Utility Tractor Maintenance Requirements: A Manufacturer’s Field Guide

Not long ago, a distributor in northern Ghana called me, frustrated that his new fleet of 85HP tractors kept breaking down mid-season. The culprit? Missed maintenance—nothing high-tech, just basic checks that fell through the cracks during the busiest planting days.

Utility tractor maintenance is governed by engine hours rather than mileage or calendar intervals, with key servicing tasks grouped at set hour marks to ensure mechanical reliability. Daily and weekly inspections of fluids, leaks, and filters are essential for minimizing in-field failures and prolonging equipment life. Engine oil and filters typically require replacement every 250–300 hours, while hydraulic and transmission systems demand careful oil selection, routine level checks, and periodic full changes.

How are utility tractor service intervals set?

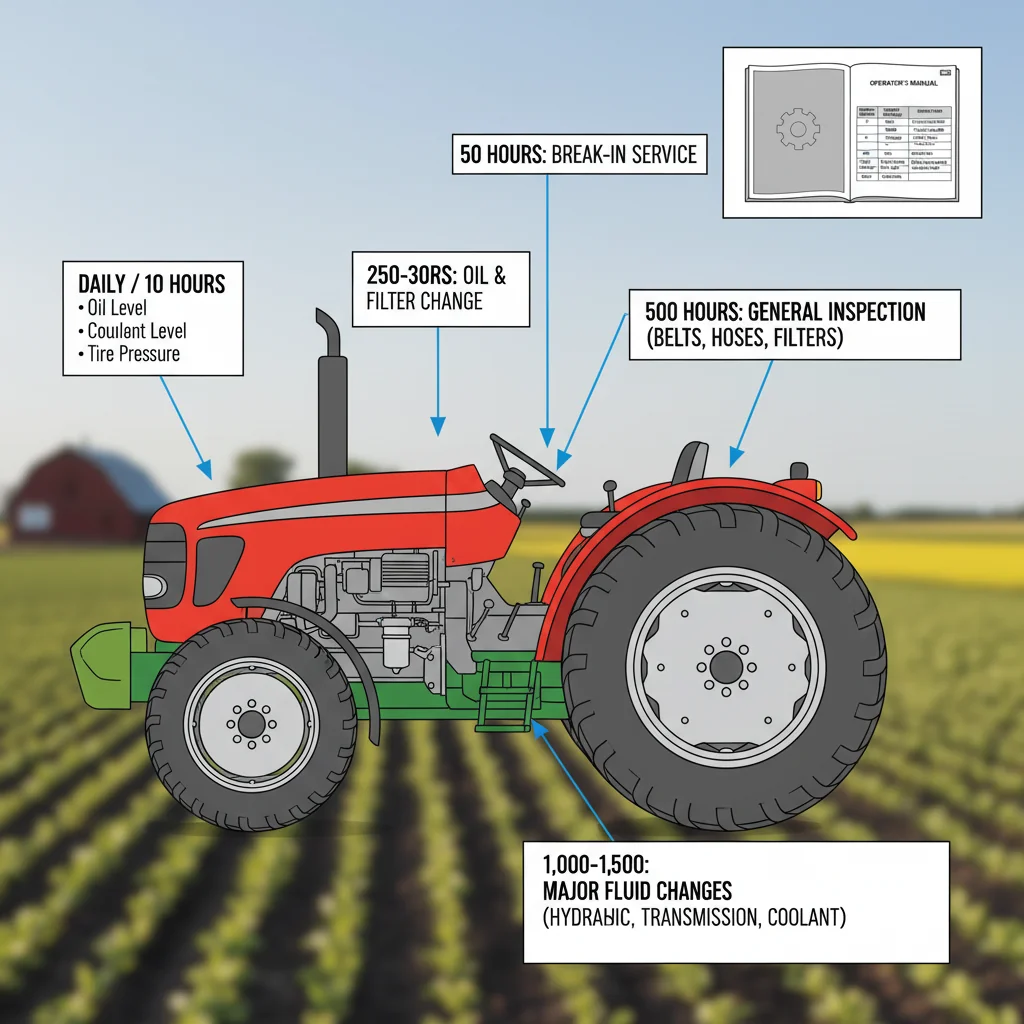

Utility tractor maintenance intervals are scheduled by engine hours, not calendar months or mileage. Key service marks include daily (or 10-hour) checks, 50-hour break-in, 250–300-hour oil and filter changes, 500-hour inspections, and 1,000–1,500-hour major fluid changes. The operator’s manual provides a required service table.

Most people don’t realize that utility tractors live by the hour meter, not the calendar. You can run a 75HP tractor for 500 hours in one planting season in Kenya, or only 200 hours a year in parts of Kazakhstan where the work is more seasonal. That’s why manufacturers set service intervals by engine hours—it's far more accurate than months or mileage. The hour marks are clear: daily checks (or every 10 hours), a 50-hour break-in service, then oil and filter changes around 250–300 hours, bigger inspections every 500 hours, and major fluid changes like transmission or hydraulic oil at 1,000–1,500 hours.

Last season, I worked with a distributor in Peru who managed a fleet of 60–90HP tractors. Their operators hit 250 hours in just four months because of double-shift harvesting. If they’d used a calendar schedule, they would have missed critical oil changes and risked engine wear. Instead, they followed the hour-based table in the manual, logging every service. That simple habit protected their warranty and, just as important, kept machines running during peak demand. I always suggest building a basic log—date, hours, job done—for every tractor. It’s simple but pays off.

Here’s what matters most: tracking by engine hours means you adapt to how hard the tractor actually works. One farmer in Bolivia told me he used to skip 500-hour inspections, thinking “once a year is enough.” But when his hydraulic pump failed early, the repair cost him almost as much as a season’s profit. Don’t ignore the hour meter—that’s your machine’s lifeline.

Service intervals for utility tractors are determined by engine hours rather than calendar time because the workload and usage intensity vary greatly by region and farming practice.True

Manufacturers use engine hours to set service intervals since tractors may be used heavily in some locations and lightly in others, making engine hours a more accurate measure of wear and maintenance needs than months or mileage.

Utility tractors require oil changes strictly every 12 months, regardless of how many engine hours are accumulated.False

Oil change intervals are based on engine hours rather than calendar time since actual usage determines oil degradation more accurately than the passage of months, especially in regions with seasonal or variable tractor operation.

Key takeaway: Utility tractor maintenance relies on tracking engine hours for all service intervals, not time or distance. Following the manufacturer’s hour-based service table protects equipment longevity, warranty, and resale value—especially in emerging markets where tractors may operate seasonally or intensively.

What daily checks reduce tractor breakdowns?

A 5–10 minute pre-operation walk-around, including checks of engine oil, coolant, fuel level, and hydraulic/transmission oil, prevents most in-field failures. Inspect under the tractor for fresh leaks and examine hoses and fittings for wear. In humid regions, drain the fuel water separator1 daily or weekly to protect injectors.

Let me share something important about reducing tractor breakdowns—it's not about complicated tools or high-tech diagnostics. Most failures start with simple issues you can spot in a daily five-minute walk-around. I’ve seen this firsthand in Brazil, where one missed coolant check led to an engine seizure during sugarcane harvest. That was a $4,000 repair and two weeks of lost work. The reality is, checking engine oil, coolant, fuel, and hydraulic or transmission oil with a dipstick or sight glass can catch 80% of problems before they become disasters.

A good habit is to look under the tractor every morning for fresh oil or coolant spots. I always tell my customers in Kenya, “If you see a dark patch under the engine, don’t ignore it.” Hoses and fittings should get a quick squeeze—if you find any soft spots, cracks, or wetness, address them before heading to the field. In humid areas like coastal Peru, water in diesel tanks is a silent killer. Draining the fuel water separator daily or at least weekly keeps injectors safe. I’ve seen too many farmers skip this step and end up with a full set of clogged injectors after just one rainy season.

Weekly, check your hydraulic oil for a milky appearance—it means water contamination, which can destroy pumps and seize the three-point hitch. This takes less than ten minutes but can save thousands in repairs. I suggest building this routine into your day. No one should start the tractor until these checks are done.

Checking and cleaning the tractor's air filter daily can prevent dust-related engine wear, especially in high-dust environments like harvest fields.True

Air filters trap dust and debris that can cause internal engine wear if allowed to enter the intake. In dusty agricultural conditions, filters can clog quickly, restricting airflow and allowing contaminants through. Daily inspection and cleaning help maintain engine efficiency and longevity.

It is unnecessary to inspect hydraulic hose connections daily because leaks develop slowly and are easily noticeable before causing damage.False

Hydraulic leaks can develop rapidly and may not be obvious until significant fluid loss or system failure occurs. Daily checks are necessary to identify small leaks or damaged hoses before they escalate into breakdowns or safety hazards.

Key takeaway: Implementing a brief daily inspection routine—checking vital fluids and inspecting for leaks—can prevent up to 80% of unexpected tractor failures. This simple, consistent habit helps detect issues early, avoiding costly breakdowns and lost productivity, especially in challenging emerging market environments.

How often change utility tractor engine oil?

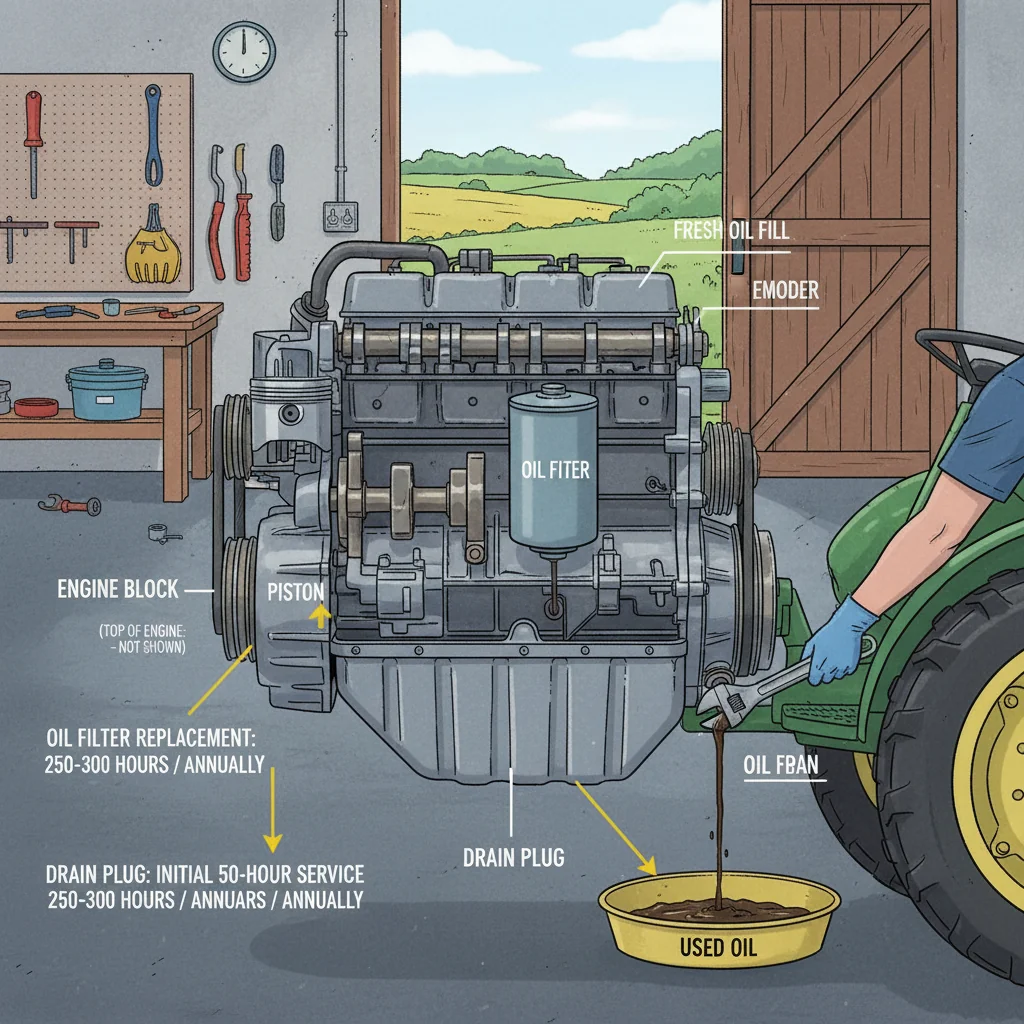

Engine oil and filters on 50–120 hp diesel utility tractors should be changed every 250–300 hours or annually, whichever occurs first. The initial change is typically at 50 hours to remove break‑in debris. Harsh conditions—such as heavy, dusty, or high‑load work—may require shortening intervals to around 200 hours.

Here’s what matters most when keeping your utility tractor running strong: engine oil and filter changes2 are not just a box to tick—they’re your main defense against costly repairs. For most 50–120HP diesel tractors, the standard is every 250–300 hours or once per year, whichever comes first. That first oil change at 50 hours is critical. I’ve seen engines in Ghana with metal shavings in the first drain—skip this step, and you risk long-term issues.

In real fieldwork, conditions are rarely ideal. If you’re working in dusty sugarcane fields in Brazil or hauling heavy loads with a front loader in Kazakhstan, oil breaks down faster. I always suggest shortening intervals to around 200 hours in those cases. It’s a small investment—on a 75HP tractor running 500 hours a year, oil and filters might cost $100–$150 annually, or just a few cents per hour. Compare that to the price of an engine rebuild, which can easily hit $2,000–$3,000 in parts and labor, especially if you’re far from a major service center.

I’ve worked with farmers in Peru who tried to stretch oil changes, thinking they’d save money. The result? Hard starting and blue smoke after two seasons—the classic signs of worn piston rings and oil breakdown. Always use oil that meets your engine’s spec, like API CI-4 or CK-4, usually 15W-40 for these tractors, and match it with a good quality filter. I recommend tracking your hours closely—reliable maintenance saves headaches. Keeping to the right intervals protects your investment, year after year.

Skipping the first 50-hour oil change on a new utility tractor can allow initial metal particles from engine break-in to circulate, increasing wear on internal components.True

During the initial break-in period, it's common for small metal shavings from manufacturing and assembly to be present in the oil. Removing these early with the first oil change helps protect the engine from premature wear and damage.

Utility tractor engine oil only needs to be changed if the oil appears dark or dirty on the dipstick, regardless of operating hours.False

Oil can degrade and lose its protective properties due to heat, contaminants, and time, even if it still looks clean. Relying solely on oil appearance ignores critical factors like additive depletion and microscopic contamination, which is why manufacturers specify change intervals based on hours or time, not just visual inspection.

Key takeaway: Sticking to recommended oil and filter change intervals—250–300 operating hours or once yearly—prevents costly engine damage. Early first changes and shorter intervals for tough conditions protect reliability, while using the correct oil and filter ensures long-term performance and reduces total ownership costs.

How to maintain utility tractor hydraulics?

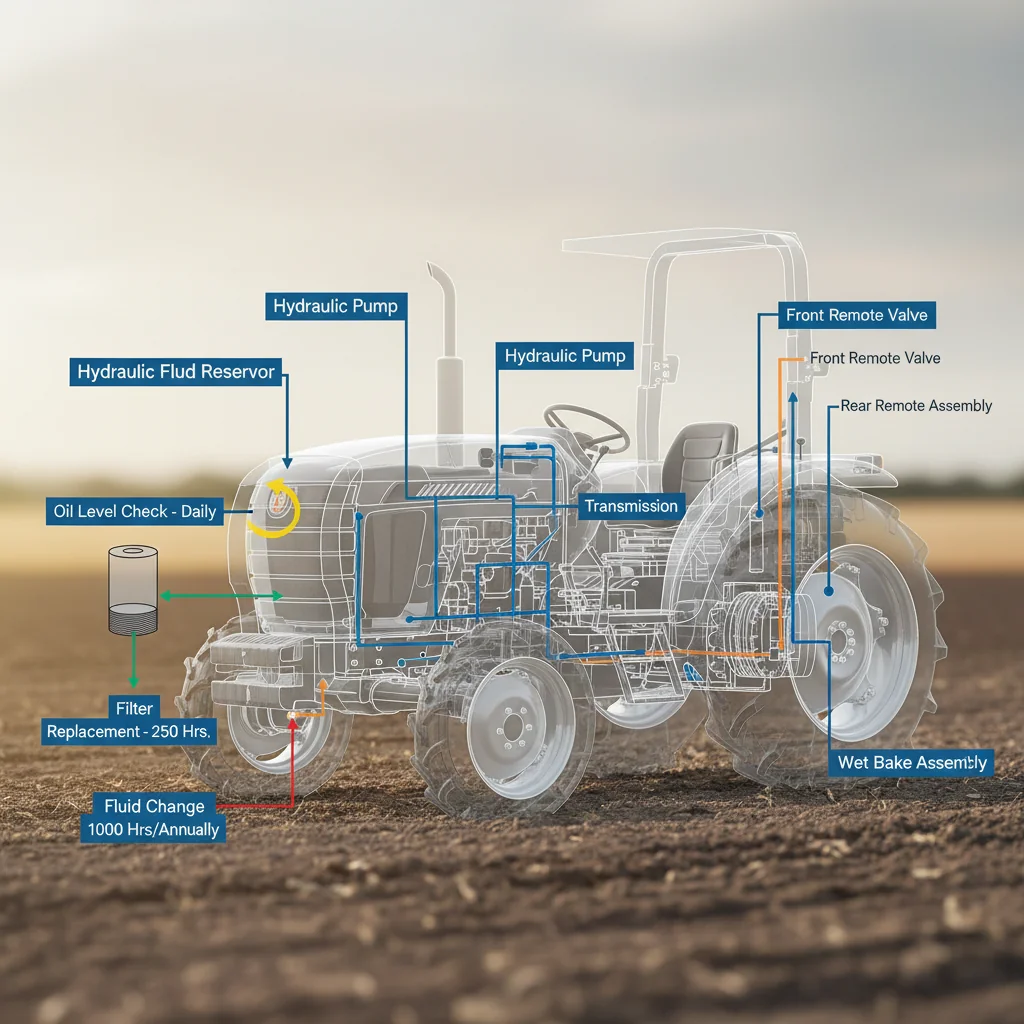

Utility tractors often use UTTO or THF oil3 for combined hydraulic, transmission, axle, and wet brake systems. Using improper oil can cause brake chatter, clutch slip, gearbox noise, and early hydraulic pump failure4. Check oil level and condition weekly. Replace filters every 500–750 hours and change oil fully at 1,000–1,500 hours, always following manufacturer guidelines.

The biggest mistake I see is people pouring in whatever oil they have on hand—AW hydraulic oil, gear oil, even used engine oil. That’s risky. Most utility tractors in Africa and Latin America use a shared hydraulic system5 for the transmission, rear axle, three-point hitch, and wet brakes. These systems need a special oil, usually called UTTO or THF. If the wrong oil goes in, you’ll hear brake chatter, feel the clutch slipping, or notice noisy gears. I had a case in northern Peru where a 75HP tractor started losing hydraulic lift and the brakes screeched after just six months—turns out, the farmer was topping up with standard gear oil from the local truck shop.

Checking oil level and condition is simple but essential. I recommend a quick check every week, especially if you’re running a loader or heavy implements. Cloudy or milky oil means water contamination—something I’ve seen often in rainy parts of Kenya. That can wreck the hydraulic pump fast. If you spot that, drain and refill right away. For most tractors, change hydraulic filters every 500–750 hours. Full oil change? Around 1,000 to 1,500 hours, but always check your manual. Skipping these intervals might save time now, but I’ve seen hydraulic pump replacements cost more than ten oil changes.

To be honest, these are jobs you can do at home if you work methodically, but never improvise with random oils. I always tell customers—using the right UTTO or THF oil and keeping to a simple service schedule is the cheapest insurance for your tractor’s hydraulics.

Using gear oil instead of UTTO or THF in a utility tractor with a shared hydraulic system can cause brake chatter and clutch slippage due to incompatible friction modifiers.True

Gear oil lacks the specific additives required for wet brakes and clutch packs in shared hydraulic systems, leading to improper operation and accelerated wear. UTTO and THF are formulated for these multi-purpose applications.

It is safe to top up a utility tractor's hydraulic reservoir with any hydraulic oil as long as the viscosity matches the manufacturer's specification.False

Matching viscosity alone is not enough; hydraulic systems in utility tractors often require specific additive packages for transmission, brakes, and wet clutches. Using an oil without the correct additives can result in component damage and reduced system performance.

Key takeaway: Proper maintenance of hydraulic and transmission systems requires using only the manufacturer-specified UTTO/THF oil, performing regular checks for oil level and contamination, and adhering to recommended filter and oil change intervals. Incorrect oil use or skipped service can result in expensive damage and downtime.

Why is cooling system care essential?

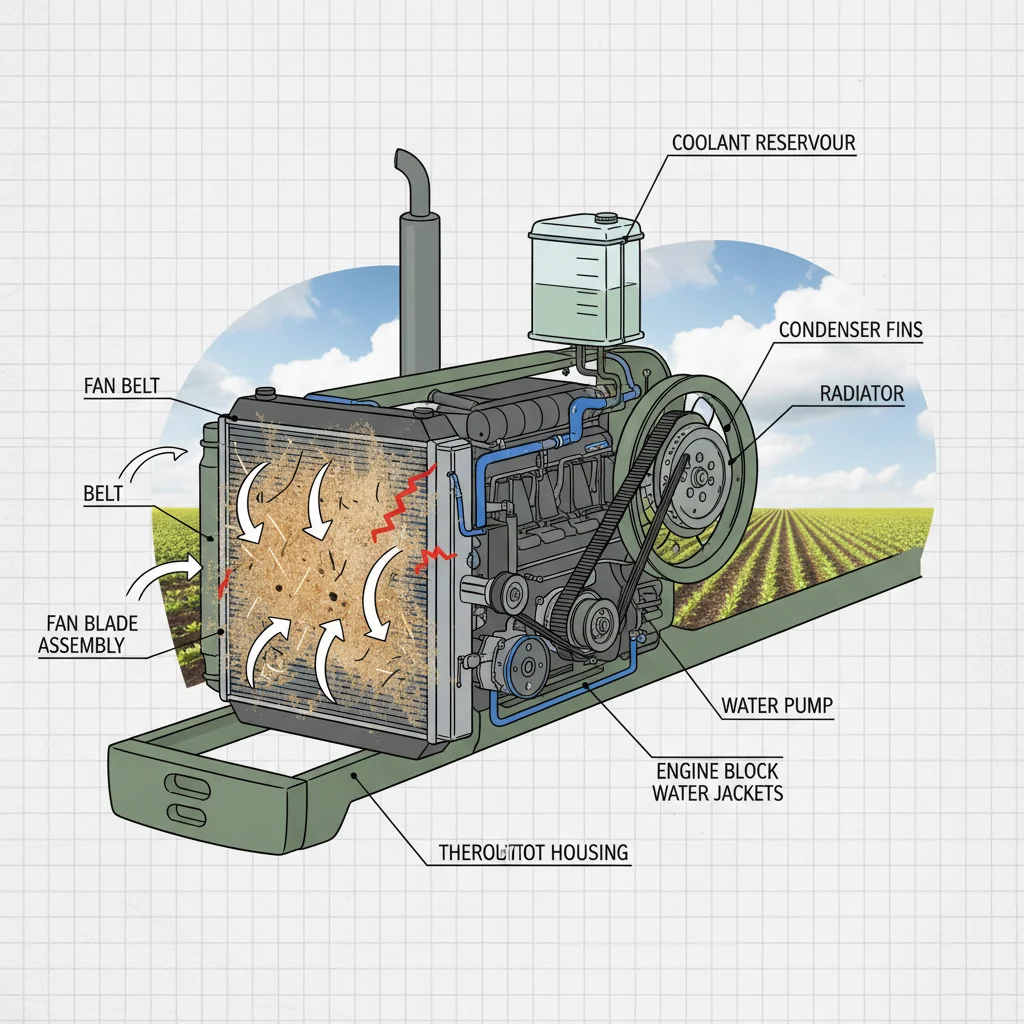

Proper radiator and cooling system maintenance is vital for utility tractors because overheating is a leading cause of engine failure. Dense radiator and condenser fins clog quickly with debris, especially in straw or dusty conditions. Daily cleaning, correct coolant use, and regular fan belt inspections prevent hidden overheating and significantly extend engine and head-gasket life.

I've worked with customers in Kenya and Brazil who learned the hard way how unforgiving tractor cooling systems can be. In dusty maize fields near Eldoret, a client ran a 75HP utility tractor for long days during harvest. After just a week, the radiator fins6 were caked with chaff, and the engine started running hot—though the dashboard gauge barely moved at first. By the time they noticed real performance loss, the cylinder head gasket was already leaking. That repair cost them nearly a month of downtime and close to $1,000 in parts and labor.

Here’s the thing: modern compact and utility tractors use dense radiator cores to save space and boost cooling. But those tight fins trap straw, dust, and seeds much faster than older, wide-fin designs. In the dry season in Bolivia, I’ve seen screens clog solid in a single day of baling hay or tilling powdery ground. If you only check the radiator weekly, you’re gambling with your engine. I always suggest blowing out the radiator and condenser from the fan side with compressed air after every shift—especially in tough conditions.

Don’t overlook coolant quality or fan belt tension either. Using plain water instead of proper coolant might seem cheaper, but it leads to internal corrosion and even cavitation damage inside the block after a couple of years. I remind every new customer: replace coolant every 2–3 years or 2,000 hours. And check those fan belts for cracks and slack every 50 hours—a slipping belt cuts cooling power and charging. A few minutes each day prevents expensive surprises down the road.

Dust and crop debris can insulate radiator fins, drastically reducing heat dissipation efficiency in utility tractors even before warning lights or gauges indicate overheating.True

Radiators rely on unobstructed airflow to transfer engine heat efficiently. Debris buildup acts as an insulating layer, impeding heat transfer long before sensors detect a temperature rise, risking severe engine damage if not cleaned regularly.

Utility tractor cooling systems require less frequent attention in tropical climates because engines are designed to tolerate higher ambient temperatures.False

In reality, higher ambient temperatures and dusty conditions in tropical climates increase thermal stress and debris accumulation, making regular cooling system maintenance even more critical, not less.

Key takeaway: Routine cleaning of radiator fins and screens, combined with regular coolant and belt checks, prevents overheating—a primary cause of tractor engine damage. These simple, scheduled maintenance steps can double engine and head-gasket lifespan, safeguarding reliability in tough field conditions.

How are tractor filters properly maintained?

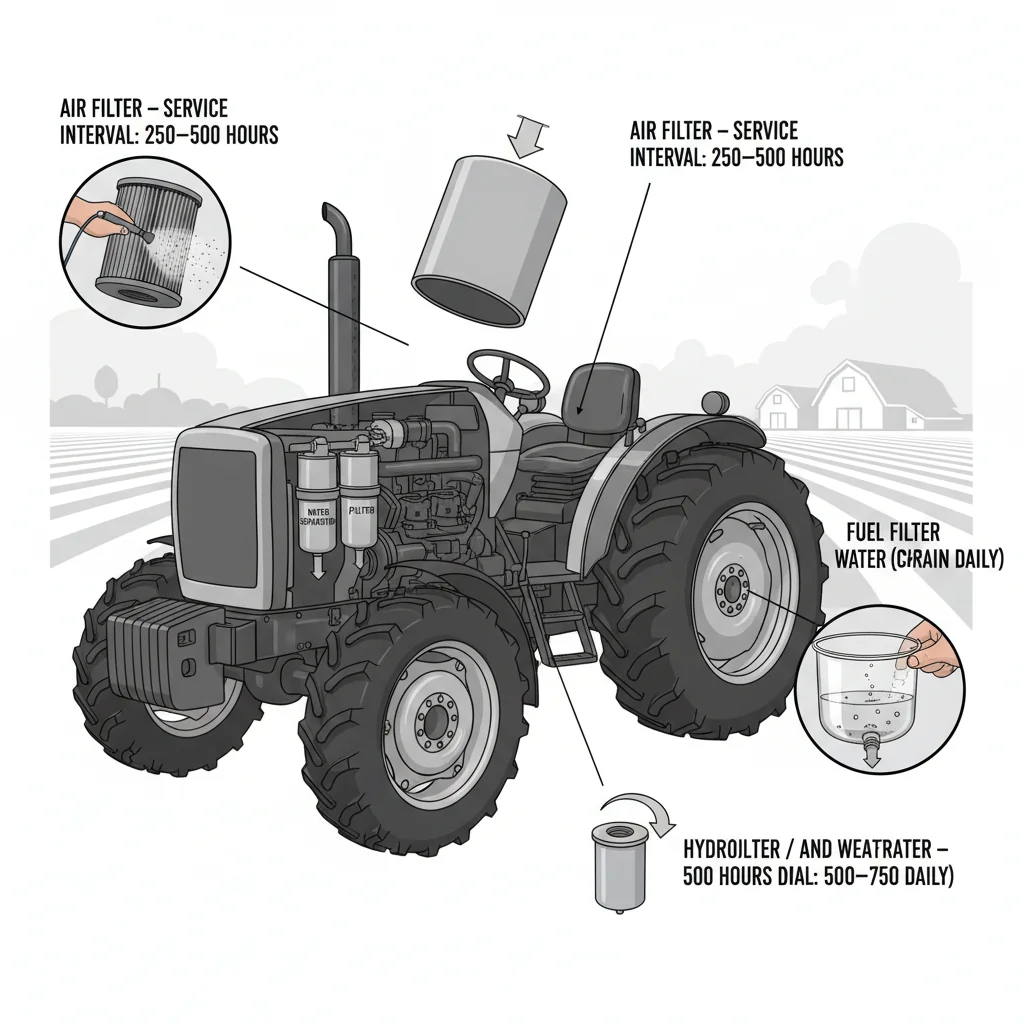

Utility tractor filters must be inspected and serviced at set intervals to prevent system contamination. Air filters require monthly checks, with outer elements cleaned using low-pressure air and replaced every 250–500 hours. Fuel filters and water separators7 need regular draining and replacement, while hydraulic filters are typically changed every 500–750 hours.

Proper filter maintenance is something too many operators overlook—until trouble starts. In dusty places like northern Kenya or southern Kazakhstan, I’ve seen fuel systems fail after just one bad season because filters weren’t checked often enough. Air filters8 are your first line of defense. I always recommend monthly inspections, but on a farm running in dry, dusty fields, you might need to look every week. When cleaning, use low-pressure air and blow from the clean side out. Replace the outer filter element when the indicator hits red or you reach 250–500 engine hours—whichever comes first. Don’t try to clean the inner “safety” element; it’s there for emergencies, and once it’s dirty, replacement is the only option.

Fuel filters and water separators are just as critical, especially in humid climates. I worked with a rice farmer in Bolivia who drained his separator every morning during the wet season to avoid injector problems. That habit saved him from costly repairs. I usually suggest replacing fuel filters every 250–500 hours, but if you notice water or debris, don’t wait—change them right away. Use only approved parts; I’ve seen cheap replacements clog systems and kill warranties.

Hydraulic and transmission filters protect your most expensive components. Change them every 500–750 hours, or sooner if you notice sluggish hydraulics or dirty oil. Most filter jobs are simple with basic tools, but keep records and receipts. In my experience, that’s the best way to keep your tractor reliable—most brands require proof of service for warranty claims.

Blowing out a tractor's air filter from the clean side with low-pressure air helps prevent pushing dust deeper into the filter media, extending its service life.True

Blowing air from the clean side outward dislodges trapped dust without forcing contaminants further into the filter, which can happen if air is applied from the dirty side. This technique preserves filter effectiveness, especially in dusty environments.

It is recommended to clean and reuse all types of tractor fuel filters as part of regular maintenance, rather than replacing them.False

Most tractor fuel filters are designed to be replaced, not cleaned and reused. Attempting to clean them can damage the filter media or leave contaminants behind, risking fuel system damage. Always follow manufacturer recommendations for replacement intervals.

Key takeaway: Regular inspection and timely replacement of air, fuel, and hydraulic filters are essential to protect utility tractor systems from dust and contaminants. Following manufacturer-recommended intervals and using approved parts ensures reliable operation and warranty compliance, especially important in emerging markets with dusty or humid conditions.

How Do Tires, Brakes, and Axles Impact Reliability?

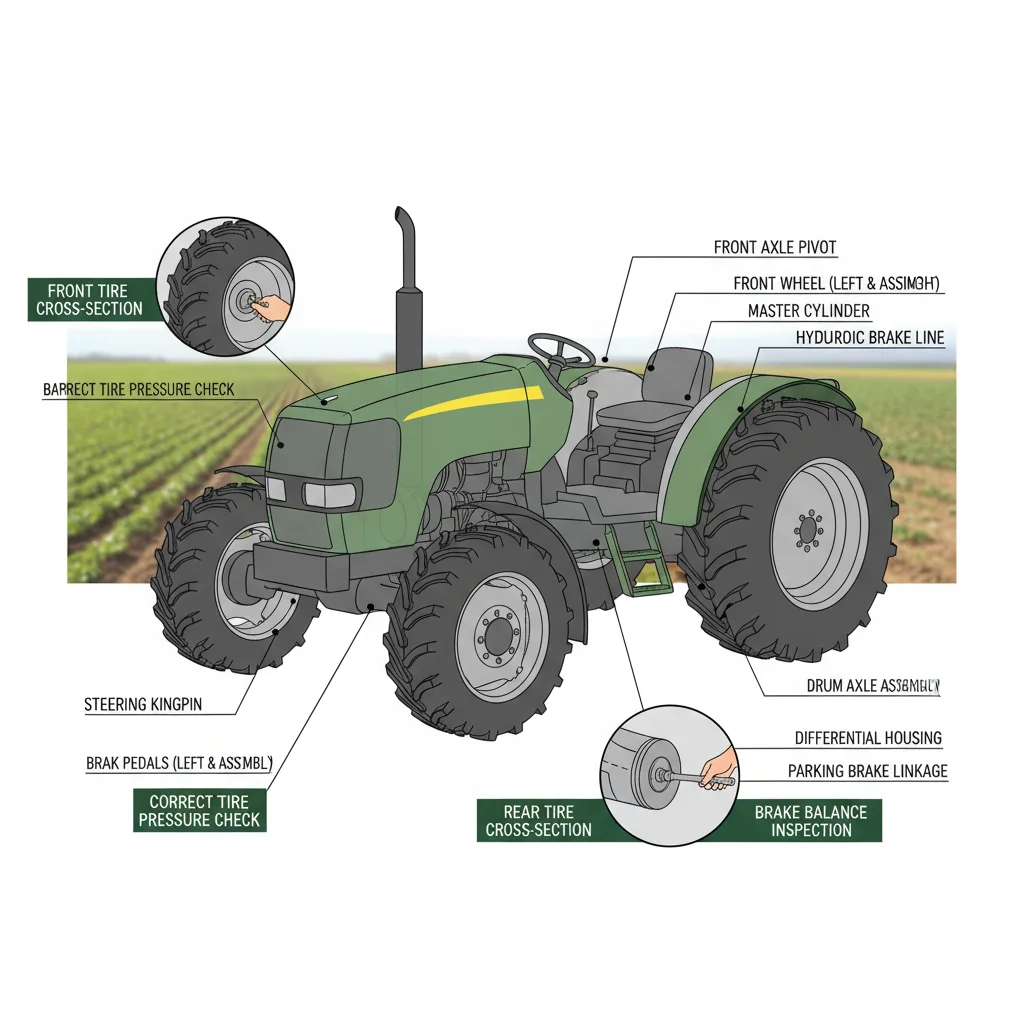

Tires, brakes, and axles are critical to utility tractor reliability. Incorrect tire pressure9 reduces traction, increases fuel consumption, and accelerates wear. Daily tire checks are advised for heavily used tractors. Regularly inspect axle pivots10, kingpins, and brake pedal balance every 250–500 hours to prevent steering issues, uneven braking, and costly wheel hub or axle repairs.

I've worked with customers who made the mistake of ignoring tire pressure and axle checks, only to face serious downtime later. In Ethiopia, a mid-sized farm ran a fleet of 80HP 4WD tractors for maize and wheat. Their operators skipped daily tire inspections—within six months, two front tires failed from sidewall damage, and fuel use shot up. They also neglected to re-torque the wheel nuts after the first week. That led to a cracked wheel hub, costing them almost three weeks waiting for replacement parts. For machines working long hours, especially with loaders, daily tire checks are not optional—they’re essential.

Tire pressure isn’t just about avoiding flats. Underinflated fronts can’t support the loader or steering—sidewalls flex and eventually split. Overinflated rears lose grip, ride rough, and wear unevenly. For a typical 4WD utility tractor, you’ll often see 28–36 psi in the front and 12–20 psi in the rear, but always check both the manual and the tire markings. I’ve seen tractors in Brazil run 4,000 hours trouble-free just by sticking to these basics.

Axle pivots, kingpins, and brake linkages need checking every 250–500 hours. If the front axle gets too much play, steering goes loose—dangerous on slopes or when carrying bales. Uneven brake pedals cause one wheel to lock up first, wearing components and risking accidents. Wet brakes, if fitted, need regular servicing to avoid expensive overhaul. My advice? Set a reminder for these checks. It’s a small effort compared to the cost of losing a whole season to preventable breakdowns.

Neglecting to re-torque tractor wheel nuts after initial use can cause the wheel hub to crack, leading to extended downtime.True

After the first hours of operation, especially on new or recently serviced tractors, wheel nuts can loosen due to vibration and settling. If not re-torqued, this can result in uneven stress and potential hub damage, making regular checks essential for reliability.

Utility tractor axles require lubrication only once per year, regardless of use or field conditions.False

Axle lubrication frequency depends on operating hours, field conditions, and manufacturer recommendations. In dusty or wet environments, more frequent lubrication is needed to prevent wear and maintain reliability. Annual servicing alone is insufficient for most working tractors.

Key takeaway: Routine checks of tires, brakes, and axles are essential for maximizing utility tractor safety, efficiency, and longevity. Follow manufacturer guidelines for tire pressures and scheduled inspections to avoid expensive repairs and minimize downtime in the field.

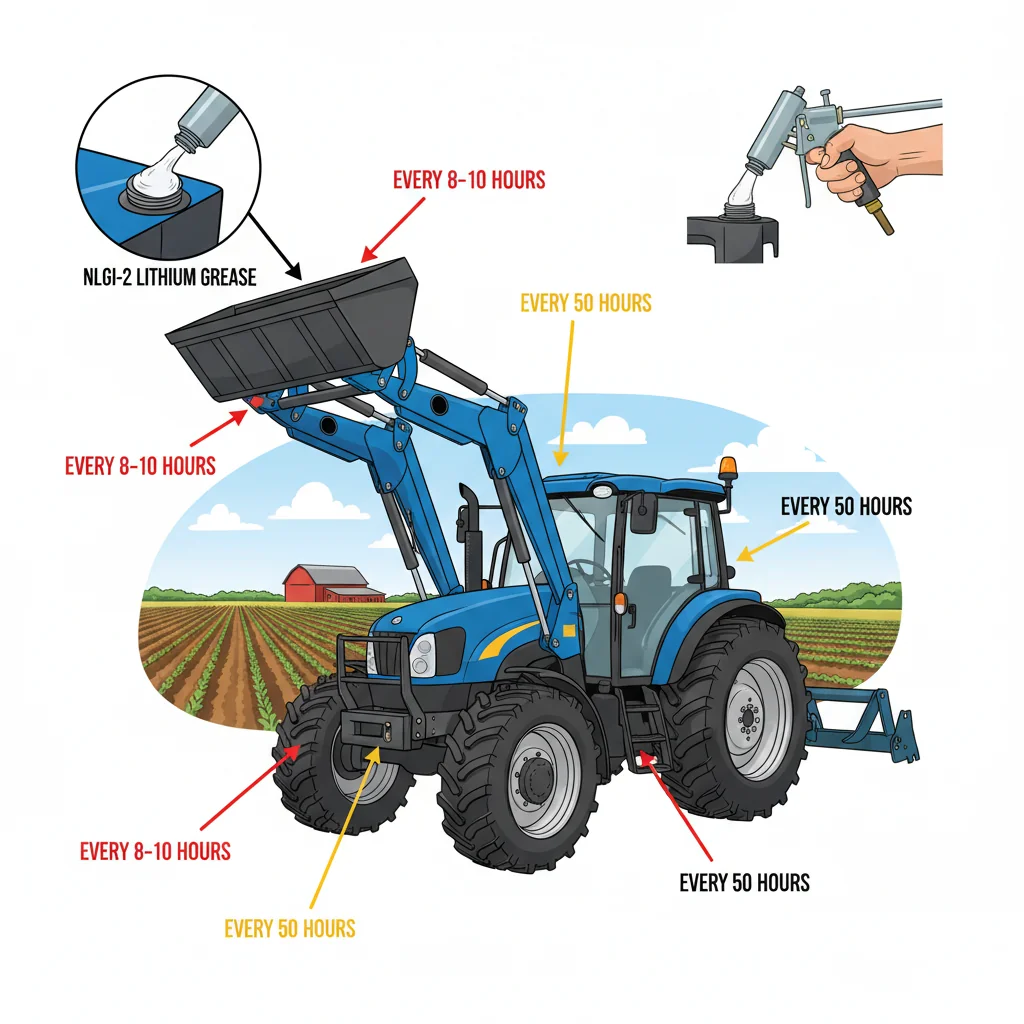

How often should tractor grease points be serviced?

Utility tractor loaders and linkages require greasing every 8–10 operating hours under heavy use. Steering joints, drawbars, and 3-point hitch pivots should be greased at least weekly or every 50 hours. Regular lubrication using NLGI-2 lithium grease significantly extends pin and bushing life, reducing costly wear and downtime.

Last month, a distributor in Bolivia called me about premature wear on loader pins. Their fleet of 80HP utility tractors was moving feed and manure daily—rough work, lots of dust. The problem? Operators skipped daily greasing, assuming once a week was enough. Within a season, loader bushings were loose and needed replacing. I explained that with constant heavy use, loader arms and bucket pivot points should be greased every 8–10 hours—essentially, each day the machine works hard. That small effort keeps dirt out and maintains a film of protection, especially where dust and mud are everywhere.

From my experience, steering joints and three-point hitch pivots last much longer when greased at least every 50 hours or once a week. In Kazakhstan, one customer doubled his front axle bushing life by sticking to this schedule—even under tough wheat stubble and dry soil. The key is using a quality NLGI-2 lithium grease. It handles high pressure and doesn’t wash out like cheaper products. A $30 grease gun and ten minutes can save thousands in rebuild costs over the tractor’s life. Loader booms, bucket pins, front axle pivots, and steering linkages are the main wear points I watch.

I always suggest marking grease intervals on a chart in the cab or workshop. Routine lubrication is a habit that pays off—especially in emerging markets where parts can take weeks to arrive. Keep it simple and regular, and you’ll avoid breakdowns that sideline your tractor during the busiest season. That’s real reliability in the field.

Loader arm and bucket pivot points on utility tractors working in dusty, high-load conditions should be greased every 8–10 operating hours to prevent accelerated wear.True

In demanding environments, contaminants and heavy use increase friction and wear at pivot points. Regular greasing forms a protective barrier, reducing metal-to-metal contact and flushing out debris, which is why daily servicing is recommended for such applications.

It is sufficient to grease all tractor loader pivot points once a week, regardless of operating conditions.False

Frequency of greasing should match the severity of use and environmental factors. In harsh, dusty, or high-load situations, weekly greasing is inadequate; daily lubrication is necessary to prevent premature wear and costly repairs.

Key takeaway: Consistent greasing of utility tractor loaders, linkages, and pivot points using quality lithium grease can double or triple component lifespan. Routine lubrication—daily for high-use pins, weekly for pivots—prevents expensive wear, supports field reliability, and minimizes downtime, especially in demanding agricultural environments.

What Are Key Utility Tractor Maintenance Tasks?

Seasonal and annual utility tractor maintenance includes pre-season 250–500 hour services11 such as oil and filter changes, air and fuel filter replacement, lubrication, and thorough inspections for leaks and wear. Post-season tasks involve deep cleaning, fluid top-off, hose and belt checks, and timely repairs. Annual professional inspections and coolant replacement12 every 2–3 years are also recommended.

Let me share something important about keeping utility tractors reliable, especially if your season is short and intense. In regions like northern Kazakhstan, farmers often run their tractors nonstop for weeks during planting and harvest. The reality is, skipping a 250–500 hour service—oil, filters, greasing—can mean a breakdown at the worst possible time. I’ve seen this cost operators at least two full working days. For a 90HP 4WD tractor, that’s a loss nobody wants in the middle of sunflower harvest. Always schedule these services before the season starts, not after it’s already too late.

After the busy period, don’t just park the tractor and walk away. Deep cleaning is more than just looks—it prevents crop residue from trapping moisture and rusting frame components. I tell customers in Bolivia to check coolant and hydraulic fluid levels after every major job. Hoses and belts crack faster in hot, dusty conditions. A quick inspection now often catches small leaks before they turn into bigger repairs. If you spot wear or minor damage, fix it right away. Waiting until next season usually means higher parts costs and longer downtime.

Many owners ask if a professional inspection is really necessary. My advice? Book one annual check at your local dealer. They can spot early wear in clutches, brakes, or bearings—issues that aren’t obvious until they fail under load. Coolant needs changing every 2–3 years, even if it looks clean. And for storage, keep the tractor dry, cylinders retracted, and battery disconnected if possible. These simple steps help avoid hard starts and electrical headaches when you need the machine most.

Neglecting to check and clean the radiator and cooling system during regular maintenance can lead to engine overheating, especially during periods of continuous operation.True

Continuous operation generates substantial heat, and debris buildup in the radiator can restrict airflow, causing the engine to overheat and potentially fail. Regular cleaning is an essential, yet sometimes overlooked, maintenance task.

It is unnecessary to inspect the hydraulic system fluid levels during scheduled utility tractor maintenance, as these systems are sealed and do not lose fluid under normal conditions.False

Hydraulic systems can develop leaks or lose fluid through normal operation, so checking and topping off hydraulic fluid is a critical part of routine maintenance to prevent loss of implement function and potential damage.

Key takeaway: Consistent pre- and post-season maintenance, including scheduled servicing, inspections, and professional checkups, is essential for reliable tractor operation. Addressing wear and fluid needs outside peak usage reduces breakdown risk and extends equipment life, especially in demanding agricultural environments. Annual coolant checks and proper storage further safeguard long-term performance.

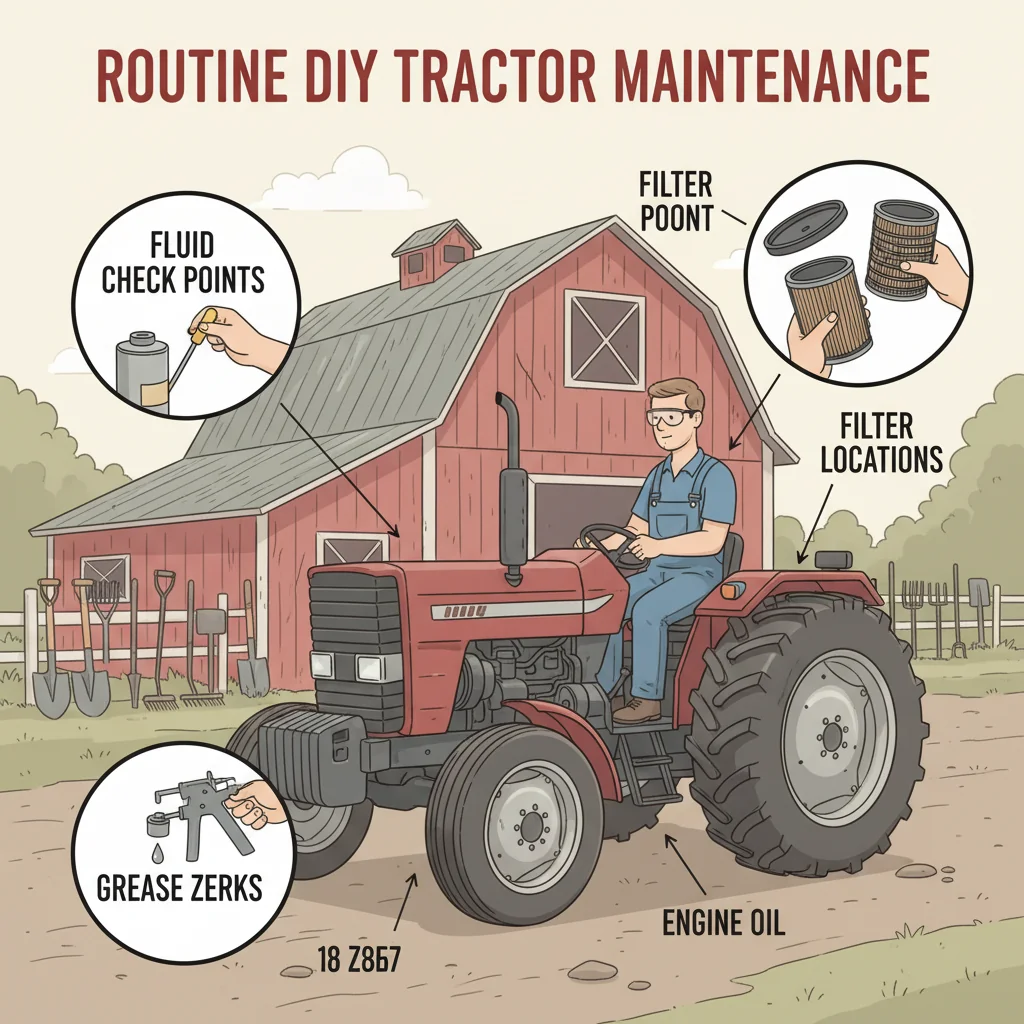

Which Tractor Maintenance Tasks Are DIY-Safe?

Routine maintenance tasks—such as fluid level checks, greasing, air and fuel filter changes, oil changes, and radiator cleaning—are generally DIY-safe for utility tractors if the operator follows the manufacturer’s manual, uses approved fluids and filters, and keeps records. Critical repairs to engines, transmissions, hydraulics, or electrical systems should be left to authorized dealers.

Last season, I spoke with a farmer in Brazil who wanted to save money by doing all his own tractor maintenance. He handled regular oil changes, checked the coolant, and kept the air filter clean with no issues at all. These kinds of daily and scheduled maintenance tasks are generally safe for careful owners to do themselves and can significantly reduce operating costs.

Most routine jobs—such as checking and changing engine oil, topping up coolant, greasing fittings, and replacing air or fuel filters—do not require special tools. Clear instructions are usually provided in the operator’s manual. I’ve seen operators in Kenya and Kazakhstan manage these basics very well, as long as they used approved fluids and kept a simple maintenance log.

However, once maintenance crosses into core systems, the risk rises quickly. Hydraulic repairs, internal engine work, clutch or transmission adjustments, and electrical or ECU diagnostics should always be handled by authorized dealers. Mistakes in these areas can turn small problems into major failures, cause extended downtime during peak seasons, and potentially void the tractor’s warranty.

Here is a clear comparison of DIY-safe tasks versus work best left to professionals:

| Task Type | DIY-Safe | Dealer Only | Notes |

|---|---|---|---|

| Oil / filter changes | Yes | Use correct oil grade and keep maintenance records | |

| Greasing / lubrication | Yes | Follow all listed grease points and intervals | |

| Air / fuel filter replacement | Yes | Keep spare filters clean and properly stored | |

| Coolant check / top-up | Yes | Only use approved coolant types | |

| Belt and hose inspection | Yes | Replace only if access is simple | |

| Hydraulic leak repair | Yes | Incorrect repair can damage valves and pumps | |

| Transmission / clutch work | Yes | Requires special tools and calibration | |

| Internal engine repair | Yes | High risk, may void warranty | |

| Electrical / ECU diagnostics | Yes | Needs dealer diagnostic equipment |

Replacing a tractor's hydraulic seals can require specialized tools and knowledge, making it unsafe for most DIY maintenance situations.True

Hydraulic systems operate under high pressure and improper handling can lead to further damage or injury. Specialized tools are often needed to reseal components correctly, so this task is best left to trained technicians.

All tractor air filter cleanings should be performed by a certified mechanic to avoid damaging the engine.False

Checking and cleaning tractor air filters is a routine procedure designed for operator maintenance. With basic precautions, most owners can safely handle this task without risk to the engine.

Key takeaway: Most basic utility tractor maintenance is manageable for attentive owners using proper procedures and materials. However, attempting complex repairs on core systems can compromise safety, void warranties, and lead to major failures. Always defer critical diagnostics and repairs to qualified dealer technicians.

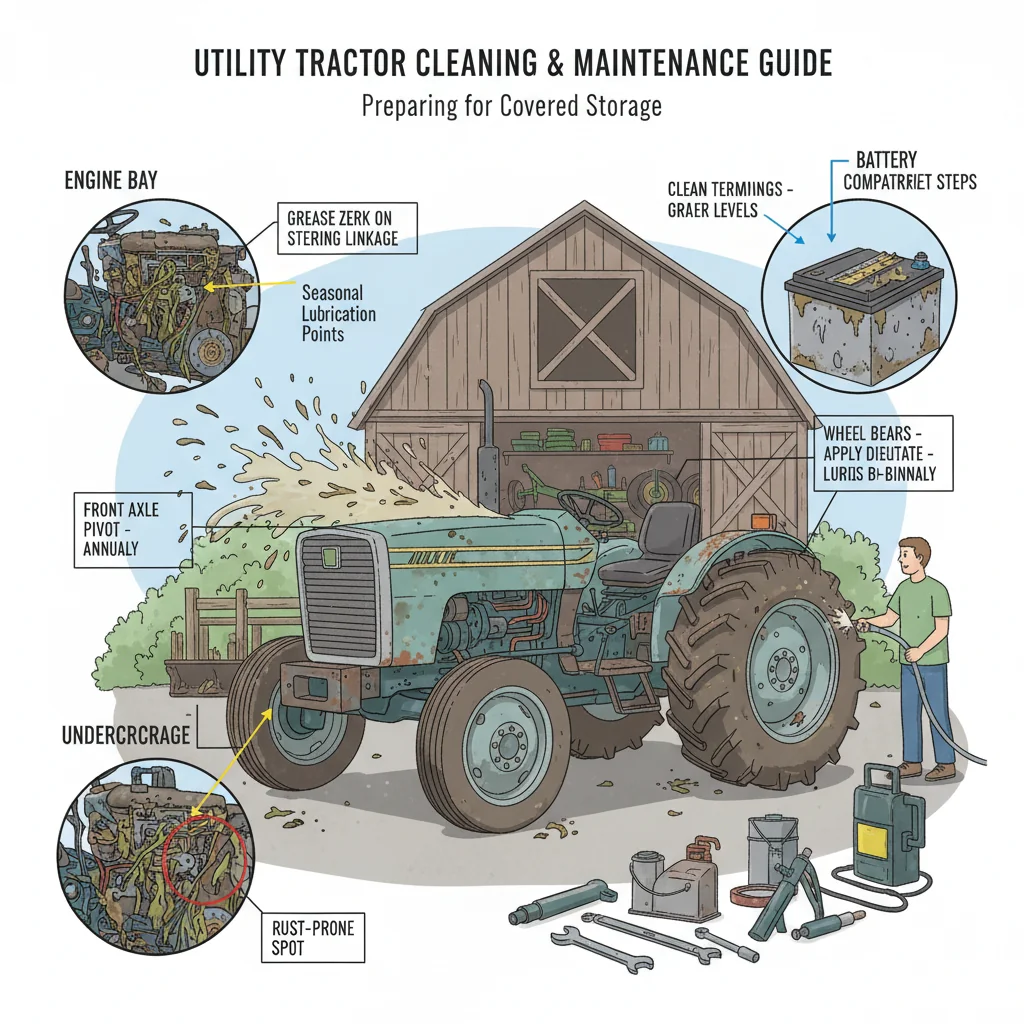

How do cleanliness and storage impact utility tractor?

Cleanliness and proper storage directly extend utility tractor lifespan and increase resale value. Dirt and debris conceal leaks, promote rust, and overheat components. Thorough cleaning after corrosive use, seasonal lubrication, covered parking, and battery maintenance prevent costly deterioration, make inspections easier, and signal professional care to future buyers.

To be honest, cleanliness is often overlooked because it seems cosmetic, but it’s actually a core part of tractor maintenance. I’ve seen farms in Brazil where muddy axles and caked-on chaff hid a slow hydraulic oil leak for weeks—by the time anyone noticed, the repair cost was double what it could have been. Built-up debris traps moisture against metal, especially on the frame, wheel hubs, and three-point hitch. That’s how rust gets a foothold. I always tell customers: regular washing, especially after working in salty or corrosive soils, pays off in fewer surprises down the line.

Keeping the cab tidy is just as important. Clean glass means better visibility, and dust-free controls last longer. In Kazakhstan, I visited a cooperative where operators wiped down the controls every day and replaced the cabin air filter every season. Their tractors were ten years old but looked five, and they sold quickly when it was time to upgrade. A clean machine also means you spot issues early—like coolant stains around the radiator or a missing bolt on the PTO guard.

Storage makes a huge difference, too. If you park under a simple roof—even just a tarp over the engine—you reduce sun, rain, and dust damage. At season’s end, I suggest greasing all exposed chrome, especially on hydraulic cylinders, and disconnecting the battery to avoid discharge. These steps don’t cost much, but they add years to the machine’s working life. A tractor that looks well cared for tells buyers you’ve looked after everything inside, too.

Frequent cleaning of a utility tractor’s undercarriage can help reveal early signs of hydraulic leaks or seal failures that would otherwise be masked by accumulated dirt and debris.True

Dirt and crop residue can conceal fluid leaks, making it difficult to spot maintenance issues until they become severe. Regular cleaning exposes hidden problems, allowing for timely repairs and lower maintenance costs.

Storing a utility tractor outdoors on a gravel surface is just as effective as indoor storage for preventing rust and corrosion.False

Outdoor storage exposes metal surfaces to moisture, temperature changes, and UV damage, which can accelerate rust and degrade components. Indoor storage provides a controlled environment, significantly reducing the risk of corrosion and extending the tractor’s lifespan.

Key takeaway: Regular cleaning and careful storage are essential maintenance practices for utility tractors. They prevent hidden damage, rust, and mechanical wear, making it easier to identify issues early. A well-presented tractor not only operates reliably but also commands a higher resale price.

What Makes Tractor Maintenance Easy?

Tractors designed for easy maintenance feature ground-level access to engine oil and fuel filters, tool-free removable radiator screens, swing-open hoods, grouped grease banks, and clear sight glasses. Using common oil types and locally available filter and belt sizes reduces downtime. Simplified service points and digital hour-meter reminders help ensure regular upkeep, supporting long-term reliability and lower total ownership costs.

From my experience, buyers often overlook how much daily downtime is caused by poor access to basic service points. I’ve seen this first-hand on farms in Peru—a 75HP tractor with a complicated hood latch and hidden oil filter meant the operator skipped checks for days at a time. When filters are tucked behind panels or require special tools, maintenance gets delayed, especially during peak planting or harvest. It’s not just about convenience; it’s about catching small issues before they grow.

Last year, an importer in Kazakhstan called me about a new fleet of utility tractors. Their mechanics loved that the radiator screens slid out by hand, no wrenches needed. It took less than five minutes to clean the screens every morning, even in dusty summers. They also appreciated grouped grease banks—just three points to hit, all reachable from the ground. That simple design saved their team at least an hour each week across six machines. Over a season, that’s real time and money.

I always suggest opening every panel yourself before buying. Can you reach the engine oil and fuel filters from the side, without standing on a tire? Sight glasses for checking hydraulic oil and coolant levels are another big win—no guessing, no mess. If the tractor uses a single type of oil for both transmission and hydraulics, stocking spares is much easier. For small fleets or first-time buyers, these details encourage regular upkeep and keep running costs predictable. Reliable access equals reliable operation.

Utility tractors designed with side-mounted, tool-free engine panels significantly reduce maintenance delays during busy seasons.True

Side-mounted, tool-free panels allow operators to quickly access filters, dipsticks, and other service points without needing special tools or lengthy disassembly, which encourages regular checks and reduces the risk of skipped maintenance.

Utility tractors equipped with fully electronic service monitoring systems no longer require manual inspection of oil or air filters.False

While electronic service monitoring can alert operators to some issues, most utility tractors still require physical inspection and replacement of oil and air filters, as sensors cannot always detect filter blockages or wear with complete accuracy.

Key takeaway: Prioritizing ease of maintenance—like accessible service points, common parts, and tool-free panels—reduces daily service time and encourages regular upkeep. This is crucial for maximizing reliability, uptime, and minimizing long-term costs, especially for first-time owners and fleet operators in emerging markets.

Conclusion

We’ve looked at why tracking engine hours—not just time or kilometers—is the foundation of proper utility tractor maintenance. From what I’ve seen in the field, following the manufacturer’s hour-based service table really does make a difference, especially in regions where tractors might work hard during harvest and then sit idle. Too many owners get caught by “the second-year surprise”—unexpected repairs because early services were skipped. If you’re unsure which intervals matter most, or want to double-check parts availability in your area, just ask. I’ve worked with importers and farmers in over 30 countries and I’m happy to share what’s worked in real-world conditions. Every operation is unique, so choose what keeps your tractor reliable for the long haul.

References

-

Explains how draining the fuel water separator protects injectors from water contamination, reducing costly repairs and downtime. ↩

-

Provides expert guidelines on optimal oil change intervals to prevent costly engine repairs and extend tractor life. ↩

-

Detailed explanation of UTTO and THF oils, their role in combined hydraulic and transmission systems, and why correct oil choice prevents damage. ↩

-

Insight into causes of hydraulic pump failure due to wrong oil use, with practical tips to avoid costly repairs and maintain tractor performance. ↩

-

Explains risks of DIY hydraulic repairs and why professional service is critical to avoid costly tractor downtime during harvest. ↩

-

Explore how dense radiator fins impact cooling efficiency and why regular cleaning prevents costly engine failures in tractors. ↩

-

Explains how proper draining and replacement prevent injector problems and costly repairs, especially in humid climates. ↩

-

Provides expert guidance on air filter inspection intervals and cleaning methods to prevent engine damage in dusty farming conditions. ↩

-

Explains how correct tire pressure improves traction, reduces fuel use, and prevents costly tire damage for heavy-duty tractors. ↩

-

Details the role of axle pivots in steering performance and how regular inspections prevent expensive repairs and downtime. ↩

-

Detailed guide on essential 250–500 hour maintenance tasks to prevent costly tractor breakdowns during critical farming seasons. ↩

-

Explains the importance of coolant replacement every 2–3 years to avoid overheating and extend tractor engine life. ↩