Why Are Common Rail Diesel Engines Preferred for High-Performance Tractors?

Last month in southern Kazakhstan, I watched a contractor’s 180hp tractor pull a heavy cultivator through sticky clay, barely dipping in rpm. His neighbor’s older machine kept stalling at the same spot. The difference? One ran a modern common rail diesel, the other relied on old-school mechanical injection.

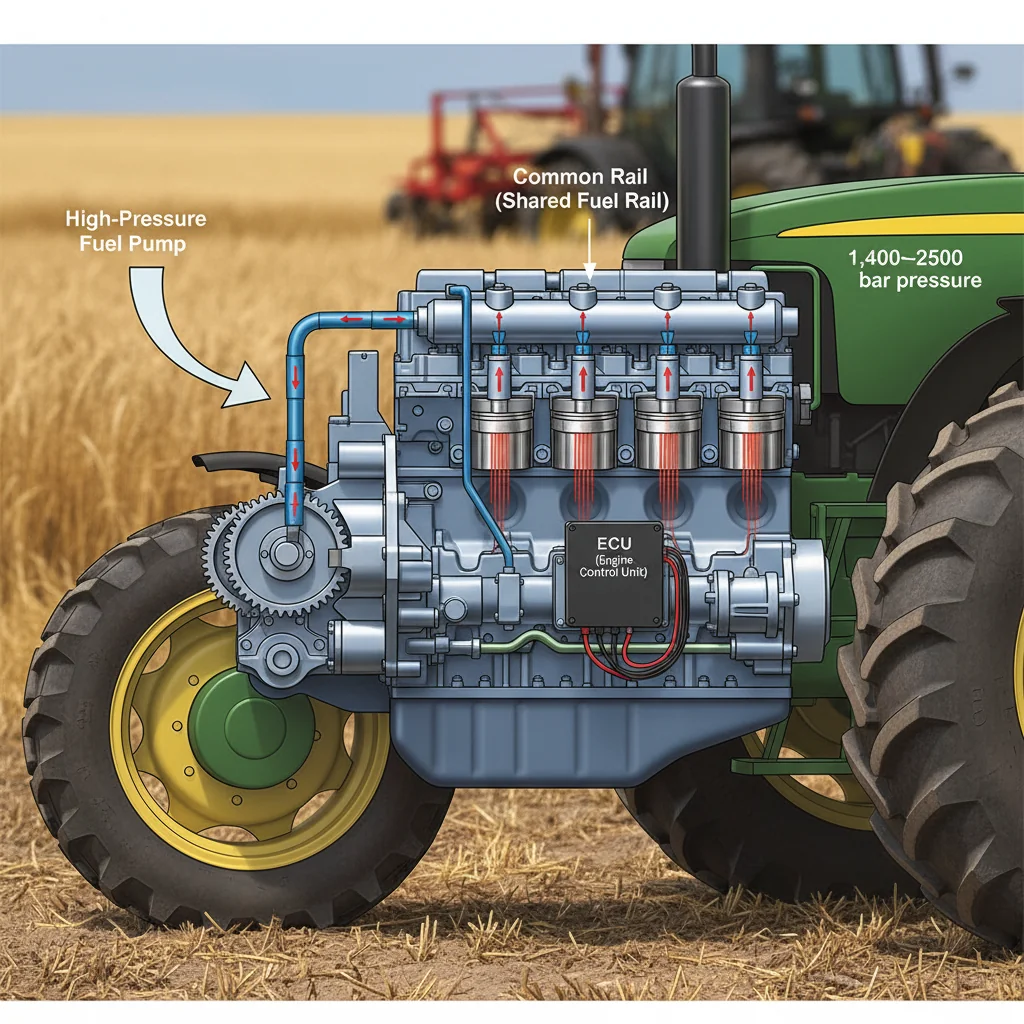

Common rail diesel engines deliver superior high-performance tractor operation by maintaining consistently high fuel rail pressure—typically 1,400–2,500 bar—regardless of engine speed. Electronic injectors, controlled by an engine control unit, enable multiple precise injections per cycle, optimizing combustion, torque rise1, and fuel efficiency. This system supports advanced power management, smoother PTO operation, and compliance with stringent emissions regulations that are impossible for mechanical systems to meet.

How Do Common Rail Diesel Systems Work?

Common rail diesel engines use a high-pressure pump to supply a shared fuel rail, maintaining 1,400–2,500 bar pressure. Electronically controlled injectors2 precisely deliver fuel multiple times per cycle, with the ECU constantly adjusting timing and quantity. This results in superior combustion, improved low-rpm torque3, better fuel efficiency, and smoother operation compared to older mechanical injection systems.

Most people don’t realize just how much the fuel system affects a tractor’s day-to-day power. I remember visiting a large operation in northern Vietnam where the owner switched from older mechanical injection units to common rail models rated at 160HP. The difference was clear—tractors pulled heavy planters at low RPM without bogging down, and fuel use dropped sharply. That’s because common rail systems keep injection pressure steady—typically between 1,400 and 2,500 bar—no matter the engine speed. You get strong torque even at low revs, which is exactly what you want for tough fieldwork or wet soil.

Let me share something important about real-world performance. Mechanical fuel systems tie injection timing and pressure directly to engine speed. When you slow down, pressure drops, spray quality suffers, and combustion gets smoky. In Kazakhstan, I’ve seen farmers struggle with cold starts and rough running in older 120HP tractors because the old injectors just can’t keep up. With common rail, the ECU (engine control unit) constantly adjusts injection timing and quantity based on load, rpm, and temperature. This means you get smoother operation, less knocking, and cleaner exhaust—especially important where emissions standards are tightening.

From my experience, the real advantage shows up over a full season. One Brazilian customer told me his 180HP common rail tractors needed less frequent filter changes and oil stayed cleaner, thanks to more complete combustion. Plus, features like power management and CVT optimization only work with this level of fuel control. If you’re choosing a high-performance tractor, I suggest looking for a reliable common rail system—it’s the foundation for both power and efficiency.

Common rail diesel systems enable precise, multi-stage fuel injection events during each combustion cycle, which improves engine efficiency and reduces emissions in high-performance tractors.True

Unlike older mechanical systems, common rail injectors are electronically controlled, allowing for multiple injections (such as pilot, main, and post-injection) per cycle. This improves combustion control, leading to better fuel atomization, smoother operation, and cleaner exhaust.

Common rail diesel engines require significantly higher engine RPM to maintain injection pressure compared to mechanical injection systems.False

In reality, common rail systems use a high-pressure pump and accumulator (the 'rail') to keep fuel pressure constant, independent of engine speed. This allows for optimal injection pressure even at low RPMs, unlike mechanical systems where pressure depends on engine speed.

Key takeaway: Common rail diesel systems offer precise fuel delivery and sustained high injection pressure, enabling better performance, fuel economy, and emissions control in high-performance tractors. This technology supports advanced features like power management and CVT optimization, making it standard for modern tractors in the 120–400 hp range.

How Do Common Rail Engines Boost Power?

Common rail diesel engines maintain high rail pressure at all engine speeds, allowing precise fuel delivery and atomization. The ECU adjusts injection timing and quantity for optimal torque rise—often 30–45%—and a wide constant-power band. This enables high-performance tractors to maintain rpm under heavy load, reducing stalling and increasing field productivity.

Let me share something important about how common rail engines actually make a difference on real farms. Unlike older mechanical injection systems, common rail keeps fuel pressure high at all engine speeds. That means the injectors can spray a fine mist of diesel exactly when the engine needs it—no matter if you’re working at 1,600 rpm or pushing up to 2,200 rpm. The electronic control unit (ECU) constantly tweaks injection timing and fuel volume, so when the engine starts to bog down in tough soil, it automatically delivers more fuel. This is what creates a strong “torque rise”—often 30–45% above rated torque—which keeps your tractor pulling even as speed drops.

I’ve seen this firsthand in Kazakhstan, where farmers work heavy chisel plows on black soil. One customer upgraded from a 150HP mechanical pump tractor to a similar horsepower model with common rail. The old tractor would stall or lose too much speed when hitting a wet patch. The new one kept its rpm steady, so he covered an extra 8–10 hectares per day with fewer gear changes. That’s real productivity you can feel in the seat—not just numbers on a brochure.

Here’s the thing: a wide constant-power band means you can work at 1,700 rpm instead of pushing the engine at 2,200 rpm all day. That saves fuel and reduces wear, especially on PTO-driven implements like maize shellers or rice threshers. I always suggest looking at torque rise and power band width—not just peak horsepower—if you want reliable performance under tough field conditions.

Common rail diesel engines allow for multiple fuel injections per combustion cycle, which helps optimize power delivery and reduce engine noise in high-performance tractors.True

This is true because the electronic control unit (ECU) in common rail systems can command multiple injection events—such as pilot, main, and post-injections—within a single combustion cycle. This leads to smoother combustion, better torque characteristics, and less engine noise compared to older mechanical systems.

Common rail diesel engines require manual adjustment of fuel injection timing for different engine speeds to maintain optimal performance.False

This is false because common rail systems use an electronic control unit (ECU) to automatically and precisely control injection timing and duration in real time, eliminating the need for manual adjustments regardless of engine speed.

Key takeaway: Common rail diesel engines enable tractors to deliver more usable power and consistent performance under tough field conditions by maximizing torque rise and maintaining a broad constant-power range. This technology supports higher productivity, fewer gear changes, and improved efficiency compared to older mechanical systems.

How Much Fuel Do Common Rail Engines Save?

Common rail diesel engines deliver 5–15% better specific fuel consumption4 than older mechanical systems, thanks to finer fuel atomization and precise injection timing. For a 180 hp tractor logging 800 hours annually, this equates to 1,600 liters of fuel and $1,760 saved per year—significantly reducing operating costs.

Here’s what matters most when you’re weighing up fuel efficiency: real numbers, not just manufacturer claims. I’ve seen too many buyers in Vietnam and Kenya focus on horsepower or price, while ignoring how much diesel their new tractor will actually burn each year. With common rail engines, the savings are not just a small bonus—they can reshape your whole operating budget. These systems inject fuel at higher pressure and with better timing, so you get finer atomization and more complete combustion. The result? Specific fuel consumption drops by 5–15% compared to traditional mechanical injection.

Take a mid-size 180HP tractor running heavy loads—think disc plowing or deep ripping. In the rice fields around Can Tho, I’ve watched farmers average about 20 liters per hour over a typical season. Over 800 working hours, that’s 16,000 liters of diesel. Swap in a common rail engine, and you’re saving around 1,600 liters each year—roughly $1,760 at current fuel prices. Over a six-year stretch, that’s nearly $10,000 staying in your pocket, even after accounting for the odd injector or sensor replacement.

For large farms or contractors in places like Brazil, fuel is often the biggest running cost after labor. Common rail engines also let you operate at lower revs while still delivering solid torque, which cuts fuel use even further. I always suggest comparing real-world specific fuel consumption—measured in grams per kWh—between models. And don’t just trust the brochure. Test under your own field conditions, with your implements and typical loads. That’s how you spot the true fuel saver.

Common rail diesel engines can maintain more consistent fuel injection pressure across varying engine loads, which leads to more stable and efficient fuel consumption during field operations.True

This is true because common rail technology allows precise electronic control of fuel injection timing and pressure, adapting to engine demand in real-time. This results in better combustion efficiency and reduces wasted fuel, especially during fluctuating workloads common in agricultural settings.

Common rail diesel engines require significantly higher-grade diesel fuel than conventional mechanical-injection engines, or they will lose all fuel efficiency benefits.False

This is false because while cleaner fuel is generally better for any engine, common rail systems are designed to operate efficiently with standard diesel fuel available in most markets. Their efficiency advantages come from advanced injection control, not from requiring specialized fuel.

Key takeaway: Common rail diesel engines provide substantial fuel savings—typically 5–15%—over traditional mechanical injection systems. Over several years, these savings often exceed the additional upfront cost of the technology, making common rail engines a cost-effective choice for high-performance tractor operations.

How Do Common Rail Engines Manage PTO Loads?

Common rail diesel engines use electronic control units (ECUs) to instantly adjust fuel injection timing5 and quantity in response to load changes. This rapid adaptation maintains consistent engine rpm and PTO speed, ensuring stable implement performance and reducing stalls, especially during demanding tasks like baling, harvesting, or planting.

The biggest mistake I see is underestimating how quickly PTO load can shift in the field—especially if you’re running a baler or forage harvester. I worked with a customer in Brazil who used older 120HP models on rough sugarcane fields. Every time the PTO load jumped—say, when the baler hit a heavy patch—the engine would bog down, PTO rpm dropped, and bale density suffered. Since switching to a 140HP tractor with a common rail engine, he tells me the difference is night and day. The ECU senses the load spike and immediately adjusts the fuel injection. PTO speed barely wavers, even when the baler is working flat out.

Here’s what actually happens inside the engine. When the PTO sees a sudden load increase—like a heavy swath or a tough section of ground—the common rail system reacts in milliseconds. The ECU increases fuel quantity and tweaks injection timing so engine rpm stays steady. That means 540 or 1,000 rpm at the PTO stays almost constant. For the operator, this translates to fewer stalls, more consistent bale size, and smoother operation. I’ve seen this firsthand in Vietnam, where rice farmers run 90HP units for both field and rice mill work. The common rail engines handle rapid load changes much better than the old mechanical types.

If you’re managing different implements—planters, sprayers, heavy tillage—across a season, one well-matched common rail tractor can often do the job of two older, more specialized machines. I suggest looking beyond just horsepower and checking how the engine holds PTO speed under real working loads. That’s what keeps productivity up and headaches down.

Common rail diesel engines can respond to sudden PTO load changes by adjusting fuel delivery in real-time, helping maintain stable PTO rpm under varying field conditions.True

Common rail systems use electronic control to precisely meter fuel to each injector based on load demands. When the PTO load increases, the ECU detects the change and quickly increases fuel delivery, enabling the engine to recover rpm more rapidly and keep PTO-driven implements operating consistently.

Unlike conventional fuel systems, common rail engines cannot compensate for rapid PTO load fluctuations, making them less suitable for demanding baling or harvesting operations.False

Common rail engines are actually preferred in these scenarios because their electronically controlled fuel injection allows rapid and accurate adjustment to changing loads. This is the opposite of conventional mechanical systems, which often lag in response and can struggle to maintain PTO performance under variable field conditions.

Key takeaway: Common rail diesel engines provide immediate response to variable field loads and PTO demands by electronically adjusting fuel delivery, resulting in steadier PTO speeds and more consistent implement output. This enhances versatility and efficiency, often allowing one modern tractor to replace multiple older models.

How Do Common Rail Engines Meet Emissions?

Common rail diesel engines meet strict emissions regulations by allowing precise electronic control of injection timing, pressure, and multiple injection events per cycle. This fine control, paired with aftertreatment systems6 like EGR, DOC, DPF, and SCR, significantly reduces NOx and particulates while maintaining high power and fuel efficiency in modern tractors.

I've worked with customers in Vietnam who were surprised at how quickly emission laws changed—one year they could import basic 120HP mechanical tractors, and the next, only common rail models passed inspection. That’s a headache if you’ve got a fleet to upgrade. The reality is, high-horsepower engines just can’t meet Stage IV or Tier 4 emissions on mechanical injection alone. You need common rail to get that fine control over fuel timing and pressure—otherwise, NOx and particulates spike, and regulators won’t let those tractors on the road.

From my experience, common rail systems allow you to adjust injection events down to the millisecond. A customer in Brazil runs over 300 hectares with two 180HP units—both use multiple injection events per cycle, at pressures up to 1,800 bar. The result? Clean exhaust, full torque, and fuel consumption that’s actually a bit better than their old mechanical models. They also have EGR (exhaust gas recirculation), plus DPF (diesel particulate filter) and SCR (selective catalytic reduction) bolted on. These aftertreatment systems work together: EGR cuts combustion temperatures, DPF traps soot, SCR neutralizes NOx.

I always suggest thinking ahead—if your region is moving to stricter rules, a non-compliant tractor’s value drops fast. You might find it hard to register, resell, or export in a few years. With common rail, you can meet current standards and keep your options open. That flexibility matters if your business relies on trading up or moving tractors between countries.

Common rail diesel engines can precisely adjust injection timing and pressure multiple times per combustion cycle, which helps them reduce both nitrogen oxides (NOx) and particulate emissions to meet modern agricultural emission standards.True

Unlike mechanical injection systems, common rail systems electronically control fuel delivery, allowing for multiple injections and finer atomization. This flexibility enables more complete combustion and better control of emissions, helping engines comply with strict regulations like Stage IV and Tier 4.

Mechanical injection systems in high-horsepower tractors can achieve the same emission reductions as common rail systems by simply using higher quality diesel fuel.False

While fuel quality can influence emission levels, mechanical injection systems lack the precise electronic control over timing and pressure needed to meet stringent emissions standards. High-quality fuel alone cannot compensate for the limitations in mechanical systems, especially for NOx and particulate control required by modern regulations.

Key takeaway: Common rail technology enables high-horsepower tractors to comply with evolving global emission standards, safeguarding legal operation, improving resale value, and supporting market flexibility. This system’s precise fuel management is essential for meeting environmental regulations without sacrificing performance or fuel economy.

How Durable Are Common Rail Diesel Engines?

Common rail diesel engines feature robust pumps, rails, and injectors designed for high pressures, often delivering 6,000–8,000 hours of injector and pump life, with engines exceeding 10,000 hours when properly maintained. Reliability depends on clean fuel and regular service, as fine clearances and sensitive electronics require diligent filtration and scheduled maintenance.

To be honest, the spec that actually matters is how well you keep your fuel system clean—more than any single horsepower rating or torque number. Common rail diesel engines are built tough and can easily reach over 10,000 hours if serviced correctly. But their injectors and high-pressure pumps7 work at extreme tolerances. Even a little dirt or water in the fuel can cause big trouble. I’ve seen farms in Peru lose expensive injectors in under 2,000 hours just from poor filtration. That’s a costly mistake, especially when a replacement injector can cost as much as a month’s wages for a tractor operator.

Last month, a customer in Kazakhstan called after his 100HP tractor started losing power during peak planting. The problem? He’d stretched filter change intervals to save money. The result was clogged injectors—repairing them took almost a week and set the whole operation back. This kind of downtime hurts more than people expect, especially in short growing seasons. On the other hand, I’ve worked with rice growers in Vietnam who use quality filters, drain water traps religiously, and stick to the service schedule. Their tractors routinely see 7,000–8,000 hours on original injectors and pumps.

The reality is, common rail engines absolutely can deliver long, reliable life. But you can’t ignore maintenance or hope for “field fixes” with basic tools. I always suggest investing in good filtration and making sure your service techs know how to check and clean every part of the fuel system. That’s what keeps these engines working—year after year.

Common rail diesel engines are especially sensitive to fuel quality because their injectors operate at much higher pressures and tighter tolerances than older mechanical systems.True

The high-pressure injectors in common rail engines require extremely clean fuel, as even small contaminants or water can cause rapid wear or failure, which is less of a risk in older, lower-pressure systems.

Common rail diesel engines can tolerate unfiltered or contaminated fuel just as well as traditional mechanical diesel engines.False

Unlike traditional mechanical systems, common rail engines have precision components that are easily damaged by dirt or water in the fuel, making them much less tolerant of poor fuel quality.

Key takeaway: Common rail diesel engines in high-performance tractors offer impressive durability and engine life, but their reliability hinges on excellent fuel cleanliness and regular professional maintenance. Proper filtration and adherence to service intervals help maximize lifespan, offsetting the complexity introduced by electronics and high-precision components.

How Does Fuel Quality Impact Common Rail Reliability?

Common rail diesel engines are highly sensitive to fuel contamination8. Particles over 5–10 microns or water in diesel can damage injectors and high-pressure pumps, leading to costly failures. Effective dual-stage filtration9—including a ≤5 μm fine filter and water separator—is critical for maintaining system reliability, especially where fuel quality is inconsistent.

Last month, an importer in Peru called me after several brand-new 90HP tractors ran into trouble—injectors failed in less than 300 hours. The culprit? Dirty diesel straight from roadside drums. With common rail systems, even tiny particles or a bit of water can cause big headaches. I’ve seen injectors scored by grit smaller than a human hair, and pumps seize up from a few drops of water. Older mechanical engines shrugged off mediocre fuel, but common rail units demand much cleaner diesel to stay reliable.

In Southeast Asia, I visited a rice cooperative where tractors often refuel from mobile tankers. Filtration was an afterthought, and the operators only changed filters when the engine started losing power. Within a year, three machines needed full injector sets—each costing over $1,500, not to mention at least a week of downtime per tractor. That’s a heavy price for small-scale farmers. The reality is, filtration and water separation aren’t just “nice to have” options—they are essential insurance in regions with variable diesel quality.

To be honest, I always suggest checking the tractor’s fuel system before signing any contract. Look for dual-stage filtration with a fine filter rated at 5 microns or better, plus a clear water separator bowl. Drain the separator every few days if humidity is high or fuel storage is basic. It’s a small task that can prevent major failures. Ask about local injector and pump availability, too—parts delays can stretch downtime from days to weeks. With proper care, common rail reliability holds up even in tough markets.

Common rail diesel engines use high-precision injectors that can be permanently damaged by fuel contamination smaller than 5 microns.True

Common rail injectors operate under extremely high pressures and have tight tolerances, making them especially vulnerable to extremely fine particulates that would not affect older mechanical systems.

Because common rail systems are more advanced, they can tolerate poor quality diesel fuel better than older mechanical engines.False

Common rail diesel engines are actually more sensitive to fuel impurities due to their precise components and higher injection pressures, making clean fuel essential for reliability.

Key takeaway: Fuel quality directly affects common rail diesel system reliability. Investing in proper filtration and regular maintenance is essential, especially in regions with variable diesel quality. Neglecting fuel quality risks expensive injector and pump failures, plus significant tractor downtime. Always assess fuel system design before purchasing high-performance tractors.

How Do Common Rail Engines Improve Comfort?

Common rail diesel engines improve operator comfort by precisely controlling fuel injection timing and pressure. This technology enables pre-, main-, and post-injection events, resulting in smoother combustion, reduced diesel knock, lower noise levels, and less vibration. These enhancements minimize driver fatigue during long hours in the cab, particularly on high-performance tractors handling heavy workloads.

The biggest mistake I see is underestimating how engine smoothness affects your workday. On paper, most buyers just look at horsepower and torque. But after a full day in the cab—especially during plowing or hauling—noise and vibration matter much more than people realize. I’ve been on farms in Kazakhstan where older mechanical-injection engines left operators exhausted after eight hours, even though the tractors had plenty of power. The harsh diesel knock and rattling chassis made it tough to focus, and some crews swapped drivers midday just to cope with the fatigue.

Here’s what makes common rail engines different. By controlling fuel injection in three stages—pre-injection, main, and post-injection—the engine manages combustion much more gently. This means less sudden pressure in the cylinders and far fewer vibrations passing through the frame and seat. I’ve seen this first-hand on mid-size 90HP models used for rice cultivation in Vietnam. Operators told me the quieter engine sound at 1,600 rpm made a big difference, especially when working long days with rotary tillers or heavy PTO loads. The smoother idle also helped—less shaking means less wear on both the tractor and the operator.

If you’re comparing tractors, I suggest listening carefully during a demo. Run the engine at typical working speeds—around 1,500 to 1,800 rpm—and pay attention to the sound and feel under load. Comfort doesn’t show up in the brochure specs, but it directly impacts how much work you get done each day. Over a season, less fatigue adds up to better productivity and fewer complaints from your crew.

Common rail diesel engines reduce operator fatigue by delivering fuel in multiple, precisely timed injections, which minimizes vibration and harsh engine noise during long workdays.True

Unlike mechanical injection systems, common rail technology allows for multiple injections per combustion cycle, smoothing out engine operation and reducing the jarring vibrations and knocking sounds that contribute to operator fatigue.

Common rail engines increase in-cab vibration levels compared to mechanical-injection engines due to higher fuel pressures.False

While common rail systems do operate at higher fuel pressures, their precise control of injection timing and quantity actually reduces combustion harshness, leading to smoother and quieter engine operation, not increased in-cab vibration.

Key takeaway: Common rail diesel engines deliver noticeably smoother, quieter operation for tractor operators, especially during extended work periods. By minimizing vibration and noise through advanced fuel delivery, they significantly reduce fatigue and improve overall comfort, which has a direct positive impact on productivity and long-term operator well-being.

Why Choose Common Rail Diesel in Tractors?

Common rail diesel engines are preferred in 120–400 hp tractors due to stricter emissions standards and demand for fuel efficiency. These systems deliver 5–15% lower fuel consumption, better low-rpm torque, and improved PTO stability, outweighing the added complexity for high-hour, high-performance use.

Here's the thing—when emissions rules tightened in places like Brazil and Kazakhstan, I watched many farmers hesitate over the shift to common rail diesel engines. They're not simple like the old mechanical pumps, but in that 120–400 hp range, they're now the standard for a reason. A contractor in Mato Grosso told me his 180HP unit with common rail used about 12% less fuel than his older model on the same heavy disc harrow. Over a long planting season, that saved him enough to cover a big chunk of his annual maintenance budget.

The big gain isn’t just fuel savings. Common rail systems deliver stronger low-rpm torque, which means you hold steady PTO speeds when baling or running a sprayer—even if engine load jumps. I’ve seen this firsthand in Vietnam, where rice farms run PTO implements for hours on end. The improved stability cuts downtime and keeps productivity up, especially when you’re covering 100+ hectares with each tractor. Plus, meeting newer emissions standards means your investment holds value longer if you plan to resell.

There’s a trade-off. These engines are more sensitive to poor diesel quality, and repairs require electronic diagnostics—not just a basic toolkit. I always suggest, especially if your farm is far from a good dealer or fuel is inconsistent, keep at least one older, simple tractor for emergencies. But for any main tractor working long hours or heavy loads, common rail’s efficiency and power control usually pay off. For high-hour operations, it’s the smart business move.

Common rail diesel engines in tractors allow for multiple injections per combustion cycle, which improves engine smoothness and reduces noise compared to traditional mechanical injection systems.True

This is true because the electronic control in common rail systems can deliver precise fuel amounts at different points in the cycle, resulting in smoother operation and quieter engine performance.

Common rail diesel engines in tractors require less maintenance than older mechanical injection systems because they have fewer components.False

This is false because common rail systems are more complex, relying on high-pressure pumps, sensors, and electronic controls, which can increase maintenance demands compared to simpler mechanical pumps.

Key takeaway: For high-performance and high-hour tractors, common rail diesel engines provide significant fuel savings, regulatory compliance, and better power management, making them the industry standard despite higher complexity and maintenance demands. Simpler engines may still suit low-hour operations or areas with limited dealer support.

What Should Be Compared in Common Rail Engines?

When evaluating common rail diesel engines for tractors, compare torque curve and torque rise, maximum rail pressure10, combustion strategy, emissions aftertreatment compatibility, and fuel system protection. Also assess dealer diagnostic capabilities and parts availability. Superior local support frequently outweighs the appeal of top-tier specs if rapid service and parts access are essential.

From my experience, buyers often focus on headline horsepower or fuel efficiency, but overlook the real differences between common rail engines. In Kazakhstan, I visited a farm running both older mechanical injection and newer common rail models—on heavy clay, the tractors with a stronger torque rise (over 35%) pulled plows noticeably better at lower rpm. That meant less stalling and fewer gear changes during peak season.

I always suggest checking not just the torque peak, but how quickly the engine builds torque as rpm drops under load.

Another key comparison is maximum rail pressure and fuel quality tolerance. Higher rail pressure (1,600–2,000 bar) means finer fuel atomization, which improves combustion and power. But I’ve seen in Vietnam and Peru that not all common rail systems handle low-quality, higher-sulfur fuel well.

You need to see how many fuel filters are included, the micron rating (at least 5 microns is safer), and whether there’s a water separator you can drain daily. That’s what protects your injectors and high-pressure pump from damage.

Beyond specs, dealer support often makes or breaks the value of a common rail tractor. I’ve seen farmers in Kenya waiting two weeks for a single injector—while their fields sit idle. So I suggest asking dealers about laptop diagnostic tools, how many trained techs they have, and typical lead times for parts like injectors or fuel pumps.

Sometimes, a model with slightly lower specs but strong local support will keep you running when it matters most.

A key advantage to compare in common rail engines is the speed and shape of torque rise, as engines with a steeper torque curve maintain power more effectively under varying loads.True

Torque rise determines how well a tractor can handle sudden increases in load without stalling or requiring frequent gear changes, which is particularly valuable in heavy fieldwork conditions.

Common rail engines always have higher peak horsepower than equivalent mechanical injection engines, regardless of tuning or application.False

While common rail systems offer more precise fuel delivery and can improve efficiency, peak horsepower depends on overall engine design and tuning—mechanical injection engines can still be tuned for similar or even higher power in some cases.

Key takeaway: Tractor buyers should evaluate not only engine specifications like torque rise and rail pressure, but also emissions compatibility and fuel system protection. Dealer support, diagnostic tools, and fast access to parts can be more critical than the engine’s headline numbers in real-world farming scenarios.

Conclusion

We've looked at why common rail diesel engines are now the standard for high-performance tractors, especially when it comes to power, fuel efficiency, and emissions. From what I see in the field, the real value of these systems shows up over long working hours—steady performance and better fuel use matter more than just peak horsepower. But I always remind buyers: don’t let impressive specs distract you from the basics like parts support and serviceability. That’s where the "spec sheet gap" can catch you. If you have questions about which engine type fits your needs or want to talk through real-world experiences, feel free to reach out. Every farm is different—choose what actually works for your conditions.

References

-

Understand the concept of torque rise and how a 30–45% increase helps tractors maintain power under heavy load for better field work. ↩

-

Understand how electronically controlled injectors optimize fuel delivery timing and quantity for better combustion and power. ↩

-

Learn why stronger low-rpm torque enhances PTO stability and productivity during heavy-duty agricultural tasks like baling and spraying. ↩

-

Understand specific fuel consumption metrics and their impact on tractor operating costs, with real-world savings examples from common rail engines. ↩

-

Learn how precise fuel injection timing reduces diesel knock and vibration, leading to smoother engine operation and less operator fatigue. ↩

-

Learn the roles of EGR, DOC, DPF, and SCR in reducing harmful emissions and meeting stringent tractor emission standards with expert technical insights. ↩

-

Explore the critical role of injectors and high-pressure pumps in engine life and how maintenance prevents costly failures. ↩

-

Details the impact of particles and water in fuel on injector damage and pump failure, highlighting the need for clean diesel in common rail systems. ↩

-

Explains how dual-stage filtration protects injectors and pumps by removing particles and water, reducing costly failures in diesel engines. ↩

-

Understand how higher maximum rail pressure enhances fuel atomization, combustion efficiency, and engine power output. ↩