What to Look for in a Utility Tractor: Manufacturer’s Practical Guide

The other day, I watched a farmer in northern Kazakhstan get his “new” imported tractor bogged down before sunrise—too heavy for his soft spring field, and not enough PTO power for his wide tiller. That’s a story I’ve seen play out across three continents, and it always starts with the same question: How do you choose the right utility tractor?

Selecting a utility tractor demands careful consideration of engine and PTO horsepower, ensuring implement requirements are met with a proper power reserve. Tractor weight, wheelbase, and ground clearance directly impact traction, stability, and field performance, while excessive mass may lead to soil compaction. Transmission choice—hydrostatic, synchronized gear, or power shuttle1—affects operator fatigue and task suitability.

How Much Horsepower Does a Utility Tractor Need?

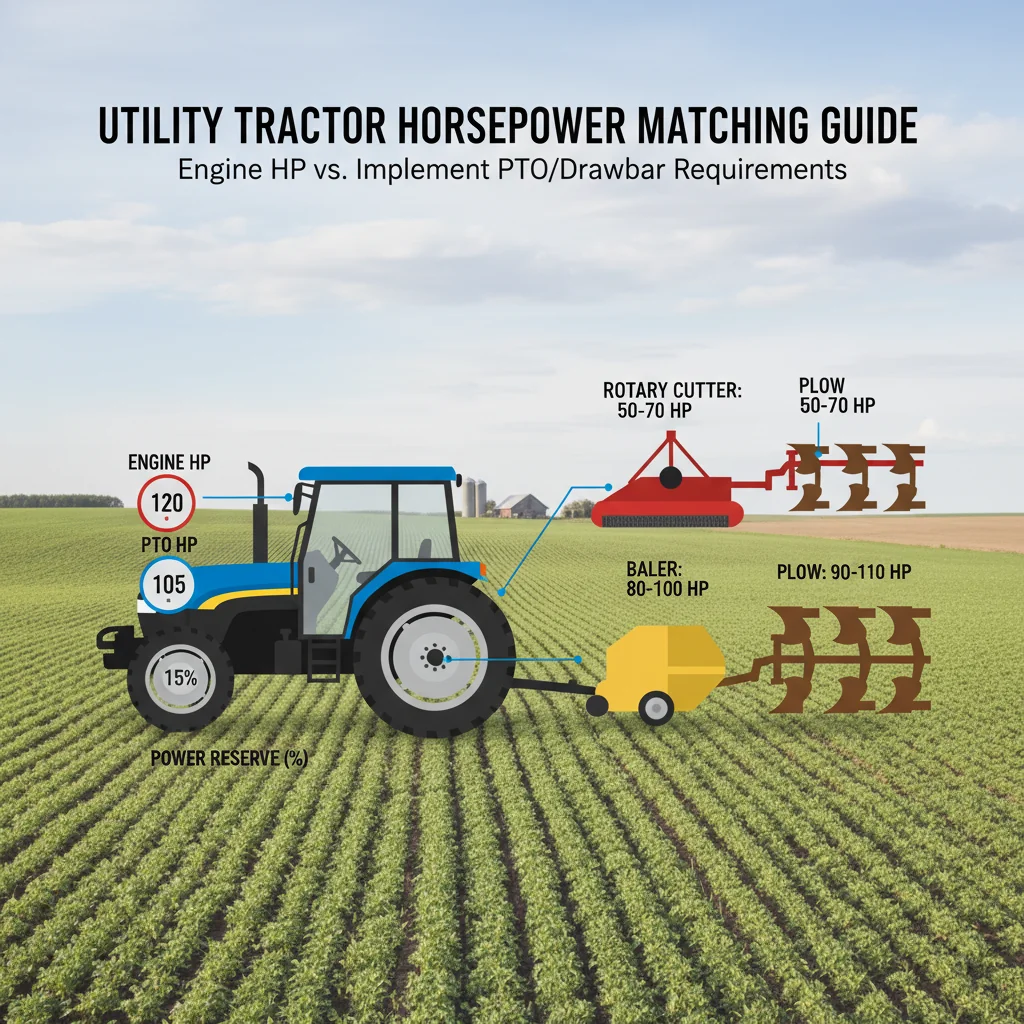

Utility tractor horsepower should match the heaviest implement and planned tasks, not just acreage. For 10–50 acres with varied work, 50–90 hp is typical. Always confirm PTO horsepower meets implement needs; this is usually 80–90% of engine hp. Maintain a 15–20% power reserve for difficult conditions.

Most people don't realize that horsepower needs depend more on your implements than on your acreage. For example, I worked with a distributor in Peru who wanted tractors for mixed work—loader tasks, mowing, and light tillage—across 40 hectares. They originally thought a 75HP unit would be enough for everything. But when they added a 2.5-meter disc harrow, the PTO couldn’t keep up, especially in wet clay soils after rain. The tractor bogged down, and fuel use spiked. We switched to a 90HP model with PTO output around 75HP, and suddenly every implement ran smoothly, even under tough conditions.

Here’s what matters most when sizing power: start with your heaviest implement and check its PTO requirement. For a 2-meter rotary tiller, you’ll need at least 45–60HP at the engine—meaning PTO output of roughly 36–54HP. If you plan to run a 2-meter flail mower in heavy grass or a 2.5-meter disc, you’ll want 60–90HP at the engine, which gives you 48–81HP at the PTO. Always confirm the PTO rating, not just the engine number—PTO is what actually drives your implements.

I always suggest leaving a 15–20% power reserve. Hills, wet fields, or dense crops can demand more than you expect. Too little power and you’ll work the tractor flat out, burning more fuel and risking breakdowns. Too much, and you waste money on fuel and bigger tires. If you think your farm will grow or you’ll upgrade implements soon, consider stepping up one size in horsepower now. That’s usually cheaper than replacing your tractor later.

A utility tractor’s required horsepower can vary significantly depending on the type and width of the implement used, even if the total acreage remains the same.True

Implement demands, such as a wider tillage tool or heavier loader, often require more horsepower, regardless of field size. The power needs are driven by the implement’s load, not just how much land you have.

If your acreage is under 50 hectares, any tractor with at least 75 horsepower will be sufficient for all typical utility tasks.False

Horsepower needs depend on the specific implements and operations, not just acreage. Certain implements or soil conditions can require more than 75 horsepower, even on smaller farms.

Key takeaway: Select utility tractor horsepower based on the most demanding implement and intended fieldwork, prioritizing PTO power over engine ratings. Avoid oversizing for efficiency, but consider one size up if future implement upgrades are likely. Maintain a power reserve for challenging terrain or crop conditions.

How Do Weight and Size Affect Tractor Stability?

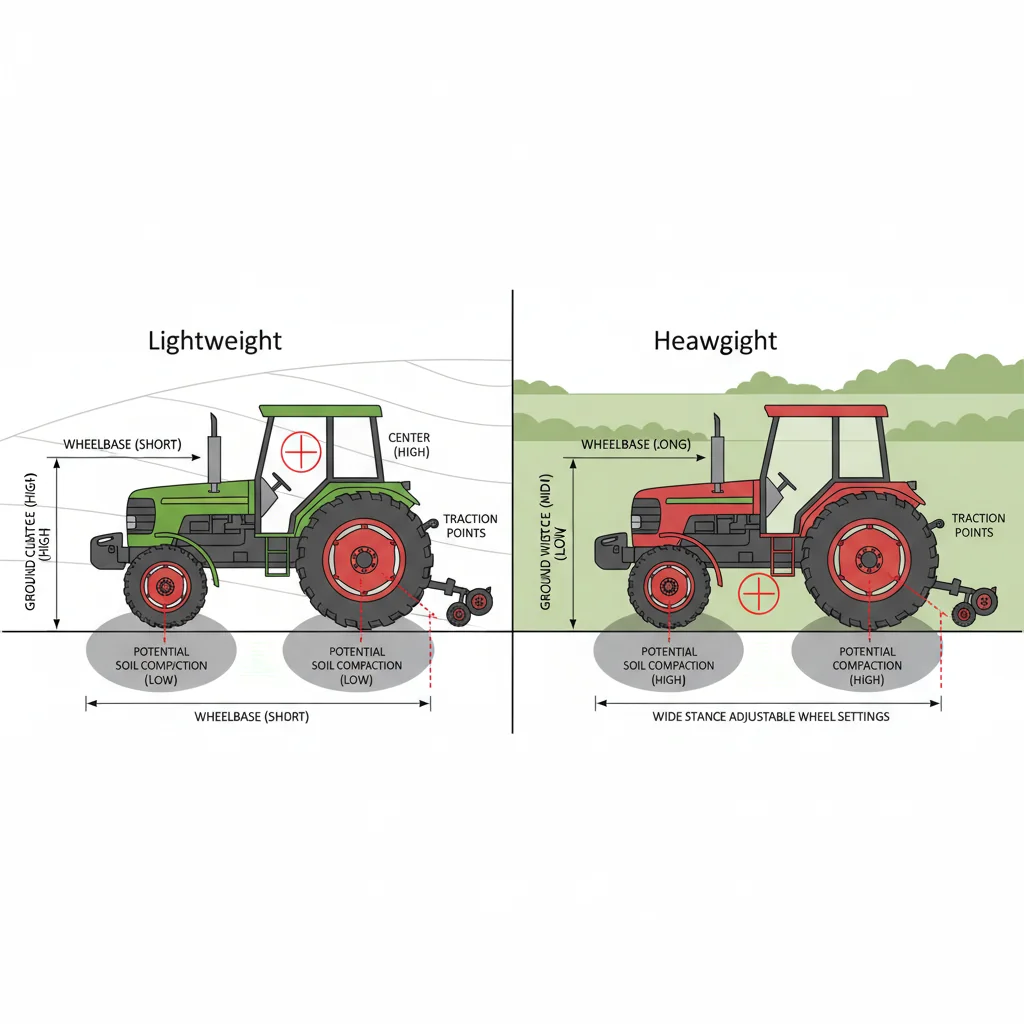

Tractor weight and dimensions directly impact traction, stability, and soil compaction. Heavier tractors offer improved grip and loader stability, especially on slopes, but excessive weight can damage wet fields and lawns. Balanced wheelbase and adjustable track width are vital for hillside safety. Ground clearance should match field conditions and operational needs.

I've worked with customers who made this mistake—choosing a tractor based on engine power alone, only to find it unstable on their hillside fields. Take a case from Peru: a client bought a 75HP utility tractor for mixed crop work. On paper, the specs looked perfect. But in the field, the machine felt top-heavy during loader work, especially when carrying wet silage up a slope. The problem wasn't power—it was the tractor's narrow wheelbase and not enough base weight for the terrain. Here's what matters most when you think about stability: weight, dimensions, and ground clearance all work together.

A heavier tractor—say around 4,000 kg with ballast—offers better grip, especially for plowing or using a front loader. But too much weight on wet clay or soft soils, like those in parts of Kenya or Bolivia, just means you risk getting stuck and compacting your fields. I always tell buyers to check if the wheelbase and track width2 feel wide enough for their slopes. Many standard tractors allow you to adjust rear wheel spacing, which can make a big difference on uneven ground. Ground clearance is another detail that's often missed. For row crops or rough pasture, you might want 400–500 mm clearance to avoid getting hung up. But if your main job is flat mowing or transport, a lower stance keeps the machine steadier.

A tractor with a wider wheelbase and lower center of gravity is significantly more stable on slopes than one with the same engine power but a taller, narrower frame.True

Stability on uneven terrain depends more on the tractor's geometry and weight distribution than on engine power alone; a wider wheelbase and lower center of gravity reduce the risk of rollover, especially when carrying loads on slopes.

Increasing engine horsepower alone will automatically improve a tractor’s stability on hilly terrain, regardless of its weight or wheelbase.False

Engine horsepower affects pulling and lifting capacity, but does not address stability. Stability is primarily determined by weight distribution, center of gravity, and wheelbase, not by the amount of engine power.

Key takeaway: Tractor weight, size, and clearance must align with farm terrain and jobs. Sufficient base weight is essential for stability and traction, but excess mass increases compaction risks. Proper wheelbase, track width, and clearance ensure safety and efficiency while preventing costly fit and field issues.

Which Utility Tractor Transmission Is Best?

Transmission selection depends on primary tasks: Hydrostatic (HST) suits frequent loader work with smooth pedal control; synchronized gear systems provide durability for heavy draft jobs; power shuttle excels in repetitive forward-reverse operations; CVT/powershift enables precise speed for specialty work. Test in real conditions to ensure operator comfort and productivity.

Let me share something important about utility tractor transmissions: what works best really depends on your daily routine, not just what looks good in a brochure. I’ve seen plenty of buyers in Latin America get excited about hydrostatic drive, only to find it doesn’t suit their heavy tillage work. Hydrostatic (HST) is smooth and simple—just a pedal, no clutch—making it perfect for loader jobs or mowing around tight orchards. But if you’re pulling a plow all day, an HST can feel sluggish and won’t match the efficiency of a mechanical transmission. Last year in Kazakhstan, a customer running 100HP 4WD units for large grain farms asked me if power shuttle was worth the extra cost. For their operation—lots of bale stacking and yard work—it absolutely made sense. With a power shuttle, you switch from forward to reverse using just a lever, no clutching needed. That saved their operators time and spared them a lot of fatigue, especially moving bales during harvest.

On the other hand, for pure draft work like deep tillage, I always suggest synchronized gear systems. They’re robust, simple, and easy to repair—critical if your local mechanics are more familiar with basic engines than electronics. Here’s a quick comparison table based on what I’ve seen in the field:

| Transmission Type | Best For | Power Range | Ease of Repair | Typical Use |

|---|---|---|---|---|

| Hydrostatic (HST) | Loader, mowing, orchards | 40–90 HP | Easy | Loader work, mowing, orchard tasks |

| Synchronized Gear | Heavy draft work | 60–120 HP | Very Easy | Plowing, deep tillage, field pulling |

| Power Shuttle | Frequent F/R operations | 80–150 HP | Medium | Bale handling, yard work, loaders |

Synchronized shuttle transmissions are often preferred for loader work in utility tractors because they allow quick forward-reverse shifts without fully stopping the tractor.True

Synchronized shuttle transmissions use a lever and internal synchronizers to enable smooth, clutch-assisted direction changes, making them ideal for repetitive loader tasks where frequent shifting is needed.

Hydrostatic transmissions are always more fuel-efficient than manual transmissions in utility tractors, regardless of the task.False

Hydrostatic transmissions can actually be less fuel-efficient during heavy drawbar work because of power losses in the hydraulic system, whereas manual transmissions transmit power more directly and efficiently in such conditions.

Key takeaway: Choosing the right utility tractor transmission is crucial for reducing operator fatigue and maximizing productivity. Match hydrostatic, synchronized gear, power shuttle, or CVT/powershift options to daily operational needs, always testing the tractor under realistic working conditions to confirm suitability for key farm tasks.

Why is 4WD crucial for utility tractors?

4WD is vital for utility tractors working on mixed terrain, as it maximizes traction and safety. A 4WD 65 HP tractor3 can outperform a 75 HP 2WD model on wet soils, slopes, or with loader attachments. Optimal tire type and ballast further improve stability and pulling power.

Here’s what matters most when you’re comparing utility tractors for real farm work: 4WD isn’t just a “nice-to-have”—it’s the difference between finishing the job and getting stuck. I’ve seen this firsthand in places like central Kenya, where a customer with a mixed-crop farm struggled every rainy season using a 75HP 2WD tractor. Even with more horsepower, his machine spun out on soft ground, and loader work was risky on slopes. When he switched to a 65HP 4WD model, he pulled the same implements with less wheel slip, and loader handling became much safer—especially with heavy maize bales.

The real secret is how 4WD transfers power. On soft or uneven soil, it lets all four wheels grip, so more engine output turns into forward movement instead of wasted spinning. This isn’t just talk—I’ve watched 4WD 65HP tractors out-pull 2WD 75HP units in Bolivian soybean fields after heavy rain. The 4WD models finished tillage in one pass, while the 2WDs bogged down and lost hours recovering.

Tire setup and ballast make a big difference too. I always suggest R1 (agricultural) tires for muddy fields, or R4 (industrial) if you’re working both dirt and hard surfaces. Proper ballast—like filling rear tires with liquid or using wheel weights—keeps the tractor stable, especially when using a front loader. If you’re on slopes, widening the rear wheel spacing and checking tire pressure can help prevent rollovers.

For most small and medium farms, 4WD pays for itself quickly. You save time, reduce frustration, and work safer—especially on soft, sloped, or variable terrain.

4WD utility tractors provide substantially better traction on wet, uneven, or sloped terrain because power is delivered to all wheels, reducing the likelihood of wheel slip and improving implement control.True

With 4WD, both the front and rear axles are powered, distributing engine torque more evenly across all four wheels. This is especially valuable in muddy fields or when working on hillsides, where 2WD tractors often lose traction and control, regardless of horsepower.

A 2WD utility tractor equipped with rear ballast can match the climbing and pulling capability of a 4WD tractor on soft or hilly ground.False

While rear ballast can help improve traction by increasing weight over the drive wheels, it does not compensate for the lack of powered front wheels. On soft or sloped surfaces, 2WD tractors are still prone to spinning out or losing steering control, whereas 4WD tractors maintain traction and stability by engaging all wheels.

Key takeaway: For small and medium farms, 4WD offers superior traction, stability, and safety—especially in soft fields, loader work, or hilly conditions. Proper tire selection and ballast enhance these benefits, making 4WD a practical investment over higher horsepower in most utility tractor applications.

What Hydraulic Flow and Lift Ratings Matter?

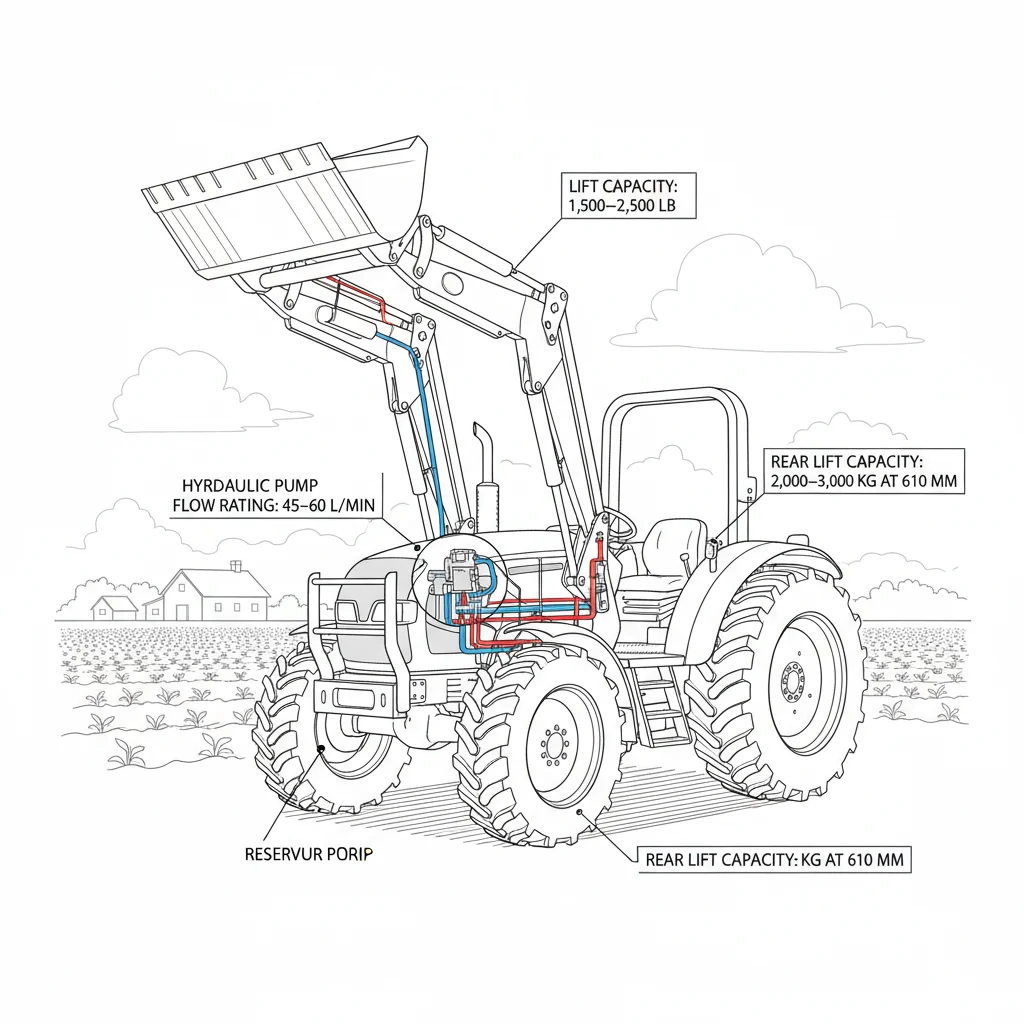

Hydraulic performance defines a utility tractor’s real capabilities. For efficient loader work, total hydraulic flow should be at least 45–60 L/min (12–16 gpm). Loader lift capacity4 at full height should reach 1,500–2,500 lb (700–1,100 kg). Three-point hitch lift at 610 mm behind the balls is critical—2,000–3,000 kg is common in upper utility classes.

The biggest mistake I see is buyers looking only at horsepower and forgetting the hydraulics. Hydraulics actually decide what your tractor can do—especially for loader work and heavy implements. I’ve seen too many farms in Kazakhstan frustrated because their new 80HP tractors couldn’t lift a full bucket of gravel or raise a heavy disc harrow. The problem? Hydraulic flow was barely 40 L/min, and the loader lift at full height was under 1,200 kg. That slows down every job and limits the tools you can use.

Here’s what matters in the field: for regular loader use, total hydraulic flow should be at least 45–60 L/min (12–16 gpm). This keeps your loader cycles fast, so you aren’t wasting time waiting for the arms to raise or dump. I always recommend checking the loader’s lift capacity at full height—not just at the pivot pin. For most farms, a loader that can handle 1,500–2,500 lb (700–1,100 kg) at full height is enough for gravel, logs, or fertilizer pallets. Anything less, and you’ll end up making extra trips or struggling with basic tasks.

Don’t overlook the three-point hitch, either. It’s not just about the maximum lift at the balls—check the rated capacity at 610 mm behind the balls. That’s where most implements actually hang. On larger utility models, I like to see at least 2,000–3,000 kg there, especially if you’ll run plows, planters, or sprayers. I suggest verifying this spec before you buy. It makes all the difference when you’re in the field, not just looking at a brochure.

A tractor with high engine horsepower but low hydraulic flow may struggle to operate modern loader attachments efficiently, regardless of its power rating.True

Hydraulic flow rate determines how quickly and effectively attachments like loaders and backhoes can move. Even with ample engine power, insufficient hydraulic flow limits the speed and capacity of hydraulic implements, making the tractor less productive for certain tasks.

As long as a tractor's engine has enough horsepower, it will always be able to lift heavy implements or loads without issue.False

Engine horsepower and hydraulic lift capacity are separate specifications. A powerful engine cannot compensate for a weak hydraulic system; if hydraulic flow and lift ratings are low, the tractor will be unable to raise or handle heavy attachments, regardless of engine strength.

Key takeaway: Utility tractors must be evaluated beyond horsepower—hydraulic flow, loader lift at full height, and three-point hitch capacity at 610 mm behind the balls are crucial for real-world performance. For loader and implement work, check these specifications, not just manufacturer headline numbers, to ensure practical versatility.

How Do Hitch Category and PTO Specs Match?

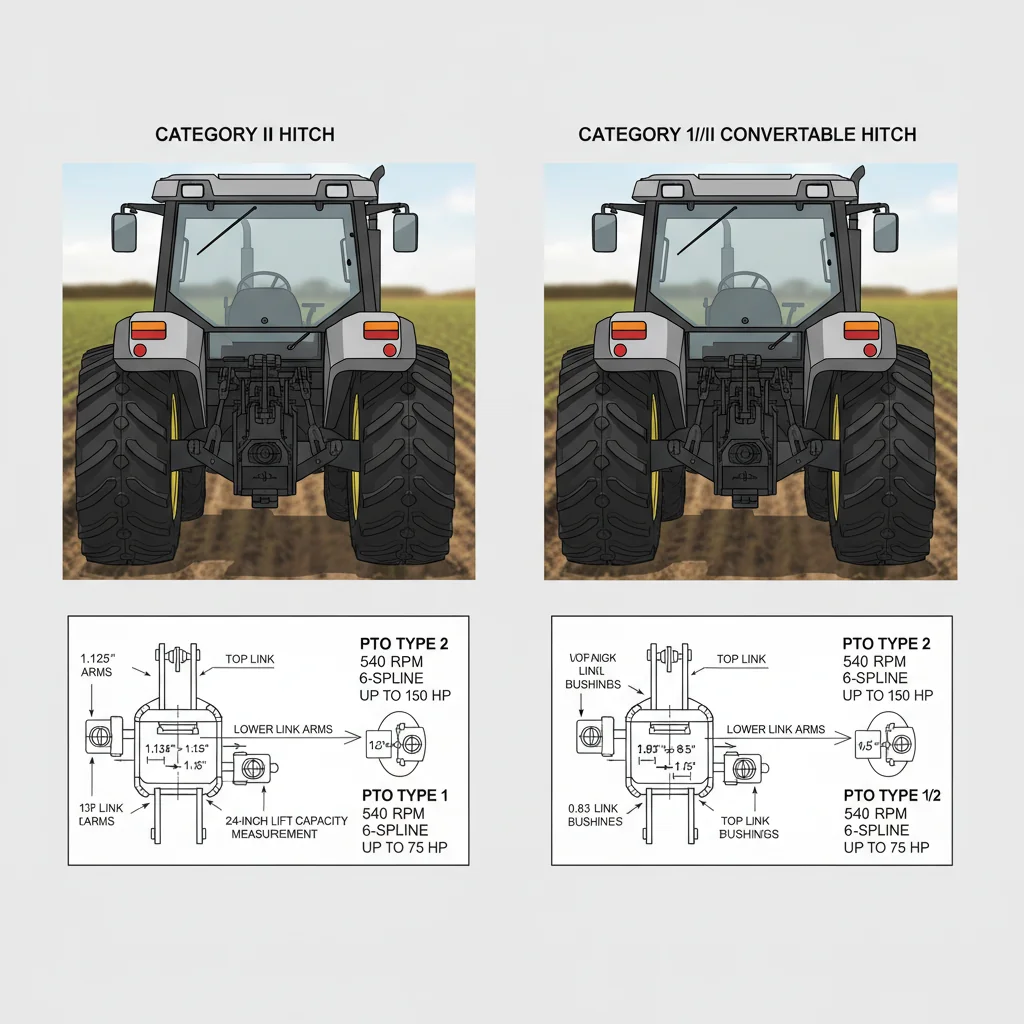

Correct hitch category and PTO specifications are essential for safe implement compatibility. Category II or convertible I/II hitches suit most 40–100 hp tractors; verify pin size and lift capacity at 24" behind the balls. Confirm PTO speed5 (540 rpm standard), spline type, and horsepower rating to ensure proper implement performance.

Last month, a distributor in Peru called after his customer struggled to mount a heavy disc harrow on a 75HP tractor. The hitch was rated for 1,800 kg at the balls, but when we checked the capacity at 24 inches behind the balls—the real working point—it dropped to around 1,300 kg. That made transport risky and limited field use. I see this a lot: buyers focus on the HP and overlook the three-point hitch category and lift specs. For most 40–100HP tractors, Category II hitches6 are common. But some models offer convertible I/II setups, which sounds flexible until you realize older implements in the region might have Category I pins and need bushings or adapter pins.

If you're moving up in tractor size, expect some extra costs for new pins or even new implements. The PTO is another area where details matter. Most tractors in Africa and Latin America run a 540 rpm PTO with a six-spline shaft. But I’ve seen exporters send out units with 1000 rpm shafts or different spline counts, leading to headaches on delivery. Always check the PTO speed, spline type, and rated PTO horsepower. For example, a 60HP tractor might only deliver 50HP at the PTO—enough for a medium rotary tiller, but not for a heavy baler. I always suggest matching your heaviest implement’s requirements to the tractor’s PTO spec, not just the engine power. Before finalizing a deal, look at drawbar size and hitch geometry too.

The lift capacity of a tractor's three-point hitch is always measured at the hitch balls, not at 24 inches behind them.False

Manufacturers often specify two lift capacities: one at the hitch balls and another at a point 24 inches behind the balls, which more accurately reflects the real load the hitch can handle in field conditions. The capacity at 24 inches is usually lower due to leverage effects.

A tractor's PTO horsepower and three-point hitch lift capacity are independent specifications, so a high PTO rating does not guarantee the hitch can safely lift heavy implements.True

PTO horsepower describes the tractor's power output for running implements, while three-point hitch lift capacity measures how much weight the hitch can raise and carry. It's common for tractors to have strong PTO performance but a limited hitch lift, or vice versa, so both specs must be checked for compatibility with intended implements.

Key takeaway: Matching a utility tractor’s hitch category and PTO specifications to implement requirements ensures safe, efficient operation and avoids costly retrofits. Always verify hitch lift capacity, PTO speed, spline configuration, and power output before purchase to prevent compatibility problems and unsafe modifications.

Which Comfort and Safety Features Matter Most?

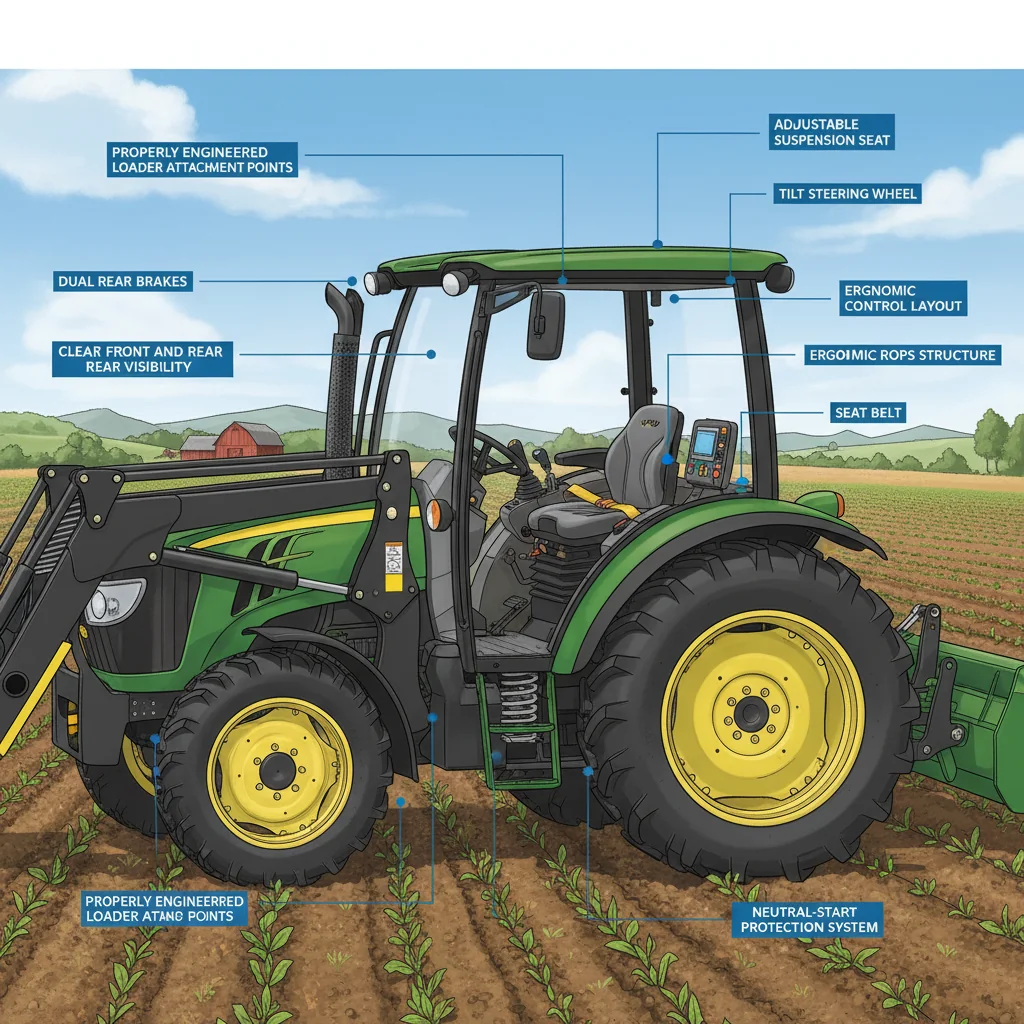

Prioritize an adjustable suspension seat7, tilt steering, and ergonomic controls for operator comfort during long workdays. Essential safety features include a certified ROPS8 or cab, seat belt, reliable dual rear brakes, and neutral-start protection. Good visibility, wide rear track, correct ballast, and engineered loader attachments further enhance safety and reduce operator fatigue.

To be honest, the spec that actually matters is how comfortable you feel after four hours behind the wheel. I’ve spent days in the field with farmers in Brazil and Kazakhstan—what wears you down fastest is a stiff seat or controls you can’t reach easily. Adjustable suspension seats and tilt steering make a huge difference. One customer in Mato Grosso switched to a utility tractor with a proper suspension seat, and his operators said back pain dropped off almost overnight. That’s not marketing talk—it’s what keeps people working productively until the job’s done.

Let’s compare the comfort and safety features that really matter. You’ll see why some features are worth every cent.

| Feature | Why It Matters | Field Example | Sally’s Advice |

|---|---|---|---|

| Suspension seat | Reduces shock and fatigue over rough ground | Brazil: 8-hour mowing shifts | Always test seat adjustability |

| Tilt steering | Custom fit for different operators | Kenya: Multiple shift teams | Key for shared tractors |

| Ergonomic controls | Prevents twisting, speeds up routine tasks | Peru: Loader work | Look for logically placed levers |

| Certified ROPS / Cab | Essential rollover protection | Kazakhstan: Slope fields | Never skip ROPS or seat belt |

| Dual rear brakes | Reliable stopping, safer control on slopes | Bolivia: Hilly terrain | Test braking on a loaded run |

| Loader with positive lock | Prevents accidental drops, improves operator safety | Nigeria: Feed handling | Use engineered, matched loaders |

A utility tractor equipped with an adjustable suspension seat can significantly reduce operator fatigue during long fieldwork sessions.True

Adjustable suspension seats absorb vibrations and shocks from rough terrain, which helps prevent discomfort and musculoskeletal strain over extended periods. This ergonomic improvement is especially noticeable during multi-hour shifts.

High-visibility hoods are primarily designed to reduce cabin noise rather than improve operator safety.False

High-visibility hoods are actually engineered to enhance the operator's line of sight, making it easier to monitor implements and surroundings, thereby increasing safety. Noise reduction is typically addressed through cab insulation and soundproofing, not hood design.

Key takeaway: Comfort and safety features such as ergonomic seating, intuitive controls, ROPS or cab protection, and reliable braking systems are essential in utility tractors. These elements reduce fatigue, increase productivity, and help prevent accidents, making them critical considerations for long workdays in diverse agricultural environments.

How Do Dealer Support and Warranty Affect Costs?

Dealer support, warranty terms, and lifetime costs significantly impact a utility tractor’s total cost of ownership. Factors such as fuel efficiency at working loads, service intervals, parts pricing, and regional resale value vary by manufacturer. Strong local dealer support and comprehensive, clearly-defined warranties ensure better uptime and lower long-term expenses, often outweighing differences in initial purchase price.

I've seen too many buyers focus only on the sticker price, then regret it after the first big repair. In Zambia last year, a distributor shared how two farms chose similar 85HP tractors—one with a strong local dealer and one with a distant importer. The first farm had three breakdowns during peak harvest, but their dealer sent a mechanic within 24 hours and had parts in stock. The other farm waited over a week for spares to arrive from another country. That lost time cost them more than the difference in purchase price.

Dealer support really does make or break your uptime. I always suggest visiting the dealer's workshop before you buy. Ask how many tractors like yours they support locally. Can they get critical parts—fuel pumps, hydraulic filters, clutch plates—within two days? Do they offer on-site service, or will you be hauling your tractor 200 kilometers for repairs? A slightly less-known brand with excellent local backup can outperform a famous name if the support is weak.

Warranties look similar on paper but vary a lot in practice. Some cover only the engine block, while others include hydraulics and transmission. Check the fine print—hour limits, required dealer servicing, and what counts as "wear and tear." In Brazil, I met a farmer who thought his powertrain warranty covered a failed PTO (that’s the shaft running your implements), but it didn’t. He had to pay for parts and labor himself.

My advice? Don’t just compare headline years or horsepower. Dig into service intervals, parts prices, and what’s actually covered—because that’s where your real costs add up over time.

A utility tractor with strong local dealer support can minimize downtime during critical seasons because authorized dealers typically stock common replacement parts and provide rapid on-site repairs.True

Local dealer networks are trained and equipped to handle breakdowns quickly, reducing the operational costs associated with extended equipment downtime, especially during peak agricultural periods.

Warranty coverage from an overseas tractor importer usually guarantees the same speed of repairs and parts availability as that from a local dealer.False

Overseas importers often face logistical delays in shipping parts and dispatching service personnel, which can significantly extend repair times compared to local dealers who maintain in-country inventory and staff.

Key takeaway: Evaluating utility tractors requires looking beyond initial price. Dealer support strength, warranty coverage, and true lifetime costs—including fuel, maintenance, and resale value—can make a substantial difference in long-term profitability and operational reliability.

Why Is Service Access Critical in Tractors?

Service access and maintenance friendliness impact long-term costs and reliability. Tractors requiring difficult access to oil dipsticks, filters, or batteries increase labor expenses and risk skipped maintenance. Features like slide-out radiator screens, labeled grease points, and tool-free panels enable fast, routine servicing—supporting engine life of 6,000–8,000 hours and lowering total ownership costs.

Here’s something I always check first when I visit a farm—how fast can you reach the oil dipstick and air filter? In places like Bolivia or rural Ghana, I’ve watched farmers struggle to change an air filter because the panel needed three different wrenches. That means time lost and, too often, skipped maintenance. I’ve seen it add up: one customer in Paraguay told me their “bargain” 80HP tractor ended up costing more in downtime than a better-designed model, just because basic service took twice as long.

Simple design features make a real difference. Slide-out radiator screens, tool-free side panels, and marked grease points sound minor, but they save hours over a season. For example, on a 90HP utility tractor I helped spec for a Zambian distributor, routine checks went from nearly an hour to under 20 minutes. That meant their team actually followed the 50-hour service schedule—no shortcuts, less engine wear, and no surprise breakdowns during planting. If changing the hydraulic filter or topping up coolant requires pulling apart half the hood, most owners put it off. The result? Shorter engine life and higher repair bills.

I always suggest opening the hood yourself before buying, or at least asking the dealer to demonstrate. Can you reach the battery, fuel filter, and fuse box in under two minutes? If not, think twice. A tractor that’s easy to service will reliably push past 6,000 hours—sometimes even 8,000—before needing major work. It’s a simple check, but it pays off for years.

Tractors designed with tool-free access panels for routine service points like air filters and oil dipsticks tend to have significantly lower maintenance-related downtime in the field.True

Tool-free service access reduces the time and effort required for routine maintenance, making it more likely that operators will complete these tasks on schedule, which keeps the tractor running efficiently and minimizes time lost to avoidable breakdowns.

All modern utility tractors are designed so that any operator can easily access all service points without using any tools.False

While some newer tractor models prioritize tool-free access, many utility tractors—including recent models—still require basic tools to reach certain service areas, especially in cost-sensitive or less advanced designs.

Key takeaway: Easy service access and user-friendly maintenance features directly affect a utility tractor’s lifespan and operating costs. Choosing a model with quick, straightforward access to key components ensures routine tasks aren’t skipped, maximizes uptime, and helps the tractor reach its full engine hour potential.

How Should Utility Tractors Be Field-Tested?

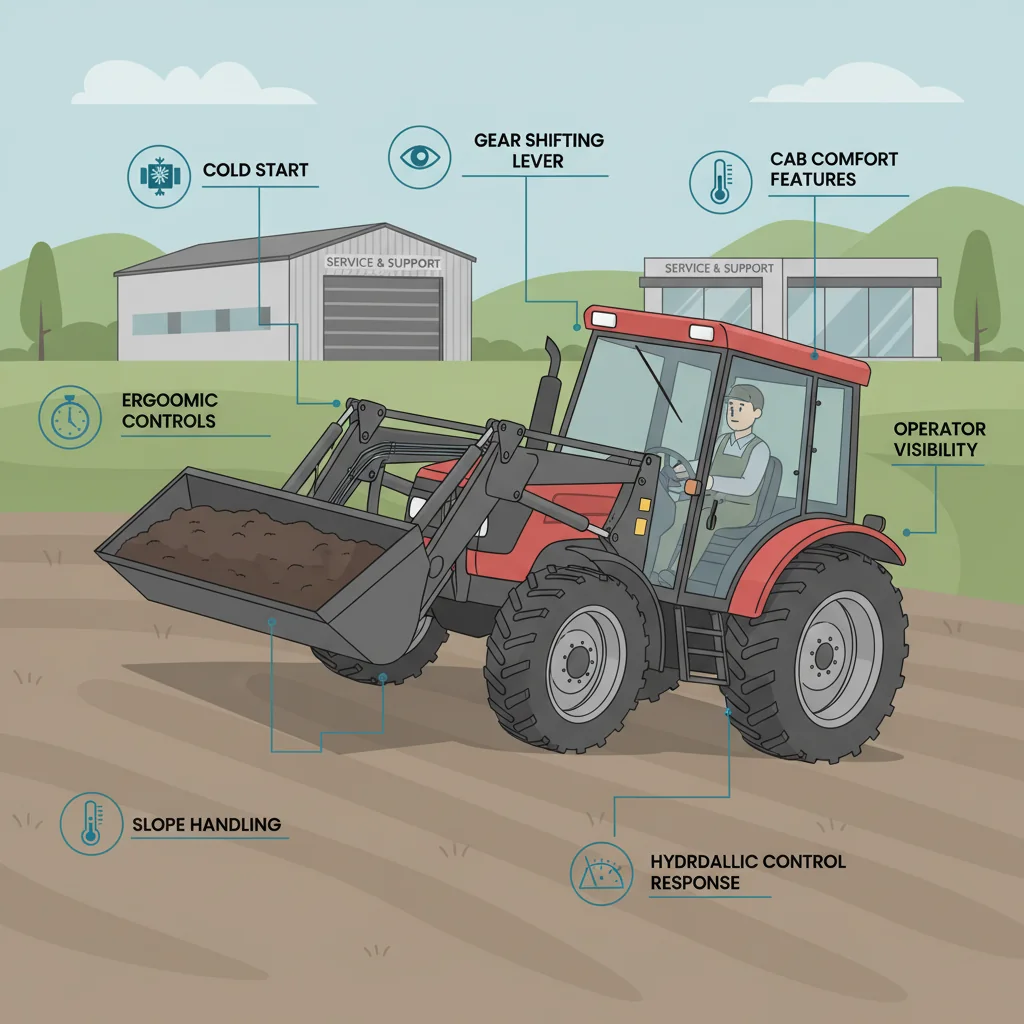

A thorough field-test of utility tractors involves operating the machine under real working conditions, ideally on-site with the heaviest implement or a full loader bucket. Key evaluation points include cold starting, gear shifting, hydraulic response, slope handling, control ergonomics, visibility, and cab comfort. Dealer support, workshop quality, and local service reputation must also be assessed.

One thing I see far too often—buyers take a quick spin around the dealer’s yard and call it a “test.” That’s not enough. If you want to know how a utility tractor will perform, you need to see it work with real loads in real conditions. For example, in Mozambique, I watched a customer test a 75HP 4WD tractor with a six-disc plow on their own field. The key was starting the engine cold at sunrise, when the temperature was barely above 10°C. That’s when you see if the battery, starter, and fuel system are up to the job—especially important in regions with cool mornings or unreliable diesel quality.

Once running, shift through every gear under load. Don’t just idle around—attach your heaviest implement or fill the loader bucket, and run the PTO (that’s the power take-off) at full speed. In Bolivia, a farmer once realized the hydraulic pump couldn’t keep up with loader cycles after only twenty minutes of real work. He’d never have noticed in an empty yard. Pay attention to three-point hitch response, too. Does it lift a full planter or sprayer quickly, or does it groan and slow down?

I always suggest talking to the dealer’s mechanics before you buy. Ask how long routine repairs take and whether they stock common spares like filters and hydraulic seals. Walk through the workshop if you can. I’ve seen too many “showroom hero, field zero” cases where the tractor looked great on delivery, but local service just couldn’t keep up. The real test is performance in the field—and the support behind it.

Cold-starting a utility tractor in the early morning is an important part of field testing because it reveals how well the battery, starter motor, and fuel system work under real-world conditions.True

Cold starts can expose weaknesses in electrical and fuel systems that may not appear when the engine is already warm. These issues are especially relevant for tractors operating in cooler climates or starting work at dawn, making this a practical and revealing test.

Testing a utility tractor's performance on a flat, paved surface is sufficient to determine how it will handle real field conditions.False

A flat, paved surface does not replicate the variable traction, uneven terrain, and actual load stresses found in real agricultural fields. Only field testing with actual implements and loads will accurately reveal the tractor’s capabilities and potential weaknesses.

Key takeaway: Real-world field-testing with actual implements and conditions, combined with honest evaluation of dealer capabilities, is essential for choosing a utility tractor that delivers reliable performance and service for years. A spec-sheet alone cannot predict true suitability or long-term satisfaction.

Conclusion

We've talked through the main points to consider when choosing a utility tractor, especially around matching horsepower to your toughest jobs and looking beyond just engine numbers. From my experience, the buyers who get the most value look at PTO power, hitch capacity, and how easy it is to get parts—not just what's printed on the spec sheet. I've seen too many people caught out by "parts roulette" when they need repairs in the middle of the season. If you have questions about which tractor matches your implements or your local conditions, feel free to reach out. I'm always happy to share what’s worked for real farmers. Every farm and every field is different—choose the tractor that truly fits your needs.

References

-

Learn how power shuttle transmissions enable quick forward-reverse shifts without clutching, reducing operator fatigue during repetitive yard and bale work. ↩

-

Learn why balanced wheelbase and adjustable track width are crucial for maintaining tractor stability on hillsides and uneven fields. ↩

-

Explore how 4WD 65 HP tractors outperform higher horsepower 2WD models on wet soils and slopes, improving traction and safety. ↩

-

Learn how loader lift capacity impacts farm productivity and the importance of full-height lift ratings for heavy loads. ↩

-

Explains PTO speed standards like 540 rpm and their impact on implement performance and export challenges. ↩

-

Detailed overview of Category II hitch specs and compatibility for 40–100 hp tractors, helping buyers avoid costly mismatches. ↩

-

Explore how adjustable suspension seats reduce shock and fatigue, enhancing operator comfort during long agricultural workdays. ↩

-

Learn why certified ROPS are essential for protecting operators, preventing injuries, and complying with safety standards in farming. ↩