Tractor Impact on Farm Efficiency: Manufacturer Insights for Real-World Results

A few months back, a distributor in Tanzania told me his customers were racing against the rains, trying to finish land prep with oxen before the fields turned to mud. He asked—could a 60 hp tractor really make that much difference, or was it just a big expense for smallholders?

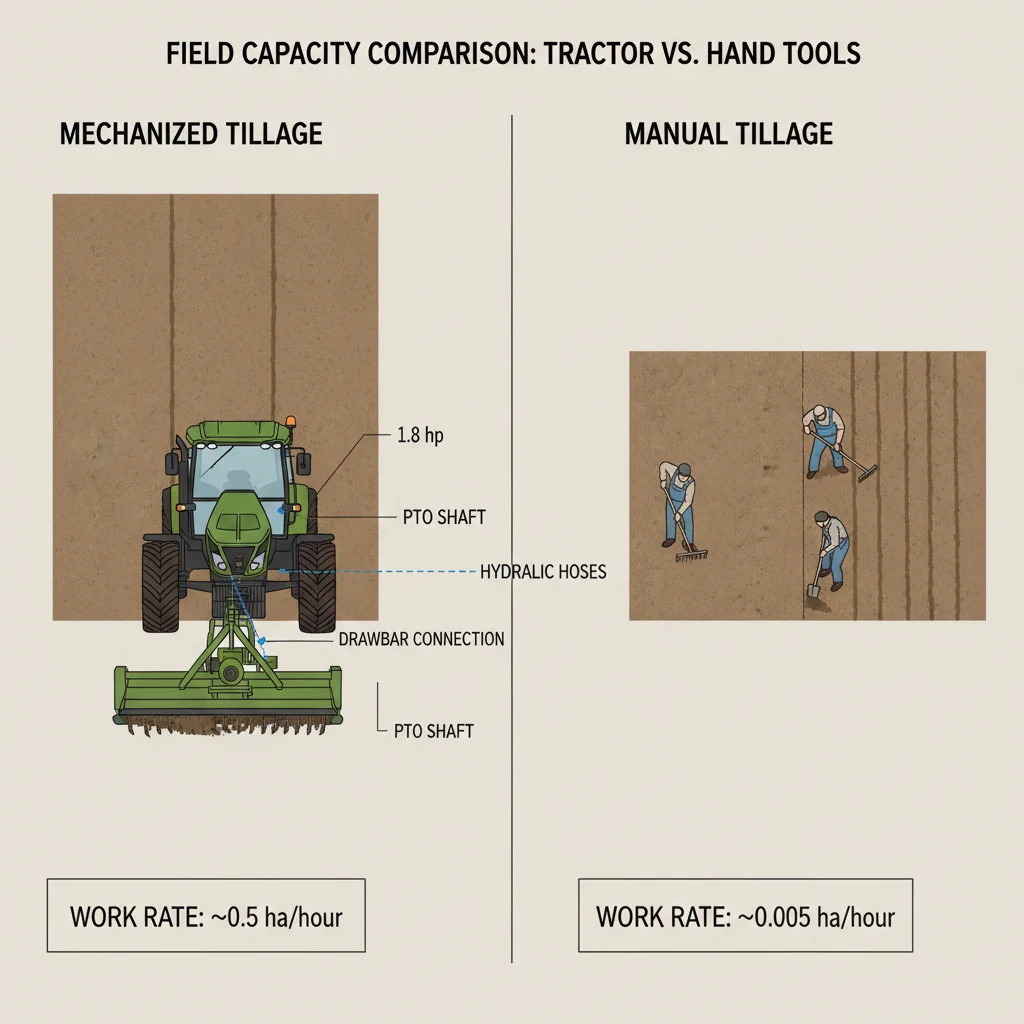

Mechanized tractors fundamentally increase farm efficiency by transforming fuel into sustained drawbar, PTO, and hydraulic power, enabling the operation of wide and heavy implements at consistent work rates. Field capacity often improves 6–10 times over manual or animal traction, particularly for primary tillage1, planting, and short-distance transport. The greatest efficiency gains occur when tractor horsepower is matched precisely to implement size and soil type, optimizing fuel use and reducing downtime.

How Do Tractors Increase Field Capacity?

Tractors dramatically increase field capacity by converting fuel into continuous drawbar, PTO, and hydraulic power. A 60 hp tractor with a 1.8 m rotavator can prepare 0.6–0.8 ha/hour, compared to 0.05–0.1 ha/hour using manual or animal traction—a 6–10× improvement in work rate.

Most people don’t realize just how much a conventional tractor can change the rhythm of a farm. I’ve seen this firsthand on midsize maize operations in Kenya. Before switching, farmers with animal traction could barely finish land prep before the rains. Once they brought in a 60HP tractor with a 1.8-meter rotavator, they covered at least 0.7 hectares per hour. What took a week by oxen dropped to one long day. This isn’t just about speed—it’s about hitting the critical windows for planting and spraying.

The real boost comes from how tractors convert fuel to multiple types of power. Drawbar pulls heavy tillage tools, the PTO (power take-off2) runs implements like sprayers or mowers, and a reliable hydraulic system lifts and adjusts equipment on the go. In Peru, one customer using a compact 50HP model with a three-point hitch and basic PTO finished both plowing and seeding on 30 hectares in under five days. That same job took almost three weeks with manual labor. The difference? Consistent power, no breaks for tired animals, and the ability to pull wider, heavier implements.

To be honest, many first-time buyers underestimate the impact on yield. I always suggest estimating your main seasonal jobs—how many hectares, and how much time you have before the rain or dry spell hits. If you can’t finish with manual or animal labor in that window, a tractor isn’t just a convenience—it’s the reason your harvest gets in on time. Consider the labor saved and the extra yield. For most, the investment pays back much faster than expected.

Tractors equipped with mounted implements like rotavators enable farmers to complete critical field operations within narrow planting windows, which helps ensure optimal crop establishment and yield.True

Unlike animal traction, tractors allow timely and efficient coverage of large areas, minimizing delays that can result in missed planting periods and reduced yields. This is particularly important in regions with short rainy seasons.

Using a tractor always leads to higher fuel and input costs compared to animal traction, regardless of operational scale or crop type.False

While tractors do require fuel and maintenance, their efficiency in covering more land per hour can lower overall input costs per hectare, especially on larger farms. The impact on costs varies with farm size, crop, and how effectively the tractor is used.

Key takeaway: Tractors offer a 6–10× boost in field capacity versus manual or animal labor, enabling timely completion of critical farm operations. This efficiency can lead to significant yield gains and labor savings, making tractors a cost-effective investment for farms seeking higher productivity and reliability.

Which Farm Tasks Gain Most with Tractors?

Tractors deliver the highest efficiency improvements in primary tillage, seedbed preparation, seeding, planting, fertilizing, spraying, and short-distance field transport. Compact tractors3 excel at multi-tasking jobs—mowing, loader work, hauling, and PTO applications—especially in tight spaces, providing up to 30% higher output efficiency versus oversized machinery on mixed or smaller farms.

Let me share something important about where tractors truly deliver the biggest efficiency gains. The work that eats the most time and labor—like primary tillage, seedbed preparation, seeding, and fertilizing—is where the right tractor can change everything.

For example, in southern Brazil, I worked with a grower who switched from oxen to a 75HP 4WD4 unit for plowing and harrowing. His team used to cover only 1.5 hectares a day. With the tractor, they managed 7 hectares—more than four times the area, even with the same crew.

Short-distance field transport is another area where tractors deliver clear advantages, especially after rain. In Kenya’s sugarcane belt, a 70HP tractor pulling a 5-ton trailer replaced two pickup trucks for hauling cane from muddy fields. The tractor could reach plots the trucks never managed, and it cut field-to-yard trips by half. That kind of flexibility is hard to match with road vehicles.

On mixed or smaller farms, compact tractors in the 45–60HP range are often the real multi-taskers. I’ve seen these units in Bolivia moving bales, running pumps, mowing, and shaping vegetable beds—all in a single day. Their turning radius, often under 4.5 meters, means less wasted time on each pass and less crop damage in orchards or tight plots.

Field data and local studies in Peru suggest compact tractors can deliver up to 30% higher output in high-hour, repetitive jobs compared to larger, bulkier machines that are less maneuverable in confined spaces.

Tractors provide the largest efficiency gains during primary tillage and seedbed preparation because these tasks require high, sustained draft power that is impractical to achieve with animal or manual labor.True

Primary tillage and seedbed preparation involve heavy soil manipulation over large areas, which demands continuous, high-powered pulling that tractors are specifically designed to handle. This makes them vastly more efficient than human or animal labor for these tasks.

Tractors have the greatest impact on efficiency during harvesting because their horsepower is primarily used to power cutting mechanisms and loaders.False

While tractors can assist with hauling and powering some harvest equipment, the most significant efficiency gains from tractors are seen in tasks that require substantial draft power, like tillage and planting. Dedicated harvesters and specialized machinery, not general-purpose tractors, are typically used for the primary harvesting actions.

Key takeaway: Tractors maximize efficiency in core field operations such as tillage, seeding, fertilizing, and transport. Compact models are especially valuable for mixed or smaller farms, offering significant productivity gains on high-hour tasks and in confined areas. Prioritize tractor selection based on the most frequent and labor-intensive jobs.

How Does Tractor Power Matching Boost Efficiency?

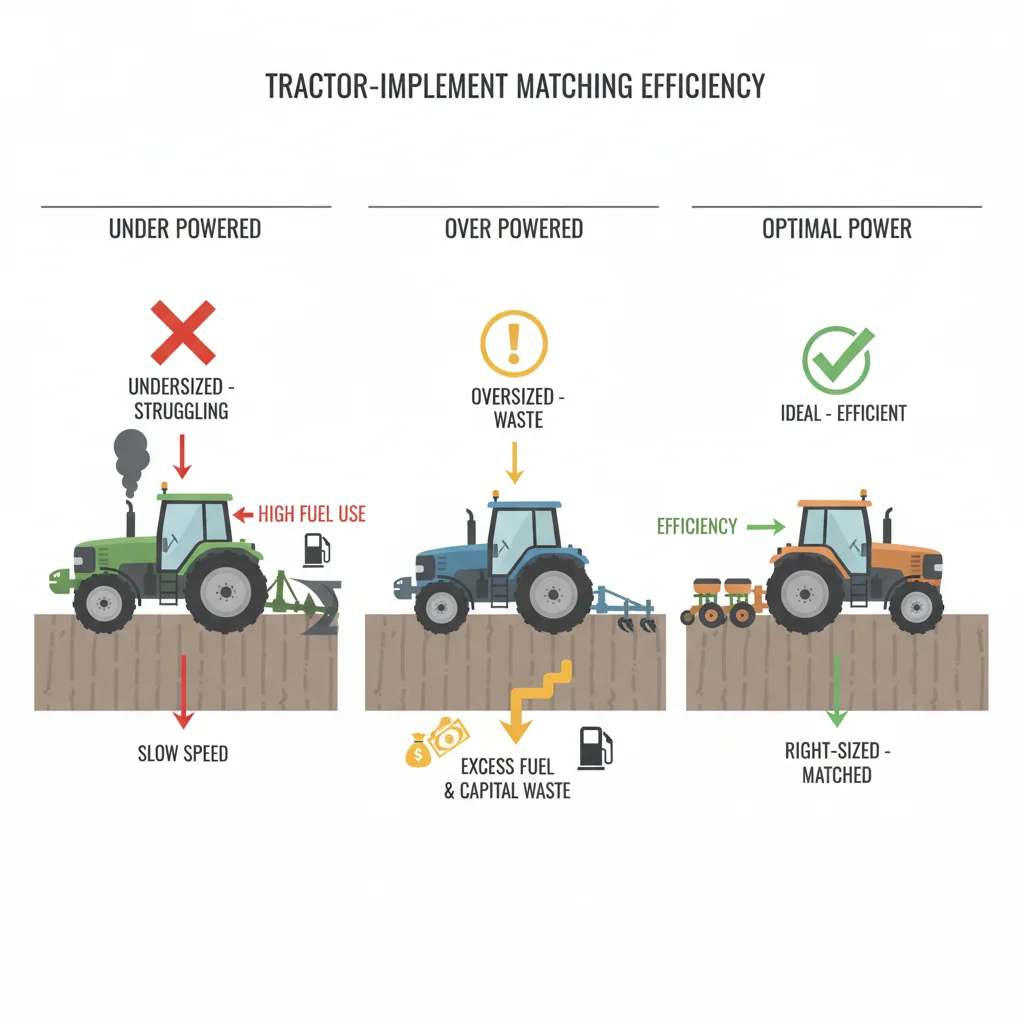

Right-sizing tractor horsepower5 to implement and soil type maximizes efficiency. Undersized tractors operate slowly and consume more fuel per hectare, while oversized units waste fuel and capital. A tractor working at 60–80% of rated power6 improves speed, lowers fuel use, and reduces breakdowns in real-world farm conditions.

The biggest mistake I see is farmers picking tractors based just on engine horsepower, without thinking about how their implements and soil type actually use that power. Last year, a distributor in Bolivia asked me why his customers’ 40HP compact tractors struggled with 2-meter rotavators in heavy clay. The tractors crawled at 3 km/h, burned more diesel per hectare, and the engines overheated by midday. Meanwhile, a neighbor running a 55HP unit with the same implement finished fields almost twice as fast—no overheating, less fuel, and far fewer repairs.

I’ve worked with vegetable growers in Kenya who swung the other way—buying 90HP tractors for light plowing and spraying. Sounds powerful, but those engines barely reached 40% of their rated load most days. Result? Fuel use per hectare shot up by nearly a third, and their capital sat tied up in an oversized machine. They told me it looked great in the showroom, but day-to-day, it was just wasting money.

Here’s what matters most when matching tractor power: aim for a unit that works at 60–80% of its rated power for your main jobs, not occasional heavy tasks. Check your main implement’s recommended HP, then add 10–15% for heavy soils or hilly land. Make sure your three-point hitch and PTO can also handle the load—these details matter as much as engine size. I always suggest matching the tractor to your real field work, not just what looks impressive on paper. That’s how you boost efficiency and avoid costly surprises.

Properly matching tractor power to implement size and soil conditions reduces engine strain and fuel consumption during field operations.True

When tractor horsepower is well-matched to the demands of the implement and the resistance of the soil, the engine operates within its optimal efficiency range, leading to less stress, cooler running temperatures, and more efficient fuel use.

A tractor with higher horsepower will always perform field tasks more efficiently, regardless of implement size or soil conditions.False

Excess horsepower does not guarantee efficiency if the implement is too small or soil conditions do not require it. Overpowered tractors can waste fuel and may not translate to better performance if not properly matched to the task.

Key takeaway: Selecting a tractor with horsepower closely matched to main implement demands and soil type ensures optimal work speed, minimizes fuel consumption, and extends equipment lifespan. Oversized or undersized combinations lead to inefficiencies and higher operational costs. Aim for 60–80% power utilization in standard tasks.

How do transmission choices affect efficiency?

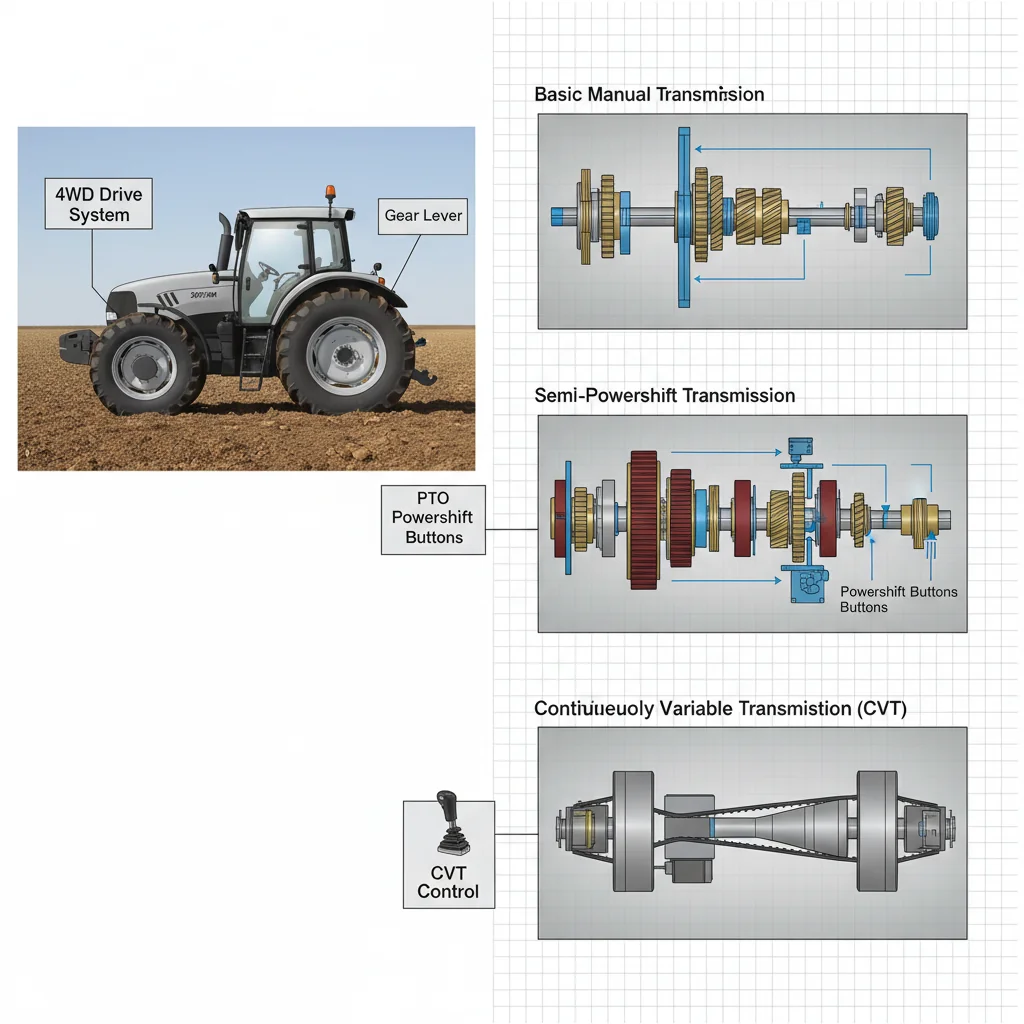

Transmission and drive systems directly impact farm tractor efficiency. Advanced options like semi-powershift and continuously variable transmissions (CVT) maintain optimal engine rpm, while features such as 24F/24R gears and eco road gears minimize fuel waste. Four-wheel drive (4WD) improves traction by 10–20% over 2WD in challenging conditions.

To be honest, the spec that actually matters is how your transmission and drive system handle real field work—not just what’s printed for horsepower. I’ve seen farmers in Brazil with 90HP tractors struggle in wet sugarcane fields because they chose 2WD and a basic 8F/4R gearbox. Their tractors spun and burned fuel, but couldn’t keep pace with the workload. When they switched to a 4WD model with 24F/24R gears, traction improved by about 15%, and they burned noticeably less diesel per hectare. The wider gear range also meant they could match ground speed to task, whether working slowly with a planter or moving quickly with a trailer on the road.

One Kenyan importer told me he regretted skipping creeper gears for his vegetable growers. Why? Regular low gears couldn’t deliver the slow 0.5–1 km/h speeds needed for transplanting while keeping the PTO at the right rpm. His customers ended up idling or riding the clutch, which wears parts and wastes fuel. In rice fields, I always recommend 4WD because it cuts slip, especially after rain. Even a 60HP 4WD unit can outperform a 75HP 2WD in muddy conditions—real-world efficiency, not just numbers on a brochure.

The reality is, choosing the right transmission and drive isn’t about buying the fanciest option—it’s about matching your fields and jobs. I suggest looking at your main crops, soil, and tasks before you decide. A well-matched setup saves fuel, reduces wear, and keeps your operation moving smoothly all season.

A tractor with more forward and reverse gear ratios allows the operator to match ground speed more precisely to field conditions, which can improve fuel efficiency and reduce wheel slip.True

Having a greater range of gear ratios means the tractor can operate closer to its optimal engine speed and torque range for various tasks, leading to better traction and more efficient power delivery. This reduces unnecessary fuel consumption and minimizes soil compaction from excess wheel slip.

A 2WD tractor with a basic gearbox is always more efficient than a 4WD tractor with a more advanced transmission, regardless of field conditions.False

While 2WD tractors can be lighter and simpler, they often struggle with traction and efficiency in challenging field conditions. 4WD and advanced transmissions provide better power transfer and adaptability, leading to higher efficiency in many real-world agricultural scenarios.

Key takeaway: Transmission type, gear range, and drive layout influence real-world tractor performance more than headline horsepower alone. Selecting the right combination for local field conditions—such as 4WD for traction or creeper gears for precision tasks—can improve fuel efficiency, reduce wheel slip, and boost operational productivity.

How Do Tractors Affect Total Cost of Ownership?

Tractors impact farm economics by balancing total cost of ownership (TCO) against labor savings and yield gains. TCO factors include purchase price, fuel, maintenance, repairs, wages, finance charges, and resale value. Efficient models reduce fuel use and downtime, accelerating payback, especially when annual usage exceeds 600–800 hours.

Here’s what matters most when looking at the real cost of running a tractor: it’s not just the sticker price. I’ve seen too many buyers in Peru and Kenya focus on upfront cost, only to be caught off guard by fuel bills, maintenance, and repair downtime. For example, a 70HP tractor working 600 hours a year will use around 8 to 10 liters of diesel per hour. If diesel is $1 per liter, you’re spending close to $5,000 each year just on fuel. That’s before you factor in oil changes, filters, worn tires, or even wages for a skilled operator—costs that add up fast over the season.

Last month, a farmer in Kazakhstan asked why his three-year-old tractor was suddenly costing more to keep running. I looked at his service records—turns out, his model needed frequent oil changes every 250 hours, and parts weren’t always available. Lost time in peak planting season hit his yields. That’s why I always suggest looking at service intervals7 and local parts support, not just horsepower. With newer models offering 500 to 750-hour intervals, you spend less time in the workshop and more time in the field.

If your annual usage is under 600 hours, I’ve seen success with shared ownership or custom work—especially in places like Bolivia, where smallholders combine forces. This spreads fixed costs over more hectares, lowering your cost per hectare. I recommend running the numbers on fuel efficiency8 and resale value as well. A reliable, efficient tractor pays for itself much faster when it’s working hard, not sitting idle.

The total cost of ownership for a tractor is heavily influenced by the machine’s average fuel consumption and maintenance intervals, which vary depending on how intensively the tractor is used.True

Fuel and routine maintenance make up a large portion of ongoing costs, and these expenses fluctuate based on usage patterns and workload, not just the initial purchase price.

Tractors with higher horsepower always have a lower total cost of ownership because they complete tasks faster, saving on fuel and maintenance.False

While higher horsepower tractors may finish tasks more quickly, they often consume more fuel per hour and can incur higher maintenance costs, which may actually increase the total cost of ownership rather than reduce it.

Key takeaway: Evaluating tractor investment requires understanding TCO—including direct and indirect costs—against measurable savings in labor and increased productivity. High annual utilization, fuel-efficient models, and shared ownership can maximize economic returns and shorten the payback period for farm operators.

How do fuel efficiency and maintenance boost uptime?

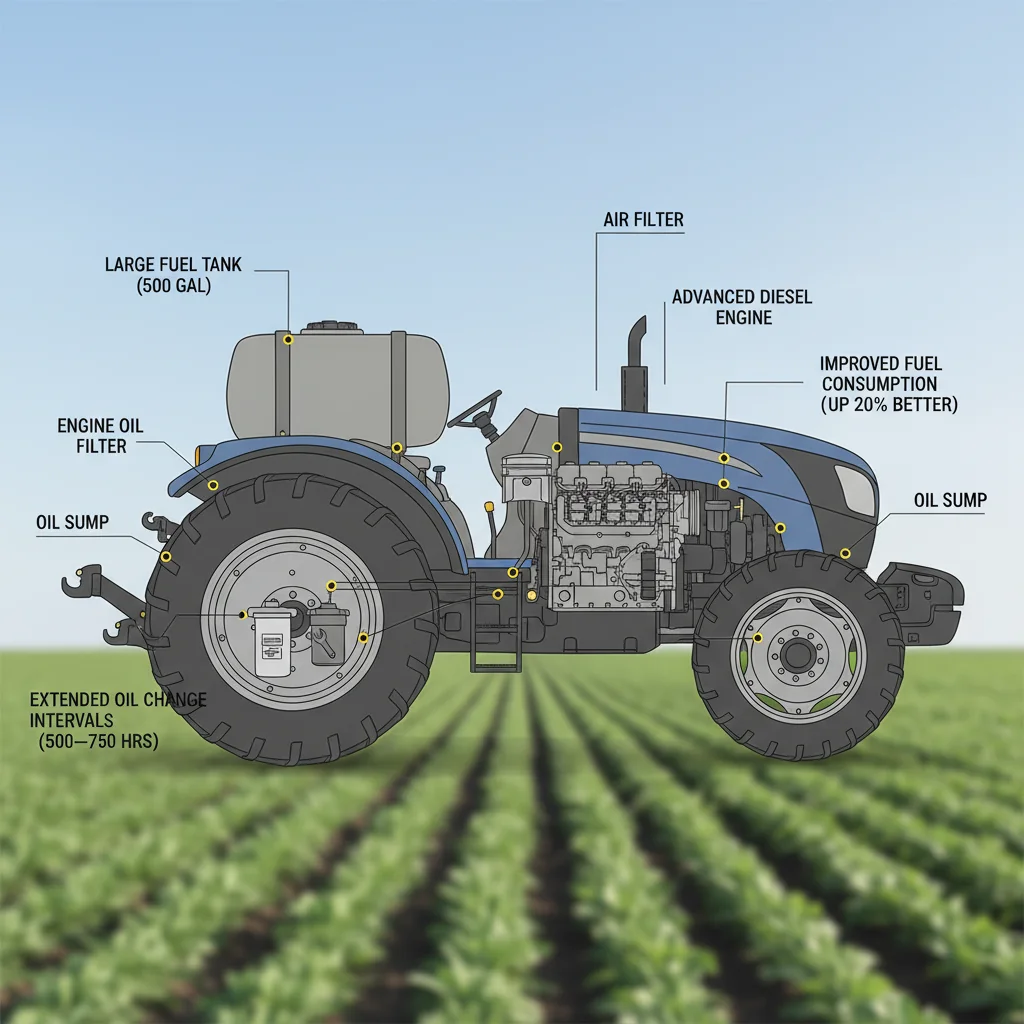

Modern tractors enhance uptime by improving fuel efficiency and extending service intervals. New mid-range models deliver up to 20% better fuel consumption and feature larger tanks for longer field work. Extended oil and filter changes, from 500 to 750 hours, reduce scheduled maintenance downtime by 25%, provided routine checks are maintained.

Let me share something important about boosting tractor uptime: it’s not just about the engine—fuel efficiency and proper maintenance make the real difference out in the field. I’ve seen this firsthand on a large maize farm in Kazakhstan. They switched to newer 90HP tractors with larger 600-liter fuel tanks. The result? Each unit worked through long harvest days without refueling, saving several hours of downtime every week. When you multiply that across a fleet, the impact is huge—especially in regions where fields are spread out and fuel delivery can be delayed.

But here’s the thing: even the most efficient engine loses its edge if basic upkeep slips. I visited a client in Bolivia who pushed their oil changes past 750 hours, thinking they could stretch service intervals even further. What actually happened was a drop in performance and a clogged air filter that increased fuel use by almost 10%. Regular checks—cleaning air filters, changing oil and filters, using the right grade of oil, and inspecting belts—keep the tractor running at its best. It’s simple, but I see too many operators skip these steps during busy seasons.

I always suggest planning your main services right after planting or harvest. Keep a stock of common filters and fluids on the farm so you’re not waiting on parts. Watch your hour meter closely. These habits mean your tractor is ready when the weather is right, not sitting in the shed. That’s how you keep your cost per hectare down and your operation running smoothly.

Using tractors with larger fuel tanks can significantly reduce downtime during peak field operations, as operators spend less time refueling and more time working.True

Larger fuel tanks extend runtime between refueling stops, which is especially valuable during continuous operations like planting or harvesting, where every hour counts.

Routine maintenance is only necessary for tractors that are over five years old, as newer models do not require regular servicing to maintain uptime.False

All tractors, regardless of age, require routine maintenance to ensure optimal performance and prevent unexpected breakdowns. Neglecting maintenance on new tractors can lead to premature wear and reduced reliability.

Key takeaway: Boosting farm efficiency relies on advanced tractor fuel economy and longer maintenance intervals. Regular basic care—such as clean air filters and timely oil changes—remains essential. These measures keep tractors available during crucial work periods and help lower the cost per hectare.

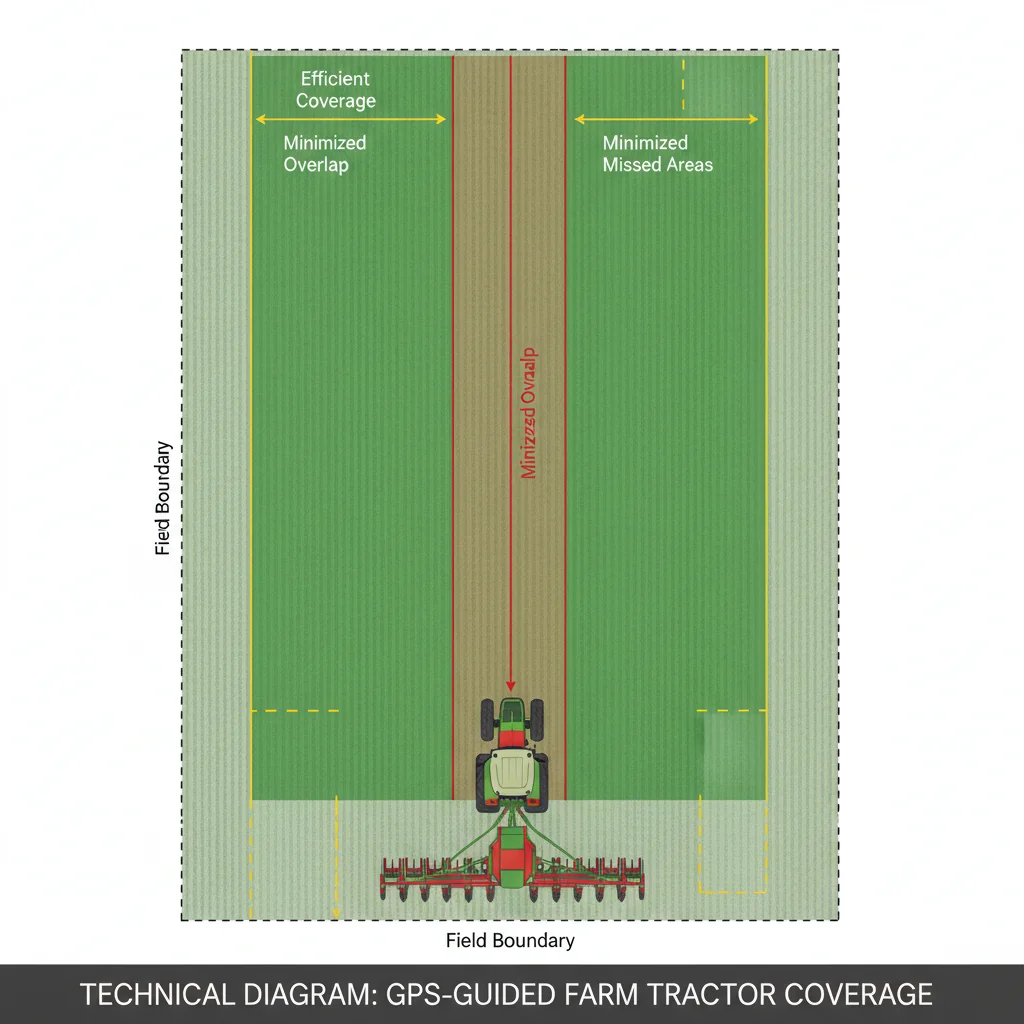

How does GPS guidance boost tractor efficiency?

GPS guidance, auto-steer, and section control technologies enable tractors to minimize overlap and missed areas during planting, fertilizing, and spraying. Field studies show these precision features can increase overall farm efficiency by up to 25% and crop yields by 30%, while reducing seed, fertilizer, and chemical use by 5–10% in broadacre operations.

Last month, a contractor in Kazakhstan called me, frustrated about wasted inputs on his 150-hectare wheat fields. He’d just upgraded to a 120HP tractor with basic GPS guidance and was surprised how much his overlap dropped during fertilizing. Before, his operators would double-cover as much as 8% of the field—easy to do with wide booms and long days. With even a simple lightbar, they cut overlap to around 3%. That’s real savings: on a farm that size, using less fertilizer and seed quickly adds up over the season.

From my experience, the biggest jump in efficiency comes with auto-steer and section control—especially on broadacre fields over 100 hectares. I’ve seen operators in Brazil run 16-row planters for 12-hour shifts. With GPS auto-steer, their rows stay straight and skips almost disappear. One farm manager told me he saved at least five days of work during planting, and input costs dropped by about 10% thanks to reduced overlap. Fatigue is another hidden cost. Auto-steer lets drivers focus on monitoring implements, not fighting the steering wheel all day.

For smaller or irregular fields, entry-level guidance is often enough. But on large commercial farms, I always suggest looking at section control—this shuts off individual planter or sprayer sections automatically. It’s not just about savings; it makes record-keeping easier too. Still, I warn customers: don’t underestimate the learning curve. Good dealer training and reliable local support are just as important as the technology itself. That’s what keeps efficiency gains real, not just brochure promises.

GPS guidance systems on tractors can reduce operator fatigue by allowing them to focus less on manual steering and more on monitoring implement performance.True

With GPS guidance, the tractor maintains a precise path automatically, lessening the mental and physical burden on the operator. This can lead to better attention to implement adjustments and overall productivity, especially during long workdays.

GPS guidance eliminates the need for any operator intervention during field operations, making manual input completely unnecessary.False

While GPS guidance automates steering and helps maintain accurate passes, operators are still required to monitor the equipment, manage headland turns, and respond to unexpected field conditions or system errors. Manual oversight remains essential for safe and effective operation.

Key takeaway: Precision agriculture tools like GPS guidance and integrated data platforms significantly improve efficiency, save input costs, and optimize yields. Adoption depends on field size and crop type, with advanced features delivering rapid ROI in larger operations. Proper dealer training and support are essential for successful technology integration.

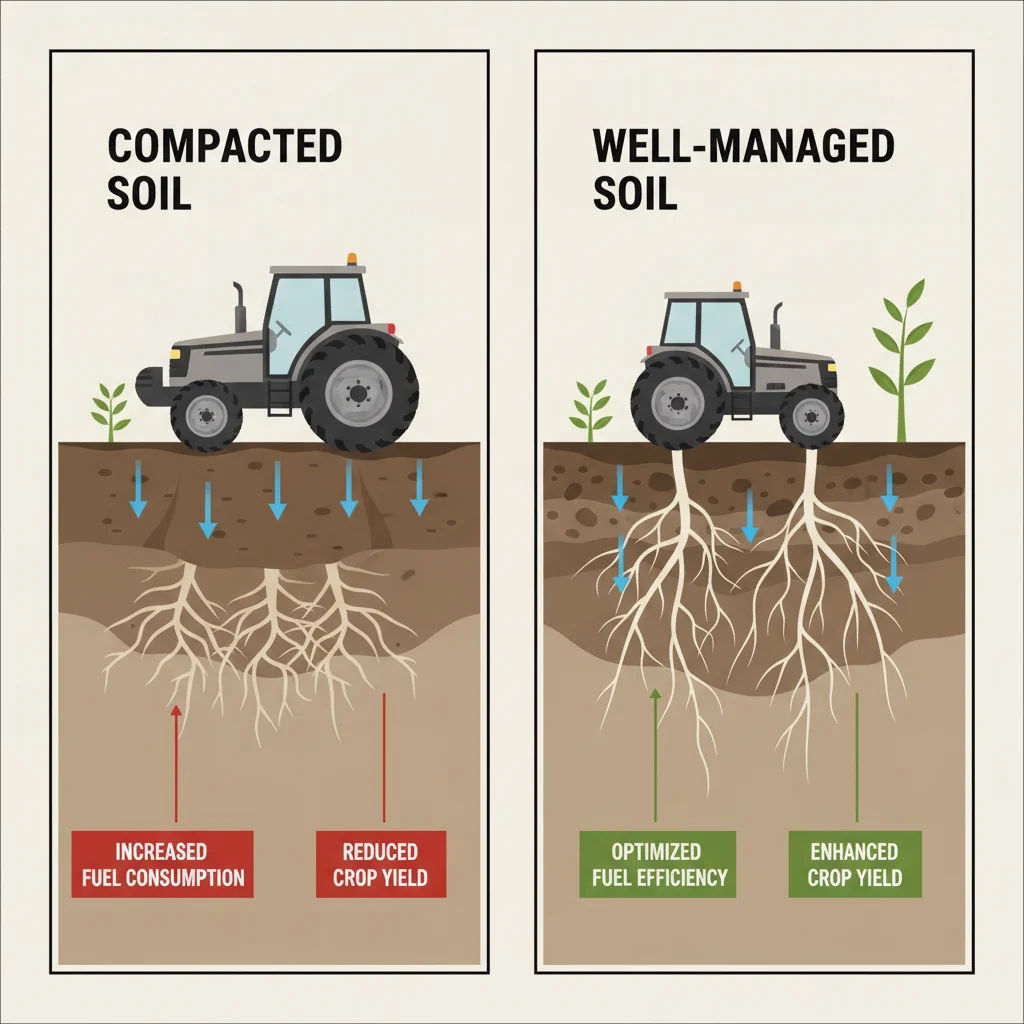

How does soil compaction affect tractor efficiency?

Soil compaction from heavy tractors reduces farm efficiency by restricting root growth and water infiltration, lowering yields and increasing fuel use for tillage. Compact tractors, proper tire selection, and controlled traffic practices minimize compaction, potentially boosting output efficiency by 30% and reducing fuel consumption by 5–10% in managed fields and orchards.

I’ve seen soil compaction9 quietly drain efficiency from farms in places like Bolivia and Kenya. When a heavy tractor rolls over wet ground, it squeezes the earth, forming a dense layer about 15 to 25 centimeters deep. Roots struggle to push through, and water can’t move down easily. The effect? Yields drop, and every tillage pass takes more fuel and power—sometimes up to 10% more. I met a distributor in Kyrgyzstan who noticed his customers burning extra diesel after just one rainy season with a 90HP 4WD tractor. They weren’t overworking the machine, but the soil itself had become harder to work. That’s the hidden cost of compaction.

Compact tractors—think 45 to 60HP units with narrower frames—apply less ground pressure. On small fields or orchards, especially in Latin America, I’ve measured up to 30% better output per hectare when operators stick to lighter machines or limit their passes. Wider tires or duals also help spread the load, reducing rutting and slippage. I always suggest checking tire pressures and only working ground that’s firm enough to hold the tractor without deep tracks. For tillage, try to keep wheel slip in the 8–15% range. That’s where you get the best balance between grip and soil protection.

Controlled traffic makes a big difference as well. Some Kazakh growers now keep all tractors running on the same set of tracks, and they’ve told me it stabilized their yields and cut fuel bills by around 5–10%. Managing compaction isn’t extra work—it’s what keeps your tractor, and your crops, working efficiently.

Soil compaction caused by repeated tractor passes increases rolling resistance, which forces the tractor engine to work harder and results in higher fuel consumption during field operations.True

Compacted soil creates a denser surface, making it more difficult for tractor tires to move efficiently. This means the tractor must exert more power, especially during tillage or planting, leading to increased fuel use and reduced operational efficiency.

Using a heavier tractor on compacted soil will always improve traction and reduce fuel use compared to a lighter tractor.False

While heavier tractors can sometimes provide more traction, on compacted or wet soils they often worsen compaction and increase rolling resistance, which actually raises fuel consumption and decreases efficiency rather than improving it.

Key takeaway: Managing soil compaction is essential for maximizing tractor efficiency. Using compact tractors, appropriate tires, and traffic control strategies preserves soil structure, stabilizes yields, and lowers draft power and fuel requirements, making these practices particularly valuable for intensively managed small fields and orchards in emerging markets.

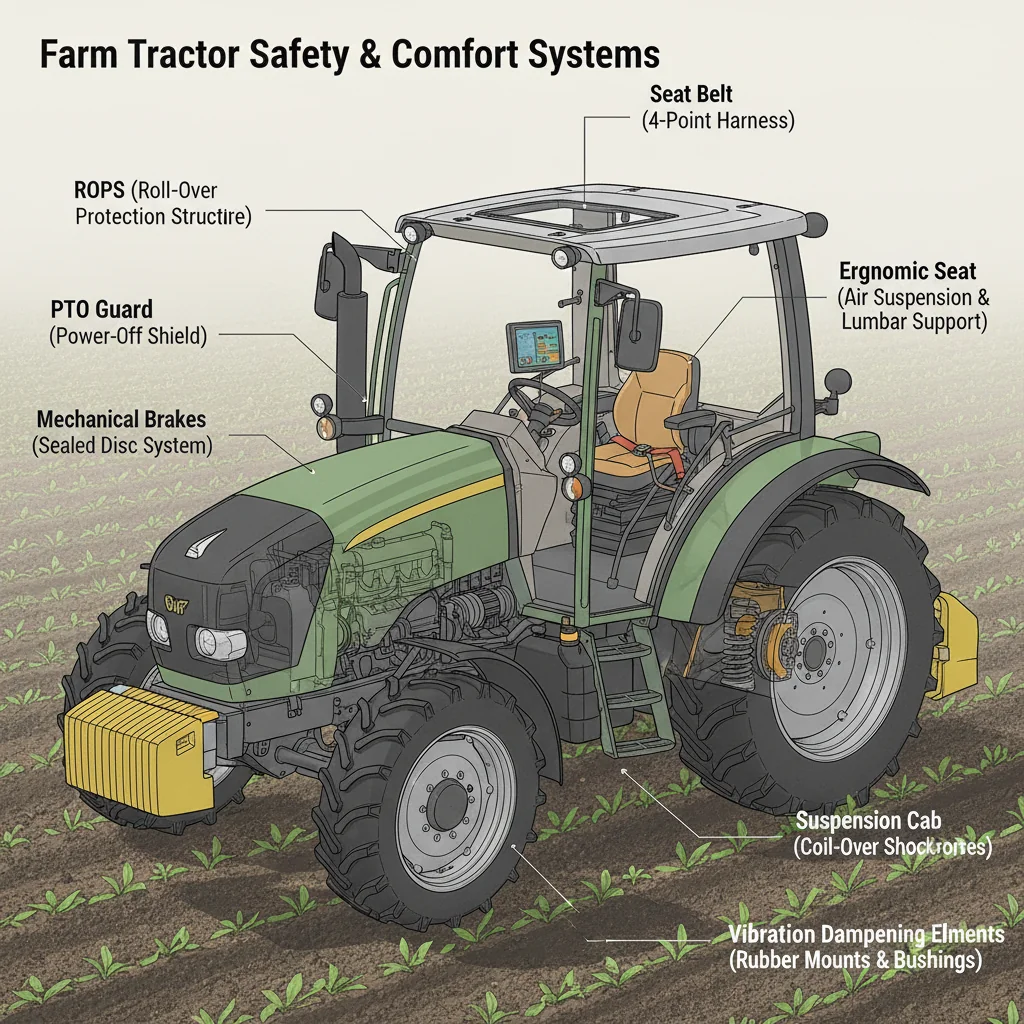

How do safety and comfort boost tractor efficiency?

Safety features like ROPS10, seat belts, PTO guards, and reliable brakes are essential for maintaining farm productivity by preventing accidents and machine downtime. Operator comfort11—via cab suspension, ergonomic seats, and vibration reduction—reduces fatigue, supporting better decision-making, straighter passes, and consistent daily output, especially during long work hours.

Let me share something important about tractor safety and comfort—these aren’t just “nice to have” features. I’ve seen what happens when they’re ignored. In Bolivia last year, a customer tried to save costs by buying a basic 75HP tractor with no ROPS or seat belt. Within weeks, a rollover on a muddy hillside left the machine out of service for over a month and the operator nursing a serious injury. That single incident delayed their harvest and cost them more than the price difference for proper safety equipment. ROPS (Roll-Over Protective Structure) and a working seat belt make a real difference—especially in hilly regions or where trailer loads are heavy. For any tractor above 50HP, I always suggest making these non-negotiable.

Comfort may sound secondary, but after watching operators in Ghana during peak season, I’ve changed my mind. On sugarcane farms, drivers often log 12-hour days, sometimes in 35°C heat. Cabs with basic suspension, decent seats, and vibration isolation aren’t luxury—they’re a necessity. When the seat is hard or the cab vibrates, fatigue builds fast. I’ve seen operators make poor gear shifts, miss straight lines, or even overlook implement issues after a long, rough shift. Over weeks, this adds up to wasted fuel, uneven fields, and more breakdowns.

The reality is, a safe and comfortable operator is a productive one. I recommend always checking for PTO shaft guards, reliable brakes, and hitch points that match your implements. Training matters too—remind your crew to disengage PTO before leaving the seat. These small steps keep work moving and people safe across the whole season.

Tractors equipped with ergonomic seating and climate control reduce operator fatigue, enabling longer and more consistent work periods during critical planting and harvesting windows.True

Ergonomic design and cabin comfort features help maintain operator alertness and productivity, especially during long shifts, which directly supports timely farm operations and reduces the risk of costly delays.

The presence of safety features like ROPS and seat belts has no measurable impact on farm productivity because operators can simply work more cautiously to avoid accidents.False

Relying solely on operator caution is not sufficient; accidents can still occur due to unforeseen circumstances. Safety features like ROPS and seat belts not only protect the operator but also minimize downtime and equipment loss, both of which are critical for maintaining farm productivity.

Key takeaway: Prioritizing tractor safety features and operator comfort directly supports sustained productivity in real-world conditions. Reliable ROPS, seat belts, and proper PTO shielding help prevent severe incidents, while comfortable, low-fatigue cabins enable operators to work efficiently throughout long shifts and variable weather windows.

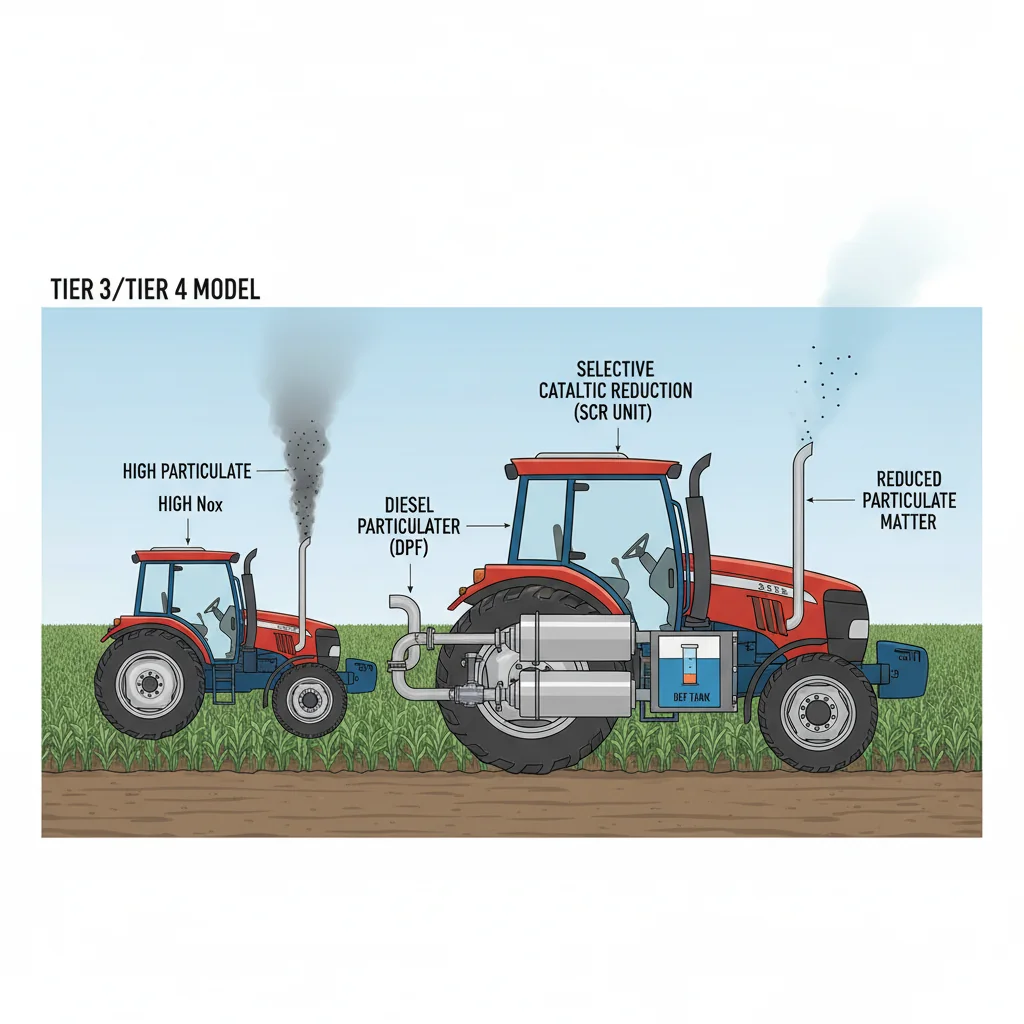

How Do Emissions and Future-Ready Features Influence Tractor?

Tightening global emissions standards require advanced after-treatment systems in new tractors, such as Stage V technology12, to cut particulate matter and NOx versus older Tier 3/Tier 4 models. Alternative-fuel and electric tractors lower greenhouse gases and running costs, while future-ready platforms support remote diagnostics and upgrades, impacting purchase decisions and long-term value.

Many buyers ask me if investing in Stage V or alternative-fuel tractors13 is worth the higher upfront cost. Here’s what I see on the ground: in places like Peru, stricter emissions rules are coming fast. Two years ago, a distributor I know in Lima faced heavy fines for importing Tier 3 models that didn’t meet updated standards. The result? They had to retrofit expensive after-treatment systems—costing thousands per unit—just to get the tractors released from customs.

The impact isn’t just about compliance. Cleaner-burning engines and after-treatment systems, like diesel particulate filters and SCR, mean less downtime and fewer clogged injectors if you use good fuel. I’ve seen methane-powered tractors in Brazil drop fuel costs by around 30% when farmers have access to local biogas. Electric tractors are showing up too—mainly in small livestock farms near cities where charging is easier. But for most rural areas, high-voltage charging and battery costs still make diesel the practical choice for now.

When looking at future-ready features, I advise importers and large farmers to consider these points:

- Local emissions regulations – Check what’s required now, and what’s changing in 3–5 years.

- Fuel type and availability – Diesel is still king in most regions, but biogas or electric makes sense if infrastructure exists.

- Upgrade paths – Some models let you add remote diagnostics or update software later, keeping the tractor current.

- Resale value – Tractors with modern emissions tech and digital features often fetch more on the used market.

I suggest weighing the higher initial price against long-term savings and future-proofing. That’s how you avoid expensive surprises down the road.

Stage V tractors often come equipped with advanced telematics and diagnostics systems that can proactively alert operators to potential maintenance issues, reducing unplanned downtime in farm operations.True

Stage V compliance often drives manufacturers to include modern electronic controls and monitoring systems. These features enable predictive maintenance and remote diagnostics, which help farmers address issues before they escalate and improve operational efficiency.

Tractors that meet higher emissions standards, like Stage V, always consume less fuel than older Tier 3 models under all working conditions.False

While Stage V tractors are designed to reduce harmful emissions, their fuel consumption is not universally lower. In some scenarios, the after-treatment systems required for emissions compliance can increase fuel use, especially under heavy loads or frequent idling.

Key takeaway: Modern tractors with advanced emissions controls, alternative-fuel options, and digital upgrade paths improve compliance and efficiency. Buyers should balance initial costs with long-term savings, local regulations, and the ability to access new features, ensuring both operational and resale advantages over the equipment’s lifecycle.

Conclusion

We’ve looked at how tractors can multiply your field capacity and make key farm tasks more efficient compared to manual or animal labor. From what I’ve seen, the biggest difference comes not just from the engine size, but from choosing a model that matches your real working conditions—soil type, implement needs, and, most importantly, parts availability. I’ve watched too many buyers fall into “parts roulette,” only to face weeks of downtime during the busy season. If you have questions about specific models, attachments, or want honest input based on what’s worked for farmers in your region, feel free to reach out. Every farm is different—choose what actually works for your needs.

References

-

Explore how primary tillage improves soil preparation and boosts crop yields with expert insights and practical examples. ↩

-

Understand PTO’s role in running implements like sprayers and mowers, crucial for maximizing tractor versatility and farm productivity. ↩

-

Learn why compact tractors excel at multi-tasking and increase efficiency by up to 30% on smaller farms with tight spaces. ↩

-

Learn how 4WD improves traction by 10–20% and reduces fuel consumption in challenging field conditions, backed by real-world examples. ↩

-

Explains how matching tractor horsepower to implements and soil type reduces fuel use and breakdowns, boosting farm productivity. ↩

-

Details the benefits of operating tractors within 60–80% power range, including faster work, lower fuel consumption, and fewer repairs. ↩

-

Expert analysis on how longer service intervals reduce downtime and maintenance expenses, improving tractor efficiency and yield. ↩

-

Explore how improved fuel efficiency reduces refueling stops, boosting tractor uptime and operational productivity on large farms. ↩

-

Explore how soil compaction limits root growth and water infiltration, reducing yields and increasing fuel consumption in farming. ↩

-

Detailed insights on Roll-Over Protective Structures (ROPS) highlight how they prevent accidents and reduce costly downtime on farms. ↩

-

Explores how ergonomic seats, cab suspension, and vibration reduction reduce fatigue and improve productivity during long work hours. ↩

-

Explore how Stage V technology reduces particulate matter and NOx emissions, meeting strict global standards with advanced after-treatment systems. ↩

-

Learn about methane-powered and electric tractors that lower emissions and fuel expenses, with real-world examples from Brazil and urban farms. ↩