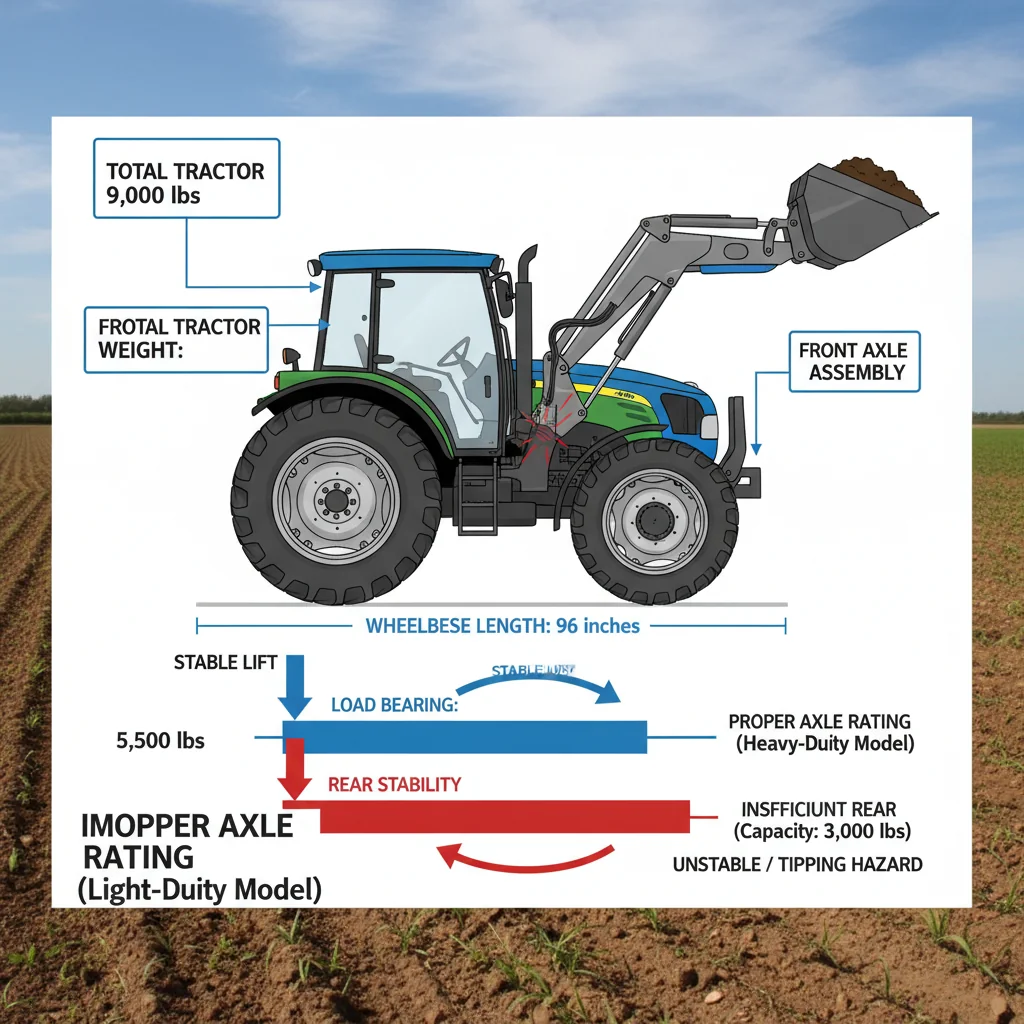

A utility tractor’s safe lifting ability depends not just on horsepower, but on total operating weight, wheelbase, and—critically—front axle ratings6. Heavier, longer-wheelbase models provide greater stability and allow full use of high hitch or loader capacities, while under-rated front axles often cause costly structural failures in lighter tractors.

I've worked with customers who made this mistake—choosing a tractor just for its engine power, only to find out the front axle couldn't handle heavy loader work. In Bolivia, a client bought a 95HP unit with a loader rated to lift nearly 2,000 kg. On paper, it looked perfect for their maize and sugarcane operations. But after six months, the front axle bearings wore out and the loader mounts started to crack. Why? The tractor's own weight was under 3,800 kg and the wheelbase was short. That made it unstable with heavy loads raised up front, especially hauling wet silage.

The reality is, safe lifting is much more about the tractor’s weight, wheelbase, and front axle rating than raw horsepower. Heavier models—think 4,500 kg and up, with a longer wheelbase—give you a wider stance and more secure footing. That allows you to use the full capacity of your three-point hitch or loader without risking damage. I’ve seen mid-size 90HP tractors with strong axles safely handle 2,500 kg at the rear and 1,500 kg up front, while lighter “economy” models struggle at half those numbers.

To be honest, I always suggest checking the front axle capacity in the spec sheet, not just the loader’s advertised lift. Ask the dealer how the loader frame is attached—is it tied into the gearbox and rear axle, or only the engine block? For regular heavy lifting, spend on weight and structure, not just horsepower. It saves costly repairs and downtime in the long run.

A tractor's front axle and chassis design can be more limiting for loader work than engine horsepower, as insufficient axle strength or poor weight distribution can lead to structural failures even if the engine could theoretically handle the load.True

Loader work stresses a tractor's frame and axles, not just its engine. If the front axle or chassis isn't rated for the loader's weight, repeated heavy lifting can cause premature wear, bearing failure, or cracking, regardless of engine size.

As long as a tractor has enough horsepower, it can safely handle any loader attachment within that engine power range, regardless of axle or chassis specifications.False

Horsepower alone does not determine safe loader operation. Axle ratings, chassis strength, and the tractor's own weight are critical for safely supporting heavy loader attachments; ignoring these can lead to equipment failure and safety hazards.

Key takeaway: Utility tractor lifting safety hinges on matching loader and hitch capacity to the tractor’s operating weight, wheelbase, and front axle rating. Prioritizing structural strength and axle capacity over raw horsepower helps avoid axle failures, broken mounts, and expensive repairs during regular heavy-duty field work.

How Should Tractors Be Ballasted for Lifting?

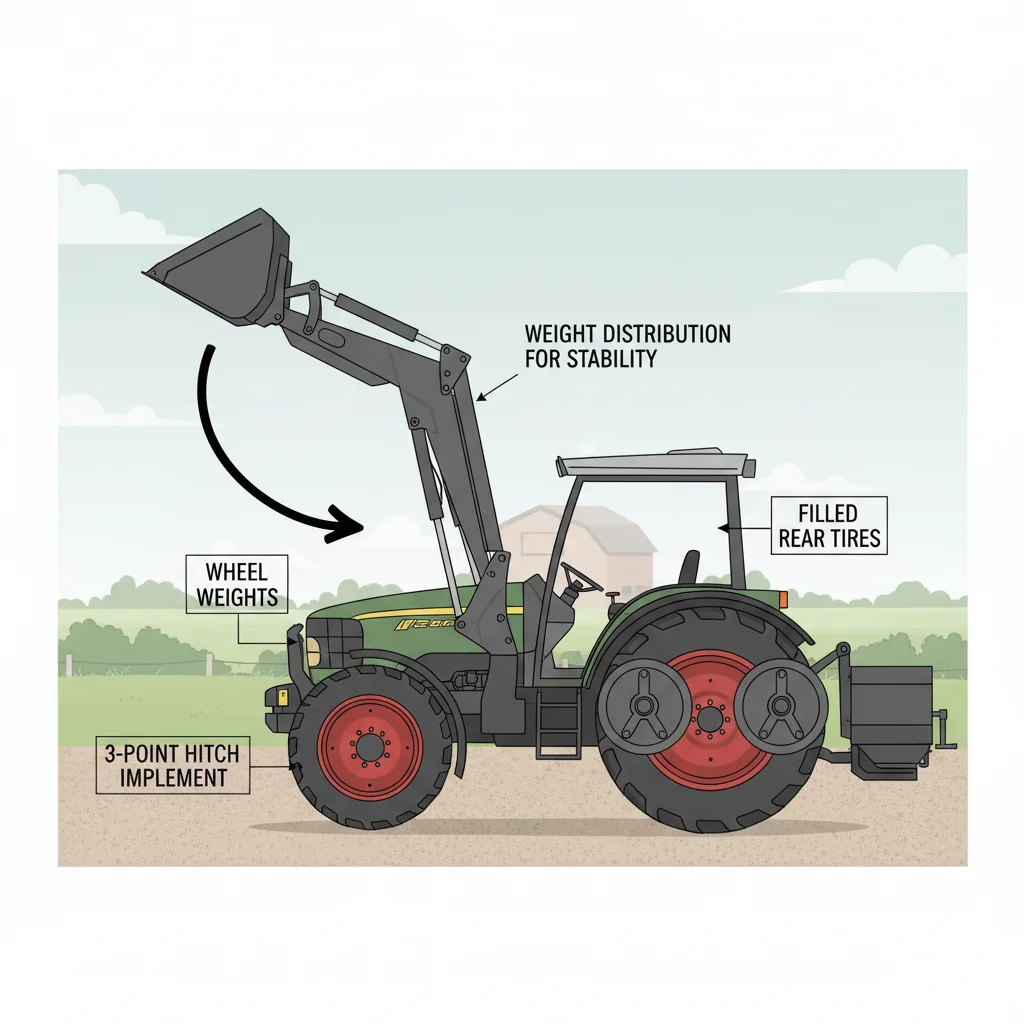

Proper tractor ballast is critical for safe heavy lifting. Aim for rear counterweight7 matching or nearing the loader’s maximum lift—typically 1,800–2,600 lb for a loader rated at 1,200 kg (2,600 lb). Use filled rear tires8, wheel weights, or compact 3‑point implements to optimize stability and reduce rollover risk.

Last month, a farm manager in northern Kazakhstan called me about a stability issue. They had a 90HP utility tractor with a loader rated for around 1,200 kg, but the back end kept lifting when moving big alfalfa bales. The loader could handle the weight, but without enough ballast on the rear, every trip across uneven ground felt risky. This is a textbook example—strong loader, not enough counterweight, and suddenly, even a heavy tractor feels unpredictable.

From my experience, the safest approach is to match your rear ballast to the loader’s maximum lift. For a loader with 2,600 lb (about 1,200 kg) lift, you want at least 1,800–2,600 lb of counterweight at the back. Most operators use a combination of filled rear tires (liquid ballast), cast iron wheel weights, and a compact 3-point implement. I always recommend keeping the ballast as close to the tractor as possible. A box blade, weight rack, or even a dense homemade block works—just avoid long implements that swing out behind you.

I’ve seen in Brazil how skipping proper ballast can lead to accidents, especially on slopes or when braking with a full loader bucket. Ballast shifts weight off the front axle, improves steering, and keeps your center of gravity low—absolutely critical for safety. Always keep your loader load low when moving, use 4WD if your tractor has it, and widen the rear wheel track if possible. For regular loader work, invest in a dedicated ballast box or a heavy, compact implement. It’s cheap insurance against rollover risk.

Adding liquid ballast to rear tires increases both traction and stability when lifting heavy front loads with a utility tractor.True

Liquid ballast in rear tires lowers the tractor's center of gravity and shifts weight toward the rear axle. This reduces the risk of rear lift, improves traction, and helps counterbalance heavy implements or loads handled by a front loader.

Front wheel weights are more effective than rear ballast for preventing a utility tractor from tipping backward when using a front-end loader.False

Front wheel weights add mass to the front axle, which does not help counterbalance a heavy load on the loader. Rear ballast is essential for shifting the tractor's center of gravity rearward, which is what actually prevents the back end from lifting.

Key takeaway: Matching rear ballast to loader capacity ensures safety and stability, minimizing rollover risk. Use filled tires, wheel weights, or a compact 3-point implement positioned close to the tractor for best results, especially during heavy loader work, on slopes, or when handling large bales.

How Do Hydraulic Specs Affect Loader Speed?

Hydraulic flow rate9 and control layout directly impact loader productivity. Higher total pump flow—typically 70–90 L/min for 80–100 hp tractors—enables faster lift and dump cycles, while dual pump systems10 prevent performance loss when steering. Lower-horsepower models may lift similar weights but operate much slower due to limited GPM.

Most people don't realize that hydraulic flow rate affects loader speed much more than raw lifting power. I’ve seen this firsthand on farms in Brazil, where two 90HP tractors handled the same 800 kg bucket but finished loading at totally different speeds. The difference? One had a combined hydraulic flow of nearly 85 L/min, while the other managed only about 55 L/min. That extra flow meant the loader arms cycled up and down twice as fast—saving at least an hour over a day of moving silage.

The layout of the controls also plays a big role. From my experience, a well-placed loader joystick lets an operator react quickly and make smoother movements. On some older models in Central Asia, the loader lever sits awkwardly far from the seat, making rapid bucket work exhausting. One client in Kazakhstan told me his workers lose patience after just a few hours—slow controls and low flow add up to real fatigue and lost productivity.

If you’re running daily loader jobs—like feeding cattle or loading trucks—don’t just look at engine size or lift specs. The real question is: how many liters per minute can the hydraulic pump deliver, and does the system have a separate pump for steering? Dual pump setups keep loader speed high even when you’re turning, which is essential for tight barnyards or busy yards. I always suggest checking for a durable transmission, good cooling, and a solid loader frame. Loader speed is about the whole hydraulic package, not just horsepower. For most buyers, that’s the difference between a tractor that keeps up with your workload and one that falls behind.

A tractor with a higher hydraulic flow rate can cycle its loader arms significantly faster, even if its lifting capacity is identical to another machine.True

Hydraulic flow rate determines how quickly hydraulic cylinders can extend and retract, directly affecting the loader’s operating speed. Two tractors with the same lifting capacity but different flow rates will raise and lower their loaders at noticeably different speeds.

A tractor’s engine horsepower is the primary factor that determines how quickly its loader can cycle up and down.False

Loader cycle speed depends mainly on hydraulic system flow rate, not engine horsepower. While engine power is important for overall tractor performance, it does not directly control how fast hydraulic fluid moves through the system to operate the loader.

Key takeaway: Loader efficiency depends on more than lifting force—hydraulic flow rate, pump configuration, and ergonomic controls are critical. For daily heavy loader work, prioritize tractors with adequate GPM, robust cooling, and durable frames to ensure both speed and long-term reliability.

How to Maintain Loader Hydraulics and Axles?

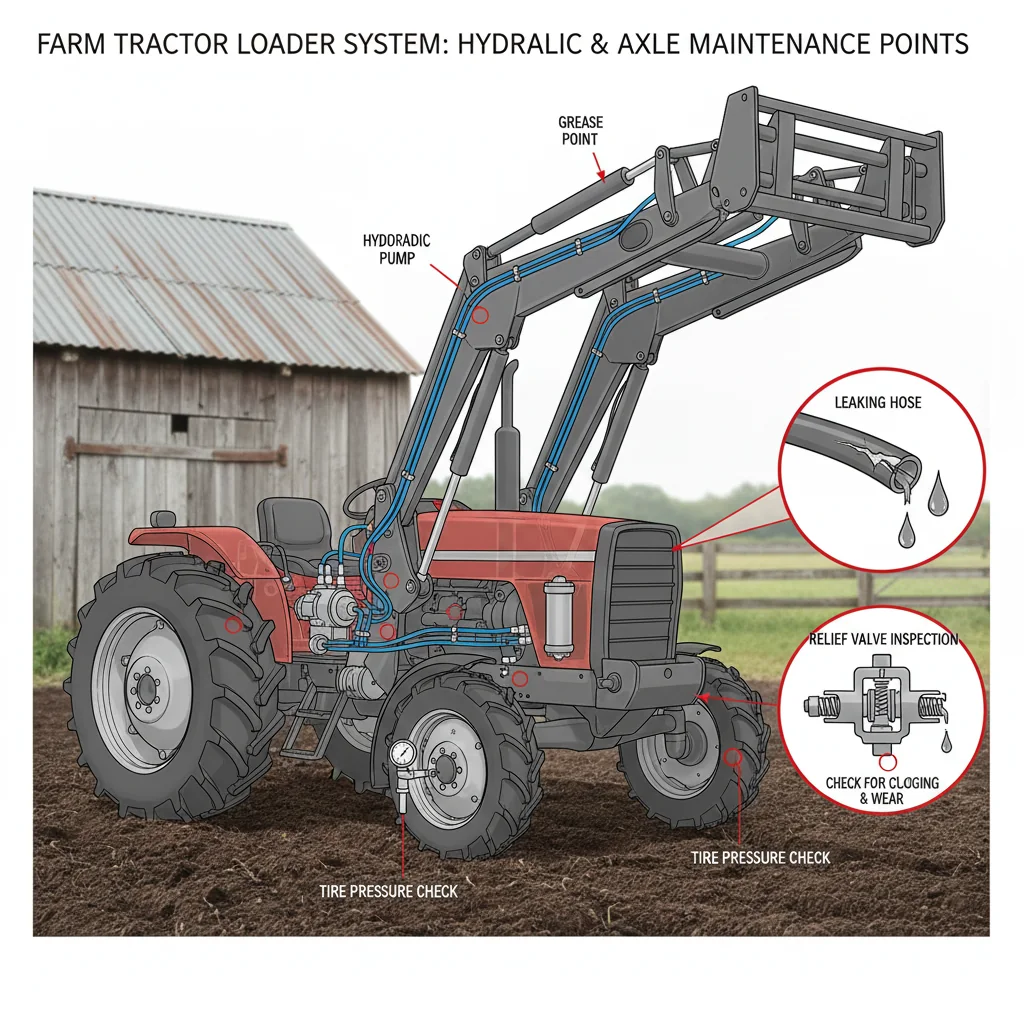

Heavy loader use accelerates wear on hydraulics, loader, and axles. Adhering to manufacturer intervals for hydraulic oil and filter changes11 prevents pump and valve damage. Regularly inspect hoses, couplers, and relief valves for leaks or pressure loss. Grease loader pins and bushings12 daily, check axle pivots, and maintain correct tire pressures for safe lifting.

To be honest, many tractor owners underestimate how quickly loaders and axles wear out under daily heavy work. I’ve seen this first-hand in southern Brazil, where a fleet of 80HP utility tractors ran front-end loaders almost eight hours a day. Within six months, several units had worn bushings, leaking hoses, and even axle pivot play—just from skipping basic maintenance. Loader work is tough on hydraulics and the front end, so you can’t treat it like light field jobs. Hydraulic oil is a big one. Dirty or old oil damages pumps and valves, especially if you’re running loaders in dusty or hot conditions. I always recommend following the loader’s service interval, not just the tractor’s engine hours. For example, most manufacturers call for hydraulic oil and filter changes every 500 hours, but if you’re in Kenya or northern Kazakhstan lifting heavy bales every day, I’d check at 400 hours instead. Don’t ignore small leaks or damp spots on quick couplers and hoses—a blocked coupler or low oil can quietly cut your lift power by 10–20%. If your loader slows down or gets weak when hot, have a mechanic check system pressure. Relief valves or a worn pump are usually to blame. Loader pins and bushings need daily grease—no exceptions if you’re in dusty areas. Excessive play makes the loader unpredictable and can crack the frame. Inspect front axle pivots and kingpins for heat, metal dust, or looseness. I’ve seen collapsed kingpins in Peru simply from ignoring daily checks.

Loader hydraulic systems on utility tractors should have their oil and filters changed more frequently than the main transmission, because loader work causes higher contamination and thermal stress.True

Loader operations generate more debris and heat in the hydraulic system due to frequent cycles and heavy loads, which accelerates oil degradation and filter clogging compared to transmissions that may operate under steadier conditions.

Front axle pivot bushings on utility tractors only require maintenance if you notice steering difficulty or noise, since they are not part of routine servicing.False

Axle pivot bushings are a wear point that should be checked and lubricated regularly as part of routine maintenance, not just when problems are noticed. Neglecting them can lead to premature wear and costly repairs.

Key takeaway: Consistent maintenance of hydraulics, loader pins, axles, and tire pressures is critical for safe, reliable lifting with utility tractors. Neglecting these areas directly increases the risk of system failures, unpredictable loads, and costly downtime. Follow loader-hour-based service intervals to address the unique stress of frequent heavy lifting.

Can Tractor Lift Ratings Be Trusted?

Tractor lift ratings, especially from lesser-known import brands, are often quoted at ideal points such as pivot pins or breakout force, not real working positions. For accurate performance, verify lift at full height (500 mm forward of pins) and 3-point capacity13 24" behind the ball ends.

Let me share something important about tractor lift ratings that many buyers overlook. Not all lift numbers mean the same thing in the field. On paper, you might see a loader rated for 1,800 kg, but that figure is often measured right at the pivot pins—where the leverage is most favorable. In real working conditions, especially once you move the load 500 mm forward or raise it to full height, the true capacity can drop by several hundred kilograms.

Last year, a distributor in Peru ran into this problem when they brought in a batch of 75HP utility tractors. The spec sheets looked great—front loaders “rated” for 1,500 kg. However, once their biggest customers tried handling bulk fertilizer bags, they struggled to lift more than around 1,100 kg at working height. The farmers were frustrated. The issue? The published numbers didn’t reflect real-world use—they were static lab numbers, not field-tested results.

I always recommend asking for lift curves or at least the capacity 500 mm ahead of the pins for loaders, and 24 inches behind the ball ends on the three-point hitch. If the supplier can’t provide this, be cautious. For continuous loader work, I suggest derating the catalog number by at least 20–30%. On rough ground, reduce it even further. Before any large fleet purchase, test one unit with weighed loads—bulk bags, steel blocks, whatever you have. This simple check can save you from mismatched machinery and costly downtime.

Loader lift ratings published by manufacturers are typically measured at the pivot pins, not at the bucket edge, which means the actual lifting capacity at the working point is often significantly lower.True

This is true because the pivot pin location offers the most favorable leverage. As the load moves farther from the pivot pins—such as to the front edge of the bucket—the mechanical advantage decreases and the lift capacity drops. This is a key reason why field performance may not match the specs on paper.

Utility tractors can safely lift their rated maximum capacity at any point along the loader arms, regardless of load placement.False

This is false because the lifting capacity of a tractor loader decreases as the load is positioned farther from the pivot pins. The further the load is from the pivot, the greater the leverage working against the loader, reducing its safe lifting ability and potentially compromising stability.

Key takeaway: Lift ratings on import or private-label utility tractors may overstate real-world performance. Always demand documented lift capacities at standard working positions, apply a safety derating, and test with known weights before making large purchases to avoid costly mismatches or equipment failures.

Conclusion

We've looked at what really matters for utility tractor lifting—hydraulics, cylinder size, and overall chassis strength, not just engine horsepower. From my experience, the best results come when buyers pay close attention to hydraulic specs and make sure they’re not falling for the “spec sheet gap”—where impressive numbers on paper don’t match up in the field. Before you settle on a model, I suggest double-checking the loader’s rated lift at full height and confirming how quickly you can get spare parts locally. Have questions about specs, attachments, or what works best in your region? I’m happy to share what I’ve seen succeed for real farmers—just reach out anytime. Every farm has its own needs, so choose what truly fits your conditions.

References

-

Explore the role of hydraulic pressure in lifting heavy loads, including pump flow rates and pressure ranges critical for tractor performance. ↩

-

Understand how chassis strength and frame design impact lifting capacity and prevent structural failures under heavy loads. ↩

-

Explore how the 3-point hitch enhances tractor stability and supports heavy implements with lift capacities up to 9,000 lb. ↩

-

Understand how wheelbase length impacts tractor stability and safe use of loader capacities, especially under heavy front loads. ↩

-

Details why basing tractor lift capacity on the heaviest load prevents frame damage and extends equipment lifespan. ↩

-

Explore how front axle ratings determine safe lifting limits and prevent costly structural failures in tractors under heavy loader use. ↩

-

Explains how matching rear counterweight to loader lift capacity improves tractor safety and prevents rollover risks during heavy lifting. ↩

-

Details how liquid ballast in rear tires enhances tractor stability and reduces rollover risk, especially when handling heavy loads on uneven terrain. ↩

-

Explore how varying hydraulic flow rates impact loader cycle times and overall tractor productivity with real-world examples. ↩

-

Understand how dual pump systems maintain hydraulic performance during steering, preventing speed loss and improving loader efficiency. ↩

-

Explains how timely oil and filter changes prevent pump and valve damage, ensuring loader reliability and longevity. ↩

-

Details the importance of daily greasing to reduce wear and maintain smooth loader operation under heavy use. ↩

-

Learn the importance of 3-point capacity measurements behind the ball ends and how it impacts the real lifting power of tractors in the field. ↩