Cold-weather farming presents unique obstacles—engines refusing to start and slippery fields are just some challenges I’ve faced. Finding solutions became essential to protect my harvest, machinery, and peace of mind.

Winter tractors are essential for cold-weather farming due to their reliable start-up technologies, heated cabs, superior traction, specialized fuel and hydraulics, winter attachments, operator safety features, and maintenance access—all designed for the harshest conditions.

When winter arrives, having the right tractor determines whether work continues smoothly or stalls in the cold. Let’s explore why winter tractors are specifically engineered to handle these demanding environments and how their features keep cold-climate operations productive and safe.

1. What’s the Essential Secret Behind Reliable Tractor Starts in Winter?

Frustrated by tractor engines struggling to fire up on freezing mornings? Persistent starting trouble wastes work hours and risks costly engine wear. Winter-specific tractor tech delivers proven solutions for dependable cold-weather starts.

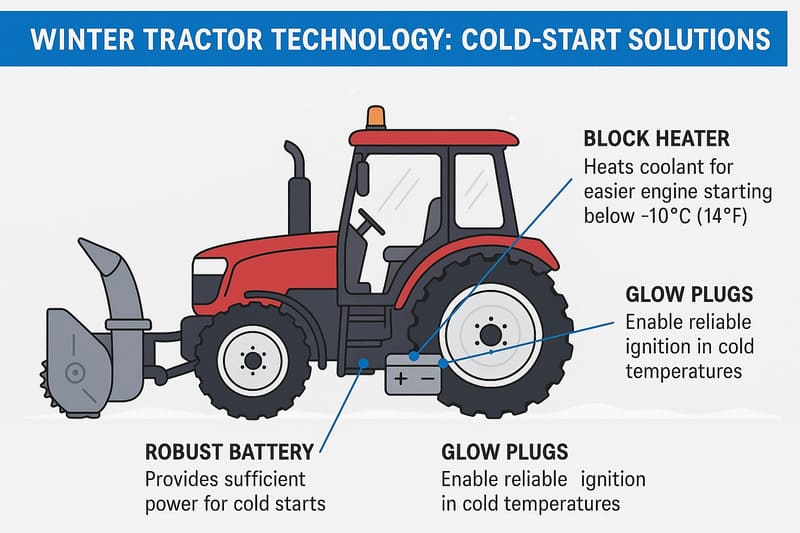

Tractors built for winter feature critical cold-start technologies—block heaters, glow plugs, and robust batteries—ensuring reliable engine ignition below -10°C (14°F). These components minimize downtime, reduce engine stress, and prevent wear caused by repeated failed starts.

Understanding the Science of Cold-Weather Diesel Starts

Why Do Tractor Engines Fail to Start in Cold Conditions?

Diesel engines1 naturally struggle in low temperatures because:

- Diesel fuel thickens, impairing atomization and combustion.

- Oil viscosity increases, creating more internal friction.

- Conventional batteries have reduced cranking power in the cold.

Without intervention, these factors contribute to hesitant ignition, unburned fuel, and engine wear.

The Trio of Cold-Start Technologies

A trio of cold-start aids is engineered into winter tractors to tackle unique challenges:

| Technology | Role in Cold Starts | Benefit |

|---|---|---|

| Block Heater | Preheats engine coolant or oil before ignition | Faster, smoother starts |

| Glow Plug | Heats intake air for better diesel combustion | Rapid, reliable ignition |

| Heavy-Duty Battery | Delivers high cranking amps in low temperatures | Engine turns over consistently |

Block Heaters: Warming Up for Success

Block heaters use electrical elements to preheat the engine coolant or oil. When the operator attempts a start, properly warmed fluids flow freely and moving parts have less resistance. This ensures the starting process doesn’t overstress components, particularly critical for large farm tractors parked outdoors overnight.

Glow Plugs: Ignition Assurance in Any Weather

Diesel combustion relies on hot, compressed air to ignite fuel. In winter, glow plugs2 compensate for low ambient air temperatures by rapidly heating the air inside intake chambers. This fast, localized warmth makes ignition almost instantaneous, reducing the number of failed starts and incomplete combustions.

Heavy-Duty Batteries: Power Where It Counts

Cold weather saps battery power at a time when the engine needs maximum torque. Standard-issue batteries often underperform in sub-zero conditions, leading to slow cranking and start failures. Winter tractors are fitted with heavy-duty batteries3 engineered for high cranking amps and deep-cycling, ensuring sufficient starter motor power every time.

Why Reliable Cold Starts Protect Your Tractor Investment

Repeated failed starts don’t just waste time—they incrementally damage the engine. Unburned fuel can wash down cylinder walls, stripping away lubricants and accelerating internal wear. Cold-start systems prevent this scenario by getting the engine running smoothly on the first try, preserving performance and prolonging engine life.

Investing in Winter-Ready Tractors Pays Off

Choosing tractors equipped with advanced cold-start solutions ensures consistent reliability, even in extreme winter cold. Block heaters, glow plugs, and heavy-duty batteries combine to maximize uptime while protecting engine health during the harshest seasons.

Winterized tractor models equipped with proven cold-start technology are essential for farmers and operators facing sub-zero conditions. These components assure dependable starts, reduce costly downtime, and extend your tractor’s service life, making them a smart investment for reliable farm performance all winter long.

Block heaters, glow plugs, and heavy-duty batteries are essential technologies that help tractors start reliably in winter conditions.True

The content explains that these components are critical for enabling diesel tractors to start smoothly and consistently in cold weather, minimizing engine strain.

Standard tractor batteries provide adequate cranking power for reliable cold starts during freezing winter temperatures.False

The content specifies that standard batteries often underperform in the cold, and only heavy-duty batteries engineered for high cranking amps ensure reliable starts in winter.

2. What Is the Essential Secret Behind Heated Tractor Cabs for Winter Farming?

Winter can be brutal for tractor operators. Exposure leads to discomfort, fatigue, and even dangerous health risks. Discover how insulated, heated tractor cabs offer the ultimate climate shield and productivity boost.

Insulated and heated cabs in modern tractors are vital for winter farming. These features keep interior temperatures comfortable, protect operators from harsh weather, reduce fatigue, and ensure consistent productivity even when outdoor conditions are extreme.

Understanding the Impact of Insulated and Heated Tractor Cabs

Why Operator Comfort Matters in Freezing Conditions

Winter work exposes tractor operators to wind chill, freezing temperatures, and persistent dampness. Prolonged exposure not only causes discomfort but can also lead to severe health issues such as hypothermia or frostbite. Even mild cold stress can significantly reduce focus, reaction time, and stamina, undermining the efficiency of farm operations—especially during critical tasks like snow removal or winter crop maintenance.

How Heated Cabs Counter Winter’s Challenges

Modern tractor cabs employ advanced insulation materials and high-capacity heating systems. These work together to create a micro-climate inside the cab, shielding operators from external weather extremes. The insulation, often comprised of dense foam panels and multi-layered glass, minimizes temperature loss. Meanwhile, integrated heaters—sometimes featuring programmable thermostats4—ensure temperatures remain above freezing, regardless of conditions outside.

Key Benefits of Heated and Insulated Tractor Cabs

| Feature | Operator Benefit | Farm Productivity Impact |

|---|---|---|

| Premium cab insulation | Reduces heat loss and drafts | Sustains optimal performance |

| Integrated high-output heating system | Maintains comfortable temperatures | Minimizes downtime and breaks |

| Wind/snow resistance cab design | Protects against extreme weather | Ensures timely winter operations |

| Ergonomic interior and controls | Reduces fatigue and strain | Maximizes efficiency on long days |

Real-world Productivity Gains

A tractor with an insulated, heated cab5 directly influences operator well-being. Comfortable working conditions translate into longer, more focused work sessions, which are especially valuable during short daylight hours. Fatigue and distraction rates drop, cutting accidents and errors. In addition, the risk of missed work due to illness from exposure is significantly reduced.

Beyond Comfort—Safety First

Operator safety is paramount in winter. Slippery surfaces, icy machinery, and sudden storms can strike without warning. A warm, well-insulated cab ensures that should an operator need to wait out poor weather, they remain safe and protected. Features such as rapid defrosting of windows6 further improve visibility, reducing accident risk.

Comparing Traditional vs. Modern Cabs

| Factor | Traditional Uninsulated Cabs | Modern Insulated & Heated Cabs |

|---|---|---|

| Internal temperature | Often below freezing | Consistently above freezing |

| Operator fatigue | High | Low |

| Health risk | Elevated risk | Significantly reduced |

The Future of Tractor Cab Comfort

Technical advances continue to refine cab insulation and heating. Expect smarter climate controls7, improved thermal barriers, and quieter cab interiors. As climate unpredictability rises, insulated, heated cabs are shifting from luxury to necessity for anyone committed to winter farming.

Winter-ready tractors equipped with insulated, heated cabs8 aren’t just about comfort—they’re vital for safeguarding operators and maintaining productivity. These innovations have become the backbone of safe, efficient, and reliable winter farming operations.

Heated and insulated tractor cabs help protect operators from cold-related health risks such as hypothermia and frostbite during winter farming.True

The content states that insulated and heated cabs protect operators from harsh winter conditions and reduce the risk of severe health issues caused by cold exposure.

Traditional uninsulated tractor cabs maintain a comfortable internal temperature above freezing during winter.False

The content explains that traditional uninsulated cabs often have internal temperatures below freezing, increasing health and fatigue risks.

3. What Is the Essential Secret Behind Tractor Traction on Icy Terrain?

Slippery winter conditions threaten tractor safety and productivity. When wheels spin or slide, essential farm tasks quickly become dangerous or impossible. Here’s how specialized traction systems solve these frustrating winter problems.

Specialized traction systems for tractors use advanced drive configurations and enhanced tire setups to maximize grip, prevent slippage, and keep winter operations safe, efficient, and reliable—even in extreme icy or snowy conditions.

The Science of Winter Traction Systems

Why Standard Tractors Fall Short in Winter

Ordinary tractor tires and drivetrains struggle9 when ice or compacted snow covers working areas. Without proper traction, even simple maneuvers such as starting, turning, or climbing small inclines can result in loss of control10. Ineffective traction also leads to:

- Increased risk of accidents or rollovers

- Slower operations due to frequent stops and starts

- Reduced effectiveness of snow removal or hauling tasks

Key Traction System Enhancements

To overcome these hazards, winter-ready tractors feature several tailored systems. Here’s a closer look:

| Traction Enhancement | Description | Winter Benefit |

|---|---|---|

| Four-Wheel/All-Wheel Drive | Engages all wheels for even power distribution | Improved control and stability on slopes |

| Heavy-Duty Tires | Deep treads cut through snow for better ground contact | Maximized grip on slippery surfaces |

| Tire Chains | Metal chains wrap tires, biting into ice and packed snow | Drastically reduces slippage |

| Weight Kits/Ballast Boxes | Extra weight over drive wheels increases downward force | Enhanced tire contact and traction |

How These Features Work Together

-

Drive Configuration

Four-wheel drive (4WD) and all-wheel drive (AWD) systems11 synchronize power delivery to every tire, allowing tractors to move forward even if some wheels momentarily lose grip. This is crucial when maneuvering over unplowed fields, icy hauls, or slippery slopes. -

Tire Selection

Heavy-duty, deep-tread tires12 are engineered for maximum snow ejection and ground engagement. Patterns are designed to channel snow and mud away, reducing buildup and maintaining reliable traction throughout winter tasks. -

Tire Chains

Fitting chains over rear (or all) tires creates dozens of contact edges that grip irregular surfaces. This not only prevents spinning but also shortens braking distances on steep or icy descents. -

Ballast and Weight Kits

Added weights or ballast boxes are mounted close to or directly on the drive axles. The increased downward force enhances tire-to-ground friction, making it harder for wheels to lose traction—even under stress from heavy attachments or steep gradients.

When Do Traction Systems Matter Most?

Winter traction enhancements13 come into play across several critical farm and ranch tasks:

- Plowing and clearing snow from driveways, fields, and access roads

- Transporting feed, hay, or equipment across ice-blanketed terrain

- Safely ascending or descending hilly property during adverse weather

By integrating multiple traction strategies, operators can maintain full command of tractor movements and avoid costly downtime.

Specialized tractor traction systems—including advanced drive configurations, deep-tread tires or chains14, and strategic weighting—are essential for safe, efficient operation in icy and snowy environments. These features collectively enable tractors to conquer winter terrain, keeping vital farm tasks on track when conditions are toughest.

Specialized tractor traction systems, such as all-wheel drive, deep-tread tires, tire chains, and ballast weights, are essential for maintaining grip and safety on icy terrain.True

The content details how these features maximize traction and ensure reliable tractor operations in winter conditions.

Standard tractor tires without any enhancements are sufficient to prevent slippage and accidents on icy or snowy surfaces.False

The text explains that ordinary tractor tires struggle in winter, leading to loss of control and increased accident risk without specialized traction systems.

4. What’s the Essential Secret to Reliable Tractor Hydraulics in Winter?

Hydraulic hiccups can ruin winter ops. Thickened fluids slow implement movements and risk component damage. The solution? Specialized hydraulic fluids keep your tractor performing—even on the coldest days.

The essential secret behind reliable winter tractor hydraulics is using low-viscosity or synthetic fluids formulated for sub-zero temperatures, ensuring consistent implement control and preventing performance loss no matter how cold it gets.

Understanding Winter’s Impact on Tractor Hydraulic Systems

How Cold Temperatures Affect Hydraulic Fluids

When working conditions plunge below freezing, standard hydraulic fluids lose their optimal flow properties. Since hydraulic systems rely on fluid movement to transfer power, any increase in viscosity15—in simple terms, becoming thicker—translates to slower cylinder actuation16, delayed loader responses, and greater strain on pumps and valves. In severe cases, this can result in incomplete lifting or poor implement control.

The Critical Role of Fluid Viscosity

Fluid viscosity directly dictates hydraulic performance. Examine the comparison:

| Temperature (°C) | Conventional Fluid Viscosity (cSt) | Winter-Grade Fluid Viscosity (cSt) |

|---|---|---|

| 25 | 46 | 46 |

| 0 | 110 | 68 |

| -20 | 340 | 130 |

At sub-zero temperatures, standard fluids thicken considerably, while winter-grade options remain more fluid, providing reliable power transfer needed for attachments like front loaders or snow blowers.

Choosing the Right Hydraulic Fluid

Opt for fluids specifically labeled as “low-viscosity,” “synthetic,” or “cold-weather” by recognized standards (such as ISO 46 HV17, ISO 32, or OEM-rated winter blends). These formulations contain additives and base oils that inhibit thickening and enhance pumpability, reducing startup wear and helping maintain quick, precise implement movements—even before the system fully warms up.

Maintenance Steps for Cold-Weather Hydraulic Performance

- Pre-Season Changeover: Always replace standard fluids with winter-blend oils before temperatures drop.

- Regular Checks: Monitor fluid levels and clarity, as moisture contamination and oxidation can accelerate in winter.

- Warm-Up Protocol: Always allow engine and hydraulics a brief idle period at startup, giving fluids time to circulate and stabilize viscosity before heavy use.

- Inspect Seals and Hoses: Cold-induced contraction can stress rubber components, so check for leaks or signs of brittleness as part of your winter readiness routine.

Why Synthetic Fluids Outperform in Extreme Cold

Synthetic hydraulic fluids offer a more stable viscosity across broad temperature swings. They reduce the risk of internal component wear, allow quicker system response at key control points, and help minimize downtime—crucial for operations relying on loader or blade work in freezing temperatures.

Key Takeaways

Winter tractor performance depends on hydraulic fluid selection. Low-viscosity and synthetic fluids maintain proper flow and component protection, ensuring fast, dependable loader and implement response—even during deep-freeze conditions. Proactive fluid management stands as the essential secret to cold-weather tractor reliability.

Using low-viscosity or synthetic hydraulic fluids is essential for maintaining reliable tractor hydraulic performance in winter.True

The content states that specialized low-viscosity and synthetic fluids prevent thickening, ensuring consistent performance and implement control in cold temperatures.

Standard hydraulic fluids provide the same level of performance as winter-grade fluids in sub-zero temperatures.False

The text explains that standard hydraulic fluids thicken in the cold, reducing performance, while winter-grade fluids remain more fluid and effective.

5. What’s the Essential Secret Behind Reliable Winter Tractor Fuel Systems?

Frozen diesel can halt a farm tractor in its tracks—costing time and money. Discover how today’s tractors defeat cold-weather fuel issues for consistent, powerful winter performance.

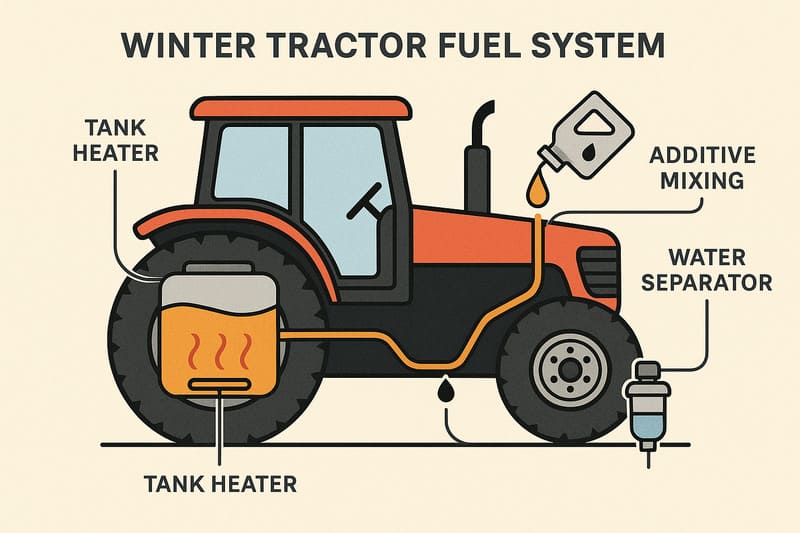

The essential secret lies in specialized fuel management using tank heaters, anti-gel additives, and water separators to ensure that farm tractor engines start reliably and run smoothly even in the harshest winter conditions.

How Cold Temperatures Affect Tractor Fuel Systems

In freezing climates, diesel fuel is vulnerable to “gelling.”18 Gelling occurs when waxes in diesel solidify, thickening fuel and blocking filters. Left unchecked, this leads to fuel starvation, injector failure, and engine stoppage19.

Why Diesel Gels in Winter

Diesel’s hydrocarbon makeup means wax particles liquefy at standard temperatures but crystallize when the thermometer dips below freezing. Gellied fuel forms sludgy blockages that prevent normal operation. As tractors rely on precisely calibrated high-pressure fuel injection, even minor interruptions can cause severe engine stress.

Key Winter-Proofing Solutions

Modern winter tractors employ multi-layered defenses against frozen fuel:

| Winter-Proofing Measure | Purpose | Benefit |

|---|---|---|

| Fuel Tank Heater | Warms diesel above cloud point | Prevents gelling inside tank |

| Cold-Weather Diesel Blend | Lower wax content / improved flow | Resists solidification in cold |

| Anti-Gel Additives | Modify wax crystallization behavior | Maintains smooth flow at low temps |

| Water Separator | Removes moisture from fuel lines | Prevents ice formation and clean burn |

Detailed Approach to Cold-Weather Fuel Management

-

Fuel Tank Heaters20: These devices, often electric or coolant-driven, maintain the diesel above its gelling point. This is crucial if tractors are stored in unheated barns or frequently start in bitter cold.

-

Cold-Weather Diesel Blends and Additives: Diesel suitable for winter use either contains a lower proportion of wax or is enhanced with anti-gel chemical additives. These additives lower the cloud and pour points, ensuring fuel remains liquid as temperatures drop.

-

Water Separation for Ice Prevention21: Water is ever-present in diesel fuel due to condensation, contamination, or humidity. Water separators extract this moisture before it reaches sensitive injection systems. Without these, minute ice crystals can clog lines and leave tractors stranded mid-task.

Engine Injection System Protection

Cold-induced clogs most severely impact high-pressure injector units22, where precise fuel atomization is critical. Even slight interruptions from wax or ice can injure injectors, causing poor combustion, hard starts, and expensive repairs. The combined approach of heating, blending, and separating builds a formidable shield.

Preventive Measures for Tractor Owners

To ensure smooth winter operation:

- Always refuel with winter-grade diesel from reliable sources.

- Routinely check water separators for contaminants23 and drain moisture as recommended in the operator’s manual.

- Install and test tank heaters prior to frost season.

Key Takeaways for Winter Tractor Fuel Reliability

Farm tractors must overcome unique winter fuel challenges. By using tank heaters, anti-gel additives, and water separators, tractor operators can prevent gelling, ice blockages, and engine failures—delivering dependable performance and equipment longevity in any temperature.

Anti-gel additives help prevent diesel fuel from gelling in winter tractor fuel systems.True

Anti-gel additives modify the crystallization of wax in diesel fuel, helping it flow smoothly even at low temperatures.

Cold-weather diesel blends have a higher wax content than regular diesel fuel.False

Cold-weather blends actually contain less wax or are formulated with additives to prevent gelling, not more.

6. What’s the Secret to Ultimate Tractor Efficiency for Winter Tasks?

Cold weather can halt farm productivity, causing delays and safety risks. Winter brings unique challenges—from packed snow to icy surfaces. The secret? Equip your tractor with specialty winter attachments.

Specialized winter tractor attachments such as snow blowers, spreaders, and snow blades ensure efficient and versatile performance during harsh winters. Quick-attach systems enable rapid implement changes, boosting productivity and operational safety in cold conditions.

Understanding Winter Tractor Attachments: Built for Efficiency

Key Winter Attachments

Winter tractors, unlike standard models, are engineered to handle the extreme conditions of snow, ice, and freezing temperatures. Their effectiveness lies in the ability to accept a wide array of cold-weather-specific attachments24. Each implement addresses a specific seasonal challenge, enabling continuous, safe, and efficient farm operations25.

The following table outlines common winter attachments, their primary purposes, and core benefits:

| Attachment Type | Primary Use | Core Benefit |

|---|---|---|

| Front Snow Blower | Removing deep or drifted snow | Clears paths rapidly and evenly |

| Rear Snow Blower | Clearing driveways/laneways | Maintains access to remote areas |

| PTO-Driven Salt/Sand Spreader | Distributing de-icing materials | Increases surface traction |

| Heavy-Duty Snow Blade | Plowing snow efficiently | Handles compacted/heavy snow loads |

| Driftscraper | Leveling wind-packed drifts | Restores surface for safe use |

How Quick-Attach Systems Maximize Productivity

Changing between heavy implements in freezing temperatures is traditionally time-consuming and frustrating. Modern winter tractors solve this with quick-attach systems26—engineered mechanisms that let operators switch from a snow blower to a salt spreader (or any other compatible implement) in just minutes. This innovation removes downtime, elevating both convenience and safety.

The benefits of these systems include:

- Rapid Transitions: Seamlessly move between attachments as job demands shift throughout the day.

- Reduced Exposure: Limits the operator’s time outside the cab during subzero conditions, minimizing health risks.

- Maximized Tractor Investment: By allowing year-round use, a single tractor can perform the tasks of several machines.

Tailoring Attachment Choices to Conditions

Not every winter is the same. Deep snow after a blizzard may call for a front snow blower’s power, while icy paths need a salt/sand spreader’s precision27. Farm managers should assess their most frequent winter challenges and prioritize attachments offering the most value for those tasks. Collaboration with operators regarding daily pain points often leads to the most productive setups.

Safety and Efficiency: The Dual Value

Well-matched attachments do more than clear the way—they protect operators and livestock, prevent machinery from becoming stranded, and uphold the overall productivity of the farm. The critical edge comes from the right combination of implements and the flexibility of quick attachment processes.

Winter Tractor Attachments: Summary

Winter tractor attachments such as snow blowers, blades, and spreaders combine with quick-attach systems28 to ensure maximum efficiency, safety, and adaptability. The right winter-specific implements empower farms to operate reliably throughout harsh weather, keeping downtime and risks to an absolute minimum.

Quick-attach systems on winter tractors enable operators to switch between attachments rapidly, improving efficiency and safety during winter tasks.True

The content explains that quick-attach systems allow for fast implement changes, reducing downtime and operator exposure to cold, thus enhancing productivity and safety.

Standard tractors without specialized winter attachments perform just as efficiently in snow and ice as winter-equipped models.False

The content indicates that winter tractors with specialized attachments are engineered for efficiency in snow and ice, whereas standard tractors lack these capabilities and attachments.

7. What Are the Essential Tractor Safety Upgrades for Cold Weather?

Slips, falls, and weather-exposed controls threaten operator safety during winter. Unaddressed, these hazards lead to downtime and injury. Enhanced winter tractor safety features are the proven solution.

Enhanced winter tractor features—such as non-slip steps, high-visibility lighting, and enclosed control panels—significantly reduce slip, fall, and equipment risks, ensuring safer operations for tractor operators during harsh cold-weather conditions.

Why Is Winter Tractor Safety So Critical?

Winter months introduce ice, limited daylight29, and freezing moisture that directly affect farm tractor operations. These environmental challenges dramatically increase the likelihood of slips when entering or exiting the cab, as well as impair visibility and compromise sensitive equipment control panels. Modified tractor equipment is crucial not only for operator safety but for sustaining productivity throughout severe seasons.

Slip and Fall Risks: The Invisible Winter Hazard

Cold-weather farming surfaces gather frost and ice, especially around tractor steps and work zones. Operators frequently mounting or dismounting are especially at risk. Injuries from slips can result in lost workdays, medical costs, and reduced morale. The implementation of robust non-slip step surfaces30 is a primary defense. Modern designs integrate textured alloys or treated polymer finishes that maintain grip even during extreme wet or icy conditions. Regular inspection and prompt clearing of tractor steps are also vital practices.

Navigating Low Light: The High-Visibility Advantage

In winter, daylight hours shrink and sudden weather shifts—like fog or heavy snow—further reduce visibility. This poses significant risks for operators both in-field and in transit. Enhanced tractor lighting technology, including LED work lights31 and reflective striping32, is engineered to maximize visibility in all conditions. These upgrades not only help operators see obstacles and terrain but also ensure bystanders and other machines can spot the tractor during twilight or inclement weather.

| Safety Feature | Purpose | Typical Location |

|---|---|---|

| Non-slip step surfaces | Prevents slips and falls on icy or wet steps | Entry points, footrests |

| High-visibility lights | Illuminates surroundings, signals presence | Headlights, cab perimeter |

| Enclosed control panels | Shields electronics from ice, moisture | Operator cab, console |

Protecting Controls and Electronics

Cold, wet conditions threaten tractor electronics with moisture ingress, ice buildup, or even complete electrical failure. Tractors purpose-built for winter now feature fully enclosed control panels and sealed cabs33. These enhancements prevent water or ice from damaging switches, wiring, and display screens. Not only do they minimize technical malfunctions, they also ensure that critical controls remain reliable and responsive even in a blizzard.

Integrating Multi-Layered Safety

Safety is rarely the result of a single upgrade. Instead, leading tractor designs employ a systems approach, fusing non-slip materials, advanced lighting, and protective enclosures seamlessly. For operators, this means fewer worries over unpredictable slips, improved nighttime performance, and consistently safe, functional interfaces regardless of outside weather. A proactive maintenance regime34—regularly checking for worn anti-slip surfaces, replacing lights, and testing seals on control panels—maximizes the value of these enhancements.

Key Takeaways for Tractor Operators

Winter-readied tractor safety upgrades—non-slip steps, high-visibility lighting, enclosed controls—are essential in reducing cold-weather risks. These enhancements safeguard operators, minimize costly injuries, and ensure tractor functionality, supporting safer and more reliable farming throughout the harshest months.

Non-slip step surfaces help prevent slips and falls on icy or wet tractor steps during winter.True

The content emphasizes that non-slip steps are a key defense against slip and fall injuries in cold-weather conditions.

High-visibility lighting is unnecessary for tractor operation during the winter months.False

High-visibility lighting is described as essential for maintaining safe operations and preventing accidents in low-light winter conditions.

8. What’s the Ultimate Secret to Winter Tractor Reliability and Serviceability?

Cold starts, slow maintenance, and unclear tractor windows can threaten winter farm operations. Downtime disrupts schedules and risks productivity. Fortunately, specialized winter tractors solve these pain points for operators.

The ultimate secret to winter tractor reliability is well-designed access points for crucial maintenance, ensuring easy servicing of batteries, fluids, and visibility aids, so your tractors power through winter with reduced downtime and maximized dependability.

Accessible Maintenance: The Overlooked Game-Changer in Winter Tractor Performance

Why Routine Maintenance Is Harder in Winter

Winter amplifies the challenges of tractor care. Frigid temperatures sap batteries, thicken oils, and worsen visibility as snow and ice build up. Tasks that are straightforward in other seasons can be painful and slow in subzero climates. Gloves, freezing hands, and shorter daylight compound the pressure on operators to complete service tasks quickly and correctly.

Key Areas of Maintenance Access Simplified

Winter-ready farm tractors now come equipped with deliberately designed access solutions. Here’s how improvements target common cold-weather issues:

| Area | Challenge in Winter | Enhanced Access Solution |

|---|---|---|

| Battery compartment | Weak, slow, or dead batteries; glove handling | Large, easy-opening panels and direct access points for quick jump-starts |

| Engine oil & fluids | Thickened oils; difficult top-ups | Clearly marked, glove-compatible reservoirs and easy-reach dipsticks |

| Washer fluid & wipers | Constant build-up on glass | Large-capacity tanks, robust wipers, and heater-equipped washer lines |

With these features, operators spend less time fumbling with panels or struggling to check levels. For example, quick-open battery covers eliminate the need for extra tools or gloves-off exposure. Similarly, high-visibility reservoirs mean fill levels can be checked at a glance, even in low light.

Maintenace Access and Operator Safety

Efficient service access35 is not just a matter of convenience—it directly impacts safety and uptime. Cold-induced fatigue and slower dexterity increase risk during maintenance. By ensuring that essential points—like hydraulic fluid or coolant—are quick to locate and open, tractor manufacturers minimize exposure to the elements and the risk of mistakes or minor injuries.

Impact on Tractor Longevity and Downtime

Regular maintenance is even more critical in winter, as minor issues (a slow-starting battery, low coolant) can rapidly lead to bigger breakdowns. If operators can quickly check and top up fluids or jump-start in minutes, small problems are caught before harming essential systems. This approach preserves the tractor’s life36 and avoids emergency repairs during peak farm demands.

Comparative Maintenance Downtime

| Scenario | Average Downtime (Traditional) | Average Downtime (Winter Tractor) |

|---|---|---|

| Battery jump-start | 30 minutes | 10 minutes |

| Fluid checks/refills | 20 minutes | 5 minutes |

| Wiper/washer service | 15 minutes | 5 minutes |

As the table demonstrates, tractors with optimized maintenance access slash downtime by up to two-thirds—a crucial difference during fast-paced winter operations.

The Bottom Line for Farm Operations

Ultimately, these tractor features are not luxury upgrades. Minimizing obstacles to cold-weather maintenance protects productivity, reduces stress for operators, and keeps costly machinery working when needed most. Investing in winter tractor models with these access enhancements directly translates to more reliable winter performance and lower risk of mid-season breakdowns.

Winter-ready maintenance access means more time in the field and less in the shop—keeping you ahead of winter’s challenges.

Winter tractor reliability hinges on service-friendly access to batteries, fluids, and visibility tools37. Purpose-built access points cut maintenance time, ensure dependable starts, and help sustain productivity through winter’s harshest conditions. Investing in these features minimizes downtime and maximizes tractor longevity.

Winter tractors with specially designed access points reduce maintenance downtime significantly.True

The content explains that enhanced accessibility to batteries, fluids, and visibility aids allows for faster and easier maintenance, cutting downtime by up to two-thirds.

Improved maintenance access in winter tractors has no effect on operator safety or tractor reliability.False

The content highlights that better access improves both safety and reliability by making routine checks quicker and reducing exposure to cold, as well as preventing bigger issues from developing.

Conclusion

Winter tractors are indispensable for cold-weather farming, providing reliable operation, safety, and efficiency through specialized engineering adapted to harsh conditions and critical winter-specific agricultural tasks.

-

Understanding the challenges Diesel engines face in cold weather can help you prevent starting issues and maintain engine health. ↩

-

Discover why glow plugs are essential for quick, reliable ignition in cold weather, reducing failed starts and incomplete combustion. ↩

-

Understand how heavy-duty batteries provide the necessary power for cold starts, preventing downtime and start failures in harsh climates. ↩

-

Discover how programmable thermostats can optimize heating, save energy, and maintain ideal temperatures for operators in freezing weather. ↩

-

Learn how an insulated, heated cab can boost comfort and productivity, making long work sessions safer and more efficient, especially in harsh weather. ↩

-

Discover how rapid defrosting of windows enhances visibility and reduces accident risk, ensuring safer operation in winter conditions. ↩

-

Learn how smarter climate controls can enhance comfort and efficiency in tractor cabs, making winter farming safer and more productive. ↩

-

Discover why insulated, heated cabs are now a necessity for winter farming, ensuring operator safety and consistent productivity in harsh conditions. ↩

-

Learn how standard tractor tires and drivetrains perform poorly on icy or snowy surfaces and discover solutions to improve winter traction and safety. ↩

-

Understand the dangers of losing control of tractors in winter, and find expert advice on preventing accidents and improving operational safety. ↩

-

Learn how advanced drive systems help tractors maintain traction and stability in challenging winter environments, ensuring reliable operation and safety. ↩

-

Discover why specialized tire designs are essential for effective snow ejection, mud clearance, and consistent traction during demanding winter tasks. ↩

-

Learn about the most effective winter traction enhancements to ensure your tractor operates safely and efficiently in icy and snowy conditions. ↩

-

Discover how deep-tread tires or chains can significantly boost your tractor's grip and stability on slippery winter terrain, reducing the risk of accidents. ↩

-

Understanding how increased viscosity impacts hydraulic systems helps prevent equipment failure and ensures efficient operation in cold environments. ↩

-

Learning about the causes of slower cylinder actuation can help you troubleshoot and maintain hydraulic equipment for reliable performance in winter. ↩

-

Discover the benefits and applications of ISO 46 HV hydraulic fluid, especially for maintaining optimal machinery function in cold-weather conditions. ↩

-

Learn how cold weather causes diesel fuel to gel and what steps you can take to prevent costly tractor breakdowns during winter. ↩

-

Understand the serious consequences of cold-induced fuel system issues so you can protect your tractor and avoid unexpected downtime. ↩

-

Learn how fuel tank heaters can prevent diesel from gelling, ensuring reliable tractor starts and operation in extremely cold conditions. ↩

-

Discover why water separation is essential to avoid ice blockages in diesel engines, protecting your equipment from costly downtime and repairs. ↩

-

Understanding high-pressure injector units is crucial for maintaining engine performance and preventing costly repairs, especially in cold weather. ↩

-

Learning about water separators helps prevent fuel system damage and ensures reliable tractor operation during winter months. ↩

-

Learn about the most effective attachments to enhance your tractor's performance and safety during harsh winter conditions. ↩

-

Discover strategies and tools to keep your farm running smoothly and safely throughout the winter season. ↩

-

Learn how quick-attach systems function and why they're a game-changer for anyone needing to switch tractor implements quickly and efficiently. ↩

-

Discover why the precision of a salt/sand spreader is crucial for managing icy paths and maintaining safe, productive farm operations in winter. ↩

-

Learn how quick-attach systems can save you time and effort when switching between winter tractor implements, boosting both efficiency and safety. ↩

-

Discover how reduced daylight hours impact tractor operation and safety, and find strategies to maintain visibility and productivity during winter months. ↩

-

Learn about the most effective non-slip step surfaces to prevent dangerous slips and falls when operating tractors in icy or wet winter conditions. ↩

-

Learn how LED work lights can dramatically improve safety and efficiency for tractor operators working in poor visibility or harsh winter weather. ↩

-

Discover why adding reflective striping to tractors is a crucial step for preventing accidents and increasing visibility during low-light or foggy conditions. ↩

-

Learn how these features prevent moisture and ice from damaging your tractor's electronics, ensuring reliability and reducing costly repairs in harsh winter conditions. ↩

-

Discover the best practices for maintaining winter-ready tractors, helping you maximize safety, performance, and the lifespan of your equipment during cold months. ↩

-

Learn how efficient service access can reduce maintenance time, improve operator safety, and minimize exposure to harsh conditions during tractor servicing. ↩

-

Discover proven maintenance strategies that help extend your tractor’s lifespan and prevent costly breakdowns, especially during demanding seasons. ↩

-

Discover why easy access to key tractor components is crucial for efficient maintenance and uninterrupted operation in cold weather. ↩