How Utility Tractors Benefit Small-Scale Farmers: A Practical Field Guide

A few months ago, I watched a young farmer in Zambia struggle with a borrowed, oversized 110 hp tractor. He could barely turn it in his vegetable plots, and half his implements sat unused. That frustration could have been avoided with a properly matched utility tractor1.

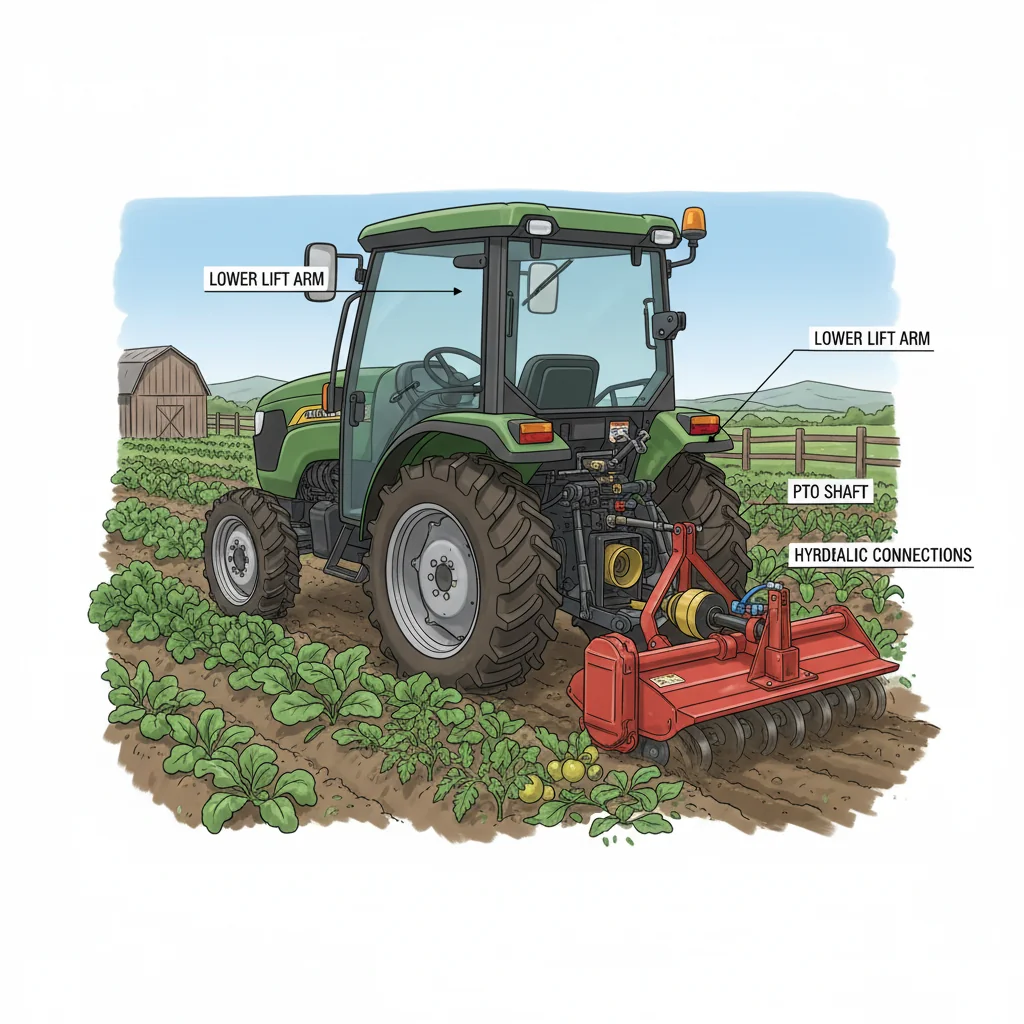

Utility tractors in the 40–90 hp range are engineered for versatility, compact size, and ease of maintenance, making them particularly suitable for small-scale farms between 1 and 30 hectares. Their three-point hitch2, 540 rpm PTO, and basic hydraulic systems enable rapid switching between implements for tillage, seeding, spraying, hauling, and material handling. Compact utility models offer strong performance in tight field layouts, reduce soil compaction, and allow effective work in mixed-crop or terraced conditions.

Why Choose Utility Tractors for Small Farms?

Utility tractors, typically 40–90 hp with a 3-point hitch, PTO, and hydraulics, are ideal for 1–30 ha farms. Compact utility models in the 50–80 hp, 4WD range offer enough power for ploughing and tillage but remain maneuverable in tight yards, orchards, and vegetable beds.

Most people don't realize that the real strength of a utility tractor isn’t just the engine—it's the combination of horsepower, PTO, and a reliable three-point hitch. Take a 60HP 4WD model with a lift capacity around 1,800 kg. That’s more than enough for a 1.8-meter rotavator or a 2-furrow plough, which covers typical small farm needs from Kenya to Peru. I’ve seen these tractors work eight-hour days handling tillage in the rainy season, then switch to pulling trailers of maize or sugarcane the next week—no fancy electronics, just dependable hydraulics and solid frame construction.

Let me share something important about maneuverability. In Central Asia, a customer with 12 hectares of mixed orchard and field crops struggled with an older, oversized tractor. It couldn’t turn between tight apricot rows or manage narrow vegetable beds. When he switched to a compact utility tractor in the 50–70HP range, his work rate improved immediately. The shorter wheelbase and 4WD let him make tighter headland turns and reduce soil compaction, especially after heavy spring rains. That flexibility meant he could handle spraying, mowing, and transport jobs without multiple machines.

I've worked with buyers who get caught up in max horsepower and forget about implement compatibility. For small farms—especially those with terraces or curved plots—the right-sized utility tractor becomes the backbone of daily operations. I suggest always checking the hydraulic output and PTO speed with your own implements in mind. That’s what keeps costs controlled and the machine useful season after season.

A utility tractor’s three-point hitch allows small-scale farmers to use a wide range of implements, making it possible to complete multiple field operations—like tillage, planting, and spraying—without needing separate specialized machines.True

The standardized three-point hitch system is a key feature that increases a utility tractor’s versatility, giving small-scale farmers flexibility to attach and operate various implements as needed for different tasks.

Utility tractors under 60HP are generally not capable of operating power take-off (PTO) driven implements such as rotavators or mowers.False

Many utility tractors below 60HP are specifically designed with PTO systems and sufficient hydraulic capacity to handle common implements like rotavators, mowers, and tillers, especially on small farms.

Key takeaway: Utility tractors provide small-scale farmers with a versatile, right-sized mechanization solution. Their compact build, appropriate horsepower, and adaptable implements make them cost-effective and practical for mixed crops, curved fields, and limited space—reducing the need for multiple machines and supporting efficient, sustainable farm operations.

How much efficiency do utility tractors add?

A 60 hp utility tractor3 with a 1.8 m rotavator4 can prepare 2–4 hectares per day on a 5–20 ha farm, dramatically outpacing manual or animal labour. Timely switching between tillage, planting, and spraying protects crop yield by meeting critical fieldwork windows, especially when family labour is limited.

Let me share something important about utility tractors and efficiency—most buyers focus on horsepower, but real gains come from what you can actually get done in a day. In Mozambique, I worked with a group of vegetable farmers managing about 12 hectares each. Before they bought their 60HP utility tractors, they relied on animal traction and family labour. Field prep for just 4 hectares took nearly a week. With the new tractors and a 1.8-meter rotavator, the same job finished in two days, even on heavy soils.

This speed isn’t just about working fast. It’s about hitting the right window after rain to avoid soil crusting and to get a strong germination. I’ve seen farmers in Brazil lose yield because they couldn’t finish planting before the sun baked the topsoil. With a utility tractor, you can switch from tillage to planting in under an hour. The three-point hitch system lets you drop the rotavator and hook up a two-row planter quickly. That means you can cover your full 10- or 15-hectare plot before the next weather change.

On smaller farms, family labour is often stretched thin, especially during peak season. One customer in Peru told me that after buying a 60HP unit, his family could focus on irrigation and weeding instead of spending days behind oxen. The PTO (that’s the shaft powering your implements) allowed him to add a sprayer, getting pest control done on schedule. I always suggest looking at how tractors help you manage time, not just tasks. That’s where the real efficiency lies.

Utility tractors allow small-scale farmers to efficiently use implements like rotavators and plows, reducing bottlenecks in field preparation compared to animal traction.True

Utility tractors provide consistent power that enables the use of a wider range of mechanized implements, which can prepare fields more quickly and thoroughly than animal traction, especially over larger areas.

Utility tractors provide the greatest efficiency gains only when operated at their maximum rated horsepower at all times.False

Operating tractors continuously at maximum horsepower is not efficient and can lead to excessive fuel consumption and wear. Optimal efficiency is achieved by matching tractor power to the implement and task at hand, often operating below maximum power.

Key takeaway: On small farms, utility tractors significantly increase fieldwork efficiency and timeliness. The ability to quickly switch implements and complete multiple operations in optimal conditions can lead to stronger crop stands and higher yields, making mechanization a strategic investment for small-scale farmers.

How do utility tractors reduce manual labour?

A 50–70 hp utility tractor equipped with a front loader, pallet forks, and trailer can replace several workers for daily chores. It enables one person to load and spread manure, move round bales, and transport feed or fencing materials efficiently, reducing labour dependence, fatigue, and injury risks on small-scale mixed farms.

The biggest mistake I see is farmers underestimating just how much manual labour a good utility tractor can replace. On a small mixed farm in Bolivia, I watched a team of five men spend a whole day moving and spreading around 20 tons of manure by hand. When they brought in a 60HP utility tractor with a front loader and trailer, one person finished the same work in less than two hours. That’s not just saving time—it’s reducing exhaustion and injury risk for the whole team.

On mixed farms in Kenya, especially where family labour is stretched thin, I’ve seen a single 55HP tractor with pallet forks handle jobs that used to require three or four workers. Moving big round bales, shifting water tanks, and transporting heavy fencing materials—all these tasks become one-person jobs with the right attachments. The hydraulic system and three-point hitch let you quickly switch between implements, so downtime drops and animals get fed or cleaned out on schedule. Clean pens and fresh bedding mean healthier livestock, and that pays off over the season.

Outside the field, these tractors pull their weight year-round. In Kazakhstan, a customer told me their 70HP unit grades driveways after snowstorms and hauls building supplies for repairs. No need to hire extra hands during off-peak months. I always suggest checking that your model has a reliable PTO and enough hydraulic outlets, so you aren’t limited when adding attachments down the road. For small farms, this flexibility is what really keeps operations efficient and manageable.

Utility tractors equipped with hydraulic front loaders can significantly reduce the risk of musculoskeletal injuries among farm workers by mechanizing repetitive lifting and carrying tasks.True

Hydraulic loaders allow a single operator to move and load heavy materials like manure or feed, eliminating the need for repeated manual lifting and carrying, which are leading causes of back and joint injuries in agricultural labour.

Utility tractors are only beneficial for large-scale operations and provide no practical labour savings for small or mixed farms.False

Even on small or mixed farms, utility tractors replace labour-intensive tasks such as hauling, spreading, and field preparation, making them valuable for reducing manual effort and improving efficiency regardless of farm size.

Key takeaway: Utility tractors significantly cut manual labour for small-scale farmers by mechanizing heavy chores like manure handling and material transport. This efficiency reduces the need for seasonal workers, minimizes physical strain, and ensures year-round productivity, making these tractors vital for mixed family-run farms.

Why match tractor size to implements?

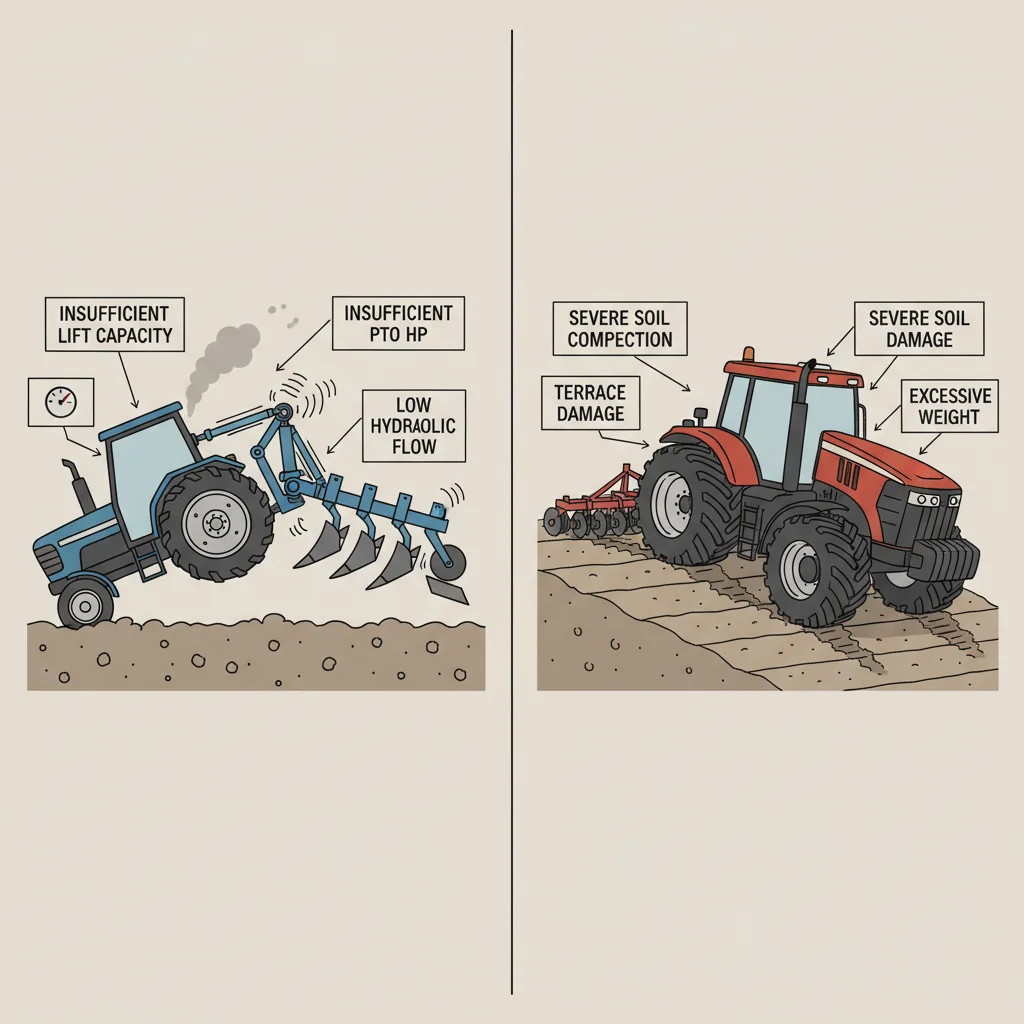

Matching tractor size and implements is essential for efficiency and safety. An undersized tractor cannot power or lift key implements, while an oversized machine risks soil compaction, damaged terraces, and stuck equipment. Correctly pairing PTO horsepower5, hydraulic flow, and lift capacity prevents costly breakdowns and stranded implements, ensuring smooth, fuel-efficient operation in small-scale farming.

Here’s what matters most when pairing tractors and implements: your tractor must physically handle the tools you plan to use, not just in theory but under real farm conditions. I’ve seen too many farmers in Peru and Nigeria invest in a 45HP model only to find it can’t reliably lift a 1,200kg plough or run a 600L sprayer with hydraulic booms. The result? Implements left sitting unused, or worse—overloading the tractor’s hydraulics until something breaks. It’s not just about “will it work?”—it’s about “will it work safely, efficiently, and all season long?”

Let me share an example from Kazakhstan. A customer bought a 90HP heavy-duty tractor for wheat fields with soft loam soil. Sounded like a good plan, but after the first rains, that 4-ton machine compacted the soil and got stuck near the field edge. Smaller terraces and bunds can’t handle that weight. Soil structure suffered, and fuel use jumped. The right fit for that operation would have been a 60–70HP unit—still enough power for a 2-furrow plough or mid-size seeder, but much lighter on the land.

From my experience, the best way to avoid these mistakes is to list your main jobs and check each implement’s real requirements. Look at PTO horsepower (for driven tools like rotavators or sprayers), hydraulic flow (some sprayers need at least 30L/min), and three-point hitch lift capacity at the ball ends. I suggest comparing your tractor’s actual data plate—not just the brochure—with your implements’ needs. This step saves money, fuel, and a lot of frustration.

Selecting a tractor with too little hydraulic capacity for your implements can cause premature failure of both the tractor’s hydraulic pump and the attached equipment.True

Hydraulic systems are engineered for specific loads; regularly exceeding these by pairing undersized tractors with heavy implements leads to overheating, seal damage, and eventual failure in both tractor and implement hydraulics.

A tractor rated at 45 horsepower can reliably operate any implement that weighs less than 1,500kg, regardless of hydraulic requirements.False

Horsepower rating alone does not determine if a tractor can safely and effectively use an implement; hydraulic flow, lift capacity, and stability are all critical factors, and a 45HP tractor may not have the hydraulic strength or chassis stability for heavy or demanding implements.

Key takeaway: Selecting a utility tractor with properly matched power, hydraulic flow, and lift capacity to the intended implements is critical. This alignment prevents equipment damage, maximizes field efficiency, and avoids unnecessary expenses—issues especially crucial for small-scale farmers working with diverse attachments and limited resources.

Is a Utility Tractor Cost-Effective?

Owning a utility tractor can be economically advantageous for small-scale farmers. For a 10 ha farm, annual contractor fees6 range from $800–1,200, while a new 50–70 hp tractor plus implements costs $18,000–25,000. Payback is often achieved in 4–6 years through saved fees, lower operating costs, and custom work income.

I get a lot of questions from farmers in Africa and Central Asia who wonder if buying a utility tractor makes sense for their size of operation. A smallholder in Kenya recently calculated he was spending almost $1,000 per year just on contractor fees for ploughing, planting, and spraying his 10-hectare farm. That’s not counting the extra days lost waiting for the contractor to arrive—sometimes missing the best planting window by a week or more. If you look at the numbers, a basic 50–70 horsepower utility tractor with core implements usually costs around $20,000 upfront. Annual running costs—mainly fuel and regular maintenance—run about $900 a year if you work 300 hours, which is typical for a small farm. Over five years, you’re looking at a total outlay of $24,500.

But if you add up avoided contractor fees over those same five years, you’re close to breaking even—especially if you use the tractor for extra tasks like hauling, water pumping, or light earthmoving. In Kazakhstan, I’ve seen farmers offset costs even faster. One customer started doing custom ploughing for neighbors at $80 per hectare. After the second season, he was already earning enough to pay for half his annual fuel and service. Modern diesel tractors also burn less fuel per hour—usually 4 to 6 liters, depending on load—and need less frequent servicing compared to older models. That means less workshop downtime and more flexibility to work when you need to.

Utility tractors allow smallholder farmers to perform field operations like ploughing and planting at the optimal time, which can lead to improved crop yields compared to relying on contractor availability.True

Having direct access to a utility tractor means farmers can work their fields exactly when conditions are ideal, rather than waiting for contractors who may be delayed. Timely fieldwork is a key factor in maximizing yields, especially with unpredictable weather.

Utility tractors are only cost-effective for farms larger than 50 hectares and do not offer financial benefits to small-scale farms.False

While utility tractors are often associated with larger farms, many small-scale farmers find them cost-effective by reducing recurring contractor costs and labor hours. The ability to use the tractor for multiple tasks throughout the year can justify the investment, even on farms smaller than 50 hectares.

Key takeaway: For small farms, investing in a utility tractor can lead to significant long-term savings and improved operational flexibility. Lower running costs, increased fuel efficiency, and the potential for custom work income can offset the initial investment within several years.

How do attachments multiply tractor utility?

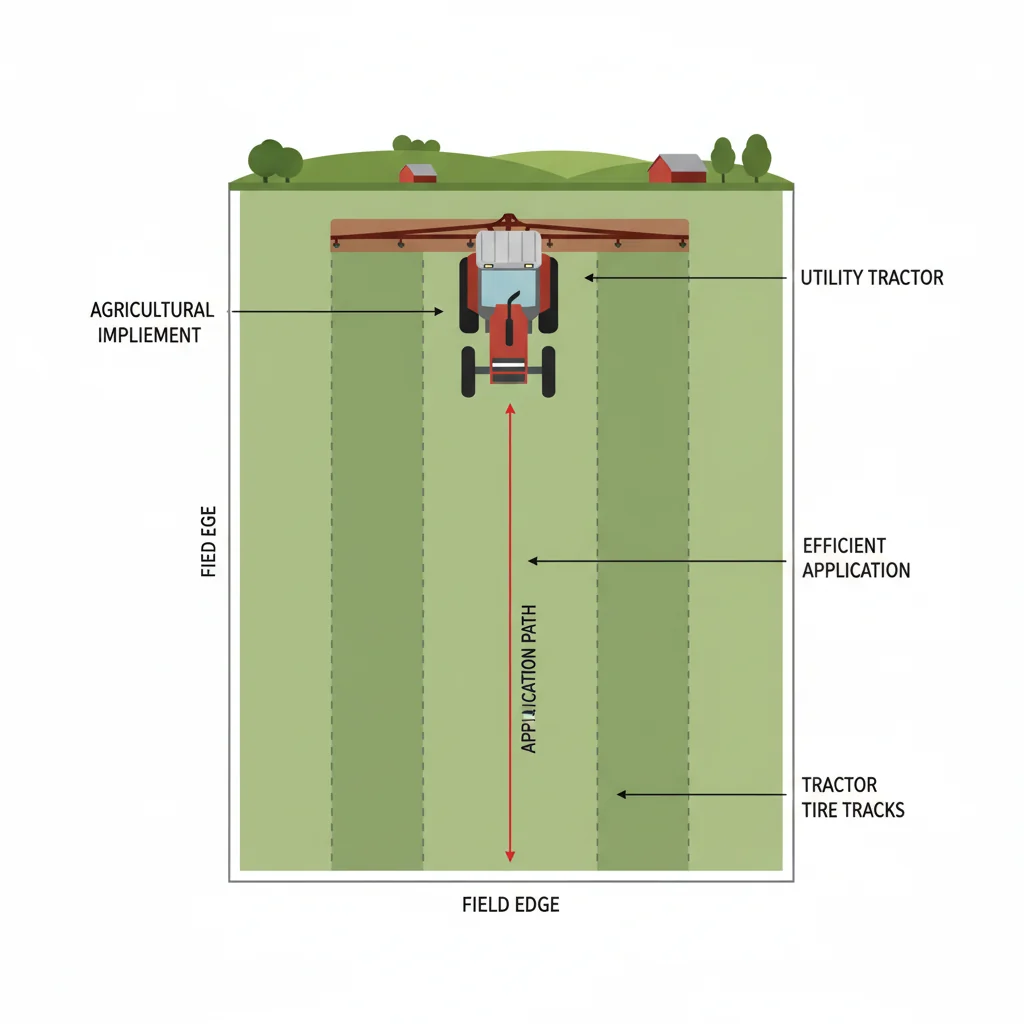

Attachments such as ploughs, planters, sprayers, and loaders connect to a utility tractor via the three-point hitch, PTO, and hydraulic remotes. This integration allows one machine, typically 50–80 hp, to perform diverse field tasks, eliminating the need for multiple specialized machines and maximizing efficiency for small-scale farms.

Let me share something important about attachments on utility tractors: they’re the real reason a 50–80 horsepower machine can cover so many jobs. I’ve seen small farms in Peru and Nigeria get by for years with just one sturdy tractor and the right set of implements. Instead of investing in multiple machines, they rotate a handful of essential tools—saving a lot of money up front and on ongoing maintenance. The three-point hitch, PTO (that’s the power take-off shaft), and hydraulic remotes turn your basic tractor into a true all-rounder.

Here’s a quick list of attachments I consider essential for most small-to-medium farms:

- Plough or chisel – for breaking and preparing soil before planting

- Rotavator or power harrow – to refine seedbeds and control weeds

- Planter or seeder – for precise, efficient crop establishment

- Sprayer – vital for pest and weed control on row crops

- Trailer – for moving harvest, inputs, or building materials

- Front loader – handling manure, feed, or loading bags and pallets

In Kazakhstan, I worked with a cooperative that started with just three attachments: a plough, a planter, and a trailer. Over two years, as their operations grew, they added a sprayer and a loader—no need to buy a new tractor. Their original 75HP model handled it all because they’d checked the hydraulic system and lift capacity matched their implements. From my experience, planning your first 3–5 attachments at the time you buy the tractor is smart.

A utility tractor equipped with a front loader and rear-mounted rotary tiller can efficiently handle both material loading and primary tillage, tasks that would otherwise require separate specialized machines on a small farm.True

Attachments designed for use with the three-point hitch and PTO allow a single tractor to perform multiple distinct operations, reducing the need for multiple tractors or dedicated equipment for each job.

Utility tractor attachments are only compatible with tractors from the same manufacturer, so small-scale farmers must purchase all implements from a single brand.False

Most modern utility tractors and attachments use standardized mounting systems like the three-point hitch and PTO, which are designed for cross-compatibility among different brands, giving farmers flexibility in choosing implements.

Key takeaway: The versatility of a utility tractor comes from its ability to use various attachments. By choosing a core set of implements suited to essential tasks, small-scale farmers can maximize equipment value, reduce costs, and adapt operations as their needs grow, rather than investing in multiple single-purpose machines.

How Does Precision Tech Aid Small Farms?

Precision agriculture features in utility tractors—such as GPS guidance7, automatic steering, and variable-rate control—enable small-scale farmers to minimize overlaps, skips, and input waste. Field trials report yield improvements and input savings leading to a 10–15% increase in net returns, especially when using light-bar guidance or auto-steer8 for spraying and fertilizing.

Last month, a farmer in northern Kazakhstan told me he’d struggled for years with wasted fertilizer and uneven spraying. His land covers about 18 hectares, mostly wheat and barley. After adding a basic light-bar guidance system to his 75HP utility tractor, he saw fuel use drop noticeably—at least 10% less than before. The real surprise was input savings. By avoiding overlaps and missed strips, he used roughly 12% less fertilizer in his first season. His yields stayed steady, but his costs dropped. For a farm that size, that meant a real boost to his bottom line.

I’ve seen similar results in parts of Brazil and Kenya, especially with farms between 5 and 20 hectares. The key is sticking to simple, reliable systems. Auto-steer kits and light-bar guidance—nothing too fancy—help farmers focus on spraying or seeding straight lines, even when fields are irregular or visibility is poor. One customer in western Kenya told me he could finally spray his maize fields without double-covering the headlands. He saved not just chemicals, but a full day of labor each week during peak season.

Some mid-range utility tractors now come with basic farm management features—field mapping, task logs, input tracking. These can be useful, but only if you have local support. I always suggest checking who can service the guidance system in your area. Overly complex dashboards are a headache if nobody nearby can repair them. For most small farms, a straightforward guidance system pays for itself quickly in lower input costs and more uniform fields.

Light-bar guidance systems on utility tractors help small-scale farmers achieve more uniform input application, reducing both overlaps and missed areas during fieldwork.True

Light-bar guidance systems provide visual cues that assist operators in maintaining straight, evenly spaced passes. This minimizes areas of overlap and omission, leading to more accurate distribution of seeds, fertilizer, and chemicals, which is especially impactful on smaller fields where every input counts.

Precision technology on small farms eliminates the need for skilled tractor operators because automated guidance completely controls the tractor's steering and speed.False

Basic precision technologies like light-bar guidance require the operator to control the tractor's steering and speed; they only provide visual assistance. Skilled operators are still essential to ensure safe and effective use of the equipment, especially on smaller or irregularly-shaped fields.

Key takeaway: Precision technology in utility tractors, like GPS guidance and auto-steer, can help small-scale farmers boost efficiency and profits by reducing input waste and improving crop uniformity. Simple, reliable systems often deliver the best value, especially on farms between 5 and 20 hectares.

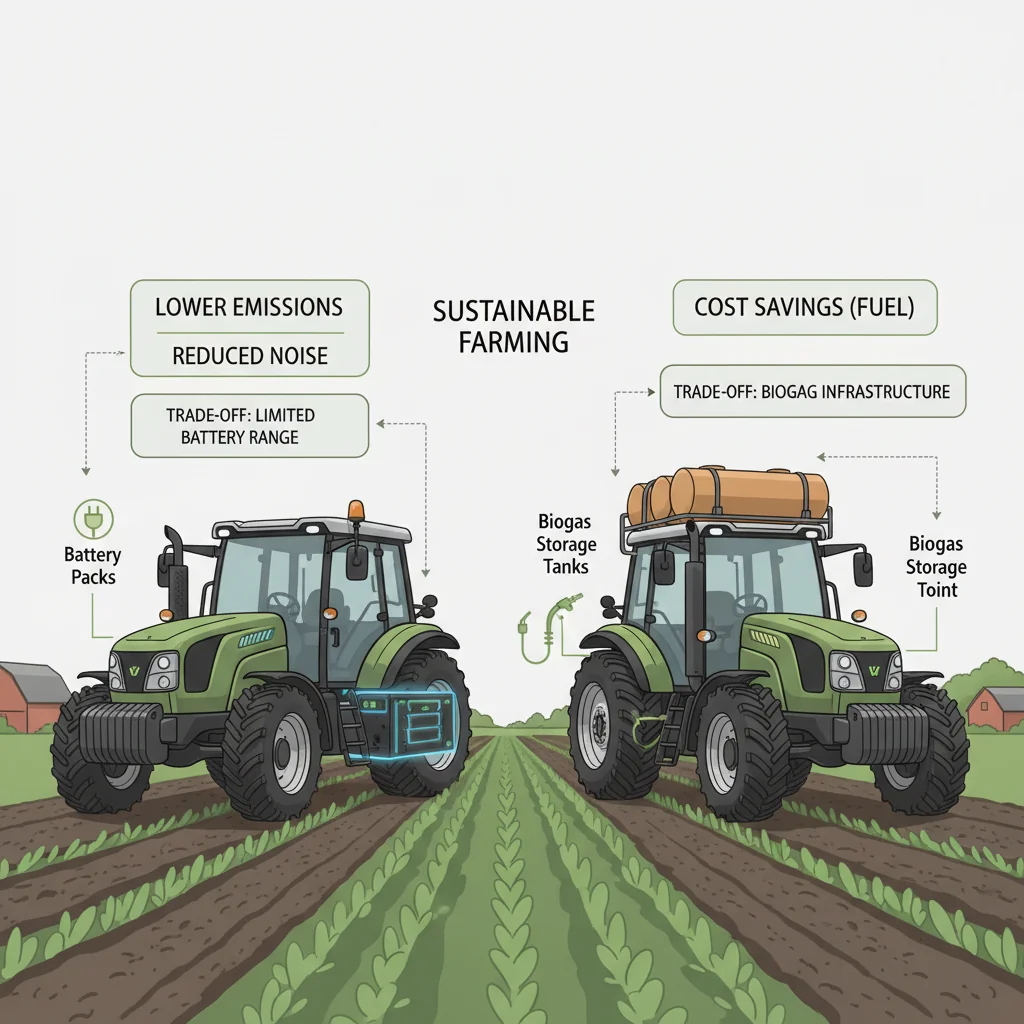

Are electric or methane tractors practical?

Electric and methane (biogas) utility tractors are increasingly viable for small-scale farmers seeking sustainability. Methane tractors can reduce fuel costs by up to 30% and lower emissions, while electric tractors9 offer zero tailpipe emissions and low noise. Trade-offs include higher upfront costs, battery range limitations, and biogas infrastructure requirements.

Last year, a vegetable grower in Peru asked me whether electric or methane tractors would actually make sense for his 10-hectare farm. He wanted to lower diesel costs and cut noise near his greenhouses. His main jobs were mowing, light tillage, and hauling crates—tasks that rarely take more than three or four hours at a time. In that scenario, I explained, a 40HP electric model with a battery rated for about five hours of operation could handle the workload. The quiet operation is a real benefit around workers and livestock. But once you need to plow large plots or work dawn to dusk, battery range becomes a problem. Recharging still takes several hours, even with a fast charger.

I've also seen methane tractors work well on dairy and poultry farms in Kazakhstan, where farmers already run biogas digesters. Instead of relying on diesel, they fuel their 75HP units using compressed biogas produced on-site. This can cut fuel costs by 25–30% and reduce exhaust emissions noticeably. But here’s the catch—if your farm doesn’t already make biogas, setting up digesters and gas storage is a big investment. And if you need to refuel in the field, portable methane supply isn’t always available.

The reality is, for farmers with consistent on-farm energy—solar or biogas—these tractors offer real sustainability and can fit short, routine jobs. But for longer fieldwork or remote areas without reliable power or gas, a modern 60–80HP diesel model is still the safest bet. I always suggest calculating your daily working hours and energy supply before deciding. This way, you avoid surprises in the middle of planting season.

Electric tractors can be especially practical for small farms where daily usage rarely exceeds the battery’s runtime, as intermittent tasks like mowing and crate hauling seldom require continuous operation.True

Battery-powered tractors are well-suited for farms with moderate workloads and frequent breaks, since many utility tasks do not demand full-shift, high-power use. This makes efficient use of the battery’s limited runtime, and reduces concerns about range compared to larger operations.

Methane-powered tractors are unsuitable for small-scale farms because they cannot deliver consistent power for light-duty tasks like mowing and hauling.False

Methane tractors can deliver steady power output comparable to diesel models, making them capable of handling typical light-duty farm tasks. Their main limitation lies in fuel availability and refueling infrastructure, not power consistency for small-scale operations.

Key takeaway: Alternative power utility tractors—electric and methane—offer compelling sustainability and operational benefits for small-scale farmers, especially when on-farm renewable energy is available. However, practical limitations in battery range, upfront costs, and fuel infrastructure may mean modern diesel models remain the most practical choice in many scenarios.

How Do Safety Features Prevent Tractor Loss?

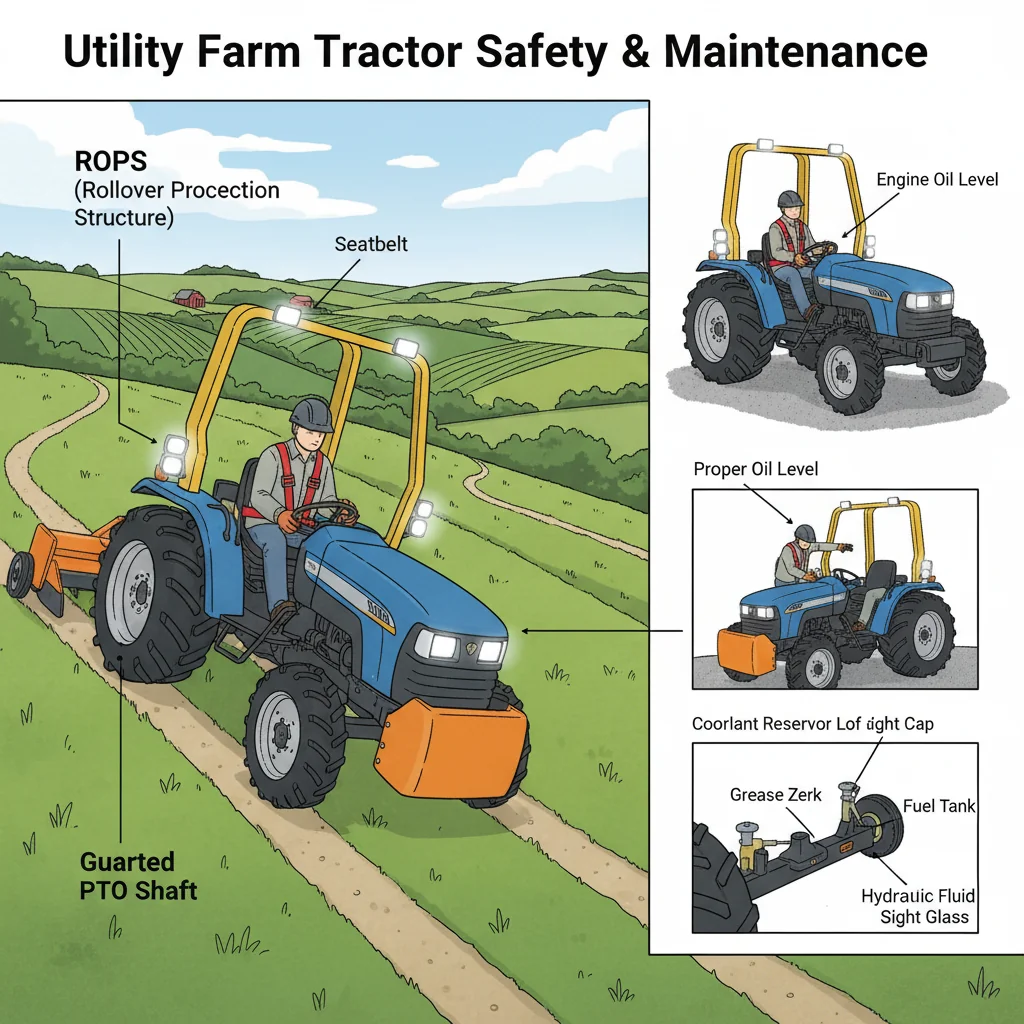

Utility tractors with ROPS, seatbelts, guarded PTO shafts, and proper lighting significantly reduce rollover and collision risks on small farms with slopes or narrow tracks. Adhering to safe operating habits and routine maintenance—daily fluid checks, greasing, and timely servicing—directly prevents injuries, equipment damage, and premature failures, securing the tractor’s long-term value.

I've worked with customers who made this mistake—focusing on price and power, but ignoring safety basics. In northern Kenya, a smallholder lost his 60HP utility tractor after a simple rollover on a sloped maize plot. No ROPS, no seatbelt, and the tractor was out of action for two months during planting. He told me, "If I'd spent a bit more on safety, I'd have had a working tractor when I needed it most."

Here's what actually keeps your investment safe and productive on challenging terrain:

- ROPS (Roll-Over Protective Structure): Protects the operator in case of a rollover. I see too many tractors still shipped without it, especially in Africa and Central Asia.

- Seatbelt: Works hand-in-hand with ROPS. Without using the belt, even ROPS can't prevent serious injury.

- Guarded PTO shaft10: Exposed PTOs are a common cause of injury when clearing weeds or changing implements. Guards cost little but prevent major accidents.

- Good lighting and reflectors: Vital for dawn or dusk work, especially on narrow tracks or when transporting produce to market.

- Trailer brake connection: For heavier loads, a working trailer brake reduces stopping distance and avoids jackknifing, especially on wet slopes.

From my experience, safe operating habits matter just as much. Keeping the loader low when moving, slowing down on field edges, and always checking for hidden ditches—all these habits prevent costly accidents. Regular maintenance is the other half of the equation.

Tractors equipped with rollover protective structures (ROPS) and seatbelts are much less likely to be permanently damaged in low-speed rollovers on uneven terrain.True

ROPS and seatbelts are designed to protect both the operator and the machine's critical components during a rollover, often preventing crushing or severe deformation that would render the tractor unusable. Without these features, even a minor rollover can cause major structural damage.

Installing additional front-end ballast on a tractor eliminates the need for operator safety features when working on sloped fields.False

While front-end ballast can improve stability and reduce the likelihood of tipping, it does not replace essential operator safety features like ROPS and seatbelts. These safety devices protect the operator and reduce equipment loss in the event of a rollover, which ballast alone cannot guarantee.

Key takeaway: Investing in safety features like ROPS and disciplined maintenance practices extends utility tractor lifespan and reduces risk of costly accidents or breakdowns. For small-scale farmers, these measures ensure the tractor is always ready during critical fieldwork periods, maximizing productivity and return on investment.

How Should Small Farmers Choose Tractors?

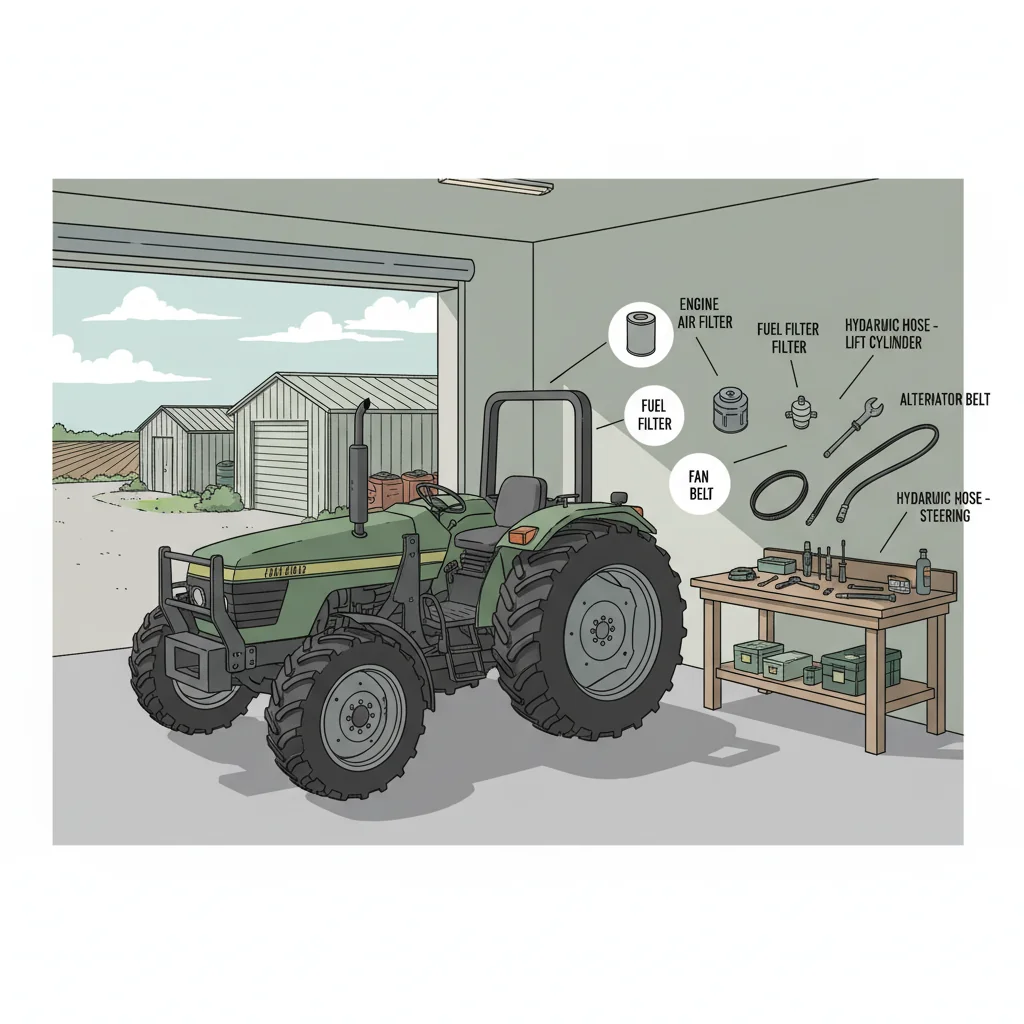

Small-scale farmers should prioritize strong local dealer support over brand prestige or horsepower, ensuring ready access to essential parts like filters, belts, and hydraulic hoses. Mid-range brands11 often provide significant cost savings without sacrificing key features. Reliable after-sales service and parts availability are typically more valuable than minor differences in brand reputation or price.

Too many small farms get caught up chasing big names or high horsepower, but that’s not what keeps a tractor running through the season. I always tell buyers in places like Bolivia and Kenya: focus on who will actually support you when something breaks. A slightly less famous 60HP tractor with a local dealer who stocks filters, clutch plates, and hydraulic hoses will outlast a “premium” model if spare parts are weeks away. I’ve seen too many farmers sidelined by a simple belt or seal that takes a month to arrive—especially during harvest.

Last year, a farmer outside Lusaka needed a replacement hydraulic pump seal. His local dealer for a mid-range brand had it on the shelf—he was back in the field the next morning. Meanwhile, a neighbor with a more expensive tractor waited nearly three weeks for an imported part to clear customs. That downtime cost him a critical planting window. It’s not just about price or brand. Who can get you running again when it really matters?

To be honest, I suggest first-time buyers in Africa or Latin America start with a new, basic 50–60HP model. Used tractors can seem like bargains, but hidden issues in the clutch or steering often mean higher costs later. Always ask local mechanics and other farmers which models hold up in your region’s soil and climate. Look at the three-point hitch capacity—make sure it matches your implements, not just the brochure specs. The right dealer and reliable support make all the difference for small-scale operations.

Utility tractors with readily available spare parts in the local market are often more reliable for small-scale farmers than premium models with limited parts support.True

A tractor's reliability for small farmers depends not only on its build quality but also on the farmer's ability to perform timely repairs. Local parts availability allows for faster maintenance and minimizes downtime, which is critical for small operations that cannot afford delays during peak seasons.

Small-scale farmers should always prioritize the highest horsepower utility tractor they can afford, as this guarantees better long-term performance.False

Excessive horsepower in a utility tractor can lead to higher fuel consumption, unnecessary wear, and increased purchase costs. Small-scale farms benefit more from matching tractor size and power to their actual field needs, and from considering available support and parts rather than focusing solely on horsepower.

Key takeaway: For small farms, the best tractor choice balances local dealer support, reliable after-sales service, and cost-effective mid-range or value brands. Prioritizing parts availability and practical support over brand image leads to fewer disruptions and better long-term performance.

Conclusion

We’ve looked at how utility tractors offer small-scale farmers a practical, flexible option for mixed crops and tight spaces. From what I’ve seen in the field, the buyers who get the most value focus less on the biggest engine and more on local support—especially parts availability and service. It’s easy to overlook these things and end up playing “parts roulette” when a simple breakdown turns into weeks of downtime. If you have questions about which tractor matches your farm or want to talk through real-world performance, feel free to reach out. I’m always happy to share what’s worked for farmers in different regions. Every farm is different—choose what actually works for your needs.

References

-

Explore how utility tractors with attachments replace multiple workers, cutting labour time and injury risks on mixed farms. ↩

-

Learn how the three-point hitch system enables quick implement changes, reducing downtime and improving farm productivity. ↩

-

Explore how a 60 hp utility tractor boosts productivity by reducing field prep time and enabling timely crop management on small to mid-size farms. ↩

-

Learn how a 1.8 m rotavator enhances soil preparation speed and quality, helping farmers meet critical planting windows and improve crop yields. ↩

-

Detailed explanation of PTO horsepower's role in matching tractors with implements, ensuring efficient and safe farm operations. ↩

-

Understand how annual contractor fees affect farm budgets and how owning equipment can reduce these recurring costs. ↩

-

Explore how GPS guidance reduces overlaps and input waste, boosting yields and cutting costs for small-scale farmers. ↩

-

Learn how auto-steer kits help farmers spray and seed accurately, saving labor and reducing chemical use on irregular fields. ↩

-

Learn about electric tractors' zero emissions, noise benefits, and battery limitations for short-duration farm tasks. ↩

-

Explains how guarded PTO shafts prevent common injuries during implement changes, highlighting cost-effective safety improvements. ↩

-

Details cost savings and reliable after-sales service from mid-range brands, helping farmers maintain tractors efficiently without sacrificing key features. ↩