How to Identify Tractor Leaks: Field Guide to Avoid Common Mistakes

Last season in Tanzania, a customer called me in a panic—his new tractor was “bleeding oil everywhere.” But when I arrived, the puddle under the axle wasn’t oil at all. That’s a mistake I see across Africa and Central Asia: not every leak is what it first appears.

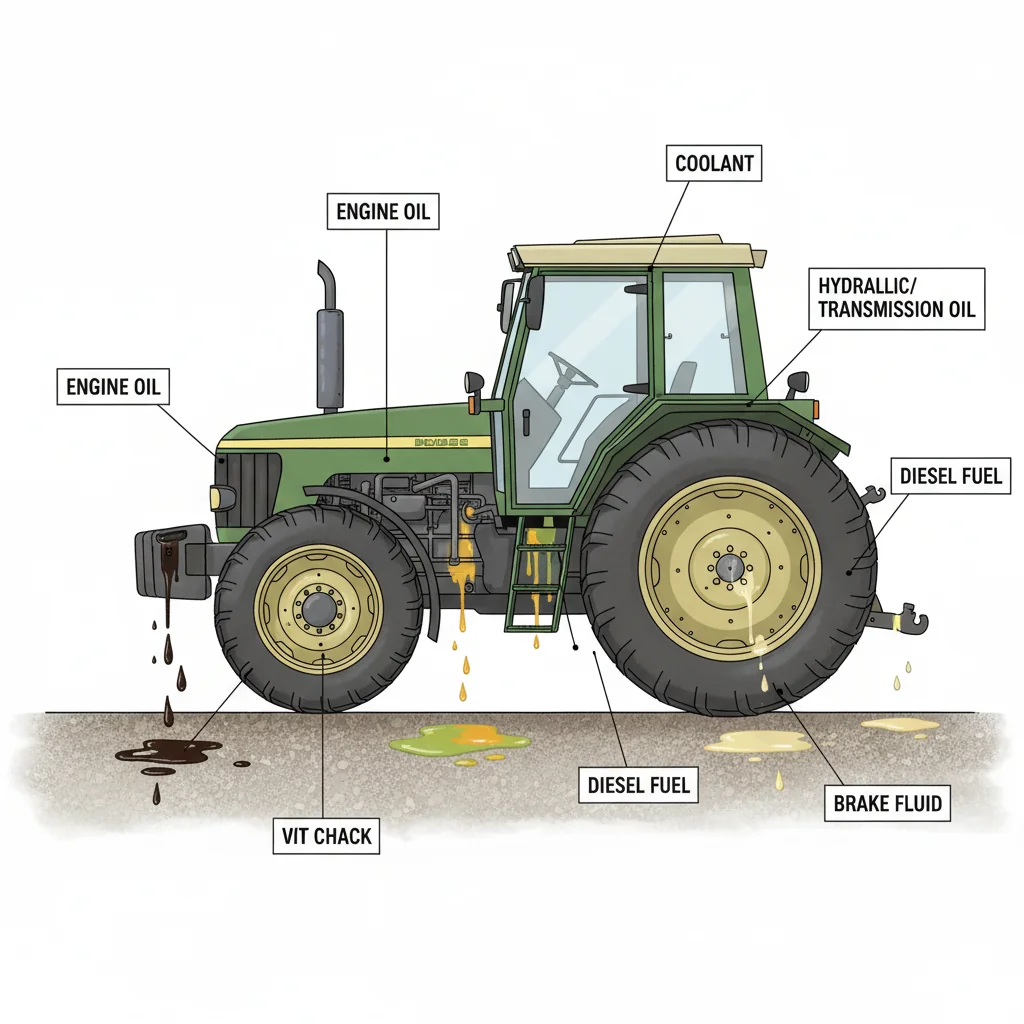

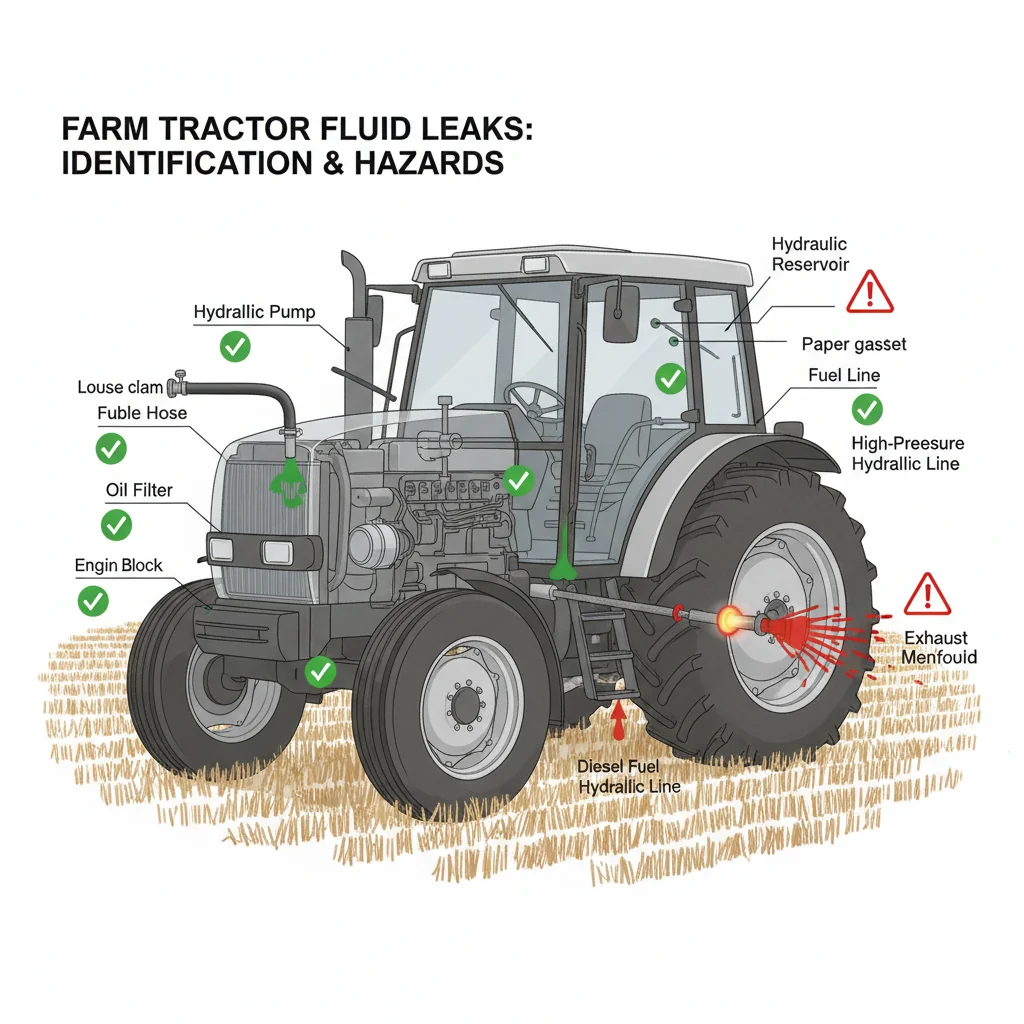

Accurate identification of tractor leaks requires careful observation of fluid characteristics and leak locations. Engine oil typically appears amber to black and collects under the engine, while hydraulic or transmission fluid is lighter and found around axles or loader circuits. Coolant presents as green, red, or yellow with a sweet odor near radiators or hoses. Diesel is clear to pale yellow with a distinct fuel smell, often near fuel tanks or injectors.

How to Identify Tractor Fluid Leaks?

Correct tractor leak identification starts by confirming which system is losing fluid. Engine oil is dark and slippery, hydraulic/transmission oil is lighter and golden, coolant is colorful with a sweet smell, diesel is thin and pale yellow, and brake fluid is very thin and clear or yellow.

Let me share something important about fluids—most people blame the wrong system when they spot a leak. The biggest mistake I see is assuming all oil under a tractor comes from the engine. That’s rarely true on the tractors I’ve supported in Brazil and Kenya. Engine oil is usually dark—amber to black—and feels slippery between your fingers. If you find it pooling directly beneath the engine block or sump, that’s your first clue. But if the oil is lighter, more golden, and shows up near the rear axle, loader controls, or hydraulic lines, you’re probably looking at a hydraulic or transmission leak. I had a customer in Peru with a 75HP tractor who spent days chasing an “engine” leak. Turned out to be a tiny split in a hydraulic return hose above the rear axle.

Coolant is another story. It’s almost always green, red, or yellow, and you’ll notice a sweet smell. I’ve seen leaks at the water pump or radiator cap go unnoticed until the engine overheats halfway through a field job. Diesel leaks are less common, but when they happen, the fluid is thin, pale yellow, and smells strong—usually found near the fuel tank, lines, or injectors. That’s a serious fire risk if it’s anywhere near the exhaust or hot engine parts.

I suggest using a clean white rag to blot any suspicious puddle. Check the color, smell, and where it’s dripping from. This simple habit helps you avoid wasting time—and lets you deal with the most urgent problems first.

Hydraulic fluid leaks on tractors are often identified by their lighter color and presence near rear axles or hydraulic lines, rather than under the engine.True

Hydraulic fluid is typically lighter and clearer than engine oil, and leaks often occur near hydraulic components at the rear of the tractor, not under the engine block. This helps distinguish hydraulic leaks from engine oil leaks.

All tractor fluids that appear golden in color are always engine oil leaks.False

Not all golden-colored fluids are engine oil; hydraulic fluid can also appear golden or light, especially when clean. Location and feel are important for accurate identification, not just color.

Key takeaway: Accurately identifying leaking tractor fluid by color, consistency, smell, and leak location prevents wasted effort and helps prioritize repairs. Recognizing the differences between engine oil, hydraulic/transmission oil, coolant, diesel, and brake fluid is essential to avoid unnecessary downtime and address urgent safety risks.

How to systematically find tractor leak sources?

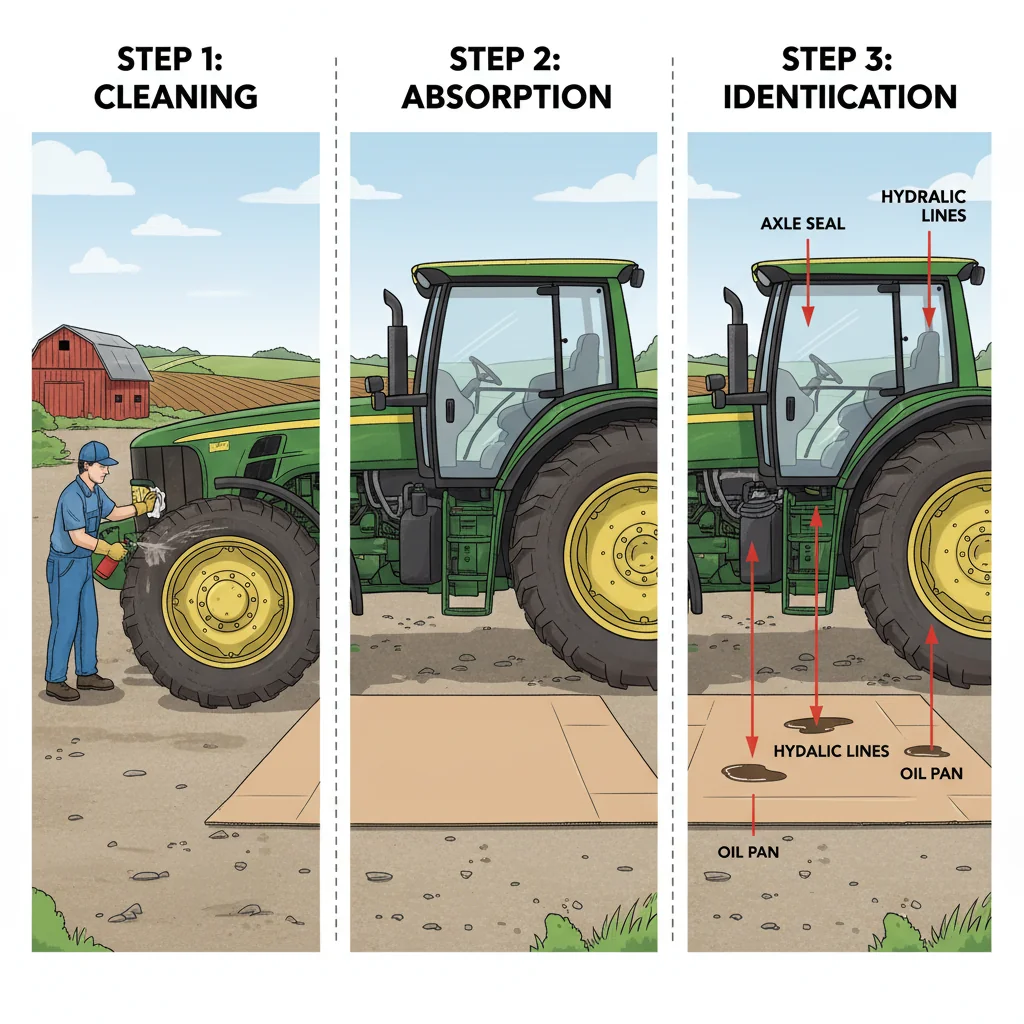

To identify tractor leak sources, first clean suspected areas with degreaser and let dry. Place clean cardboard underneath to catch drips. Run the tractor to operating temperature, then trace any wet trails upward to their origin. Repeat for slow leaks. This method avoids guesswork and pinpoints the true source.

The biggest mistake I see is jumping to conclusions about a leak’s source—especially when the tractor’s covered in old oil and dust. Last year in Bolivia, a distributor called me about a “hydraulic leak” on their new 80HP units. Mechanics kept swapping hoses and seals, but the problem never went away. When I asked if they’d cleaned the area first, they admitted it was still coated with last season’s grime. That’s why I always recommend starting with a thorough cleaning using a degreaser—otherwise, you’ll chase the wrong problem and waste both time and parts.

Once the area is clean and dry, I suggest laying a piece of clean cardboard under the tractor overnight. This simple trick pinpoints exactly where fresh drips are landing—much better than guessing from a messy floor. With a recent customer in Kenya, we found that what looked like a rear axle seal leak was actually coming from a small hydraulic line hidden above the axle. Cardboard doesn’t lie.

The next step is to run the engine until it’s at full operating temperature and work all major systems: PTO, hydraulics, steering, even the three-point hitch. This builds up system pressure and helps slower leaks show themselves. After shut-down, always trace any wetness upward—leaks travel down and out, but the actual source is almost always higher than you expect. If nothing shows right away, repeat the process after a few hours of fieldwork. This method isn’t fancy, but it’s saved my customers in Peru and Kazakhstan the cost of unnecessary repairs more times than I can count. I suggest making this systematic check part of your regular maintenance routine.

A thorough cleaning of the suspected leak area with a degreaser is essential before diagnosis, because oil and dust buildup can cause fluid to appear to be leaking from higher locations than the actual source.True

Contaminants on the tractor’s surface can cause fluids to migrate along surfaces, making it difficult to pinpoint the origin. Cleaning removes this residue and allows for accurate tracing of fresh leaks.

Replacing hydraulic hoses and seals without cleaning the area first is an efficient way to identify and fix the true source of a tractor leak.False

Swapping parts before cleaning can waste time and resources, as grime and old fluid can mislead mechanics and obscure the real source of the leak. Proper cleaning is a critical first diagnostic step.

Key takeaway: Systematically cleaning, observing, and tracing leaks upward is the most reliable way to identify tractor leak sources. This repeatable process eliminates guesswork, provides clear evidence for repairs, and ensures maintenance is both efficient and accurate—crucial for conventional tractors in emerging markets.

Where Do Tractor Leaks Most Often Occur?

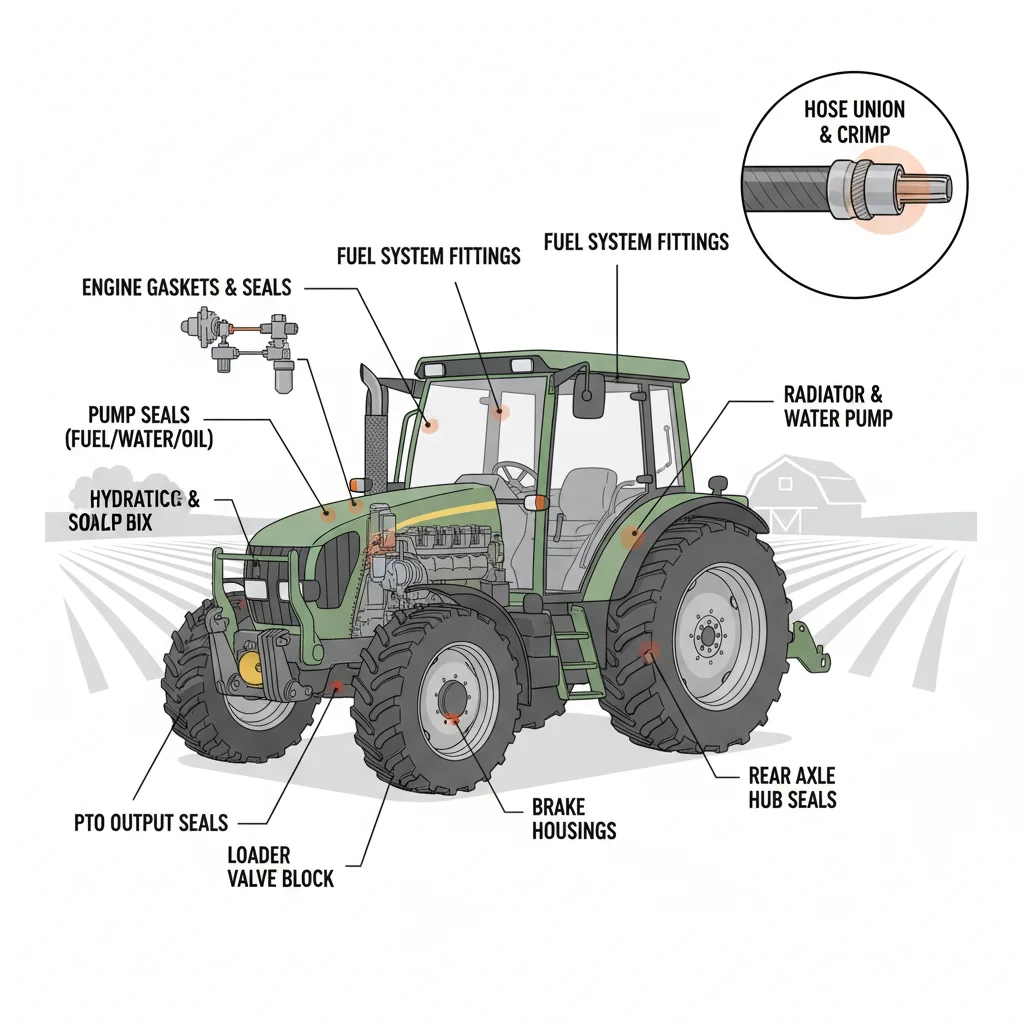

Tractor leaks most commonly occur at predictable hotspots: engine gaskets and seals1, fuel system fittings2 and pump seals, radiator and water pump areas, hydraulic pump bodies, loader valve blocks, rear axle hub seals, PTO output seals, and brake housings. New or imported tractors may also develop leaks at loose unions or hose crimps within the first 100 hours.

Last month, a contractor in northern Kazakhstan called me after noticing oil spots under several new 85HP 4WD tractors—only 60 hours on the clock. He was worried about engine damage, but after a quick video call, I spotted the culprit: loose banjo fittings on the injection pump and a small drip around the rocker cover gasket. Most leaks show up in predictable places, especially during those first 100 hours. I see this pattern a lot with new or imported tractors as seals and unions settle in.

On the engine, leaks usually start at the rocker or valve cover gasket, front and rear crank seals, oil pan gasket, or the oil filter base. The fuel system is another trouble area—tank seams, filter heads, banjo fittings, and injector leak-off lines are common offenders. Cooling system leaks? Nine times out of ten, it’s a hose clamp, radiator core, or the water pump weep hole. I’ve seen farms in Brazil lose days of work because a $2 hose clamp loosened up on a 75HP model during peak harvest. Small detail, big headache.

Hydraulic systems like the three-point hitch, loader, or steering are also leak hotspots. Look for drips at the pump body, shaft seal, loader valve block, quick couplers, or even the steering orbitrol and cylinder ends. At the rear, PTO output seals, axle hub gaskets, and brake housings are classic trouble spots. My advice? After your first week of hard fieldwork, get a torch and check every fitting, especially unions and hose crimps. Catching these early saves you hours of downtime.

Injection pump banjo fittings and rocker cover gaskets are common sources of early oil leaks in new tractors due to initial seal settling.True

During the first 100 hours of operation, seals and unions, such as those on the injection pump and rocker cover, often 'bed in' or settle, making them susceptible to minor leaks until retorqued or reseated.

Hydraulic reservoir caps are the most frequent source of oil leaks during a tractor’s first 100 hours of operation.False

While hydraulic systems can develop leaks, caps themselves are rarely the primary culprit early on; leaks are more commonly found at banjo fittings, union joints, or gasketed surfaces as new components settle.

Key takeaway: Most tractor leaks cluster at engine, fuel, cooling, hydraulic, and rear axle components. Focusing inspections on these common hotspots—especially after initial hours of operation—enables faster troubleshooting and reduces downtime from missed or misdiagnosed leaks.

How can daily checks detect tractor leaks?

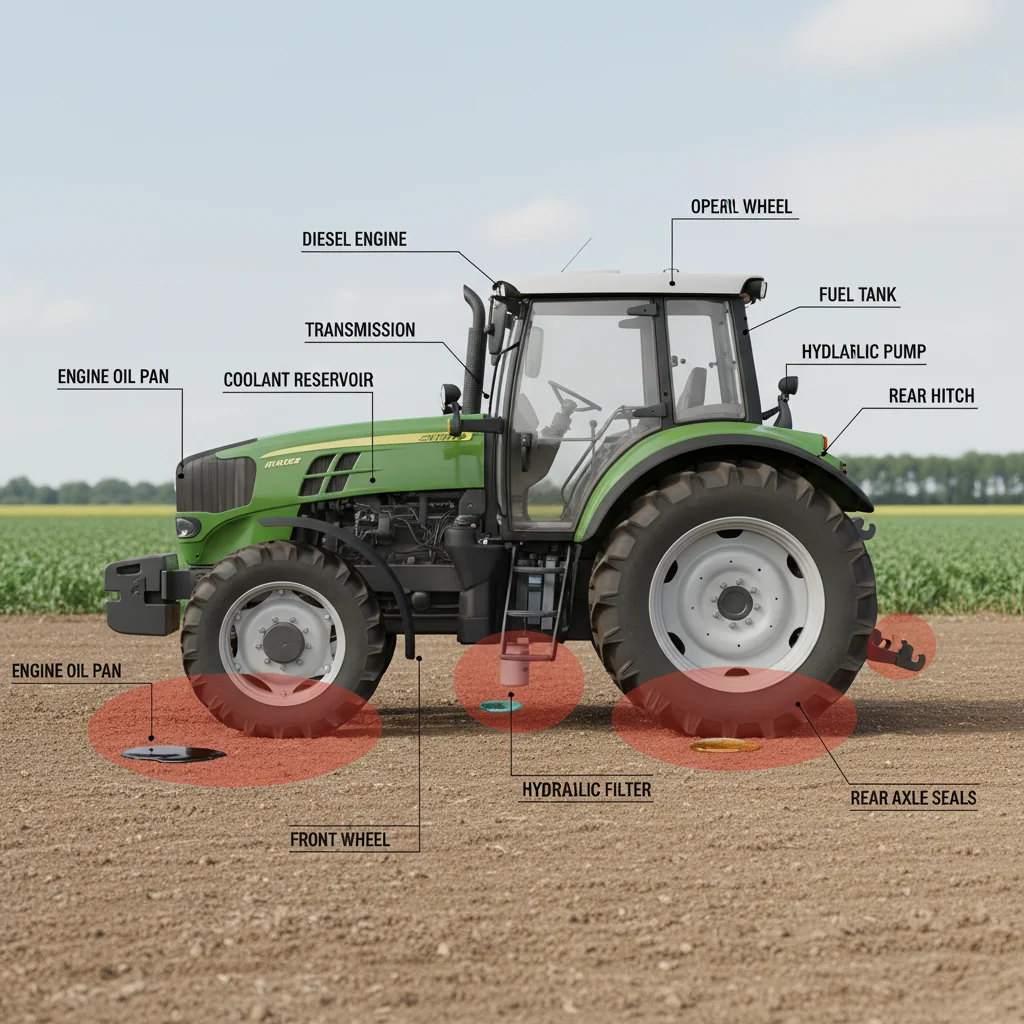

Routine daily inspections identify early tractor leaks by visually checking under the engine, mid-frame, and rear axle for fresh oil or coolant spots. Monitoring fluid reservoirs and filter areas, and listening for unusual hydraulic noises, allows operators to catch issues before they escalate, minimizing downtime and repair costs.

Most people don't realize that a five-minute daily check can save a tractor owner thousands in repairs. A simple walk-around—looking under the engine, along the mid-frame, and near the rear axle—often reveals fresh spots of oil or coolant. If you see a new stain on the ground, that's your first warning. I always tell operators in Kenya and Peru: look at the tires and rims too. Leaks here can mean a failing axle seal, which is much cheaper to fix early.

One farm in northern Kazakhstan runs a fleet of 80HP 4WD tractors on wheat and barley. Last season, their mechanic caught a slow hydraulic drip3 near the loader coupler during his morning check. By wiping the joint with a clean paper towel, he spotted fresh oil—only a few drops, but a sign of trouble. They replaced a cracked O-ring for less than $10 USD. If they'd missed it, the pump could have failed, costing over $600 and at least three days of downtime. That's the difference daily checks make.

I suggest watching fluid levels closely. If you find yourself topping up the coolant or hydraulic oil more often than usual, that means something's leaking or being lost internally. Listen, too—unusual whining or hissing from the hydraulic system often points to air entering through a bad seal. These things don't fix themselves. Early detection is the cheapest repair strategy, especially in simple mechanical tractors where every hour counts and parts can be tough to source locally.

Detecting small oil leaks during daily checks can prevent contamination of the tractor’s brake system, which often shares a common reservoir with the hydraulic system.True

In many tractor designs, the hydraulic and brake systems are interconnected, so unnoticed leaks can cause fluid cross-contamination, leading to more expensive repairs if not caught early.

Leaks detected near the rear axle during daily checks always indicate a problem with the hydraulic lift system.False

While rear axle leaks can be related to the hydraulic lift, they are more commonly caused by worn axle seals or final drive components, not exclusively by issues in the hydraulic lift system.

Key takeaway: Short, systematic daily inspections of critical areas—engine, filters, hydraulic lines, and fluid levels—help operators spot leaks early, ensuring repairs are affordable and preventing major breakdowns. Early detection, especially in simple mechanical tractors, is essential for cost-effective, reliable farm operations in emerging markets.

How to Spot False Tractor Oil Leaks?

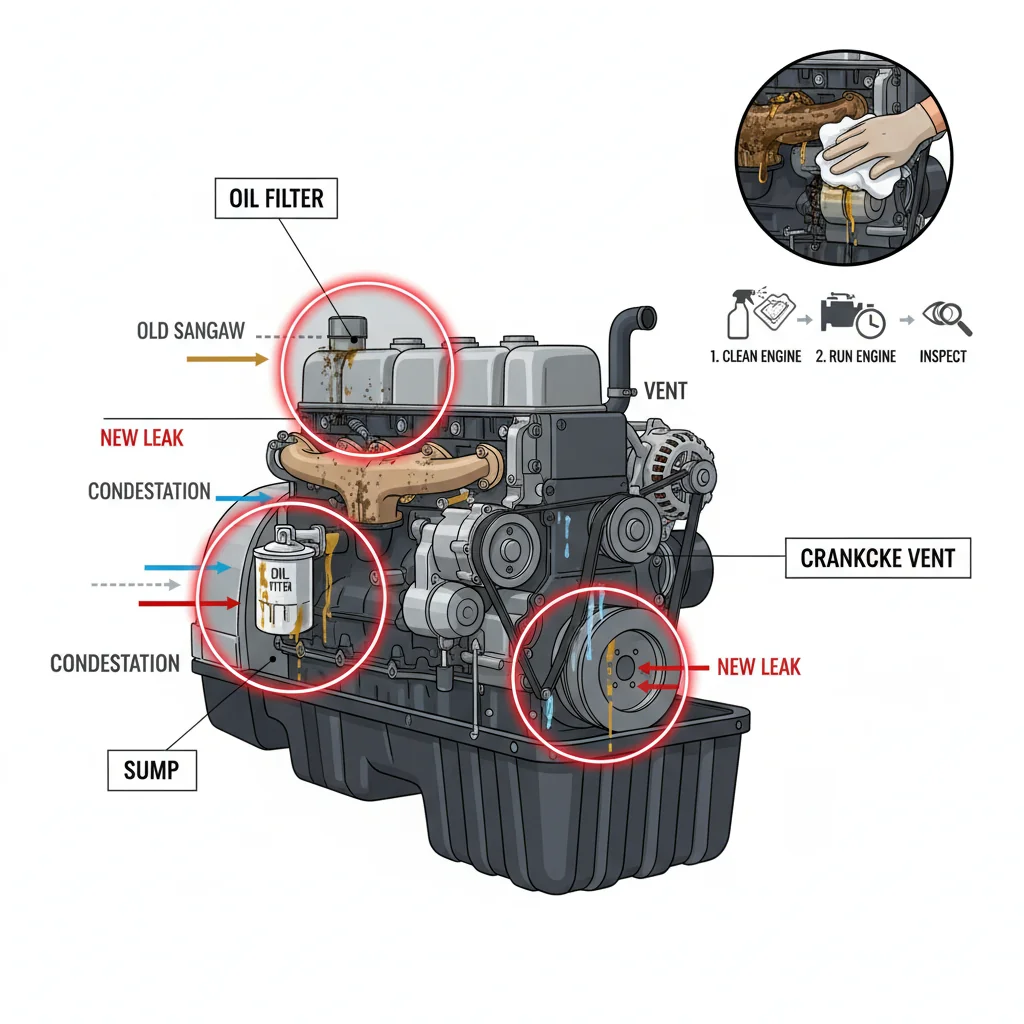

False leaks on tractors often stem from oil spilled during filter or oil changes, overfilled sumps4 venting excess oil, or harmless condensation. Thoroughly clean the suspected area, run the engine, and recheck after operation. Only genuine leaks will show a fresh trail, preventing unnecessary seal replacements.

I've worked with customers who made this mistake—chasing leaks that weren’t really leaks at all. In Peru, a distributor called me worried about a “rear main seal failure” on several 90HP tractors. The problem? After every oil change, their mechanics left residue around the filter and sump. That oil slowly traced its way down the block and dripped onto the transmission housing. It looked exactly like a gasket leak. But after a proper wash and two hours of field work, the area stayed dry. No new oil appeared. I always tell dealers: clean the engine thoroughly, especially around the filter and sump, before you go hunting for a failure.

Another trap? Overfilled sumps. I’ve seen this in Kazakhstan with a fleet of 75HP units. Operators topped up the hydraulic oil “to be safe”—well above the manual’s mark. The excess had nowhere to go except out the breather and dipstick tube. It made a mess, but the seals were perfectly fine. If you see oily residue around the breather or filler cap, check your levels against the manual, not just what “looks right.” That’s a common cause of false alarms.

Condensation is the third culprit, especially on tractors with air conditioning or after cool, damp nights. I’ve had farmers in Kenya report “clear leaks” under their 60HP machines, only to find it was harmless water from the A/C or exhaust. Here’s what matters: after a good cleaning and a solid run, only real leaks will leave a fresh, clear trail. I suggest always taking this extra step—it saves time, money, and a lot of unnecessary repairs.

Residual oil from filter changes can mimic a rear main seal leak if not cleaned properly, as it may trace along the engine block before dripping onto other components.True

Oil residue left during maintenance can follow gravity and engine contours, creating the appearance of a gasket or seal leak even though there is no actual failure. Thorough cleaning and observation after operation are essential for accurate leak diagnosis.

Any oil accumulation on the transmission housing of a tractor always indicates a failed gasket or seal.False

Oil can accumulate on the transmission housing due to improper cleaning after oil changes or from spillage during maintenance, not necessarily from an active leak or failed seal. It's important to distinguish between actual leaks and leftover residue.

Key takeaway: Properly identifying tractor leaks avoids wasted time and expense. Always clean and dry suspected surfaces, verify oil levels against the manual, and watch for fresh leaks after operation. Most persistent leaks indicate real issues; others are often residue or condensation, not mechanical failures.

Which tools detect small tractor leaks best?

Most tractor leaks can be identified using basic tools: a strong LED work light, a small inspection mirror, white paper towels, and talcum powder5 or chalk for tracing slow leaks. Cardboard or white plastic sheets highlight drip locations. A torque wrench6 ensures hydraulic and fuel fittings are tightened to correct specifications.

Here’s what matters most when you’re trying to find tiny leaks on a conventional tractor: simple, basic tools will spot 95% of problems, even when you’re far from a dealer.

In Bolivia, I visited a farm where they’d been losing hydraulic oil for weeks. Their mechanic used a basic LED work light and a cheap inspection mirror, letting him see behind the pump and under tight fittings—places you can’t reach with your hand. He pressed a white paper towel to each joint; fresh oil showed up instantly, while old stains stayed brown. No fancy equipment, just sharp eyes and patience.

For slow leaks, I’ve seen great results using talcum powder or chalk—just dust it over a clean, dry area around the suspected fitting. Any oil or fuel will leave a clear, dark trail through the powder, making the leak path obvious.

Farmers in Kenya often slide white cardboard or plastic sheets under the tractor overnight. By morning, even a few drops of fluid stand out. This method also helps you compare leak rates day to day—something that’s saved my customers at least a full working day of guesswork.

One tool you shouldn’t skip is a torque wrench. I always suggest tightening hydraulic and fuel fittings to the recommended spec—tight enough to seal, not so tight you risk cracking a casting. Many leaks I’ve seen in Central Asia came from over-tightened or loose fittings.

Consistent use of these low-cost tools keeps field downtime minimal, especially where service support is limited.

Using a white paper towel to dab around hydraulic joints can reveal fresh leaks that may be invisible to the eye, especially under dirty conditions.True

The absorbency and color contrast of a white paper towel make even small amounts of fresh oil visible, helping isolate leaks in areas where grime or old residue would otherwise hide them.

Thermal imaging cameras are essential for detecting small hydraulic leaks on tractors, as most leaks are invisible without them.False

While thermal imaging can sometimes spot leaks by detecting temperature differences, most small hydraulic leaks are easily found with basic visual tools like lights and mirrors; thermal cameras are rarely necessary for routine leak detection.

Key takeaway: Simple, affordable tools like LED lights, inspection mirrors, paper towels, talcum powder, and cardboard can quickly identify most tractor leaks. Consistent use of these tools helps prevent misdiagnosis and unnecessary service calls, supporting reliable field operations—especially in regions where specialized repair services may be limited.

When should UV dye be used for leaks?

UV dye testing7 is recommended when a leak is known to exist but its origin is not visible. The process involves adding UV-sensitive dye to the suspect system, operating the tractor, and inspecting with a UV lamp to trace even pinhole leaks or identify fluid sources in complex hydraulic areas.

Most people don't realize how tricky it can be to trace leaks on a conventional tractor, especially when hydraulic hoses run behind the engine or under the cab. I’ve seen this cause real headaches for mechanics in Kenya and Peru. You spot a wet patch under the chassis, but by the time you check, the fluid has traveled along the frame—making the true source hard to find.

That’s where UV dye testing comes in handy, and it’s something I always recommend when the visual clues just aren’t adding up.

Here's how I suggest using UV dye testing for leaks:

- Suspect system selection: Decide if you’re chasing engine oil, hydraulic fluid, coolant, or diesel. Always use a dye compatible with that fluid.

- Add the dye: Pour in the correct amount as per the kit’s instructions—usually 10–30 ml for a 60–80HP tractor’s system.

- Operate the tractor: Run it under typical load for at least 30 minutes. This lets the dye circulate and any leaks to appear.

- Inspection: Turn off the lights in your workshop or shed. Scan the suspect area with a UV lamp—leaks will glow yellow-green, even if they’re pinhole-sized.

I’ve worked with a rice farmer in Bolivia who struggled with recurring hydraulic leaks8 on a 75HP utility tractor. After weeks of guessing and swapping hoses, he tried a US$50 dye kit. Within an hour, he pinpointed two tiny leaks hidden behind the rear axle.

That single test saved him at least two days of unnecessary work.

UV dye should be used when multiple hydraulic lines run in close proximity and visual inspection cannot distinguish which line is leaking.True

UV dye allows mechanics to pinpoint the exact source of a leak even when several hoses are bundled together, as the dye will only fluoresce at the true leak origin, cutting through visual confusion caused by fluid spreading on surfaces.

UV dye can be used effectively to detect leaks in tractor coolant systems without any preparation, regardless of the coolant type.False

Not all coolants are compatible with standard UV dyes, and using the wrong dye can interfere with coolant chemistry or provide inaccurate results; it's important to ensure dye compatibility and sometimes flush or prep the system before testing.

Key takeaway: UV dye testing is a precise, cost-effective diagnostic method for tracing hidden tractor leaks, especially when multiple small leaks or migrated fluids make visual inspection difficult. It helps accurately pinpoint leak origins, reducing unnecessary repairs and downtime for both individual machines and small fleets.

When are ultrasonic or flow tests needed?

Ultrasonic and flow tests are essential when tractor hydraulic performance drops but no visible oil leak is present. Ultrasonic detectors9 reveal high-pressure leaks inside valves, pumps, or cylinders by converting sound into audible signals. Flow meters10 measure internal leakage volume, confirming loss even if no oil is seen externally.

I always tell customers—if your tractor’s hydraulics feel weak or cylinders won’t hold position, but there’s no oil on the ground, don’t just swap out parts. Internal hydraulic leaks are far trickier to spot. A good example: last year, a farmer in northern Kazakhstan called me about a 95HP tractor. His three-point hitch kept dropping overnight, and loader arms wouldn’t stay up, but the workshop couldn’t find any obvious leaks. In cases like this, visual checks won’t help. The problem often hides inside pump housings, valve blocks, or the cylinder seals themselves.

What really matters is knowing where your oil is slipping past under pressure. That’s where ultrasonic detectors come in. These handheld tools pick up high-frequency “hissing” from oil bypassing worn seals or scoring inside a valve—even before any oil escapes outside. But in my experience, finding the noise is only half the job. You still need to know how much oil you’re actually losing. That’s when flow meters are essential. In Peru, I watched a mechanic run a flow test on a 75HP unit’s hydraulic circuit—he found more than 6 liters per minute leaking internally at full pressure, even though the outside stayed bone dry. That’s enough to cause serious lift problems and overheating.

The reality is, unless you have the right equipment and some training, these tests aren’t DIY. But understanding them can save you wasted time and money. If your hydraulics act up without a visible leak, ask your technician about ultrasonic or flow testing. It’s the best way to confirm the real source before you start replacing expensive parts.

Ultrasonic or flow tests are often required to detect internal hydraulic leaks in tractor systems when there are no visible signs of oil loss.True

Internal leaks in hydraulic systems may not cause external oil leakage but can still result in weak hydraulic performance or drifting cylinders. Ultrasonic and flow tests can identify these hidden faults by detecting abnormal internal flow or pressure loss that isn’t visible during a standard inspection.

If a tractor's hydraulic components show no visible leaks, it is safe to assume that the system is functioning properly and does not require further diagnostic testing.False

A lack of visible leaks does not guarantee that the hydraulic system is free from defects. Internal leaks, such as worn seals or valves, can cause significant loss of function without any external signs. Specialized tests are necessary to detect these issues.

Key takeaway: Ultrasonic and flow tests help pinpoint hidden hydraulic leaks in farm tractors when performance issues arise without visible oil. These methods diagnose internal leaks in valves, pumps, or cylinders, guiding accurate repairs and preventing costly downtime. Professional equipment and expertise are usually required.

Are small tractor leaks dangerous long-term?

Small tractor leaks are never harmless. Even minor hydraulic, transmission, fuel, or coolant leaks can quickly escalate, lowering fluid levels and causing inadequate lubrication, weak hydraulics, overheating, or fire hazards. Delaying a simple seal or hose replacement may result in costly repairs, sudden failures, and extended downtime during critical farming periods.

Here’s what matters most when it comes to leaks: even a little drip under your tractor is a sign of a bigger problem waiting to happen. I remember a farmer in rural Peru who noticed a small hydraulic oil stain under his 75HP utility tractor—he figured it could wait until after harvest. Three weeks later, his lift arms lost power right in the middle of planting season. The leak had dropped the oil level enough to starve the pump, and he ended up needing a full hydraulic rebuild that cost over $1,200—plus nearly a week of downtime. That’s a tough lesson, especially when a new seal would have cost less than $100 and a couple hours’ work.

Slow leaks from the transmission or final drive aren’t harmless either. When oil levels drop, internal gears and bearings lose their protective film. From my experience, even running just two liters low in a 12-liter gearbox can cut component life in half and lead to noisy operation, overheating, or sudden failure. I’ve seen this happen in Kenya with a fleet of 90HP 4WD tractors—minor axle leaks ignored for a season led to expensive repairs and lost time during peak fieldwork.

Fuel and engine oil leaks are even riskier. A bit of diesel on a hot exhaust or a few drops of oil running onto belts can easily become a fire hazard. Coolant seeps, too, can corrode fittings and cause sudden hose bursts under load. My advice? Check under your tractor daily, keep a close eye on fluid levels, and never ignore even a minor leak. Early repairs save a lot of trouble and money in the long run.

A small, persistent leak in a tractor’s hydraulic system can introduce air into the system, leading to erratic operation of hydraulic implements over time.True

Hydraulic systems rely on maintaining pressure and excluding air. Even minor leaks can allow air ingress, which results in spongy or unpredictable hydraulic function, affecting equipment performance and potentially causing internal damage.

Minor leaks from a tractor’s coolant system are harmless if the engine temperature gauge shows normal readings.False

Small coolant leaks can lower coolant levels without immediately affecting temperature readings, especially during light use. Over time, this can lead to overheating or engine damage, even if the gauge initially appears normal.

Key takeaway: Ignoring small tractor leaks can severely reduce component life, create fire or safety hazards, and lead to major repair costs—especially during peak season. Immediate attention to minor leaks and daily fluid checks are essential for reliable operation and long-term savings.

Which Tractor Leaks Are Safe to Fix?

Some tractor leaks can be repaired by owners, such as tightening hose clamps, replacing rubber hoses, swapping filters, or changing simple gaskets. However, leaks involving high-pressure hydraulic lines, diesel near hot components, or repairs requiring special lifting equipment or system depressurization must be handled by qualified mechanics to ensure operator safety and prevent severe injury.

I get a lot of questions about which leaks are safe for owners to fix and which ones should go straight to a mechanic. Let’s be clear—some jobs are simple, but others are genuinely risky.

Last year, a farmer in Peru called me after trying to patch a hydraulic hose on his 80HP tractor by himself. He thought it was just a small drip, but when he loosened the fitting under pressure, oil sprayed out at high velocity. He needed stitches, and his tractor was down for days. I always remind customers: hydraulic fluid at 150–200 bar can penetrate skin. Never use your bare hand to check for leaks—use cardboard or a piece of wood instead.

From my experience, leaks are safest for owners to handle when they are low-pressure, easy to access, and far from heat sources. Typical DIY-friendly repairs include coolant hoses, valve cover gaskets, and fuel filter seals. If you can reach the part easily, the system is depressurized, and the engine is cool, you’re usually okay.

On the other hand, anything involving high-pressure lines, fuel injection components, or leaks near the exhaust and turbocharger should be left to professionals. I’ve seen a diesel leak ignite on a 4WD unit in Kenya simply because the farmer didn’t wait for the engine to cool before tightening a clamp. The fire caused over $3,000 in damage and weeks of lost work. That’s never worth the risk.

Here’s a simple reference table I share with customers when deciding whether a leak is safe to fix themselves:

| Leak Type | Owner Repair Safe? | Reason / Risk Explanation |

|---|---|---|

| Coolant hose (low-pressure side) | Yes | Low pressure, low injury risk, easy visual confirmation |

| Radiator drain plug | Yes | Simple sealing surface, minimal risk when engine is cool |

| Engine oil filter or gasket | Yes | Low pressure, slow leak, easy to verify after repair |

| Fuel filter seal (supply side) | Yes | Low pressure if system is primed correctly |

| Hydraulic return line | Sometimes | Only safe when fully depressurized and easily accessible |

| Hydraulic pressure hose | No | High-pressure fluid injection risk |

| Injector lines / injection pump | No | Extremely high pressure, precision components |

| Diesel leaks near exhaust/turbo | No | Fire and explosion hazard |

| Leaks under cab or rear axle area | No | Poor access, risk of sudden pressure release |

Rule of thumb:

If the system operates under high pressure, carries fuel, or sits near heat, it belongs in a professional’s hands. Saving a few dollars on a repair is never worth an injury, fire, or extended downtime.

Key takeaway: Owner repairs are limited to accessible, low-pressure components like hoses and filters. High-pressure or hard-to-reach leaks, especially those near hot engine parts or requiring system disassembly, pose serious risks and must be left to trained professionals to prevent accidents and severe injuries.

How to verify tractor leak repairs?

To confirm a tractor leak repair is successful, refill the system, bleed air11 per manual instructions, and pressure-test under realistic operating loads. Closely inspect the repair area for weeping during operation and after 15–30 minutes. Use cardboard, talc, or UV dye for hard-to-spot leaks, and recheck fluid levels after a full day’s use.

Let me share something important about leak repairs that gets overlooked, especially in busy seasons. Too many times, I’ve seen a mechanic patch a hydraulic line or gasket, fill up the oil, and send the tractor straight back to work. But the real test isn’t just whether it looks dry in the workshop—it’s whether it stays sealed under actual field conditions.

In northern Kazakhstan, one customer thought a steering cylinder repair was finished. After running the tractor with a heavy loader for twenty minutes, oil started weeping from the same spot. That cost him another day of downtime, plus extra fluid and labor.

To verify a repair properly, always refill the system to the mark and bleed air as the manual describes—don’t skip this, or you’ll get false results.

Pressure-test the system by putting it under real load: work the hydraulics to full relief, lift your heaviest implement, or run the PTO at rated speed. I suggest placing cardboard sheets under the repair area before you start, especially with slow leaks that might not drip right away.

In Peru, I watched a mechanic use talc powder on a transmission housing—fine white dust makes tiny leaks stand out, even on older 75HP models with worn paint.

After 15–30 minutes of operation, get off the tractor and inspect the repair area closely. Don’t just look—touch around fittings and hoses for dampness. Finally, check fluid levels again after a full workday.

Running the tractor at full hydraulic pressure after repairs is necessary to confirm that leaks have been properly fixed, because some leaks only appear under load.True

Hydraulic systems can maintain pressure even when stationary, but real-world operation—especially with heavy implements—can reveal leaks that static testing might miss. This is why post-repair testing should simulate actual working conditions.

If a tractor shows no visible leaks in the workshop after repair, it is guaranteed that the repair will hold up in the field.False

Workshop conditions do not replicate the mechanical stresses, vibration, and pressure fluctuations experienced during fieldwork. A repair that appears sealed in the shop can still fail under actual operating conditions.

Key takeaway: Always test tractor leak repairs under real working conditions and monitor for signs of persistent leaks. Visual checks, pressure-testing, and post-operation fluid inspections prevent costly downtime and protect new parts from failure. Skipping verification risks undetected leaks and unexpected breakdowns in the field.

Conclusion

We've gone through how to spot different tractor leaks by color, smell, and where they show up on your machine. From my experience, it’s the small leaks that often get ignored—until they turn into bigger problems and mean unexpected downtime. I always tell importers and farmers: take a few minutes to check, and you’ll save yourself a lot of headaches later. If you’re not sure what you’re seeing or need advice on repairs, feel free to reach out. I’m happy to share what’s worked in real fields, not just from the manual. Every farm is different—choose what actually works for your needs.

References

-

Detailed insights on why engine gaskets and seals leak, helping farmers prevent costly engine damage and maintain tractor reliability. ↩

-

Expert advice on detecting and repairing fuel system fitting leaks to avoid fuel loss and engine performance issues in tractors. ↩

-

Learn about common causes of hydraulic drips in tractors and cost-effective fixes to prevent pump failure and expensive downtime. ↩

-

Explains how excess oil in sumps leads to false leak symptoms and how to prevent misdiagnosis by checking oil levels properly. ↩

-

Details a simple, effective method using talcum powder to trace slow oil or fuel leaks, saving time and improving maintenance accuracy. ↩

-

Explains how using a torque wrench ensures hydraulic and fuel fittings are tightened correctly, preventing leaks and costly repairs. ↩

-

Detailed explanation of UV dye testing process and its effectiveness in detecting hard-to-find leaks in complex tractor hydraulic systems. ↩

-

Explains how minor hydraulic leaks can cause pump starvation, costly repairs, and downtime, with real farmer examples for practical insight. ↩

-

Explore how ultrasonic detectors identify hidden high-pressure leaks by converting sound into signals, crucial for tractor hydraulic diagnostics. ↩

-

Learn how flow meters measure internal leakage volume, confirming hydraulic loss even without visible oil leaks, vital for maintenance accuracy. ↩

-

Explains the critical role of bleeding air to avoid false leak test results and ensure hydraulic system reliability post-repair. ↩