Tractor Oil Change Intervals: Manufacturer’s Guide to Avoid Costly Mistakes

A few months ago, a distributor from Kenya sent me photos of an engine seized solid—barely 1,200 hours on the clock. His mistake? He waited for the “next 200-hour interval” but forgot the oil had already been in for nearly two years. It’s a common and costly oversight, especially in lower-hour fleets.

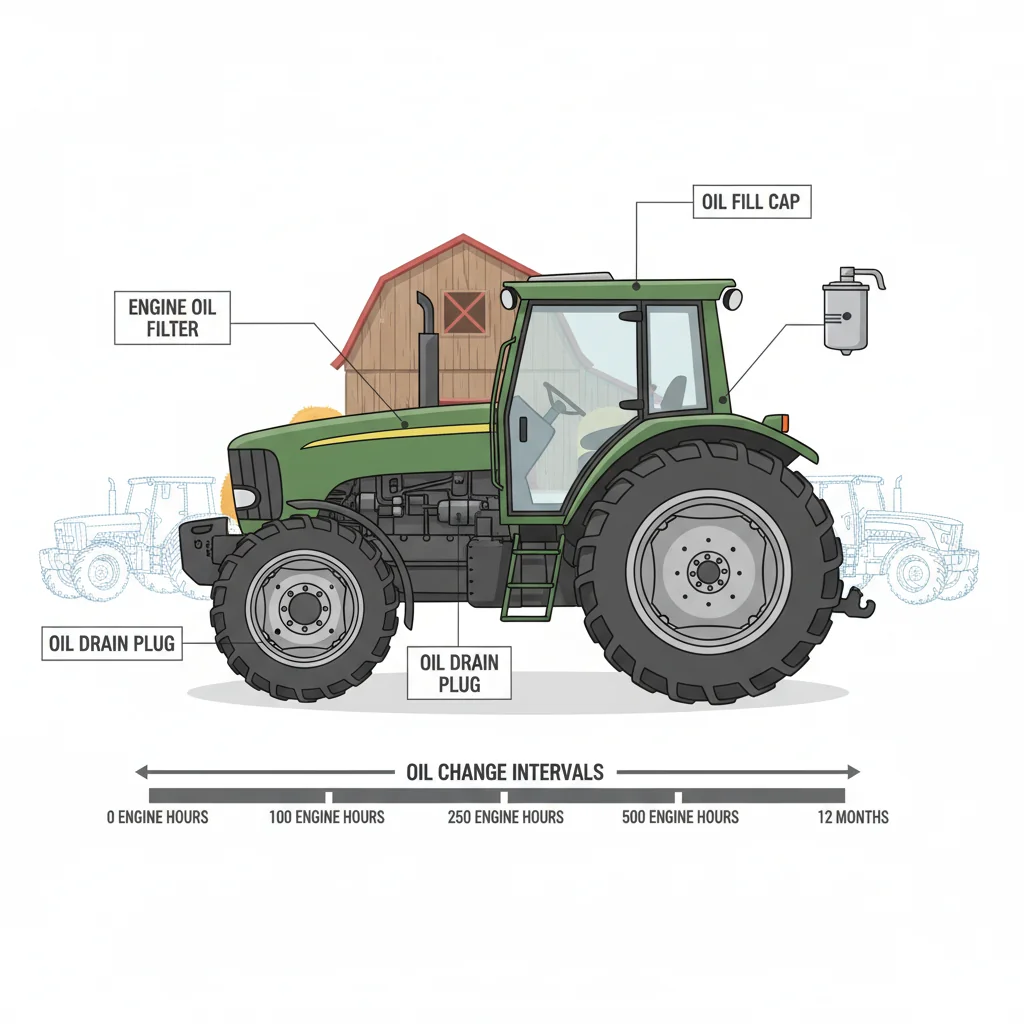

Tractor engine oil change intervals1 are determined by both engine hours and elapsed calendar time to prevent lubricant degradation and mechanical wear. Most manufacturers specify changes every 250–500 hours or every 12 months, whichever occurs first, with older or minimally filtered tractors often requiring changes at 100–200 hours. The 50-hour break-in oil change is critical after a new or rebuilt engine is placed into service, as it removes initial wear metals, assembly debris, and combustion byproducts generated during early component seating—preventing accelerated wear and premature engine damage.

What are standard tractor oil change intervals?

Most modern diesel tractors require engine oil changes2 every 250–500 engine hours or every 12 months, whichever comes first. Older models or basic filtration systems may need oil changes at 100–200 hours. Following both the hour and 12-month limits prevents harmful oil degradation3 and costly engine damage.

Most people don’t realize that engine oil change intervals are not just about the hours worked. I often get questions from buyers in Kenya and Brazil who say, “My tractor only runs 120 hours per year—do I really need to change the oil every year?” The answer is yes. Even if the hour meter is low, oil still degrades over time. Moisture, soot, and acids build up in the crankcase, especially when tractors sit unused for weeks during the dry season.

Let me share something important about older tractors or basic models with simple filtration systems. I worked with a customer in southern Kazakhstan who ran a fleet of 65HP units—no fancy electronics, just straightforward mechanical engines. Their manual called for oil changes every 200 hours or once a year. One year, they pushed it to 18 months because the tractors only clocked about 130 hours. By the next season, they saw thick, dark oil and increased engine noise. That led to a bearing failure in one machine, costing them at least two weeks of downtime during peak planting.

Here’s what matters most: always follow both the hour interval and the 12-month limit, whichever comes first. If the manual says 250 hours or 12 months, treat those numbers as a ceiling—not a target to stretch. Exceeding either limit risks heavy wear—think pitted bearings, clogged oil passages, and even turbocharger damage in higher-power models. I suggest setting reminders or marking a service calendar so you don’t miss these intervals. It’s a simple habit that saves a lot of trouble down the road.

Tractor engine oil should be changed at least once per year, even if the tractor has low annual operating hours.True

Oil degrades over time due to moisture, soot, and acids accumulating, especially when tractors sit unused for long periods. Annual changes prevent long-term engine damage, regardless of hours worked.

If a tractor is only used for a few hours each month, it is safe to skip annual oil changes and rely solely on the hour meter for maintenance scheduling.False

Oil condition deteriorates with time as well as use, so relying only on the hour meter ignores the impact of contaminants and moisture that accumulate during periods of inactivity.

Key takeaway: To maintain engine reliability and prevent wear, always follow both the engine hour interval and the 12-month maximum when scheduling tractor oil changes. Exceeding either limit allows contaminants to build up, risking serious engine damage and increased maintenance costs, especially in older or heavily-used tractors.

Why is the 50-hour oil change critical?

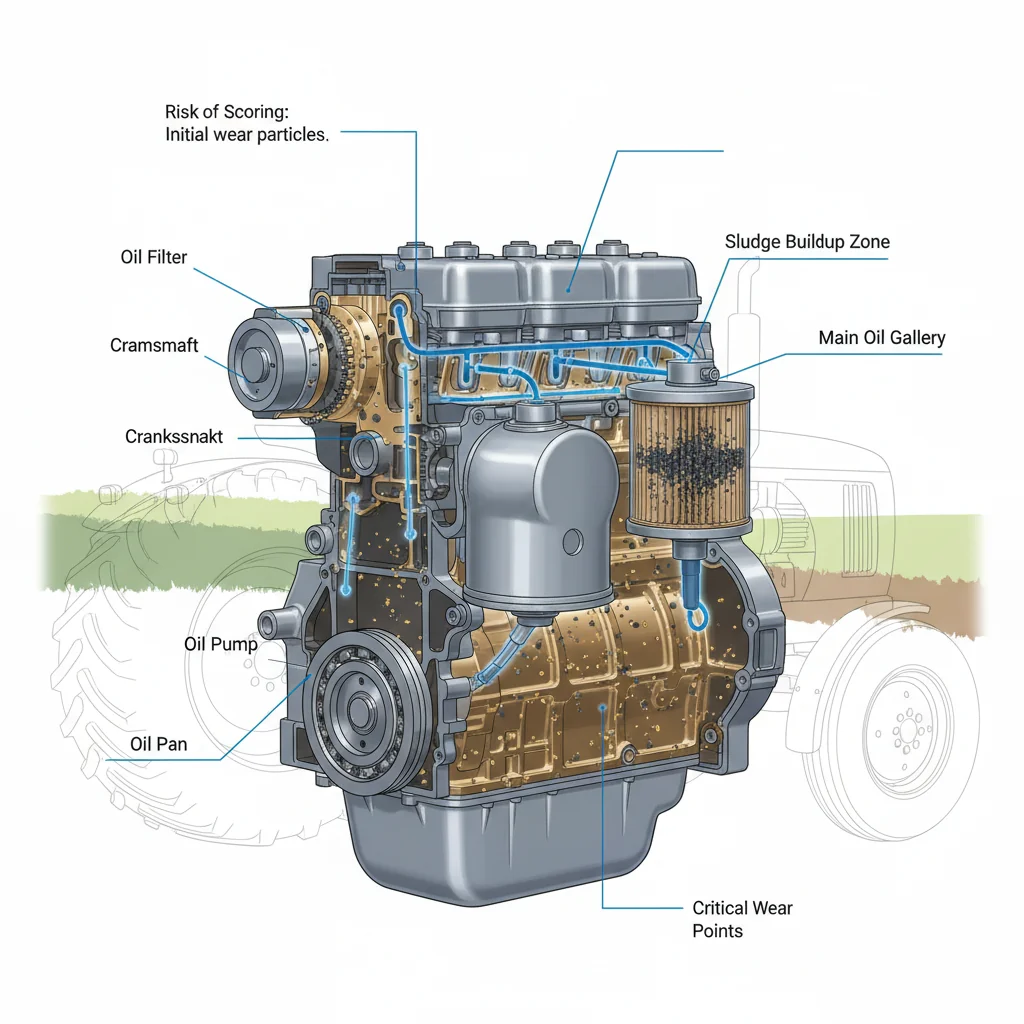

A 50-hour oil change is essential for new or rebuilt tractor engines because initial use generates microscopic metal particles and debris4 as engine components wear in. Delaying this service allows contaminants to circulate, risking scoring, early sludge buildup, and increased oil consumption. Manufacturers require this change to ensure engine longevity and reliability.

Let me share something important about the 50-hour oil change—this is not just a box to tick on your maintenance schedule. The first 50 hours of running a new or rebuilt engine are when the internal components wear in and mate together. During this period, fine metal shavings and leftover machining debris work loose. Even if the oil still looks clean, those tiny particles are there, and they keep circulating through your engine. That’s where real damage can start.

A few years ago, I worked with a distributor in northern Kazakhstan who bought a batch of 80HP conventional tractors. Some customers skipped the 50-hour service, thinking it was optional. Within six months, several units developed early bearing noise and higher oil consumption. When we drained the oil from one affected tractor, we found visible metallic flecks—clear proof that internal wear debris hadn’t been removed in time. The repair costs ended up much higher than a simple oil and filter change would have been.

From my experience, most manufacturers call for that first oil and filter change right at 50 hours, then a second one somewhere between 150 and 200 hours before moving to the standard 250–500-hour interval. If you delay, you risk scoring the cylinder liners or causing premature sludge buildup. I always suggest scheduling the first oil change before you even take delivery—make it part of your setup checklist. This small step goes a long way to protect your engine, cut down on oil burning, and avoid expensive repairs down the road.

The 50-hour oil change is crucial because initial engine break-in generates microscopic metal particles that standard oil filters may not fully capture, increasing wear if not removed early.True

During the break-in period, friction between new engine components causes fine metal debris to circulate in the oil. Many standard oil filters are not designed to catch these ultra-fine particles, making the early oil change essential to prevent accelerated internal wear.

If the oil looks clean at 50 hours, it's safe to delay the first oil change until the next scheduled interval.False

Even if the oil appears clean, harmful metal particles can be suspended in the oil and are not always visible to the naked eye. Delaying the first oil change increases the risk of these abrasive particles damaging engine surfaces.

Key takeaway: The 50-hour oil and filter change is non-negotiable for new or rebuilt tractor engines. Performing this service on schedule prevents abrasive contaminants from causing engine damage and ensures optimal performance, helping avoid early wear, oil consumption issues, and expensive repairs in the future.

When Should Tractor Oil Changes Be Shortened?

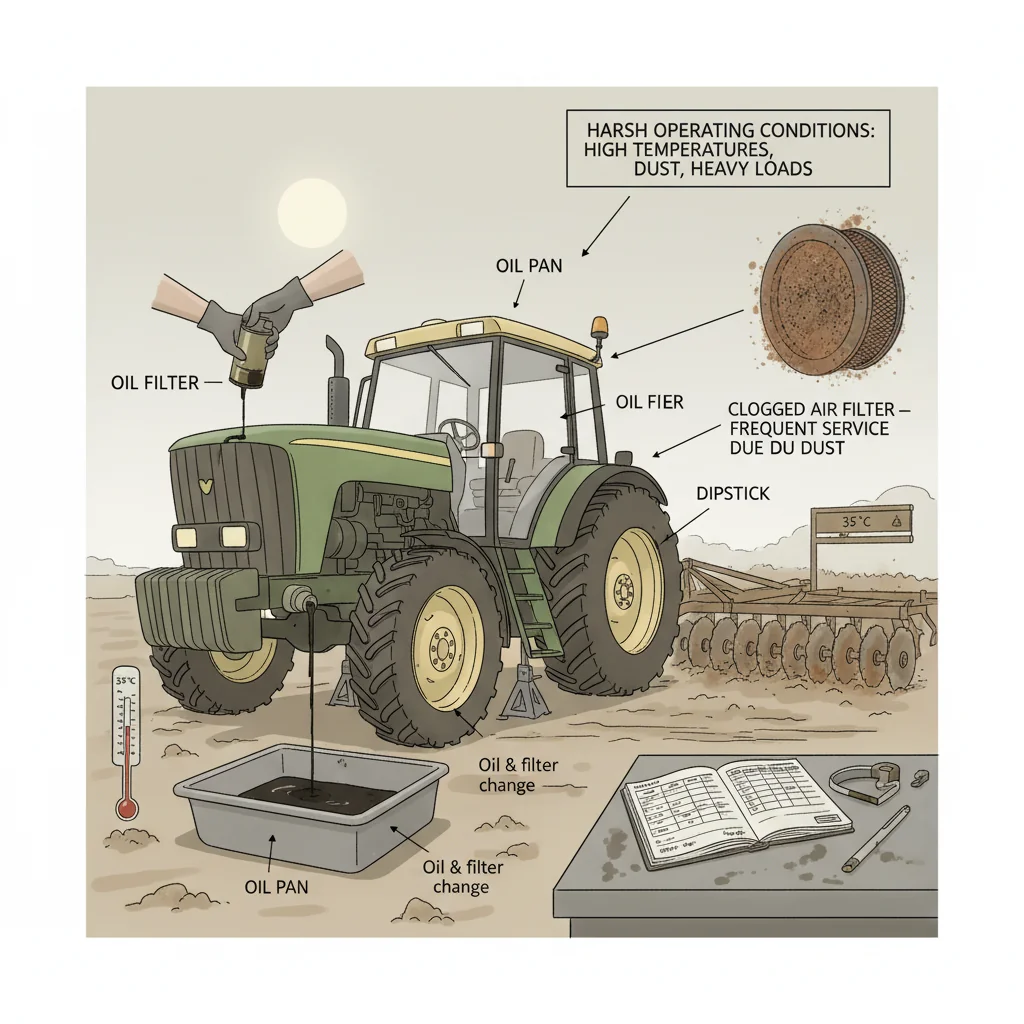

Tractor oil change intervals should be shortened by 20–40% under harsh conditions such as heavy tillage, excessive idling, high temperatures, or operation in fine dust. Manufacturer manuals provide an upper limit, but demanding workloads and frequent air filter clogging5 require more frequent servicing, sometimes every 180–240 hours instead of 300.

Here’s what matters most when deciding how often to change tractor oil—your conditions on the ground make all the difference. Manufacturer manuals give you a maximum interval, usually around 300 hours for conventional models. But that’s based on ideal lab scenarios, not heavy plowing in 40°C heat or working in fields full of fine dust. I’ve seen farms in Kazakhstan run the same 90HP 4WD units for 400 hours between changes on light transport jobs. But when those same tractors do deep tillage in sandy soils, oil quality drops fast and filters clog up much sooner.

Last season, a customer in northern Kenya called me after his 75HP tractor started losing power just 180 hours after an oil change. His team had been running rotary tillers in dry, dusty conditions. When we checked, the oil was already thick and dark, and the air filter was almost blocked. In these cases, waiting for 300 hours just doesn’t work—you risk engine wear, higher fuel consumption, and even costly failures. I always suggest checking both the oil and air filter at every 100-hour interval if you’re working in harsh conditions. If the air filter is dirty or oil looks dark, shorten your interval by at least 20–40%.

The reality is, there’s no single rule that fits every farm. Light work on clean ground allows you to stretch oil changes closer to the manual’s upper limit. But for heavy, dusty, or hot conditions, treat that number as a ceiling, not a target. Reliable performance starts with adjusting service to your actual workload.

Operating a tractor in extremely dusty conditions can require oil changes much sooner than the manufacturer's maximum interval, even if the engine hours are below the recommended limit.True

Heavy dust accelerates oil contamination and wear, making it necessary to shorten oil change intervals to maintain engine protection, regardless of hours run.

Tractor oil change intervals should always match the manufacturer’s maximum recommendations, regardless of working conditions.False

Manufacturer intervals are based on ideal conditions; real-world factors like heat, load, and dust often require more frequent oil changes to prevent engine damage.

Key takeaway: Tractor oil change intervals are not one-size-fits-all. Operators should treat the manufacturer’s maximum as a ceiling and reduce intervals significantly in dusty, hot, or heavy-load conditions to avoid costly engine wear and maintain reliability, especially for conventional tractors in emerging markets.

How does oil type affect change intervals?

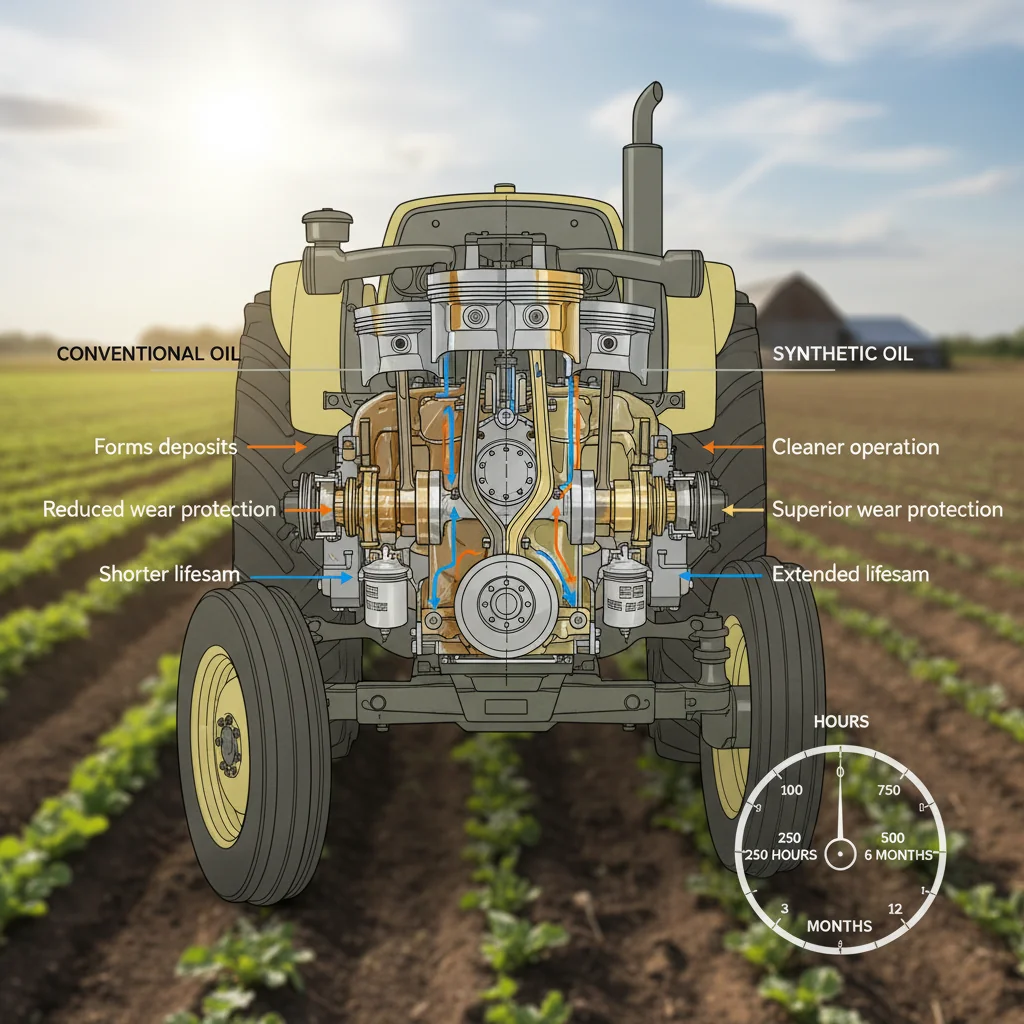

Oil quality and type directly impact safe oil change intervals in farm tractors. Oils meeting or exceeding OEM-specified API grades6, paired with quality filters, support maximum recommended hours. However, no oil—conventional or synthetic—should exceed the 12-month change interval due to risks from oxidation and moisture, regardless of engine use.

The biggest mistake I see is farmers assuming that “better” oil means you can stretch oil changes forever. That’s not how it works. Oil type—conventional, semi-synthetic, or full synthetic—mainly affects how close you can run to your tractor’s recommended hour limit, not whether you can skip the annual change. In places like Bolivia and Ghana, I’ve seen engines damaged because owners left synthetic oil in for two or even three years. The oil still looked clean, but moisture and oxidation had already started breaking it down. No oil, no matter what it says on the drum, is immune to time.

From my experience, using an oil that meets or exceeds the OEM-specified API grade (like CH-4 or CI-4 15W-40), plus a quality filter, is the safest way to reach the full recommended interval—often 300–500 hours for a 75HP tractor. If you’re running on generic or bargain oil, I suggest sticking to 200–300 hours. In Kenya, one distributor told me he cut engine failures in half just by keeping smallholder tractors on a tighter oil change schedule when using local brands.

Here’s a simple comparison table I share with customers deciding between oil types:

| Oil Type | Typical Safe Interval (Hours) | 12-Month Cap | Best Use Case | Risk if Overextended |

|---|---|---|---|---|

| Conventional | 200–300 | Yes | Older tractors, basic filtration, low cost | Sludge formation, accelerated wear, corrosion |

| Semi-Synthetic | 300–400 | Yes | Mixed fleets, moderate annual hours | Oxidation, moisture buildup, viscosity loss |

| Full Synthetic* | 400–600 | Yes | High-load use, turbo engines, severe duty | Oxidation, moisture contamination, acid buildup |

Full synthetic oil resists thermal breakdown better than conventional oil, allowing tractors to safely operate closer to the maximum recommended oil change interval set by the manufacturer.True

Full synthetic oil has greater stability at high temperatures and improved resistance to oxidation, so it provides better protection as the oil ages. This lets operators confidently reach, but not exceed, the manufacturer's specified interval.

If you use full synthetic oil, you can safely skip annual oil changes regardless of hours run or climate.False

Even the best synthetic oil degrades over time due to moisture, oxidation, and contamination, especially in humid or harsh climates. Annual oil changes are necessary to prevent engine damage, no matter the oil type.

Key takeaway: Always follow OEM hour and annual limits for tractor oil changes. Using oil that meets the correct API grade allows safe use of longer intervals, but never exceed 12 months between changes, even with synthetic oils. Conservative intervals are safest with generic or bargain oils.

How does oil analysis refine change intervals?

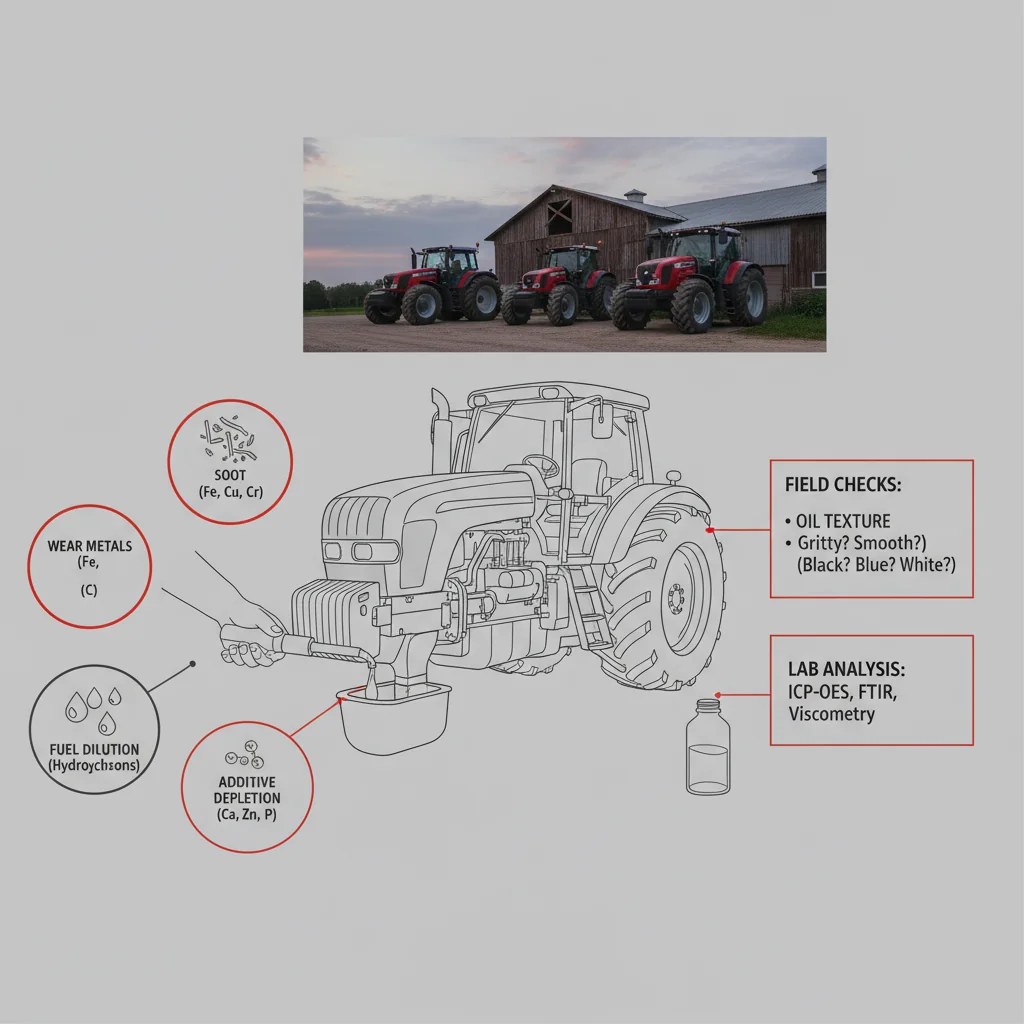

Oil analysis detects wear metals, soot, fuel dilution7, and additive depletion in tractor engines, allowing precise adjustment of oil change intervals. High-hour or multiple-tractor fleets may safely extend intervals to 400–600+ hours if lab results are favorable. Field checks—oil texture, exhaust color, and top-up frequency—complement lab data for cost-effective maintenance decisions.

Last month, a fleet operator in Kazakhstan asked me why his 110HP tractors needed oil changes every 250 hours, while a neighbor claimed 500-hour intervals with similar machines. That’s where oil analysis makes a real difference. By sending a small oil sample to a lab, you get hard numbers on wear metals, soot, and even fuel dilution. I’ve seen cases where high-quality oil and moderate conditions let some engines safely reach 600 hours between changes. But I’ve also spotted trouble—like high copper or excessive soot—at just 200 hours, especially with poor diesel or heavy loads.

For smaller farms, labs aren’t always practical, so field checks become essential. I always suggest rubbing a drop of warm oil between your fingers—if it feels gritty or smells burnt, it’s time to shorten the next interval by 20 to 30 percent. In Bolivia, a customer running older 80HP units noticed black smoke on light work. That’s a sign not to stretch intervals, and often points to a deeper engine issue. Watching your top-up rate is another field trick. If you’re adding more than 10% of the sump capacity before the next change, look for leaks or internal wear.

Here’s the thing—engine oil is cheaper than an overhaul, but unnecessary changes cost real money in high-hour fleets. Using lab data when possible, and simple field checks always, helps you move from guesswork to solid decisions. I recommend recording your results and building a pattern over time. That’s how you find the safest, most cost-effective interval for your tractors.

Oil analysis can reveal elevated levels of silicon in engine oil, which often indicates dust or dirt ingress past the air filtration system.True

Detecting silicon through oil analysis helps identify air filtration issues before they cause significant engine wear, allowing timely maintenance adjustments to extend oil and engine life.

Once oil analysis confirms the oil is still within acceptable parameters, it is safe to indefinitely postpone oil changes regardless of engine operating conditions.False

Even if oil analysis shows acceptable results, oil must still be changed at reasonable intervals because factors like additive depletion, oxidation, and environmental contamination can eventually render the oil ineffective, especially under harsh operating conditions.

Key takeaway: Using oil analysis and simple field checks enables tractor operators to move from guesswork to data-driven oil change intervals. This minimizes unnecessary maintenance costs while protecting engine health, especially important in high-hour operations or where service resources are limited.

How often should low-use tractors get oil changes?

Low-use and seasonal tractors, such as orchard or backup units, should have engine oil changed at least once every 12 months, regardless of hours used. Relying solely on hour intervals can lead to oil degradation from moisture and oxidation, risking internal rust8 and costly engine damage.

I've worked with customers who made this mistake—especially in places like Peru and western Kazakhstan, where seasonal work means a tractor might sit for months at a time. They see the manual say "change oil every 250 hours" and figure they're safe, since their machine only runs 100 hours a year. But the reality is, oil doesn't just break down from running hours. It also absorbs moisture from the air, especially in unheated sheds or humid climates. That moisture leads to acid buildup and internal rust, even when the engine is off.

Let me break down why an annual oil change matters for low-use or backup tractors:

- Moisture buildup: Every cold start and cool-down can pull condensation into the engine. Left unchanged, this water mixes with oil and forms acids.

- Oxidation risk: Even with low hours, oil sitting for a whole year starts to oxidize—weakening its protective properties.

- Internal rust: I've seen engines from orchard tractors in Bolivia with visible rust inside, simply because the oil sat too long and lost its ability to protect.

- Avoiding “second-year surprise” repairs: Skipping annual changes is a hidden cost. Internal corrosion can mean expensive overhauls later.

From my experience, the best timing is just before your main season starts. That way, you have fresh oil and filter protecting your engine during demanding work. Don’t rely on hours alone—especially for tractors that see light use. It’s a simple habit, but it saves a lot of trouble in the long run. I always suggest making the calendar your main guide for oil changes on any low-use machine.

Key takeaway: For low-use or seasonal tractors, always prioritize an annual oil change, even if the engine has not reached the manufacturer’s suggested hour interval. This prevents moisture buildup, acid formation, and internal rust, reducing the risk of long-term engine damage and costly repairs.

Why Are Fuel Filters Vital for Tractors?

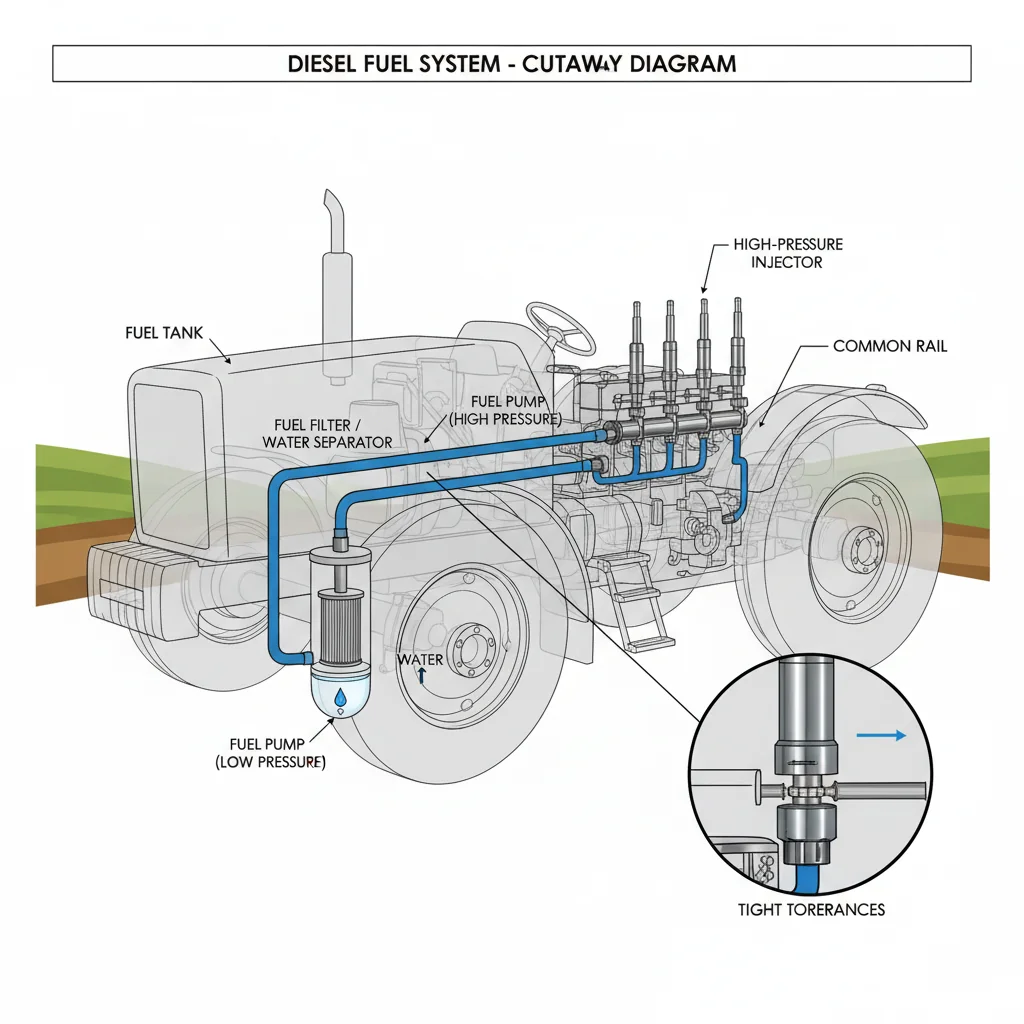

Fuel filters and water separators are crucial for protecting high-pressure common-rail diesel injectors, which operate at extremely tight tolerances. Even small amounts of dirt or water can cause injector and pump failures, leading to costly repairs. Annual fuel filter changes and frequent water trap draining are essential preventive maintenance for reliable tractor performance.

To be honest, the spec that actually matters for long-term tractor reliability isn’t always what’s printed on the engine cover—it’s the fuel system health. I’ve seen operators in Brazil and Kenya run 90HP and 120HP tractors with perfect oil change records, but forget to check the fuel filter for an entire year. The result? Suddenly, the engine won’t start, or worse, you get injector failures that cost as much as a full transmission overhaul. It only takes a few grains of dirt or a little water to destroy modern common-rail injectors, which work at pressures over 1,500 bar and have extremely tight tolerances.

Let me give you a real scenario from northern Kazakhstan. A customer bought a batch of new 100HP 4WD units for wheat seeding. Within six months, three tractors went down unexpectedly. We traced the problem to water in the fuel—condensation from half-filled storage tanks and missed water trap draining. The repairs cost more than $2,000 per injector set, not counting lost field time. After that, the farm started draining the sediment bowl every two weeks and swapping filters every 250 hours. They haven’t had another failure since.

I always suggest farmers treat fuel filter and water separator maintenance as critical, especially in places with humid weather or mixed fuel sources. Keep your diesel tanks full when possible—it reduces condensation. Check water traps and sediment bowls often, not just during annual service. And if in doubt about filter condition, replace it early. Clean fuel keeps your injectors, pumps, and engine oil healthy. That’s what really saves money and downtime in the long run.

Key takeaway: Regular fuel filter changes and water separator maintenance are more critical than engine oil intervals for modern diesel tractors. Contaminants in fuel can cause sudden, expensive injector failures, while clean fuel systems extend both injector and engine life. Prioritize proactive fuel system care to avoid major repairs.

How do tractor oil change intervals differ?

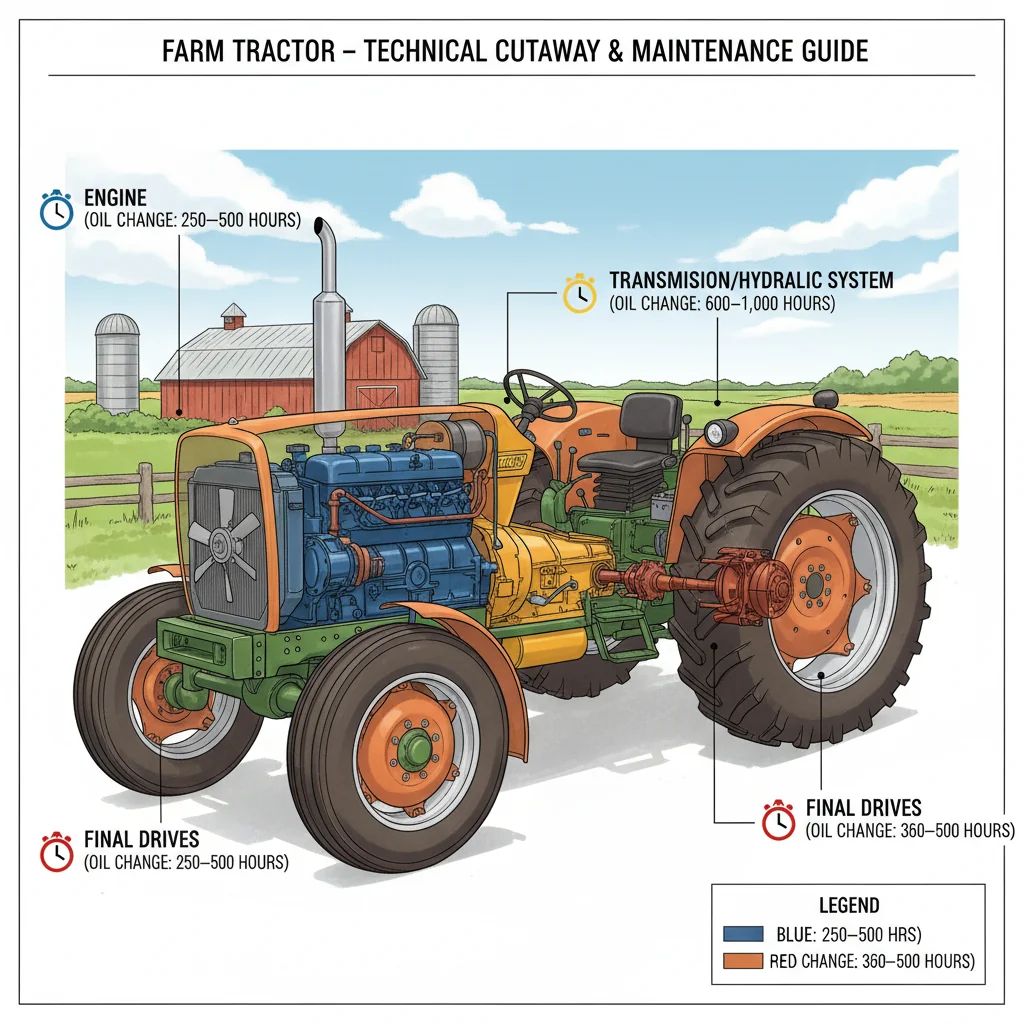

Tractor engine, transmission, and hydraulic oils have distinct change intervals. Engine oil is typically changed every 250–500 hours, while transmission and hydraulic oils9—often sharing a reservoir—require changes at 600–1,000 hours or every 2 years. Final drives and front axles have separate schedules, usually 300–500 hours, per manufacturer recommendations.

A question I get all the time from buyers in Africa and Latin America is: "Can I just change all the tractor oils at the same time?" Honestly, that approach sounds simple, but it’s not cost-effective—or safe.

Engine oil needs attention far more often, usually every 250 to 500 hours. This is because engine oil faces the hottest temperatures, constant combustion, and more contamination from dust and fuel residue. I’ve seen farmers in Kenya run a 90HP model for over 400 hours without changing engine oil, thinking the hydraulic oil interval is the same. The result? Sludge buildup, hard starting, and eventually, a costly repair that could have been avoided.

Transmission and hydraulic oils are a different story. On most conventional tractors—say, in the 70 to 120HP range—the transmission and hydraulics often share a reservoir. Their oil is more stable and can last 600 to even 1,000 hours, or roughly every two years. In Bolivia, I came across a fleet operator who changed transmission oil every time he did the engine, just to be "safe." He was wasting money—hydraulic oil isn’t cheap, and unnecessary changes add up fast. The only exception is the first change after break-in—usually at 50 hours—when metal particles from new gears need to be flushed out.

Don’t forget the final drives and front axles, especially on 4WD units. These have their own schedules, often every 300 to 500 hours. I always suggest keeping a clear log for each fluid type, not just the engine.

Transmission oil in tractors generally has a much longer change interval than engine oil because it operates at lower temperatures and is less exposed to contaminants like combustion byproducts.True

Transmission oil is primarily subjected to mechanical wear and does not face direct exposure to combustion or high heat, so manufacturers recommend changing it less frequently than engine oil.

It is safe and efficient to change the engine, transmission, and hydraulic oils in a tractor at the same interval, since they all degrade at a similar rate.False

Each type of oil in a tractor experiences different conditions and stresses; engine oil degrades faster due to heat and contamination, while transmission and hydraulic oils last longer, so synchronizing changes wastes resources and can risk engine damage.

Key takeaway: Tractor lubrication maintenance requires tracking separate change intervals for engine, transmission, hydraulic systems, and driveline components. Relying solely on engine oil schedules risks component damage or unnecessary expense. Always consult the manufacturer’s manual and maintain a clear service log for each fluid type.

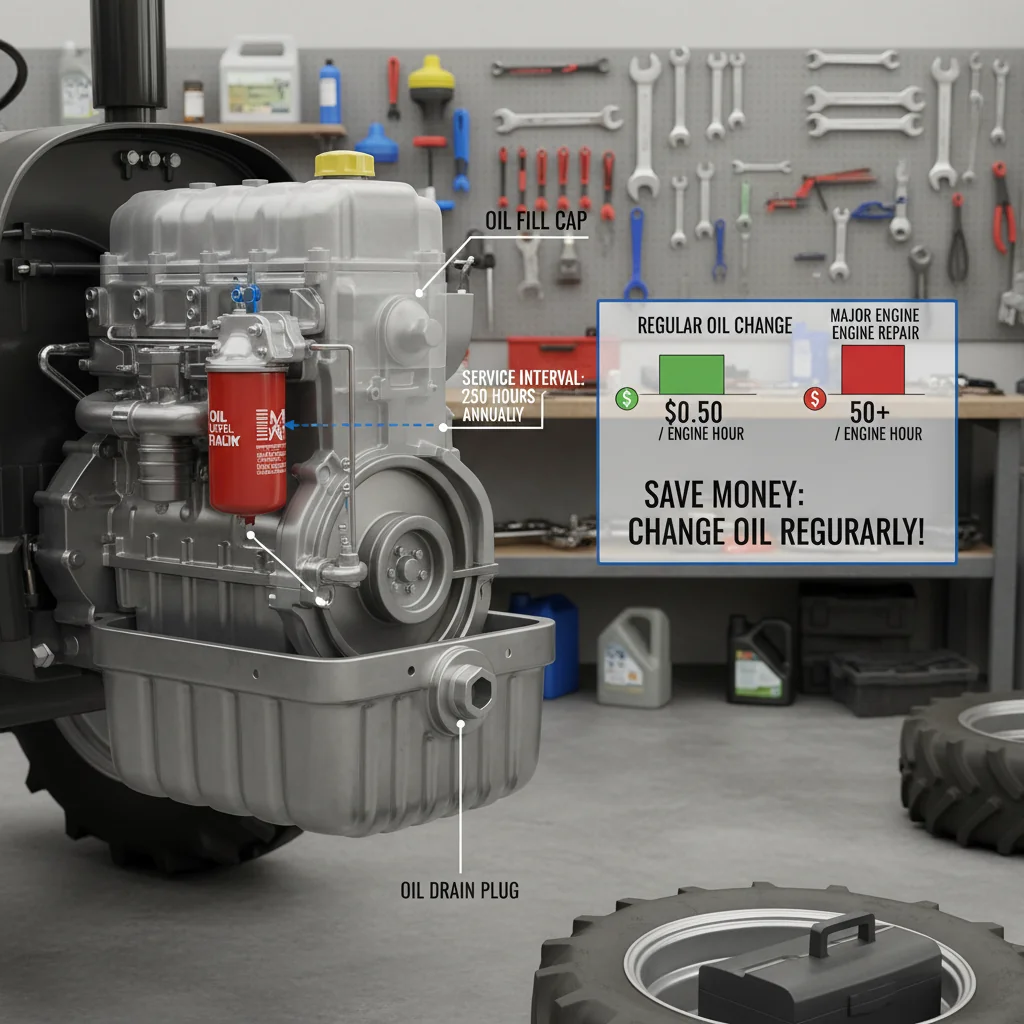

How do oil change intervals affect engine cost?

Engine oil change intervals directly impact total tractor lifecycle cost. Quality oil and filter changes typically cost far less per engine hour than major engine repairs. Following OEM intervals, adjusting for harsh or dusty conditions, and using oil analysis on high-hour tractors can minimize both unnecessary servicing and costly engine wear.

Here's the thing—many buyers worry about the upfront cost of engine oil, but overlook what happens if they stretch intervals too far. I’ve seen this firsthand on farms in Bolivia and Nigeria. One customer ran a 100HP tractor hard in dusty fields, pushing oil changes to 250 hours because filters were expensive locally. After two seasons, they faced a major overhaul: scored liners, worn rings, and low compression. That repair cost over $3,000—money that could have covered years of proper oil and filter changes.

From my experience, the real cost difference comes down to cents per engine hour versus thousands in repairs. Most 100HP tractors hold about 8–10 liters of oil; a quality oil and filter change usually runs $60–90 if you’re sourcing parts wisely. If you follow a 100-hour interval, that’s less than $1 per hour—almost nothing compared to downtime and engine rebuilds. In tough conditions—high dust, heavy loads, or old fuel—shortening intervals by 20–30% makes sense. I always suggest checking for oil darkening, high soot, or metal shavings on the dipstick as early warning signs.

But you can also go too far the other way. In Peru, I met a rice farmer changing oil every 50 hours on a lightly loaded 85HP machine. He wasted time and money—no improvement in engine life. My advice: stick to the manufacturer’s schedule, adjust for harsh use, and use oil analysis on high-hour machines if possible. Think long-term. The right interval saves far more than it costs.

Extending oil change intervals in tractors operating in dusty environments can lead to accelerated wear of engine components like cylinder liners and piston rings, resulting in higher long-term maintenance costs.True

Dusty conditions increase contamination in the oil, which, if not changed regularly, enhances abrasive wear and leads to premature engine damage that is expensive to repair.

Using high-quality engine oil always allows you to safely double the manufacturer’s recommended oil change interval without increasing engine wear or costs.False

Even premium oils cannot fully compensate for contamination from dust, fuel dilution, or heavy workloads, especially in agricultural settings. Manufacturer intervals account for these factors, and exceeding them can lead to increased engine wear and higher repair costs.

Key takeaway: Investing in regular oil changes based on manufacturer guidelines and operating conditions is far more cost-effective than risking major engine repairs. Weighing oil costs per engine hour against overhaul expenses highlights the value of timely maintenance in reducing long-term tractor ownership costs.

Conclusion

We've discussed why sticking to both the engine hour interval and the 12-month maximum for tractor oil changes is so important for long-term reliability. From my experience, skipping or stretching these intervals often leads to what I call the "second-year surprise"—unexpected engine issues that show up just when you think the tractor is running fine. It's a lot easier and cheaper to keep up with regular oil changes than to deal with major repairs later. If you have questions about maintenance schedules, oil types, or what works best for older tractors in your region, feel free to reach out—I'm always happy to share practical advice from the field. Every farm and market is different, so choose what keeps your equipment working when you need it most.

References

-

Detailed insights on optimal engine oil change intervals to prevent sludge buildup and costly repairs in tractors. ↩

-

Detailed guidance on optimal oil change intervals prevents engine damage and costly downtime in diesel tractors. ↩

-

Explains causes of oil degradation over time, including moisture and acids, crucial for maintaining tractor engine health. ↩

-

Details how microscopic metal shavings cause engine wear, sludge buildup, and increased oil consumption, highlighting maintenance urgency. ↩

-

Learn how frequent air filter clogging impacts oil quality and why it demands more frequent oil changes to maintain tractor performance. ↩

-

Explore detailed standards for engine oils that ensure optimal protection and performance in farm tractors, backed by OEM recommendations. ↩

-

Provides detailed insights into fuel dilution's impact on engine oil quality and how monitoring it prevents premature engine wear. ↩

-

Learn why moisture buildup and old oil cause internal rust, increasing repair costs and reducing tractor engine lifespan. ↩

-

Expert advice on transmission and hydraulic oil change schedules to save costs and maintain tractor performance. ↩