Import China Farm Tractors - The Ultimate Guide

Hi, I'm Sally from Cropilots. Let me guide you through this ultimate solutions page.

I am a farm tractor Senior Sales Engineer of Cropilots. This is my 6th year working with it. Click the button below for great ideas on how we can provide exceptional solutions for the best farm tractors and some advice on the import.

Table Of Contents

- 1. What is farm tractor?

- 2. Tractor product classification

- 3. Complete tractor assembly process

- 4. Tractor Engine System

- 5. Tractor Transmission System

- 6. Tractor Suspension System

- 7. Tractor PTO System

- 8. Tractor Chassis Overview

- 9. Cab vs. Awning

- 10. OEM in Tractor Selection

- 11. Recommended packaging methods for sea transportation

- 12. Tractor Quality Control Flow

- 13. Production cycle and order process

- 14. Things to note before purchasing

- 15. Customer testimonials

- 16. FAQs you may ask

For your convenience, we’ve prepared a PDF version of this page’s content. Simply provide your name and email, and the download link will be sent to you instantly.

Tractor Definition Introduction

What is Farm Tractor?

A farm tractor is a distinct piece of machinery designed primarily for agricultural tasks, especially those involving towing and pushing implements used for plowing, tilling, planting, and harvesting. Built robustly, it’s an essential vehicle in modern farming, replacing manual labor and draft animals, thereby increasing the efficiency and scale of agricultural operations.

Working Principle of Agricultural Tractors

The core principle behind the operation of a farm tractor lies in the conversion of fuel energy, usually diesel, into mechanical energy, driving the machine’s movement and functionality. When the tractor’s engine combusts the fuel, it drives pistons within cylinders. This reciprocating motion of pistons is converted into rotational motion by the crankshaft. This rotation then powers the tractor’s transmission, which manages the distribution of this energy to the wheels, allowing for movement, and to the Power Take-Off (PTO) shaft, enabling various implements to operate. The tractor’s hydraulics system further amplifies this energy to lift, lower, and control implements with precision, thereby achieving diverse farming tasks efficiently.

Classification of Tractors by Horsepower

Agricultural tractors, essential to the modern farming landscape, can be broadly categorized based on their horsepower, a critical determinant of their performance, application, and versatility. Understanding the horsepower range aids in aligning the tractor’s capabilities with the specific requirements of farming operations.

Small Horsepower Tractors

Ideal for smaller plots, gardens, and orchards, these tractors generally fall within the range of 25 to 40 horsepower. They’re nimble, easily maneuverable, and adept at tasks that don’t demand immense power, such as light tilling, mowing, and basic hauling.

Medium Horsepower Tractors

Positioned in the 40 to 100 horsepower range, medium horsepower tractors strike a balance between power and versatility. Suitable for varied agricultural operations, these tractors efficiently handle plowing, planting, and intermediate load towing.

High Horsepower Tractors

Boasting over 100 horsepower, these tractors cater to extensive agricultural operations spanning large acreages. Their substantial power output makes them indispensable for demanding tasks like deep tilling, heavy hauling, and operating large implements. They serve as the workhorses in sizable farming enterprises, ensuring high productivity and optimal results.

A Comprehensive Overview

12-Step Tractor Assembly Process

The assembly of a tractor is an intricate convergence of engineering precision and technical expertise. This 12-step process delineates a meticulous journey from multi-way valve integration to tire alignment. Each phase has been methodically developed to ensure optimal functionality, durability, and efficiency. Professionals in the agricultural machinery sector are cordially invited to witness firsthand the stringent standards and dedication embodied in each step of this assembly process.

- 1. Multi-way valve assembly

- 2. Fixed bracket assembly

- 3. Hydraulic system assembly

- 4. Radiator assembly

- 5. Cab disassembly

- 6. Cab final assembly

- 7. Control system assembly

- 8. Assembly intake, exhaust system

- 9. Fuel tank, electrical assembly

- 10. Dashboard assembly

- 11. Oil filling

- 12. Front and rear tire assembly

Optimal Engine Choices

Decoding 4-Cylinder vs. 6-Cylinder Configurations

Dive deep into the intricacies of tractor engine configurations. Our detailed comparison between 4-cylinder and 6-cylinder engines provides clarity on their respective strengths, ensuring you make an informed decision tailored to your market’s unique demands. Equip yourself with knowledge; choose what’s best for your clientele.

| Feature/Parameter | 4-Cylinder Engine | 6-Cylinder Engine |

|---|---|---|

| Power Output | Suitable for 35-120 horsepower | Ideal for tasks demanding 130 horsepower and above |

| Fuel Efficiency | Typically more fuel-efficient due to smaller size | Might consume more fuel, especially under heavy loads |

| Torque | Provides adequate torque for most farm tasks | Delivers higher torque, ideal for heavy-duty operations |

| Operational Noise | Generally quieter due to fewer moving parts | Slightly noisier given the additional cylinders |

| Vibration | Lower vibration due to compact design | Might experience more vibration but spread over chassis |

| Maintenance | Simpler maintenance; fewer components | Requires meticulous maintenance due to more components |

| Initial Cost | Usually more affordable | Typically pricier due to increased power & capabilities |

| Longevity/Lifespan | Suitable for regular farm tasks; long lifespan | Designed for intense use; robust and long-lasting |

| Application | General farming tasks, small to medium-sized farms | Large-scale farming, challenging terrains, heavy towing |

Tractor Engine Choices in Modern Agriculture

Self-Aspirated vs. Turbocharged

At CROPILOTS, we understand that making the right engine choice is paramount in the realm of agricultural machinery. Delve into our detailed comparison of self-aspirated versus turbocharged engines, each fine-tuned for specific agricultural demands. Whether your focus is on straightforward operation or robust performance, our guide sheds light on the key differences. Ultimately, the choice is yours, and we’re here to ensure you have all the information you need to make the best decision for your farming objectives.

Self/Naturally-Aspirated Engines

Advantages

- 1. Suitable for 30-60 horsepower farm tractors

- 2. Simple Design: No added complexity from turbo components, which can reduce maintenance needs.

- 3. Linear Power Delivery: Offers a predictable and steady power output without sudden surges, beneficial for certain farm tasks.

- 4. Reliability: Absence of turbo means fewer parts that can fail; these engines are often seen as more long-lasting.

- 5. Cost: Generally less expensive upfront due to simpler design.

Weakness

- 1. Limited Power: Can't match the high power output of a turbocharged engine of the same size.

- 2. Less Efficient: Typically, they don’t use fuel as efficiently as their turbocharged counterparts.

- 3. Performance at Altitude: Power tends to drop significantly at higher altitudes due to reduced oxygen levels.

Turbocharged Engines

Advantages

- 1. Suitable for above 60 horsepower farm tractors

- 2. Enhanced Power: Turbochargers provide a significant boost in power output, beneficial for heavy-duty tasks.

- 3. Fuel Efficiency: Generally more fuel-efficient than naturally aspirated engines, especially under load.

- 4. Performance at Altitude: Maintains better performance at higher altitudes compared to naturally aspirated engines.

- 5. Compact Size for Power Output: They allow for a smaller engine to produce more power, potentially reducing weight.

Weakness

- 1. Complexity: Added components can mean more maintenance and potential for parts to fail.

- 2. Turbo Lag: There can be a slight delay in power delivery until the turbo "spools up", which might not be ideal for certain precision tasks.

- 3. Cost: Typically, a more expensive option due to the additional turbocharger system.

Powering Precision Across the Spectrum

Engine Brands

At CROPILOTS, we meticulously pair our tractors with engines that enhance performance and durability.

For tractors operating under 60 horsepower, we’ve selected the dependable Laidong engines, renowned for their efficiency and resilience.

For medium to large horsepower requirements, the Weichai engine range stands as our premier choice, offering unmatched power and longevity.

We pride ourselves on flexibility and, understanding varied needs, are also equipped to integrate alternative brands such as YTO upon customer requests.

Our aim is to ensure that each tractor we produce is powered by the best, tailored specifically to your requirements.

Our Journey Towards Greater Sustainability

Emission Standards

At CROPILOTS, we’re ever-evolving in our commitment to sustainability and innovation. Currently, our tractors are equipped with engines compliant with Euro II and Euro III emission standards. While we recognize the global trend towards even higher standards, we remain dedicated to continuous improvement and progress. Our tractors provide reliable performance for varied markets, and as we journey forward, our commitment is to adapt, innovate, and strive for even greater benchmarks in the near future. Your partnership and feedback are invaluable to us in this journey of betterment.

Precision-Driven Transmission

Gearbox Mastery

The heart of any tractor lies in its ability to transfer power seamlessly, and our gearbox system stands as a testament to this philosophy. At CROPILOTS, we understand the diverse demands of different terrains and tasks. That’s why we’ve optimized our gearboxes to cater to the unique requirements of various horsepower ranges:

Robust Gears

For our tractors within the small to medium horsepower bracket, we’ve employed robust gears, specifically engineered for enhanced durability. The very essence of these gears lies in their ability to withstand the rigorous demands of daily farming activities, ensuring prolonged gearbox lifespan and reducing the frequency of maintenance.

Reinforced Helical Gears

Transitioning to our high-horsepower range, we incorporate reinforced helical gear transmission. These gears are not just about strength; they’re about precision. Their helical design ensures a smoother meshing of gears, leading to reduced noise and vibrations. Moreover, their reinforced nature ensures that they offer higher reliability, even under intensive workloads.

Clutch Configurations

Clutches play a pivotal role in the tractor’s transmission system, offering seamless power transfer and effective torque management. At CROPILOTS, we offer two primary configurations for our clutches, each catering to distinct operational requirements:

Single-Acting Clutch

- 1. Simplicity: Single-acting clutches are straightforward in design and operation, making them easier to maintain and service.

- 2. Cost-Effective: Given their less complex structure, these clutches are generally more cost-effective, both in terms of initial purchase and long-term maintenance.

- 3. Direct Transmission: Their singular operational nature ensures a direct and unambiguous transfer of power, ideal for tasks demanding consistent power delivery.

Double-Acting Clutch

- 1. Versatility: The double-acting clutch offers the ability to manage the transmission and PTO separately, enabling operations like stationary PTO work without stopping the tractor.

- 2. Enhanced Control: Operators can control the engine and implements independently, providing finer control especially during complex maneuvers or tasks.

- 3. Reduced Wear: With the ability to manage power delivery in a more nuanced manner, there's often reduced wear on the tractor's overall transmission system, prolonging its life.

Pioneering Suspension System

Pivotal Role of Rear Three-Point Suspension

In the vast realm of agricultural machinery, the method of connecting tractors to implements is of paramount importance. While there are several methods like traction, suspension, and semi-suspension, the rear three-point suspension stands out as the most widely adopted and versatile.

Over the years, advancements in the rear three-point suspension system have enhanced its durability and ease of use. As we continue to develop and refine our tractors, the rear three-point suspension remains a testament to our commitment to providing farmers with reliable and efficient solutions for every agricultural need.

What is the Rear Three-Point Suspension?

The rear three-point suspension is essentially a system that employs three linkage points at the rear of the tractor. These linkages – typically two lower and one upper – provide a stable and secure connection between the tractor and the implement.

Advantages of the Rear Three-Point Suspension

It accommodates a wide range of implements, from plows to seeders, making it a universally favored choice among farmers.

The design allows for easy vertical adjustments, ensuring optimal implement positioning depending on the farming task at hand.

The direct linkage ensures that power from the tractor is efficiently transferred to the implement, maximizing performance.

The triangular design of the linkage points ensures a stable connection, reducing the chances of implement detachment or uneven weight distribution.

At CROPILOTS, we’re dedicated to driving innovations that elevate the standards of agricultural machinery. Our advanced suspension system stands testament to this commitment. Here’s an insight into its two paramount features:

High-Pressure Lift with Dual Hydraulic Cylinders

- 1. Consistent Lifting Power: Equipped with dual hydraulic cylinders, our high-pressure lift system delivers a steady lifting force. This consistent power ensures machinery remains stable, mitigating risks of faltering midway during operations.

- 2. Enhanced Load Handling: The dual-cylinder setup amplifies load-bearing capacity, allowing for secure handling of heavier implements or payloads.

- 3. Increased Durability: High-pressure systems, when combined with dual cylinders, reduce wear and tear on individual components, ensuring longevity and reduced maintenance intervals.

Reinforced Tow Hook Device

- 1. Superior Traction Capability: Our tow hook, made with reinforced materials, ensures a large traction force. This means more stable, secure, and efficient towing, even in challenging terrains or with heavier equipment.

- 2. Reduced Equipment Strain: A reinforced design ensures optimal weight distribution during towing operations, reducing strain on the tractor and ensuring longer operational life for both tractor and towed equipment.

- 3. Versatility: Built for durability and strength, our tow hook is compatible with a wide range of agricultural implements, making it a versatile choice for diverse farming needs.

Power Take Off (PTO) System

What is PTO: An Overview

The Power Take-Off, commonly abbreviated as PTO, is an essential component of modern tractors, serving as the primary mechanism for transferring power from the tractor’s engine to external implements and machinery. Functioning as a splined drive shaft, the PTO connects to the tractor at one end and provides power to a variety of agricultural tools at the other, effectively turning the tractor into a versatile mobile power source.

In essence, the PTO allows the tractor’s engine to supply power not just for its mobility, but also to drive machinery used for tasks such as mowing, tilling, and plowing. This system’s versatility is underscored by the array of implements compatible with it, ranging from rotary tillers to balers. By providing a standardized method of power transmission, the PTO system ensures that tractors remain central to a myriad of agricultural operations, enhancing productivity and efficiency in the field.

A Guide for Optimal Efficiency

Common Tractor PTO Speeds

Selecting the appropriate PTO speed is paramount. It not only ensures the efficiency and efficacy of the implement but also safeguards both the tractor and the implement from potential wear and tear. Familiarizing oneself with these standard speeds, and understanding their respective applications, is crucial for achieving the best results in the field.

This is the standard speed for many agricultural tasks, including mowing, baling, and light tilling. Implements operating at this speed are designed for tasks that require a balance between torque and speed, making it one of the most versatile PTO rates.

Designed for high-power-demand tasks, this speed delivers double the rotations of the 540 RPM setting. Often utilized for heavy-duty tilling, deep plowing, or powering large machinery, it's suited for operations requiring enhanced power and faster operational speeds.

Some modern tractors come equipped with a dual-speed PTO option. This allows operators to switch between 540 and 1000 RPM, granting greater flexibility in matching the tractor's power output to the specific demands of various implements.

While less common, some tractors offer a ground speed PTO. This unique system adjusts the PTO speed in alignment with the tractor's ground speed, ensuring consistent operational rates for certain implements, like manure spreaders, that require such synchronization.

PTO Spline Numbers

Elaborating on the spline number of the PTO (Power Take-Off) shaft can be important, especially for those involved in the purchase, maintenance, or manufacturing of tractors and their corresponding implements. The spline number signifies the number of grooves on the shaft, which determines the compatibility between the tractor’s PTO and the implements it powers.

When choosing a tractor or an implement, it’s essential to ensure that the PTO shaft’s spline number matches. This not only ensures efficient power transmission but also prolongs the lifespan of the equipment. Always consult the tractor’s manual or manufacturer specifications to confirm the correct spline configuration.

Ensuring that the tractor's PTO shaft and the implement's input shaft have matching splines is crucial. An incorrect match can result in improper engagement, leading to premature wear, equipment damage, or reduced efficiency.

Different spline configurations can handle varying torque levels. For instance, a shaft with a higher number of splines can typically transfer more power without the risk of slipping.

Most agricultural equipment follows certain standards to ensure broad compatibility. However, deviations can occur, especially with older equipment or machinery from different regions.

Common PTO Spline Configurations

| Parameter | 6-Spline PTO Shaft | 8-Spline PTO Shaft |

|---|---|---|

| Number of Splines | 6 | 8 |

| Functionality | This configuration, featuring six rectangular notches, is typically associated with standard agricultural applications and is often linked with medium-duty tasks. | With eight rectangular notches, this configuration can handle more torque, making it appropriate for heavier-duty tasks compared to the 6-key variant. |

| Compatibility | The 6-spline design provides a stable connection between the tractor's PTO and the implement, ensuring reliable power transmission for a wide range of equipment. | As with the 6-spline, it's crucial to ensure that the tractor's PTO shaft and the implement's input shaft are compatible to guarantee efficient power transfer and reduce wear. |

| Applications | It's suitable for many general farming operations, including mowing, tilling, and others that fall within its power capacity. | Given its capability to handle increased torque, it's ideal for more demanding farming operations, such as deep tilling, heavy-duty mowing, and other intensive tasks. |

Versatile & User-friendly PTO from Cropilots

- 1. Flexible Operations: With selectable power output speeds of 540 rpm, 720 rpm, and more, our PTO system is adaptable to diverse operational needs.

- 2. Simplified Maintenance: One of the standout features is the ability to replace the PTO externally without the need to dismantle the entire gearbox. This design innovation results in significantly reduced downtime and streamlines the maintenance process.

- 3. Cost-Efficiency: Direct external replacement not only saves time but also cuts down on potential labor and part replacement costs.

- 4. Enhanced Durability: Less frequent disassembling of the gearbox means reduced wear and tear on its internal components, leading to prolonged gearbox lifespan.

Key Features and Their Significance

Chassis Overview

The chassis is a vital component of the tractor, as it plays a critical role in the overall functionality, stability, and adaptability of the machine to varied terrains and tasks.

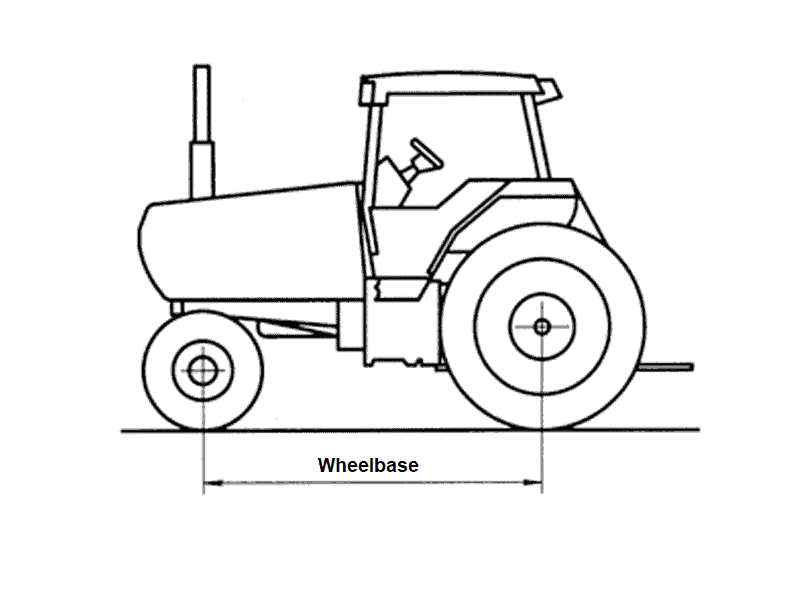

Wheelbase

Choosing between a long and short wheelbase largely depends on the specific agricultural tasks and the terrain of operation. Both have their unique advantages tailored to different farming needs.

| Aspect | Long Wheelbase | Short Wheelbase |

|---|---|---|

| Stability | Enhanced stability, especially on straight paths or level terrains. | Greater agility but might offer slightly reduced stability on straight paths. |

| Maneuverability | Might be less agile in confined spaces due to its length. | Highly maneuverable, ideal for tasks in tighter spaces like orchards or vineyards. |

| Weight Distribution | Can handle heavier attachments or loads at the back due to its balanced weight distribution. | Might require careful weight balancing when using heavy attachments. |

| Terrain Suitability | Suitable for open field operations and large flat farmlands. | Preferred for uneven terrains, hilly regions, or smaller plots due to its agile nature. |

| Turn Radius | Typically has a larger turn radius due to its length, requiring more space for turning. | Smaller turn radius allows for quick and sharp turns, especially beneficial in small spaces. |

Tread

Choosing the right tread width is essential. It not only influences the stability and performance of the tractor but also impacts the overall health and yield of the crops. Adjusting the tread for specific tasks can optimize tractor efficiency and protect soil health.

Advantages of a Wider Tread

Provides enhanced stability, especially on slopes and uneven terrains, reducing the risk of the tractor toppling.

Enables the tractor to distribute weight more effectively, especially beneficial when carrying heavy implements.

Better suited for open field operations where space is not a constraint and larger coverage per pass is required.

Advantages of a Narrower Tread

Allows the tractor to easily navigate through tight spaces, making it ideal for row-crop farming or vineyards.

Fewer wheel passes and a smaller contact area can reduce soil compaction, crucial for crops that need looser soil.

Particularly beneficial for operations in orchards, vineyards, or greenhouses where space between plants or rows is limited.

Front and Rear Axles

The front and rear axles play an instrumental role in determining a tractor’s performance, maneuverability, and durability. They not only bear the weight of the tractor and any attached implements but also effectively distribute the forces during various agricultural operations, ensuring stability and balance.

Enhanced Technology

Reinforced Sealed Axles

At Cropilots, our commitment to quality and reliability extends to the very core of our tractors. Recognizing the pivotal role of axles, we’ve incorporated reinforced sealed technology in both our front and rear axles.

- 1. Durability and Longevity: The reinforced structure of our axles ensures they can withstand intense pressures and forces, leading to longer service life.

- 2. Protection Against Elements: The sealed design effectively prevents dust, debris, and moisture from infiltrating the axle system, ensuring smooth operation in even the most challenging conditions.

- 3. Reduced Maintenance Needs: Given their robust construction and sealed nature, our axles require less frequent maintenance, reducing downtime and operational costs.

- 4. Enhanced Performance: Our axles, built to resist bending and torsional forces, promise consistent and efficient power transfer, ensuring optimal tractor performance across varied terrains and tasks.

Tractor Cab Options

Contrasting the Awning Model with the Air-Conditioned Cab

Choosing the right cab for a tractor is integral to ensuring both operational efficiency and operator well-being. Delve into a clear, side-by-side comparison between the straightforward functionality of the Awning Model and the comprehensive comforts of the Air-Conditioned Cab, providing a comprehensive insight into their distinct benefits, features, and suitability for varied agricultural settings.

Awning Model

| Advantages | Disadvantages |

|---|---|

| Cost-Effective: Generally less expensive than full cabs. | Limited Protection: Doesn't shield the operator as effectively from dust, noise, or flying debris. |

| Enhanced Visibility: No window frames or pillars to obstruct the view. | Exposure to Elements: Operators are more exposed to weather conditions like rain, sun, or cold. |

| Easy Access: Operators can quickly get on or off the tractor. | Lack of Climate Control: No provision for heating or cooling, making it less comfortable in extreme temperatures. |

| Lightweight: Adds minimal weight to the tractor, potentially leading to slightly better fuel efficiency. | Safety Concerns: Less protection in case of rollovers compared to enclosed cabs. |

| Simple Maintenance: Fewer components to worry about compared to full cabs. |

Cab Model

| Advantages | Disadvantages |

|---|---|

| Comprehensive Protection: Shields the operator from dust, noise, flying debris, and inclement weather. | Cost: Typically more expensive than awning models. |

| Climate Control: Equipped with heating and air-conditioning for enhanced comfort in varying temperatures. | Reduced Visibility: Window frames and pillars might slightly obstruct the view. |

| Safety: Provides a safer environment in case of rollovers or accidents. | Maintenance Complexity: More components like filters, AC units, and seals may require maintenance. |

| Reduced Fatigue: The controlled environment can lead to reduced operator fatigue, enhancing productivity. | Weight: Adds additional weight to the tractor, potentially impacting fuel efficiency slightly. |

| Noise Reduction: The enclosed structure reduces the noise level, offering a quieter operating environment. | Accessibility: Entering and exiting might take slightly longer compared to the awning model. |

Considering OEM Capabilities in Tractor Selection

Selecting a tractor, especially for large-scale agricultural endeavors, isn’t just about performance, durability, and cost. Equally crucial is the ability to tailor equipment to specific needs, to reflect branding requirements, and to meet unique aesthetic or functional preferences.

Tractor Hood Style- More than Just Aesthetics

In the competitive landscape of tractor manufacturing, offering custom solutions stands out as a hallmark of a forward-thinking supplier. One such customizable feature that holds significant value for bulk purchasing customers is the tractor hood style.

Recognizing the importance of such bespoke solutions, we are proud to offer customizable tractor hood styles, ensuring our customers don’t just get a machine, but a machine tailored to their specific requirements. It’s not just about selling tractors; it’s about providing an experience and solutions that resonate with the unique needs of every large-scale buyer.

For large-scale operations, a distinct hood design can make a fleet immediately recognizable, serving as a mobile advertisement and reinforcing brand identity across vast farmlands.

Uniformity in design ensures standardized operational procedures, making training and maintenance more systematic.

Hood Color Customization

When discussing tractors and their operational efficiency, color might seem like a mere aesthetic choice at first glance. However, for large-scale buyers, the option to customize the color of tractor hoods can bear significant strategic and branding importance.

Color customization of tractor hoods isn’t just an afterthought; it’s an integral part of a holistic approach to machinery customization. It underscores the manufacturer’s understanding of market needs, going beyond mere machinery to offer solutions that sync with the dynamic requirements of large-scale buyers.

A consistent and unique color theme can substantially reinforce an organization's image, making them stand out in a market of generic machines.

Having the flexibility to choose specific colors reflects the manufacturer's commitment to meeting client specifications, thus enhancing buyer-seller relations.

Logo Customization for Tractors

Incorporating logo customization as a feature accentuates a manufacturer’s dedication to understanding and catering to the multi-faceted needs of large-scale buyers. It’s not just about the machine’s function but also about integrating the tractor seamlessly into the larger narrative of the purchasing organization.

As bulk purchasers navigate their procurement journey, the ability to customize logos becomes an essential factor, bridging the gap between machinery and the brand ethos. It stands as a testament to a manufacturer’s forward-thinking approach, prioritizing not just performance but also brand integration and visibility.

The presence of a company logo on a tractor reaffirms its identity. It distinguishes an organization's machinery from the masses, marking each tractor as an extension of the brand itself.

A well-displayed logo can instill a sense of trust and reliability among customers. It's a visual testament to a company's commitment to quality and professionalism.

Crafting the Operator Experience

Interior Color Customization for Cab Interiors

When we think of tractors, it’s natural to consider their rugged exteriors and robust functionalities. However, the cab’s interior, where the operator spends most of their time, is an equally vital aspect that impacts the user’s daily experience.

While a tractor’s core functionalities remain paramount, the nuances of customization, like the interior color of the cab, showcase a manufacturer’s holistic approach to tractor design. It emphasizes the importance of the operator’s experience and the subtle ways in which a tractor can be more than just a machine. For discerning large-scale buyers, it’s these finer details that often make all the difference, underlining a manufacturer’s commitment to a truly comprehensive user experience.

Tractor Shipping Excellence

SKD & Complete Tractors Packaging

At CROPILOTS, our specialized packaging solutions — differentiated by tractor horsepower — epitomize a commitment to efficient transport, structural integrity, and the satisfaction of our international bulk purchasers. By understanding the nuances of global logistics and specific tractor needs, we provide bespoke solutions that harmonize precision with practicality.

Semi-Knocked Down (SKD) Packaging

For partners equipped for local assembly, the Semi-Knocked Down (SKD) packaging solution emerges as the optimal choice. Meticulously designed, this method offers:

Designed to optimize every inch, the SKD approach allows for the placement of up to 20 units within a single 40HQ container.

The strategic utilization of container space translates directly to tangible savings in transportation expenses for our partners.

Our SKD components are systematically organized and labeled, ensuring a straightforward and efficient assembly upon arrival, reducing setup time significantly.

Complete Tractor Packaging

For our higher horsepower tractors, which demand meticulous attention to detail and assembly precision, the Complete Machine Packaging is the recommended route:

This method is paramount in upholding the tractor’s structural and functional integrity throughout its transit.

A 40HQ container, when loaded under this packaging paradigm, can effectively accommodate three units, ensuring each tractor is protected yet space is utilized efficiently.

Upon arrival, these tractors, preserved in their complete form, are ready for immediate operation, eliminating any assembly lag.

Quality from the Ground Up

In every part of our operations at Cropilots, quality is not just a benchmark; it’s a way of life. We understand that when our customers invest in our tractors, they invest not just in a machine, but in their dreams, their livelihoods, and the land they love. That’s why we ensure that our products are crafted with care, precision, and a commitment to excellence.

The Process Flow & Estimation Time

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

Step 1: Negotiation (1-3 days)

At Cropilots, acquiring tractors is an engaging and precise process. Our consultation encompasses a deep understanding of your unique requirements, leading to tailored solutions that optimize your farming operations. Once we align on the ideal specifications, we finalize your order and enthusiastically proceed to the next stage of the journey.

Step 2: Pay the Deposit (within 2-3 days)

Trust steers the assembly of your tractor. A 30% deposit galvanizes our team to commence the careful crafting of your specific tractor. With the TT payment method, we ensure a frictionless transaction process. Your commitment at this stage propels the production of a tractor that epitomizes quality, performance, and sophistication.

Step 3: Mass Production (15-25 day)

With your deposit received, our adept manufacturing team takes the helm, focusing on the production and processing of your tailored tractor. Constructed with attention to every detail, your tractor is a testament to our commitment to quality and performance, designed to excel in various farming tasks.

Step 4: Quality Inspection (within 1 day)

Quality assurance is a way of life at Cropilots. After manufacturing your tractor, our expert quality control team embarks on a detailed inspection process. With meticulous attention to each component, we guarantee that your tractor mirrors our steadfast commitment to quality, functionality, and excellence.

Step 5: Arrange Shipping (15-20 days)

With the successful receipt of the outstanding 70% balance, we organize the shipping of your tractor. Our seasoned shipping partners guarantee that your tractor arrives in excellent condition, precisely on time. We oversee all sea shipping logistics, leaving you free to concentrate on your core business activities.

Step 6: Customs Clearance Matters (within 1 day)

Navigating customs clearance is effortless with Cropilots. We’ll supply you with all essential import documents like the Bill of Lading, Commercial Invoice, and Packing List, along with guidance on import duties and country-specific regulations, ensuring your tractor clears customs without a hitch.

Want to know how to compress lead times?

What to Look for in a Reliable Farm Tractor Supplier?

Comprehensive Range of Products and Support

For many buyers, having access to a diverse range of horsepower options in tractors is essential. Whether the need is for small, medium, or high-horsepower tractors, having a complete range of options ensures that the specific needs of different farming operations can be met. The flexibility to choose a tractor with the right horsepower to match the specific agricultural task can greatly impact efficiency and productivity.

Supporting Agricultural Machinery Resources

Alongside the tractors, the availability of supporting agricultural machinery resources can be equally vital. This includes attachments and implements such as ploughs, harrows, seeders, sprayers, and more. A supplier that offers a comprehensive selection of these resources ensures that the tractors can be customized and equipped to handle a wide variety of farming tasks.

Integration and Compatibility

The synergy between the tractor and its supporting equipment is crucial for optimal performance. A provider that ensures compatibility between the tractors and the various attachments ensures smooth integration. This compatibility translates to easier maintenance, better performance, and ultimately, a more streamlined farming operation.

Customization and Flexibility

Offering customizable solutions, not just in horsepower but also in the supporting machinery, demonstrates a commitment to meeting individual farming needs. From specialized attachments to unique configurations, this flexibility can be a key selling point for buyers looking for tailored solutions.

Order Follow-up

A dependable supplier doesn’t just end their relationship with you after the product has been dispatched. They should follow up on the delivery of the order, ensuring that the product arrives on time and in perfect condition. This process includes confirming that all the necessary documentation for import and export is in place, and helping you deal with any logistical issues that may arise. Regular communication regarding the order status and swift responses to your inquiries are signs of a reliable supplier. Their job isn’t finished until the product is in your hands, functioning as promised.

After-sales Service

Providing ongoing support for both the tractor and its supporting equipment is essential for long-term success. This includes parts, servicing, and training on how to properly use and maintain the complete system. Access to such comprehensive after-sales support ensures that the tractors and accompanying machinery continue to operate efficiently throughout their lifespan.

Testimonial

What they say about us

Common Questions

Most Popular Questions.

Once the order is placed and confirmed, it typically takes about 4-6 weeks for us to prepare your tractor for shipping. The shipping time itself will depend on your location, but we will provide you with an estimated delivery date once your order is ready to leave our factory.

Your tractor is prepared for shipment with utmost care. Each tractor is placed within a robust, weather-resistant casing. We ensure to secure all moving parts and provide additional cushioning and protection to vulnerable areas. This way, we ensure your tractor arrives in excellent condition, ready to perform.

Importing machinery like tractors can involve customs paperwork and potential import duties. The specifics can vary by country, but we'll provide all necessary shipping and product documentation to help smooth this process. We recommend you consult with a local customs broker to understand any potential duties.

Absolutely, we believe in empowering our customers through knowledge. We provide comprehensive operator training materials for every tractor we sell. These materials cover safe operation, routine maintenance, troubleshooting, and more.

We understand the importance of having readily available spare parts. While the tractors come with all necessary parts for operation, additional spare parts can be ordered separately from us. We maintain a comprehensive inventory to ensure we can quickly meet your needs.

Regular maintenance is essential for the optimal performance and longevity of your tractor. We recommend an initial service after the first 50-100 operating hours, and then routine maintenance every 200 hours or annually, whichever comes first. Our operator's manual provides a comprehensive maintenance schedule.

We warmly welcome our customers to visit our factory. You'll have an opportunity to see our manufacturing process, meet our team, and witness first-hand the stringent quality control measures we adhere to in producing our high-horsepower tractors.

We offer end-to-end after-sales support and our tractors come with a standard one-year warranty. This covers any manufacturing defects and includes support from our expert technical team.

Absolutely, we cater to both small and large orders. If you are interested in bulk purchasing, we offer a tiered pricing system to provide more value to our customers. As the order quantity increases, we provide progressive discounts. For example, for orders above 50 units, we offer a 10% discount, for orders above 100 units, we provide a 15% discount, and so forth. Specific details can be provided upon request as we work closely with you to ensure a mutually beneficial agreement.

Certainly, we believe in complete transparency with our customers. On average, regular maintenance for our high-horsepower tractors can be expected to cost around 1-3% of the tractor's initial purchase price annually, depending on usage intensity and conditions. This includes regular oil changes, filter replacements, and other routine checks.

In terms of parts replacement, we assure you that our parts are competitively priced and we can provide a detailed price list upon request. To give you an idea, a major component like an engine or transmission typically lasts for thousands of operation hours before needing significant repairs or replacement, thereby ensuring low operating costs.

Lastly, our tractors are known for their robust build and durability, which directly contributes to a high resale value. In fact, after 5 years of usage, you can typically expect a resale value of about 60-70% of the original purchase price, subject to overall condition and market demand.

We are happy to provide a detailed breakdown to give you a comprehensive understanding of the total cost of ownership.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right farm machine you want.