Leaving a tractor unused for months without proper storage precautions can lead to rust, battery failure, fluid degradation, tire damage, and pest infestations. Many tractor owners neglect key maintenance steps, only to find starting issues, hydraulic failures, or fuel system clogs when the machine is needed again.

Proper tractor storage involves selecting the right location, cleaning thoroughly, maintaining fluids, protecting the fuel system, securing the battery, preventing tire damage1, lubricating moving parts, sealing engine openings, avoiding brake seizures, covering the tractor correctly, performing periodic startups2, and preparing for reactivation. Following these best practices prevents costly repairs, extends the tractor’s lifespan, and ensures a smooth restart.

By following these 12 essential storage steps, you can ensure your tractor remains in top condition, free from unexpected breakdowns, and ready for operation when the season resumes.

Improper long-term tractor storage can lead to rust, battery failure, fluid degradation, and tire damage.True

Leaving a tractor unused without proper precautions can cause corrosion, drained batteries, clogged fuel systems, and deteriorated tires, leading to costly repairs.

A tractor can be left unused for months without any risk of mechanical issues.False

Without proper storage steps, tractors can suffer from rust, pest infestations, battery drain, and fluid breakdown, making reactivation difficult and expensive.

Let's explore each step in detail, ensuring your tractor stays protected and performs efficiently after long-term storage.

1. Choose the Right Storage Location

A tractor’s storage environment3 plays a crucial role in preserving its mechanical health. Moisture, temperature fluctuations, and direct exposure to harsh weather conditions can cause rust, battery discharge, tire damage, and fluid degradation if not properly managed.

A well-chosen storage location protects against rust, moisture damage, extreme temperatures, and environmental wear. Indoor storage is ideal, but if outdoor storage is necessary, a breathable tarp4 and dry ground conditions are essential to prevent corrosion and mechanical failures.

What Is the Best Place to Store a Tractor?

The best storage solution depends on the available space, climate conditions, and budget. Choosing the right location prevents long-term deterioration and minimizes costly repairs.

| Storage Option | Protection Level | Pros | Cons |

|---|---|---|---|

| Indoor Storage (Barn, Shed, Garage) | ★★★★★ | Best protection from moisture, UV exposure, and temperature swings | Requires proper ventilation to prevent condensation |

| Under a Canopy or Open Shed | ★★★☆☆ | Some protection from sun and rain | Exposed to humidity, dust, and potential pest issues |

| Outdoor with a Weatherproof Cover | ★★☆☆☆ | Shields from rain and sun if covered properly | High moisture risk, must use breathable tarp |

| Open Outdoor Storage | ★☆☆☆☆ | Only viable in dry, mild climates | High exposure to rain, snow, and extreme temperatures |

Whenever possible, I store my tractor indoors to shield it from moisture and temperature extremes.

Why Shouldn’t a Tractor Be Stored on Bare Ground?

Many farmers park their tractors directly on soil or grass, thinking it won’t cause harm. However, this is one of the quickest ways to accelerate rust formation5.

Bare ground retains moisture, which seeps into metal components, causing frame rust, corroded bolts, and electrical damage.

It's better that always park your tractor on a dry, solid surface6 such as:

✔ Concrete or asphalt flooring – Prevents mmoisture buildup7.

✔ Wooden planks or rubber mats – Acts as a barrier between tires and ground.

✔ Gravel or compacted dirt (if no alternative is available) – Improves drainage compared to bare soil.

What Precautions Should Be Taken for Outdoor Storage?

If indoor storage isn’t an option, proper outdoor protection is essential to prevent weather damage, UV exposure, and rodent infestations.

| Outdoor Storage Challenge | Prevention Method |

|---|---|

| Moisture and condensation | Use a breathable, waterproof tarp and allow air circulation |

| Tire degradation | Place rubber mats or wooden planks under tires |

| Rodents and pests | Seal exhaust and air intakes with steel wool or mesh |

| Snow or heavy rainfall exposure | Elevate the tractor slightly to improve water drainage |

Always make sure your outdoor-stored tractor is covered with a high-quality, UV-resistant tarp, but not sealed too tightly, as this can trap moisture and cause more harm than good.

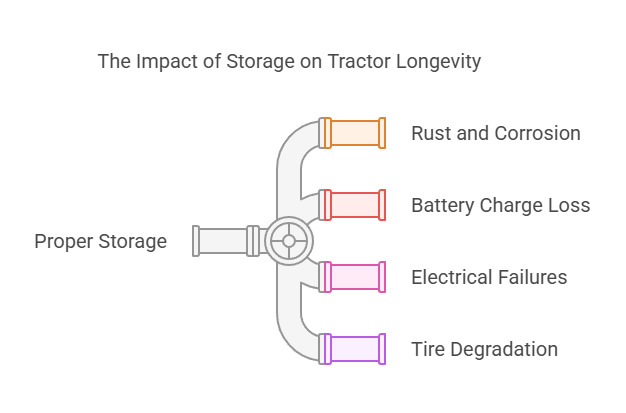

How Does Proper Storage Impact Tractor Longevity?

Choosing the right storage method isn’t just about protecting the tractor from the elements—it significantly reduces long-term repair costs and downtime.

| Without Proper Storage | With Proper Storage |

|---|---|

| Increased risk of rust and corrosion | Metal components remain protected and rust-free |

| Battery loses charge faster | Battery maintains charge longer |

| Higher moisture-related electrical failures | Electrical system stays intact and functional |

| Tires may crack, flatten, or degrade | Tires retain proper shape and pressure |

A well-stored tractor lasts longer, requires fewer repairs, and is always ready to work when needed.

Where a tractor is stored directly impacts its longevity and performance. By choosing the right location, avoiding bare ground, using protective covers, and implementing moisture control, you can make sure tractor remains in peak condition, free from rust and mechanical failures.

Proper storage is a simple step that prevents costly damage—a small investment of time that pays off with extended tractor life and lower repair costs.

Storing a tractor in a dry, covered location helps prevent rust, battery discharge, and fluid degradation.True

Moisture and temperature fluctuations cause corrosion and mechanical wear, making indoor storage or protective covers essential for long-term tractor health.

Parking a tractor on bare ground has no impact on its condition over time.False

Bare soil retains moisture, leading to rust formation, corroded bolts, and potential electrical damage, accelerating mechanical deterioration.

2. Clean the Tractor Thoroughly

Dirt, grease, and crop residue may seem harmless, but they trap moisture, accelerate rust, and attract pests. A tractor that is stored while dirty is more likely to suffer from corrosion, clogged airways, and component failures8 during long-term storage.

Cleaning the tractor before storage prevents rust, removes contaminants, and ensures the machine is free from debris that could cause deterioration.

What Are the Risks of Storing a Dirty Tractor?

If dirt and residue aren’t removed before storage, they retain moisture and accelerate metal corrosion, leading to significant long-term damage.

| Problem | Cause | Long-Term Impact |

|---|---|---|

| Rust and Corrosion | Moisture trapped in mud and grease | Weakens frame, bolts, and moving parts |

| Rodent Infestation | Crop residue attracts pests | Wires and hoses may be chewed, leading to electrical damage |

| Clogged Cooling System | Dirt buildup on radiator fins | Overheating risk when restarting the tractor |

| Hydraulic and Engine Contamination | Grease and debris near seals | Increased wear and system failures |

Always wash your tractor thoroughly before storing it to protect metal surfaces and ensure all components are free of contaminants.

How Should a Tractor Be Cleaned Before Storage?

A deep clean9 that no debris or residue remains before long-term storage.

Washing the Exterior:

- Use a pressure washer10 or hose to remove dirt, grease, and crop residue from all surfaces.

- Pay special attention to undercarriage, axles, and radiator fins, where buildup often occurs.

- Let the tractor dry completely before storage to prevent moisture damage.

Cleaning the Interior and Cabin:

- Remove any trash, food, or organic matter that may attract rodents.

- Wipe down control panels, seats, and levers to prevent dust buildup.

Protecting Metal Components:

- Apply a protective wax coat11 or anti-rust spray on exposed metal surfaces.

- Grease pivot points, linkages, and moving parts to prevent seizing.

Cleaning the tractor before storage is a simple but crucial step to prevent rust, mechanical wear, and rodent infestations. A clean tractor is a long-lasting tractor—taking the time to wash and protect it saves money on repairs and maintenance down the road.

Thoroughly cleaning a tractor before storage helps prevent rust, pest infestations, and mechanical failures.True

Dirt and crop residue trap moisture, leading to corrosion, while leftover organic matter can attract rodents that may damage wiring and components.

Storing a tractor while dirty has no effect on its condition during long-term storage.False

Moisture trapped in dirt and grease accelerates rust, while debris buildup can clog airways and moving parts, leading to deterioration over time.

3. Change Oil and Other Fluids

Many tractor owners forget to change oil12 and fluids before storage, assuming that fresh fluids are only necessary before regular use. However, old, contaminated fluids can cause internal corrosion, clogging, and system failures during long-term storage.

Replacing engine oil, hydraulic fluid13, and coolant14 before storage prevents contamination, rust, and degradation of internal components, ensuring the tractor is ready for operation when needed.

What Happens If Old Fluids Are Left in the Tractor?

When fluids sit unused for months, contaminants like dirt, water, and sludge cause internal damage to the engine and hydraulic system.

| Fluid Type | Problem if Not Replaced | Long-Term Impact |

|---|---|---|

| Engine Oil | Contains moisture and dirt buildup | Internal corrosion and engine wear |

| Hydraulic Fluid | May contain water or debris | Reduced hydraulic performance and seal failure |

| Coolant | Loses antifreeze properties over time | Risk of freezing in winter and overheating later |

| Fuel | Can oxidize and form deposits | Injector clogging and hard starts |

Make sure replace old fluids before storing tractor to prevent unnecessary wear and costly repairs.

How Should Tractor Fluids Be Changed Before Storage?

Engine Oil and Filter:

- Drain old engine oil15 while the engine is warm to remove contaminants.

- Replace the oil filter to prevent sludge buildup.

- Refill with manufacturer-recommended engine oil.

Hydraulic Fluid:

- Check for cloudy or dark hydraulic fluid16, which indicates contamination.

- Drain and refill if necessary.

- Replace hydraulic filters to ensure clean operation.

Coolant System:

- Top off with properly mixed antifreeze coolant to prevent freezing and corrosion.

- Check radiator and hoses for leaks or blockages.

Fuel System:

- Add fuel stabilizer17 to prevent diesel breakdown and oxidation.

- Run the tractor for 5-10 minutes to circulate the stabilizer through the fuel system.

- Drain water from the fuel separator to prevent injector damage.

Skipping fluid changes before storag leads to internal corrosion, clogged filters, and performance issues when restarting the tractor.

Changing oil and other fluids before storage helps prevent internal corrosion and system failures.True

Old, contaminated fluids can degrade over time, leading to rust, clogging, and reduced efficiency when the tractor is restarted.

Tractor fluids do not need to be changed before long-term storage.False

Leaving old oil, hydraulic fluid, or coolant in the tractor can lead to sludge buildup, component corrosion, and potential mechanical issues after storage.

4. Protect the Fuel System

Many tractor owners overlook fuel system maintenance18 before long-term storage, only to face clogged injectors, fuel degradation19, and hard starts when it’s time to use the machine again. Diesel fuel can break down over time, forming deposits and attracting moisture, which can cause serious engine issues.

Filling the fuel tank, using a stabilizer, and running the engine before storage prevents condensation, fuel gelling, and injector clogging20, ensuring an easy restart when the tractor is needed again.

What Happens If Fuel Is Left Untreated?

Fuel begins to degrade after just a few months, leading to contamination and engine performance issues.

| Fuel System Issue | Cause | Potential Damage |

|---|---|---|

| Condensation in the Fuel Tank | Empty or partially filled tank | Water enters the system, causing rust and microbial growth ("diesel algae") |

| Fuel Oxidation | Exposure to air over time | Forms deposits that clog injectors and fuel lines |

| Gelling in Cold Temperatures | Low temperatures without stabilizers | Fuel thickens, blocking flow to the engine |

Ensure treat tractor’s fuel before storage to avoid costly fuel system repairs.

How to Properly Store Fuel in a Tractor?

Fill the Fuel Tank Completely:

- A full tank prevents condensation, which can lead to rust and microbial growth.

- Ensure high-quality diesel fuel is used for long-term storage21.

Use a Diesel Fuel Stabilizer:

- Prevents fuel oxidation, gelling, and bacterial growth.

- Pour stabilizer into the tank and run the engine for 5-10 minutes to circulate it.

Drain the Water Separator22:

- Removes moisture and contaminants from the fuel system.

- Helps prevent injector damage and fuel line corrosion.

Consider Draining the Tank for Long-Term Storage (Over 6 Months):

- If recommended by the manufacturer, emptying the fuel tank completely can prevent fuel degradation.

- Clean or replace fuel filters before storage.

A neglected fuel system leads to clogged injectors, moisture buildup, and starting issues after storage. By filling the tank, using a stabilizer, and draining excess moisture, you can ensure tractor’s fuel remains clean and ready for smooth operation.

Properly maintaining the fuel system before storage prevents injector clogging, fuel degradation, and hard starts.True

Filling the tank, using a stabilizer, and draining the water separator help prevent moisture buildup, microbial growth, and fuel oxidation.

A tractor’s fuel system does not require any preparation before long-term storage.False

Diesel fuel can break down over time, leading to clogged injectors, condensation buildup, and starting issues if the system is not properly maintained.

5. Maintain the Battery

One of the most common issues after long-term tractor storage23 is a dead or damaged battery. Many tractor owners forget to disconnect, charge, or protect their battery, leading to slow discharge, corrosion, and even freezing in cold climates.

Disconnecting the battery, storing it in a dry location, and using a trickle charger24 prevents battery failure and ensures a strong start when the tractor is needed again.

What Happens If a Battery Is Left Untreated?

A tractor battery naturally discharges over time, and extreme temperatures can accelerate damage.

| Battery Issue | Cause | Long-Term Impact |

|---|---|---|

| Slow Discharge | Battery left connected while idle | Dead battery, requiring jump-start or replacement |

| Corrosion on Terminals | Exposure to moisture and acid buildup | Poor electrical connections, difficulty starting |

| Freezing in Cold Climates | Low charge in freezing temperatures | Battery case cracking, permanent failure |

Always disconnect and protect tractor’s battery before storage to prevent costly replacements.

How to Properly Store a Tractor Battery?

Disconnect the Battery:

- Always disconnect the negative terminal first, followed by the positive terminal.

- Store in a dry, temperature-controlled location25 away from moisture.

Use a Trickle Charger (Battery Maintainer):

- Keeps the battery fully charged without overcharging.

- Prevents sulfation, which reduces battery lifespan.

Clean and Protect Battery Terminals:

- Use a wire brush to remove corrosion from battery posts.

- Apply anti-corrosion grease26 or petroleum jelly to prevent future buildup.

Store the Battery Indoors in Extreme Cold Weather:

- If temperatures drop below freezing, remove the battery and store it in a warm place.

- A cold, low-charged battery is more likely to freeze and become unusable.

Skipping battery maintenance before storage leads to starting issues, corrosion, and premature failure. By disconnecting, charging, and protecting the battery, your tractor can start reliably when needed, avoiding costly replacements.

Proper battery maintenance during tractor storage prevents discharge, corrosion, and freezing.True

Disconnecting the battery, using a trickle charger, and storing it in a dry location help maintain charge and extend battery lifespan.

A tractor battery can be left connected and unattended for months without any issues.False

Leaving the battery connected can lead to slow discharge, corrosion, and freezing in cold temperatures, making it difficult to restart the tractor.

6. Check and Protect the Tires

Tires27 are one of the most overlooked components when preparing a tractor for storage. Improper storage can cause flat spots28, sidewall cracking, deflation, and dry rot29, leading to expensive replacements and poor performance when the tractor is put back into use.

Inflating tires, storing on a dry surface, and reducing pressure strain prevents long-term tire damage and ensures a smooth restart after storage.

What Happens If Tires Are Not Maintained During Storage?

When a tractor sits for months without proper care, tires lose pressure, develop cracks, and degrade due to environmental exposure.

| Tire Issue | Cause | Long-Term Impact |

|---|---|---|

| Flat Spots | Sitting for long periods without movement | Reduces tire lifespan, causes rough operation |

| Cracked Sidewalls | Exposure to sunlight, temperature changes | Leads to air leaks and potential blowouts |

| Tire Deflation | Slow air loss over time | Results in uneven weight distribution, damaging rims |

| Dry Rot | UV exposure, ozone damage | Weakens rubber, making tires unsafe for use |

Make sure inspect and protect my tractor’s tires before storage to avoid unnecessary wear and costly replacements.

How to Properly Store Tractor Tires?

Inflate Tires to Recommended PSI30:

- Ensures even weight distribution and prevents premature cracking.

- Check for any slow leaks before long-term storage.

Place Wooden Planks or Rubber Mats Under Tires:

- Prevents direct contact with damp ground, reducing moisture absorption.

- Protects against flat spots and sidewall deterioration.

Jack Up the Tractor Slightly (If Possible):

- Relieves excess pressure on tires, especially for long-term storage.

- Reduces the risk of deformation and permanent damage.

Keep Tires Clean and Shielded from UV Exposure31:

- Wash and remove mud, chemicals, and debris that could degrade rubber.

- If stored outside, use a UV-resistant cover to protect tires from sunlight.

Ignoring tire maintenance before storage leads to premature wear, cracking, and costly replacements. By inflating, elevating, and shielding tires from environmental damage, your tractor can remain ready for operation without unexpected tire failures.

Taking these simple steps extends tire life, improves performance, and prevents unnecessary downtime when the tractor is needed again.

Proper tire maintenance during tractor storage prevents flat spots, sidewall cracking, and dry rot.True

Inflating tires to the recommended PSI, storing on dry surfaces, and shielding from UV exposure help preserve tire integrity and extend lifespan.

Tractor tires can be stored on any surface without affecting their condition.False

Storing tires on damp ground or underinflated can cause moisture absorption, flat spots, and rubber degradation, leading to premature failure.

7. Lubricate Moving Parts

When a tractor sits idle for months, metal components are at risk of rusting, seizing, or wearing out due to lack of lubrication. Without proper lubrication32, pivots, joints, bearings, and other moving parts can develop friction, leading to poor performance and costly repairs.

Applying grease and oil before storage prevents rust, reduces friction33, and ensures smooth operation when the tractor is restarted.

What Happens If Moving Parts Aren’t Lubricated?

Without lubrication, exposed metal parts begin to dry out, corrode, and seize up during storage.

| Problem | Cause | Long-Term Impact |

|---|---|---|

| Rust and Corrosion | Moisture exposure | Weakens structural integrity and increases wear |

| Seized or Stiff Joints | Lack of grease | Reduces flexibility, requiring forceful movement |

| Increased Wear on Bearings | Dry metal-on-metal contact | Leads to overheating and mechanical failure |

| Difficult PTO Engagement | PTO shaft exposed to elements | Can jam, making implement attachment difficult |

Ensure apply fresh grease and oil to all moving parts before storage to avoid friction-related damage and ensure smooth operation.

Which Parts of the Tractor Need Lubrication?

Grease All Fittings and Joints:

- Apply grease to pivot points, steering joints, and axles.

- Use a high-quality grease that resists moisture and oxidation.

Lubricate the PTO Shaft34:

- Apply a thin layer of grease or oil to prevent rust.

- Move the shaft slightly to distribute lubrication evenly.

Protect Linkages and Hydraulic Cylinders:

- Lightly coat exposed metal rods with oil or silicone spray.

- Prevents pitting and wear on hydraulic seals.

Oil Hinges, Latches, and Pedals35:

- Spray penetrating oil on hood latches, brake pedals, and throttle linkages.

- Prevents sticking and hard-to-operate controls after storage.

Skipping lubrication before storage leads to rust, mechanical wear, and stiff controls when restarting the tractor. By greasing joints, oiling moving parts, and protecting the PTO shaft, your tractor can remain in peak condition and operates smoothly when needed again.

Lubricating moving parts before storage prevents rust, reduces friction, and ensures smooth operation.True

Applying grease and oil to joints, PTO shafts, and hydraulic components protects against moisture, oxidation, and seizing during long-term storage.

A tractor’s moving parts do not require lubrication before long-term storage.False

Without lubrication, metal components can rust, seize, or wear prematurely, leading to poor performance and costly repairs when restarting the tractor.

8. Protect the Exhaust and Engine Openings

Rodents, insects, and debris can enter exhaust pipes, air filters, and engine openings during storage, causing blockages, wiring damage, and potential engine failure. Many tractor owners forget to seal these openings, only to find their machine won’t start due to pest infestations36 or air intake obstructions.

Sealing the exhaust and engine openings prevents moisture buildup37, rodent damage, and debris-related issues, ensuring a smooth restart after storage.

What Are the Risks of Leaving Openings Uncovered?

If engine openings are left exposed, moisture and pests can cause long-term damage, leading to costly repairs.

| Problem | Cause | Potential Damage |

|---|---|---|

| Rodents Nesting in Exhaust Pipes | Mice and rats seek shelter | Blocks exhaust flow, leading to engine failure |

| Debris in Air Filters | Dust and dirt enter the intake | Reduces engine efficiency, clogs fuel system |

| Moisture in the Exhaust | Humid air condenses in pipes | Causes rust inside the exhaust system |

| Insects Blocking Small Openings | Bugs nest inside hoses or vents | Disrupts airflow, leading to performance issues |

Always seal and inspect tractor’s openings before storage to avoid unexpected damage and costly repairs.

How to Properly Seal the Exhaust and Air Intake?

Cover the Exhaust Pipe:

- Use a plastic bag or exhaust cap to seal the opening.

- Secure it with a rubber band or zip tie to prevent moisture and pests from entering.

Protect Air Intakes and Engine Vents38:

- Stuff air intakes with steel wool or mesh screen—this blocks rodents while allowing airflow.

- Avoid using rags or paper, as rodents may chew through them.

Inspect for Pest Activity Regularly39:

- Check around the engine bay and exhaust area for rodent droppings or chewed wires.

- Place rodent deterrents (mothballs, peppermint oil, or traps) near storage areas.

Leaving engine openings unsealed during storage can result in blocked exhaust pipes, damaged wiring, and moisture-related rust. By covering the exhaust, sealing air intakes, and inspecting for pests, your tractor will remain protected and starts without issues when needed.

Sealing a tractor’s exhaust and engine openings during storage prevents moisture buildup, rodent damage, and debris blockages.True

Covering the exhaust and air intakes keeps pests from nesting inside and protects the engine from moisture-related corrosion and starting issues.

Leaving a tractor’s exhaust and air intake openings unsealed during storage has no negative effects.False

Open exhaust and air intakes allow rodents, insects, and debris to enter, leading to blockages, wiring damage, and potential engine failure.

9. Engage Parking Brakes40 and Secure the Tractor

Many tractor owners assume that simply parking the tractor and engaging the brakes is enough for storage. However, long-term storage requires additional precautions to prevent brake damage, rolling hazards, and safety risks.

Improperly securing a tractor can lead to brake seizing41, tire strain, and unexpected movement. Using wheel chocks42 and periodic brake release prevents long-term issues.

What Are the Risks of Improper Tractor Parking?

Leaving a tractor parked incorrectly can cause mechanical failures that make restarting difficult.

| Storage Mistake | Cause | Potential Damage |

|---|---|---|

| Leaving the Parking Brake Engaged for Too Long | Brake pads and components seize up | Brakes may stick or fail to release |

| Parking on Uneven or Loose Ground | Tractor shifts due to ground movement | Risk of tipping or rolling away |

| Not Using Wheel Chocks | Tractor relies solely on parking brake | Brake system strain, risk of unexpected movement |

Secure your tractor correctly before storage to avoid brake issues and ensure safety.

How to Properly Secure a Tractor for Long-Term Storage?

Use Wheel Chocks Instead of Relying Solely on the Parking Brake:

- Place wheel chocks on both sides of the rear tires to prevent movement.

- If chocks aren’t available, use wooden blocks or heavy-duty rubber stops.

Release and Reapply the Parking Brake43 Periodically:

- If stored for several months, disengage and reapply the parking brake every few weeks to prevent sticking.

Park on a Level, Stable Surface44:

- Choose a solid, dry ground surface (concrete or gravel is best).

- Avoid parking on soft or uneven terrain, which may shift over time.

Store the Tractor in Neutral Gear (Unless Manufacturer Recommends Otherwise):

- Prevents strain on the transmission when restarting the tractor.

- For tractors stored on slopes, engage low gear and use wheel chocks for added security.

Improperly securing a tractor can cause brake damage, rolling hazards, and unnecessary wear. By using wheel chocks, periodically releasing the brake, and parking on a stable surface, your tractor can remains safe, stable, and ready for use when needed.

Taking these extra steps prevents mechanical failures and guarantees a hassle-free restart.

Properly securing a tractor during storage prevents brake seizing, tire strain, and accidental movement.True

Using wheel chocks, parking on a stable surface, and periodically releasing the parking brake help prevent long-term mechanical issues and ensure safety.

Engaging the parking brake is the only necessary step to secure a tractor for long-term storage.False

Relying solely on the parking brake can cause it to seize over time; using wheel chocks and periodically disengaging the brake helps prevent damage.

10. Cover the Tractor Properly

Leaving a tractor exposed to the elements during storage can lead to paint fading45, rust formation, electrical damage, and cracked rubber components. Even when stored indoors, dust, moisture, and pests can still affect critical parts.

Using a breathable, weatherproof cover46 protects the tractor from moisture buildup, UV exposure, and dirt accumulation, ensuring long-term preservation.

What Happens If a Tractor Is Left Uncovered?

A tractor that is not covered properly is vulnerable to weather damage and environmental wear, which can shorten its lifespan.

| Issue | Cause | Potential Damage |

|---|---|---|

| Rust and Corrosion | Rain, snow, and humidity exposure | Weakens metal components and body frame |

| UV Damage | Direct sunlight | Paint fading, cracked rubber hoses, and dry rot in tires |

| Moisture Condensation | Poor airflow under cover | Internal rusting and electrical issues |

| Dust and Debris Accumulation | Uncovered storage | Clogged filters, dirt buildup on controls |

Remember use the right type of cover to ensure tractor is protected from the elements while allowing airflow.

How to Choose the Right Tractor Cover?

Use a Breathable, Waterproof Cover:

- Prevents rain, snow, and moisture damage while allowing air circulation.

- Avoid plastic tarps, which trap condensation and cause rust.

Ensure the Cover Fits Properly:

- A loose-fitting cover can be blown away or allow dust inside.

- A tight cover may trap moisture—allow some airflow to prevent condensation.

Secure the Cover in Place47:

- Use straps, ropes, or bungee cords to prevent wind from lifting it.

- Ensure critical areas (engine bay, dashboard, and seat) are fully covered.

For Indoor Storage, Use a Dust-Resistant Cover48:

- Protects against dust buildup and rodent damage.

- Keeps filters, wiring, and control panels clean.

Leaving a tractor uncovered or using the wrong cover can lead to rust, weather damage, and unnecessary wear. Taking this simple step preserves the paint, mechanical parts, and overall longevity of the machine.

Using a breathable, weatherproof cover protects a tractor from moisture, UV damage, and dust accumulation during storage.True

A proper cover prevents rust, electrical issues, and rubber degradation while allowing airflow to avoid trapped condensation.

Any cover, including plastic tarps, is suitable for protecting a tractor during storage.False

Plastic tarps trap moisture, leading to rust and corrosion, while improper covers can cause overheating, condensation buildup, and material degradation.

11. Periodically Start and Inspect the Tractor

Many tractor owners assume that once the machine is properly stored, it can be left untouched for months. However, long periods of inactivity increase the risk of battery drain49, fluid degradation, rust buildup, and mechanical issues50.

Starting the tractor periodically and performing regular inspections prevent system failures, keeps components lubricated, and ensures an easy restart after storage.

What Happens If a Tractor Sits Too Long Without Being Started?

Without periodic startups, several components can deteriorate, leading to hard starts, engine problems, and hydraulic failures.

| Issue | Cause | Potential Damage |

|---|---|---|

| Battery Discharge | Lack of charging | Dead battery, requiring replacement |

| Oil and Fluid Settling | Fluids become stagnant | Dry internal parts, reduced lubrication |

| Fuel System Clogs | Fuel thickens or attracts moisture | Hard starts, injector clogging |

| Brake and Hydraulic Stiffness | Lack of movement | Sticking brakes, slow hydraulic response |

Remember start your tractor at least once a month to prevent these issues and ensure it stays in good working condition.

How to Properly Start and Inspect a Stored Tractor?

Start the Engine for 10-15 Minutes:

- Warms up the engine, allowing oil to circulate and lubricate components.

- Prevents fuel system blockages and moisture buildup.

Engage the Hydraulics and Transmission:

- Move the hydraulic levers and shift gears to keep components active.

- Ensures seals and valves remain functional.

Check for Leaks and Damage:

- Inspect Inspect hoses, seals, and connections51 for signs of fluid leaks or rodent damage.

- If leaks are found, address them immediately before they worsen.

Recharge or Maintain the Battery:

- If the tractor struggles to start, recharge or replace the battery.

- If using a trickle charger, ensure it's maintaining the correct voltage.

Remove and Reposition the Cover52 (If Stored Outdoors):

- Shake off any collected moisture, snow, or debris from the tarp.

- Allow airflow to prevent mildew and rust formation.

Letting a tractor sit for months without being started leads to battery failure, fuel system issues, and mechanical stiffness. Taking just a few minutes each month prevents costly repairs and ensures a smooth startup after long-term storage.

Periodically starting and inspecting a stored tractor helps prevent battery drain, fluid degradation, and mechanical issues.True

Running the engine circulates oil, prevents fuel system blockages, and keeps hydraulic components functional, ensuring a smoother restart after storage.

A stored tractor can be left untouched for months without any negative effects.False

Long periods of inactivity can lead to battery failure, fuel system clogs, and rust buildup, making it harder to restart and potentially causing costly repairs.

12. Preparing the Tractor for Use After Storage

After months of inactivity, immediately starting the tractor without a proper checkup can lead to engine strain53, fluid issues, or mechanical failures. Bringing a tractor back into operation requires careful inspection and step-by-step reactivation to ensure safe and efficient performance.

A thorough pre-use inspection54 ensures that the tractor’s battery, fluids, tires, and engine components are in proper working order, preventing breakdowns and costly repairs.

What Happens If a Tractor Is Restarted Without a Proper Check?

Starting a tractor immediately after long-term storage without an inspection can cause unexpected failures and safety risks.

| Issue | Cause | Potential Damage |

|---|---|---|

| Dead Battery | Loss of charge over time | Prevents startup, may require replacement |

| Fluid Contamination | Moisture or dirt in fuel, oil, or coolant | Reduces engine efficiency, clogs injectors |

| Low or Flat Tires | Air loss from inactivity | Uneven wear, risk of blowouts |

| Rodent or Debris Blockages | Nesting in exhaust, hoses, or wiring | Engine failure, electrical issues |

Follow a structured pre-use checklist before restarting your tractor to avoid unexpected damage and costly repairs.

How to Properly Reactivate a Stored Tractor?

Inspect the Battery and Electrical System:

- Reconnect the battery if it was removed.

- Check for corrosion on terminals and clean if necessary.

- Use a trickle charger to restore charge if the battery is weak.

Check and Refill Fluids55:

- Inspect engine oil, coolant, and hydraulic fluid levels.

- If fluids appear discolored, thick, or contaminated, replace them before use.

- Drain any water from the fuel separator and check fuel quality.

Inspect Tires and Adjust Pressure:

- Check for flat spots, cracks, or signs of dry rot.

- Inflate tires to manufacturer-recommended PSI for safe operation.

Remove Exhaust and Air Intake Covers:

- Check for rodents, nests, or blockages in the exhaust pipe and air intake.

- Ensure the air filter is clean before starting.

Start the Engine and Let It Idle:

- Allow the engine to warm up for several minutes to circulate fluids.

- Monitor for any unusual noises, vibrations, or warning lights.

Test the Brakes, Steering, and Hydraulics56:

- Press the brakes and clutch to ensure they respond smoothly.

- Engage the hydraulic system and PTO to check for delayed response or pressure issues.

Skipping a post-storage inspection can lead to mechanical failures, engine issues, and safety hazards. Taking these extra precautions guarantees that the machine is ready for work without costly repairs or downtime.

Properly reactivating a stored tractor prevents engine strain, fluid issues, and mechanical failures.True

Checking the battery, fluids, tires, and air intake before starting ensures safe operation and prevents potential damage after long-term storage.

A stored tractor can be started immediately without any pre-use inspection or precautions.False

Skipping a thorough checkup can lead to engine strain, contaminated fluids, battery failure, or hidden mechanical issues, increasing the risk of breakdowns.

Conclusion

Proper off-season storage protects your tractor from damage, extends its lifespan, and reduces costly repairs when it is needed again. By following these preventative maintenance steps, you can ensure that your tractor remains in top condition and is ready to work when the season resumes.

-

Discover effective strategies to protect your tractor's tires from damage while in storage, saving you from costly replacements. ↩

-

Learn about the significance of periodic startups in maintaining your tractor's functionality and preventing issues after long storage. ↩

-

Understanding the storage environment is key to maintaining your tractor's longevity and performance. Explore this link for detailed insights. ↩

-

A breathable tarp can protect your tractor from moisture while allowing air circulation. Learn more about its advantages here. ↩

-

Understanding rust formation can help you take preventive measures to protect your tractor and other equipment. ↩

-

Learning about the importance of a dry surface can enhance your equipment's longevity and performance. ↩

-

Exploring the effects of moisture buildup can guide you in maintaining your machinery effectively. ↩

-

Understanding the causes of component failures can help you take preventive measures and maintain your tractor effectively. ↩

-

A thorough deep clean is essential for maintaining your tractor's longevity and performance. Discover effective cleaning techniques. ↩

-

Using a pressure washer can save time and ensure a thorough clean. Explore its advantages for tractor maintenance. ↩

-

Applying a protective wax coat can prevent rust and corrosion. Learn the best practices for protecting your tractor's metal surfaces. ↩

-

Understanding the importance of changing oil can help prevent costly repairs and ensure your tractor runs smoothly when needed. ↩

-

Learn how proper hydraulic fluid maintenance can enhance your tractor's efficiency and longevity. ↩

-

Discover why maintaining coolant levels is crucial for preventing engine damage during storage. ↩

-

Understanding proper engine oil change techniques can enhance your tractor's longevity and performance. Explore expert insights on this topic. ↩

-

Learn the essential steps for changing hydraulic fluid to ensure your tractor operates smoothly and efficiently. This resource can guide you through the process. ↩

-

Discover why using a fuel stabilizer is crucial for maintaining your tractor's fuel system and preventing costly repairs. This information is vital for every tractor owner. ↩

-

Understanding fuel system maintenance can prevent costly repairs and ensure your tractor runs smoothly after storage. ↩

-

Learning about fuel degradation helps you take proactive steps to protect your engine and avoid issues when restarting. ↩

-

Preventing injector clogging is crucial for maintaining engine efficiency and avoiding expensive repairs when you need your tractor. ↩

-

Explore best practices for long-term diesel fuel storage to ensure optimal performance and prevent degradation. ↩

-

Learn about the significance of draining the water separator to protect your tractor's fuel system from moisture and contaminants. ↩

-

Exploring tips for long-term storage can help you protect your investment and avoid common issues like battery damage. ↩

-

Learning about trickle chargers can help you maintain your tractor's battery health effectively, ensuring longevity and reliability. ↩

-

Discover the significance of storing batteries in a temperature-controlled environment to prevent damage and ensure longevity. ↩

-

Learn about anti-corrosion grease to protect your battery terminals and enhance battery performance. ↩

-

Understanding tire storage can prevent damage and save costs, ensuring your tractor performs well when needed. ↩

-

Learn how flat spots can impact your tractor's performance and how to avoid them for better efficiency. ↩

-

Discover the causes of dry rot and effective prevention methods to extend the life of your tires. ↩

-

Understanding the correct PSI is crucial for maintaining tire health and performance. Explore this link for detailed guidelines. ↩

-

Discover effective methods to shield your tires from harmful UV rays and prolong their lifespan. This link offers practical tips. ↩

-

Exploring the significance of proper lubrication can help prevent costly repairs and extend equipment life. ↩

-

Learning about friction's impact can lead to better maintenance strategies and improved machinery efficiency. ↩

-

Understanding proper PTO shaft lubrication can enhance your tractor's performance and longevity. Explore expert tips and techniques. ↩

-

Discover the right oils for maintaining tractor hinges and latches, ensuring they operate smoothly and last longer. ↩

-

Learn about preventive measures against pest infestations that can damage your equipment and lead to costly repairs. ↩

-

Understanding moisture buildup can help you maintain your equipment's longevity and performance, preventing serious issues. ↩

-

Discover strategies to safeguard your engine from pests while ensuring proper airflow. ↩

-

Find out the importance of regular inspections to prevent rodent damage in your vehicle. ↩

-

Understanding proper parking brake usage can prevent damage and enhance safety during long-term storage. ↩

-

Discover the causes of brake seizing and effective prevention methods to ensure your tractor remains safe and functional. ↩

-

Learn how wheel chocks can secure your tractor and prevent rolling hazards effectively. ↩

-

Learn effective maintenance tips for your parking brake to prevent sticking and ensure safety. ↩

-

Understand the significance of a stable parking surface to protect your tractor from potential damage. ↩

-

Learn effective strategies to prevent paint fading on your tractor, ensuring it looks great and maintains its value over time. ↩

-

Discover how a breathable, weatherproof cover can enhance your tractor's longevity and performance by protecting it from environmental damage. ↩

-

Learn effective methods to secure your tractor cover and ensure it stays in place during windy conditions. ↩

-

Discover the importance of dust-resistant covers for indoor storage to keep your tractor in top condition. ↩

-

Understanding battery drain can help you maintain your tractor's performance and avoid unexpected failures. ↩

-

Exploring common mechanical issues can save you time and money by preventing costly repairs in the future. ↩

-

Understanding how to inspect these components can prevent costly repairs and ensure your tractor runs smoothly. ↩

-

Learn why proper cover management is essential to protect your tractor from moisture and rust, ensuring its longevity and performance. ↩

-

Learning about engine strain can help you prevent damage and ensure your tractor runs smoothly after storage. ↩

-

Understanding pre-use inspections can help you maintain your tractor effectively and avoid costly repairs. ↩

-

Fluid maintenance is vital for tractor performance. Discover detailed guidelines to keep your tractor running smoothly. ↩

-

Safety is paramount when operating heavy machinery. Learn how to effectively test these systems to ensure safe operation. ↩