Proper tractor maintenance prevents costly breakdowns, extends lifespan, and keeps farm operations running smoothly. Without regular upkeep, tractors can lose efficiency, consume more fuel, and face unexpected failures at critical times.

Farm tractor maintenance includes daily inspections, fluid checks, filter replacements, lubrication, and seasonal servicing. These steps enhance performance, improve fuel efficiency, and reduce repair costs, ensuring the tractor operates reliably year-round.

I know that maintaining a tractor can feel overwhelming, but sticking to a proper maintenance schedule makes all the difference. A well-cared-for tractor performs better, lasts longer, and saves money in the long run. Let’s explore the essential maintenance practices that every tractor owner should follow.

Regular tractor maintenance extends its lifespan.True

Routine inspections, fluid checks, and servicing help prevent wear and tear, ensuring the tractor lasts longer.

Tractor maintenance has no impact on fuel efficiency.False

Proper maintenance, such as replacing filters and checking fluids, improves fuel efficiency by keeping the engine running smoothly.

1. Follow the Manufacturer’s Manual

When I got my first tractor, I assumed general maintenance knowledge was enough. But skipping the manufacturer’s manual1 led to using the wrong fluids and missing key service intervals. It cost me unnecessary repairs and lost time in the field.

The manufacturer’s manual is the most reliable guide for keeping my tractor in top condition. It provides the correct maintenance schedules2, lubrication points, fluid types, and service intervals specific to tractor model. Following these guidelines prevents costly mistakes and ensures farm tractor runs efficiently.

How Does the Manufacturer’s Manual Help Me?

I used to rely on guesswork for maintenance, but now I stick to the manual because:

| Manual Section | Why It’s Important |

|---|---|

| Oil Change Intervals | Using the wrong oil or delaying changes can cause engine wear. |

| Filter Replacement Guide | Clogged air or fuel filters reduce efficiency and increase fuel consumption. |

| Lubrication Points | Missing grease points leads to friction, wear, and expensive repairs. |

| Hydraulic & Transmission Fluid Specs | Using incorrect fluids can damage seals and reduce performance. |

How to Use the Manual to Avoid Costly Repairs?

Instead of waiting for something to go wrong, I now use the manual as my maintenance checklist. Before servicing my tractor, I always:

- Check the lubrication schedule to ensure all moving parts are greased properly.

- Follow the exact fluid requirements for engine oil, hydraulics, and coolant.

- Inspect the recommended service intervals for belt replacements, fuel filters, and battery care.

- Use the troubleshooting section3 to diagnose warning lights and performance issues.

Skipping the manual once led to using the wrong transmission fluid, which resulted in gear slipping. That mistake cost me both time and money. Now, I never ignore the instructions provided by the manufacturer.

By following the manual, you can prevent breakdowns, save on unnecessary repairs, and keep your tractor running at peak efficiency.

Following the manufacturer’s manual helps prevent costly tractor repairs and ensures optimal performance.True

The manual provides essential guidelines on maintenance schedules, lubrication points, and fluid requirements, preventing mechanical failures.

A tractor can be properly maintained without referring to the manufacturer’s manual.False

Ignoring the manual can lead to using incorrect fluids, missing key service intervals, and causing avoidable mechanical issues.

2. Conduct Regular Inspections

I once ignored a small hydraulic fluid leak4, thinking it wasn’t a big deal. A few days later, my loader wouldn’t lift properly, and I had to stop work entirely. That minor leak turned into a costly repair and unexpected downtime.

Regular inspections help catch small problems before farm tractor turn into major failures. A quick daily check for leaks, loose hoses, worn belts, or damaged parts keeps tractor running smoothly and prevents breakdowns in the middle of important work.

What Should Look for During Daily Inspection?

I’ve learned that a quick walk-around can reveal a lot. Here’s what I check before starting my tractor each day:

| Component | What to Inspect | Why It Matters |

|---|---|---|

| Fluids | Check for leaks under the tractor, especially hydraulic fluid, engine oil, and coolant. | Low fluid levels lead to overheating, power loss, and hydraulic failures. |

| Belts & Hoses | Look for cracks, wear, or loose connections. | A snapped belt or a leaking hose can shut down my tractor unexpectedly. |

| Tires | Inspect for proper inflation, cuts, or uneven wear. | Underinflated tires reduce traction and fuel efficiency. Worn tires increase the risk of slipping. |

| Lights & Switches | Ensure headlights, brake lights, and signals work properly. | Visibility is critical, especially for night work or road transport. |

| ROPS & Seat Belt | Verify the rollover protection system (ROPS) is secure and the seat belt is in good condition. | These safety features can save my life in case of an accident. |

How Regular Inspections Save Time and Money?

A few minutes each morning can prevent hours or even days of lost work. Here’s how regular inspections have helped me avoid serious problems:

- Prevented Engine Damage: I once caught an oil leak5 early, preventing a serious engine failure.

- Saved on Tire Replacements: Checking inflation regularly can help extend the life of tires and save money.

- Ensured Safety: By always checking brakes and ROPS, you know you're working in a safe environment.

My Step-by-Step Daily Inspection Routine

To stay on top of maintenance, I follow a simple routine:

- Walk around my tractor and check for any visible leaks or damage.

- Inspect tires for proper inflation and look for any embedded debris.

- Open the hood and check belts, hoses, and fluid levels.

- Turn on the lights and test safety features like the seat belt and ROPS.

- Start the tractor and listen for unusual noises or warning signals.

Regular inspections don’t just prevent breakdowns—they give you peace of mind. When knowing tractor is in top shape, you can focus on work without worrying about sudden failures.

Regular tractor inspections help prevent major failures and costly repairs.True

Checking for leaks, worn belts, and proper fluid levels allows early detection of issues, preventing breakdowns and extending equipment lifespan.

Skipping regular tractor inspections has no impact on performance or repair costs.False

Ignoring inspections can lead to unnoticed leaks, engine damage, and tire failures, resulting in unexpected downtime and expensive repairs.

3. Maintain Fluid Levels

I once ignored my coolant levels, assuming my tractor could handle a few extra hours of work. The result? Overheating in the middle of a job, causing unnecessary downtime and potential engine damage. Since then, I’ve learned that proper fluid maintenance6 is one of the most critical aspects of tractor care.

Fluids keep tractor running smoothly by lubricating, cooling, and protecting vital components. Checking and maintaining engine oil, hydraulic fluid, coolant, brake fluid, and transmission fluid7 prevents overheating, power loss, and mechanical failure.

What Fluid Needs to Monitor and Why?

| Fluid Type | Function | Why It’s Important |

|---|---|---|

| Engine Oil | Lubricates engine components, reduces friction. | Prevents overheating and wear, ensuring a longer engine life. |

| Hydraulic Fluid | Transfers power in hydraulic systems. | Ensures smooth operation of loaders, plows, and other attachments. |

| Coolant | Regulates engine temperature. | Prevents overheating and internal corrosion. |

| Brake Fluid | Transfers force in the braking system. | Ensures responsive and reliable braking. |

| Transmission Fluid | Lubricates transmission gears and clutches. | Reduces wear and prevents gear slippage. |

How to Keep Tractor’s Fluids at Optimal Levels?

I follow a strict schedule to check and replace fluids before they become a problem. Here’s what I do:

1. Check Fluids Regularly

- Every morning before starting farm tractor, Check fluid levels8 using dipsticks and sight gauges.

- Look for low levels, contamination, or discoloration—signs that a fluid change is needed.

2. Follow the Right Fluid Change Intervals

- Engine oil: Replace it every 500–1,000 hours9, depending on workload and manufacturer recommendations.

- Hydraulic fluid: Top it off frequently and change it as needed to maintain smooth performance.

- Coolant: Flush the system annually to remove dirt and prevent overheating.

- Brake and transmission fluid: Inspect them seasonally to ensure proper function.

3. Use the Correct Fluids and Filters

Using the wrong oil or hydraulic fluid can damage seals and reduce efficiency. I always use manufacturer-recommended fluids10 and ensure that filters are replaced alongside fluid changes.

What Happens If I Ignore Fluid Maintenance?

I’ve learned the hard way that low or contaminated fluids can cause severe damage. Here are a few costly problems I’ve avoided by staying on top of fluid maintenance:

| Problem | Cause | Consequence |

|---|---|---|

| Engine Overheating | Low oil or coolant levels. | Reduced engine lifespan and possible breakdown. |

| Hydraulic Failure | Contaminated or low hydraulic fluid. | Poor implement performance and expensive repairs. |

| Transmission Issues | Dirty or degraded transmission fluid. | Gear slipping, rough shifting, or transmission failure. |

| Brake Failure | Low or old brake fluid. | Reduced stopping power, increasing accident risk. |

What Are My Simple Fluid Maintenance Routine?

- Check levels daily before starting my tractor.

- Follow scheduled oil and fluid changes11 based on hours of use.

- Use the correct lubricants and filters12 to avoid contamination.

- Flush the cooling system once a year to prevent overheating.

- Watch for leaks or warning lights that indicate low or dirty fluids.

By making fluid maintenance a priority, you can prevent expensive repairs, improve fuel efficiency, and keep your tractor performing at its best.

Maintaining proper fluid levels prevents tractor overheating and mechanical failure.True

Fluids lubricate, cool, and protect vital components, reducing the risk of overheating and damage.

Using any type of oil or hydraulic fluid has no effect on tractor performance.False

Incorrect fluids can damage seals, reduce efficiency, and lead to mechanical issues.

4. Clean and Replace Filters

I once noticed my tractor was consuming more fuel than usual and struggling to maintain power. After some troubleshooting, I found the problem—a clogged air filter13 was choking the engine. A simple filter replacement14 restored efficiency, saved fuel, and improved overall performance.

Filters protect tractor by trapping dirt, dust, and contaminants that can damage the engine, fuel system, and hydraulics. Without clean filters15, tractor has to work harder, reducing efficiency and increasing wear on critical components.

Which Filters Need to Maintain?

| Filter Type | Function | Why It’s Important |

|---|---|---|

| Air Filter | Keeps dirt and debris from entering the engine. | A clogged air filter reduces engine power and fuel efficiency. |

| Fuel Filter | Removes contaminants from diesel or gasoline. | Dirty fuel can clog injectors and damage fuel pumps. |

| Oil Filter | Removes impurities from engine oil. | Prevents engine wear and prolongs oil life. |

How to Keep Filters Clean and Functional?

I’ve learned that checking and replacing filters on time prevents bigger problems. Here’s how I handle each one:

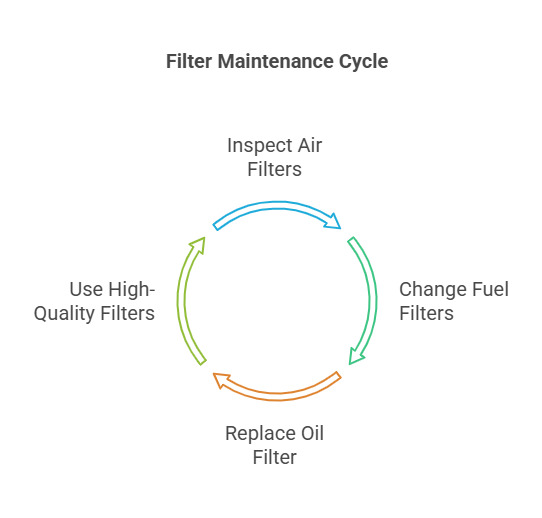

1. Air Filter: My Engine’s First Line of Defense

- Check every 50 hours—especially in dusty conditions.

- Blow out or replace clogged filters to prevent airflow restriction16.

- Use a pre-cleaner if working in dry, dusty environments.

2. Fuel Filter: Ensuring Clean Fuel Flow

- Drain old fuel before storage to prevent contamination.

- Replace fuel filters seasonally or if fuel flow seems restricted17.

- Always use clean, high-quality fuel to prevent clogs in the injectors.

3. Oil Filter: Protecting My Engine

- Change the oil filter with every oil change (every 500–1,000 hours).

- Use high-quality filters recommended by the manufacturer.

- Check for leaks around the filter housing to prevent oil loss.

What Happens If I Ignore Filter Maintenance?

Dirty filters can cripple my tractor’s performance and lead to costly damage. Here are a few issues I’ve learned to avoid:

| Problem | Cause | Consequence |

|---|---|---|

| Reduced Engine Power | Clogged air filter. | Increased fuel consumption and sluggish performance. |

| Fuel System Damage | Dirty fuel filter. | Clogged injectors and poor fuel combustion. |

| Engine Wear | Old oil filter. | Contaminants cause excessive friction and engine damage. |

What Is Simple Filter Maintenance Routine?

- Inspect air filters every 50 hours and clean or replace them as needed.

- Change fuel filters before each season to ensure clean fuel delivery.

- Replace the oil filter every time I change the engine oil.

- Use only high-quality filters and fuel to maximize engine lifespan.

By keeping my filters clean and replacing them on time, you can prevent costly repairs, improve efficiency, and keep tractor running smoothly.

Regularly cleaning and replacing filters improves tractor efficiency and fuel consumption.True

Clean filters prevent dirt and debris from restricting airflow and fuel flow, ensuring optimal performance and fuel efficiency.

Tractor filters do not impact engine performance.False

Clogged filters restrict airflow and fuel flow, making the engine work harder, reducing efficiency, and increasing fuel consumption.

5. Lubricate Moving Parts

I like to think of my tractor’s moving parts like the joints in my body. If I don’t stretch or keep my joints flexible, I start feeling stiff and sore. The same happens to a tractor—without proper lubrication18, metal parts grind against each other, causing friction, wear, and eventual failure.

Lubrication is essential for keeping tractor’s moving components running smoothly. Applying grease or oil to key points reduces friction, prevents rust, and extends the lifespan of parts19 like pivot points, hydraulic arms, and steering components.

Which Parts Need Lubrication and Why?

| Component | Function | Why It Needs Lubrication |

|---|---|---|

| Pivot Points | Allow movement in linkages and joints. | Reduces wear and prevents stiffness. |

| Hydraulic Arms | Raise and lower attachments. | Prevents seizing and ensures smooth motion. |

| Steering Components | Control the direction of the tractor. | Avoids stiffness and jerky movements. |

| PTO Shaft | Transfers power to implements. | Prevents overheating and excessive wear. |

How to Keep Tractor’s Parts Properly Lubricated?

I’ve learned that regular greasing and oiling20 save me from expensive repairs. Here’s how I keep everything running smoothly:

1. Identify and Grease Key Points

- Follow the lubrication chart in my manual to locate grease fittings.

- Use a grease gun to apply lubricant at recommended intervals.

- Wipe off old grease and dirt before applying fresh lubricant to prevent contamination.

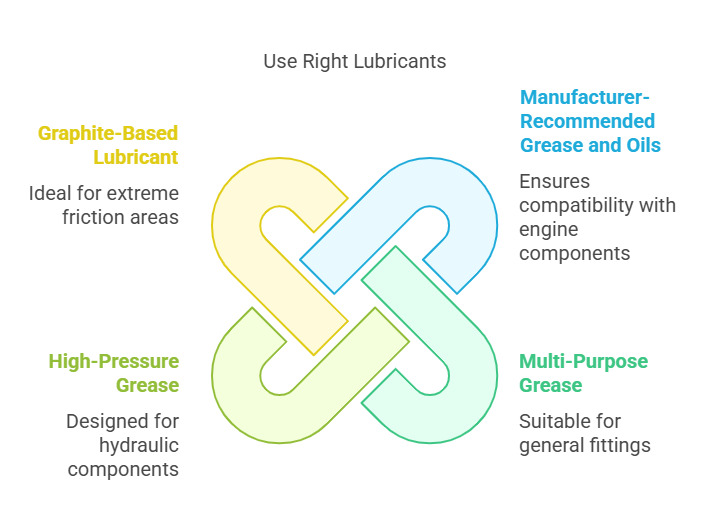

2. Use the Right Lubricants

Not all lubricants are the same! Always use manufacturer-recommended grease and oils to ensure compatibility with seals and bearings.

- Multi-purpose grease for general fittings.

- High-pressure grease for hydraulic components.

- Graphite-based lubricant for areas exposed to extreme friction.

3. Check for Dry or Worn-Out Parts

- If hear squeaking or grinding, check for dry joints.

- If a part feels stiff or sluggish, reapply grease.

- If notice rust forming, clean and lubricate immediately.

What Happens If I Skip Lubrication?

I once forgot to grease my front-end loader’s pivot points. Within weeks, it became stiff, difficult to operate, and eventually developed wear that required costly repairs. That mistake taught me a valuable lesson—lubrication isn’t just about keeping things moving; it’s about preventing damage21.

| Problem | Cause | Consequence |

|---|---|---|

| Squeaky, stiff movements | Lack of grease on pivot points. | Reduced efficiency and difficult operation. |

| Premature wear and rust | Unlubricated metal parts. | Expensive repairs or replacements. |

| Overheating in moving parts | Dry PTO shaft or steering components. | Performance loss and increased fuel consumption. |

Simple Lubrication Maintenance Routine

- Follow the manufacturer’s lubrication chart to know where and how often to grease.

- Use high-quality grease22 and apply it evenly on all moving parts.

- Check for squeaky, stiff, or dry areas and lubricate immediately.

- Clean old grease and dirt buildup before reapplying to prevent contamination.

- Keep a grease gun handy for quick and easy maintenance.

By making lubrication a routine, you can keep tractor operating smoothly, prevent costly repairs, and extend the life of its moving parts.

Regular lubrication prevents excessive wear and extends the lifespan of tractor components.True

Lubrication reduces friction between moving parts, preventing wear and ensuring smooth operation.

Skipping lubrication has no significant impact on tractor performance.False

Without lubrication, metal parts grind against each other, leading to stiffness, increased wear, and potential failure.

6. Avoid Overloading

I think of my tractor like a backpack. If I fill a backpack with just the right amount, I can carry it comfortably all day. But if I overload it with heavy books, my back hurts, my straps wear out, and I move slower. The same happens with a tractor—when it carries too much weight, the engine struggles, the transmission strains, and critical components wear out faster.

Overloading puts unnecessary stress on tractor, leading to engine strain23, transmission failure24, and hydraulic system breakdowns25. Using the right-sized implements and staying within the load limits ensures smooth operation and longer-lasting equipment.

What Happens When Overload Tractor?

| Problem | Cause | Consequence |

|---|---|---|

| Engine Overheating | Excessive weight forces the engine to work harder. | Increased fuel consumption and possible engine failure. |

| Transmission Wear | Extra load strains gears and clutches. | Gear slippage and costly transmission repairs. |

| Hydraulic System Stress | Lifting too much weight with loaders or arms. | Hydraulic leaks and pressure loss. |

| Tire Damage | Excessive weight crushes the tires beyond their limit. | Reduced traction and blowouts. |

How to Prevent Overloading?

I’ve learned from experience that pushing my tractor beyond its limits never ends well. Now, I follow a few key steps to avoid overloading:

1. Always Check the Load Capacity

- Check the operator’s manual for maximum weight limits before attaching heavy implements.

- Never exceed the recommended hauling or lifting capacity to prevent engine and hydraulic strain.

2. Match Attachments to the Task

- Use a properly sized plow, harrow, or mower instead of attaching oversized implements that slow down tractor.

- Balance front and rear weights when using a loader to prevent tipping.

3. Pay Attention to Performance Signs

If your tractor:

- Feels sluggish, it may be overworking.

- Emits black smoke, it’s burning excessive fuel due to strain.

- Struggles to shift gears, the transmission might be overloaded.

- Heats up faster than normal, it’s under too much stress.

What Happened When Overloaded Tractor?

One time, I attached a larger-than-recommended trailer for hauling hay bales, thinking it would save me time. Instead, the extra weight made my tractor overheat, and the transmission began slipping. What I thought would speed up my work ended up costing me expensive repairs and downtime.

Simple Rules for Preventing Overloading

- Follow tractor’s weight limits and never exceed them.

- Choose the right-sized implements instead of using oversized ones.

- Monitor engine temperature and fuel consumption for signs of overloading.

- Check tractor tires and hydraulics regularly to ensure they’re handling weight properly.

- Distribute weight evenly to maintain stability and avoid tipping over.

By keeping tractor within its limits, you prevent breakdowns, extend tractor’s lifespan, and improve overall efficiency.

Overloading a tractor can lead to engine strain, transmission failure, and hydraulic system breakdowns.True

Exceeding load limits puts excessive stress on critical components, leading to overheating, fuel inefficiency, and mechanical failure.

A tractor's performance is not affected by exceeding its load capacity.False

Overloading causes sluggish performance, increased fuel consumption, and potential damage to the engine, transmission, and hydraulics.

7. Care for Tractor’s Battery

I think of my tractor’s battery like my phone. If I don’t charge my phone, it dies, and I can’t use it when I need it. If I leave it in extreme heat or cold26, the battery wears out faster. The same applies to my tractor—without a well-maintained battery27, my tractor won’t start, and I’ll waste time dealing with preventable issues.

A healthy battery ensures tractor starts reliably, powers the electrical system, and runs efficiently. Neglecting it leads to corrosion, slow startups, and even total failure.

How to Maintain Tractor’s Battery?

| Battery Maintenance Task | Why It’s Important |

|---|---|

| Check battery terminals for corrosion | Corroded terminals block the electrical connection, preventing a smooth start. |

| Ensure a full charge | A weak battery struggles to power the starter, especially in cold weather. |

| Store in a cool, dry place | Extreme heat or cold shortens battery lifespan. |

How to Prevent Battery Failure?

I’ve had my share of battery problems—especially in winter when my tractor wouldn’t start because I didn’t check the battery in advance. Now, I follow a simple routine to keep my battery in top shape year-round.

1. Regular Terminal Inspection and Cleaning

- Every few weeks, check for corrosion (a white or blue buildup on the terminals).

- If see corrosion, clean it off using a mix of baking soda and water with a wire brush.

- Tighten loose connections to ensure proper power flow.

2. Keep the Battery Charged

- Run my tractor regularly to keep the battery charged, especially in colder months.

- If tractor sits unused for long periods, use a trickle charger28 to maintain battery health.

3. Store the Battery Properly During Inactivity

- For winter storage, remove the battery and store it in a dry place.

- Avoid leaving tractor outside in extreme temperatures since heat drains the battery and cold slows its chemical reaction.

What Happens If Ignore Battery Maintenance?

I once left my tractor idle for weeks without checking the battery. When I finally needed it, the battery was dead, and I had to jump-start it. That worked temporarily, but the battery’s lifespan had already been shortened. Replacing it cost me more than simply maintaining it would have.

| Problem | Cause | Consequence |

|---|---|---|

| Slow or no start | Corroded terminals or weak charge. | Wasted time, especially during urgent farm work. |

| Battery drains quickly | Extreme temperatures or long inactivity. | Reduced lifespan and frequent jump-starts. |

| Complete battery failure | Neglected charging or old age. | Expensive replacement and downtime. |

Simple Battery Maintenance Routine

- Check and clean battery terminals every few weeks to prevent corrosion.

- Ensure the battery stays charged by running my tractor regularly.

- Store the battery in a dry, temperature-controlled place during long idle periods.

- Use a trickle charger if the tractor won’t be used for a while.

- Replace the battery before it fails completely to avoid work disruptions.

By taking care of my battery, you can ensure tractor starts when need it, reducing downtime and saving money on replacements.

Regular battery maintenance ensures reliable tractor startups and extends battery lifespan.True

Cleaning terminals, keeping the battery charged, and storing it properly prevent corrosion, power loss, and premature failure.

Tractor batteries do not require maintenance to function properly.False

Neglecting battery maintenance leads to corrosion, slow startups, and potential failure, especially in extreme temperatures.

8. Seasonal Maintenance

The seasons don’t wait for me. When planting season arrives, my tractor must be ready to work. When winter sets in, I need to protect it from the cold29. One thing I’ve learned over the years is that seasonal maintenance30 is just as important as daily upkeep. If I neglect it, my tractor won’t be ready when I need it the most.

Seasonal maintenance ensures tractor is in top condition before busy periods like planting and harvest. It also protects vital components from extreme weather conditions, preventing rust, corrosion, and unexpected breakdowns.

How to Prepare Tractor for Different Seasons?

| Season | Maintenance Task | Why It’s Important |

|---|---|---|

| Spring (Planting Season) | Full inspection, tire pressure check, lubrication. | Ensures the tractor is in top shape before heavy work begins. |

| Summer (Hot Conditions) | Cooling system check, radiator cleaning. | Prevents overheating and engine strain. |

| Fall (Harvest Season) | Hydraulic system inspection, fluid top-offs. | Keeps attachments running smoothly for continuous operation. |

| Winter (Storage Prep) | Battery removal, rust protection. | Prevents freezing, corrosion, and battery failure. |

How to Get Tractor Ready for Work Before Planting & Harvest?

At the start of each season, I perform a full tractor inspection to check for any issues before I need my equipment daily.

- Inspect belts, hoses, and filters to replace worn-out components.

- Check hydraulic lines to prevent leaks during peak workload.

- Test the lights and electrical system to ensure safe operation.

- Lubricate all moving parts so nothing seizes up after months of non-use.

How to Prepare Tractor for Winter Storage?

I’ve learned that winter is the toughest season on tractors if they aren’t properly stored. Cold temperatures cause fluids to thicken, batteries to drain, and metal parts to rust. Here’s what I do to prevent damage:

1. Drain and Replace Coolant

- Flush the cooling system and add fresh antifreeze to prevent freezing and corrosion31.

2. Protect the Battery

- If you won’t be using tractor, remove the battery and store it indoors to prevent it from draining.

3. Clean and Protect Against Rust

- Wash off mud, salt, and crop residue to prevent rust buildup32.

- Apply a light coat of oil or anti-rust spray to exposed metal parts.

4. Keep Tires in Good Condition

- Inflate tires to the correct pressure before storing to prevent flat spots.

- If storing long-term, raise the tractor slightly off the ground to reduce tire stress.

What Happens If Ignore Seasonal Maintenance?

One year, I skipped my winter prep. By spring, my battery was dead, my hydraulic lines had small leaks, and my tires had lost pressure. Instead of getting straight to work, I spent days repairing problems that could have been prevented.

| Problem | Cause | Consequence |

|---|---|---|

| Frozen or corroded cooling system | Old or insufficient coolant. | Overheating, radiator damage. |

| Battery failure | Cold temperatures drain battery life. | No power, delays in starting work. |

| Hydraulic system issues | Lack of winter inspection. | Slow or weak attachment performance. |

Simple Seasonal Maintenance Tips

- Inspect and service the tractor before planting and harvest seasons.

- Check and replace coolant annually to prevent freezing.

- Remove and store the battery during long winter months.

- Lubricate all moving parts before and after heavy-use seasons.

- Clean and protect metal parts to prevent rust and corrosion.

By following seasonal maintenance, you ensure tractor runs smoothly year-round, reducing costly repairs and avoiding work delays.

Seasonal maintenance helps prevent unexpected tractor breakdowns and extends equipment lifespan.True

Performing seasonal inspections, replacing fluids, and protecting components from extreme weather ensures the tractor remains reliable and efficient.

Tractors do not require seasonal maintenance to operate effectively.False

Neglecting seasonal upkeep can lead to rust, fluid degradation, battery failure, and mechanical issues, especially in extreme weather conditions.

9. Keep the Tractor Clean

I used to think that a little dirt on my tractor was just part of farm life. After all, tractors are meant to get dirty, right? But then I noticed my engine overheating33 more often, my hydraulic system becoming sluggish, and rust creeping onto metal parts34. That’s when I realized—keeping my tractor clean isn’t just about looks; it’s about performance and longevity.

Regular cleaning prevents dirt, mud, and crop debris from clogging moving parts, reducing efficiency, and causing long-term damage. It also helps the radiator function properly, preventing overheating.

What Happens When Don’t Clean Tractor?

| Problem | Cause | Consequence |

|---|---|---|

| Overheating | Clogged radiator screens. | Engine damage, reduced efficiency. |

| Rust & Corrosion | Mud and moisture buildup. | Weakens metal parts, leading to expensive repairs. |

| Hydraulic System Issues | Dirt entering hydraulic components. | Slower response, potential system failure. |

| Reduced Visibility & Safety Risks | Dirty lights and windows. | Increased chances of accidents. |

How to Keep Tractor Clean for Maximum Efficiency?

I’ve learned that a clean tractor runs better, lasts longer, and requires fewer repairs. Now, I follow a regular cleaning routine:

1. Remove Dirt and Debris After Every Use

- Use a pressure washer or air compressor33 to blow off dust, crop residue, and mud from key areas.

- Clean around the engine, radiator, and hydraulic connections to prevent clogging.

2. Pay Special Attention to the Radiator Screens

- If radiator is clogged with dust and debris, airflow is restricted, causing overheating.

- Remove the screens and wash them gently to keep cooling system working efficiently.

3. Protect Metal Parts from Rust and Corrosion

- After cleaning, apply a rust prevention spray34 on exposed metal parts to protect them.

- If notice any rust starting, sand it off and repaint the affected areas before it spreads.

4. Keep Windows, Lights, and Mirrors Clean for Safety

- A dirty windshield makes it harder to see obstacles.

- Mud-covered lights reduce visibility during night work or bad weather.

- Wipe down my windows and lights regularly to ensure a clear view and safe operation.

What You Learned from Ignoring Tractor Cleaning?

One season, I neglected cleaning my radiator screens after working in dry, dusty conditions. Over time, dust built up, and my tractor started overheating. By the time I realized the issue, I had to flush the entire cooling system and replace a worn-out fan belt. That could have been avoided with just a few minutes of regular cleaning.

Simple Cleaning Routine for a Reliable Tractor

- Remove dirt and debris after every use to prevent buildup.

- Wash radiator screens weekly to maintain proper cooling.

- Protect metal parts with rust inhibitors to prevent long-term damage.

- Keep lights, windows, and mirrors clean to ensure visibility and safety.

By keeping my tractor clean, you canprevent breakdowns, improve efficiency, and extend its lifespan—saving time and money in the long run.

Keeping a tractor clean improves performance and prevents mechanical issues.True

Regular cleaning removes dirt, debris, and crop residue, preventing overheating, rust, and clogging of critical components.

A dirty tractor has no impact on its efficiency or longevity.False

Mud, dust, and debris can clog the radiator, slow the hydraulic system, and cause rust, leading to reduced performance and costly repairs.

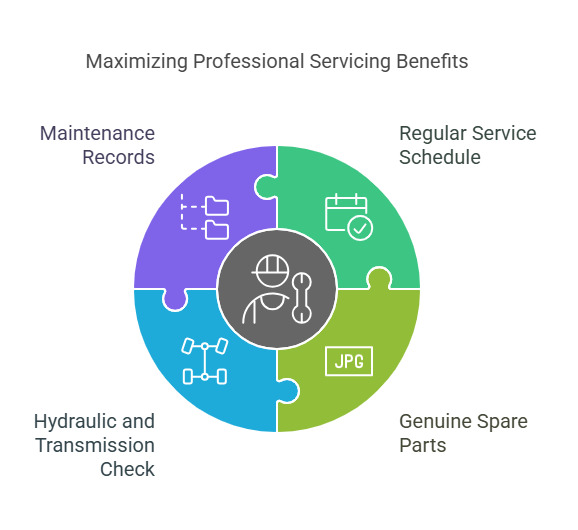

10. Schedule Professional Servicing

I can handle daily maintenance, but I’ve learned that some problems require an expert’s touch. I once ignored a small hydraulic leak, thinking I could fix it later. A few weeks passed, and suddenly, my loader wouldn’t lift properly. By the time I took it to a professional, the damage had worsened, costing me more in repairs than if I had addressed it earlier.

Regular professional servicing ensures that complex issues—like hydraulic system checks, belt replacements35, and in-depth diagnostics—are handled before they become major problems. Certified mechanics have the tools and expertise to spot hidden wear and tear that I might miss.

What Are the Benefits of Professional Servicing?

| Benefit | Why It’s Important |

|---|---|

| Early Problem Detection | Mechanics can spot issues I may not notice. |

| Hydraulic & Engine Tune-ups | Prevents power loss, leaks, and overheating. |

| Belt & Hose Replacement | Avoids sudden failures during critical farm work. |

| Brake & Transmission Checks | Ensures safe and smooth operation. |

| Software & Electrical Diagnostics | Modern tractors need computerized testing to detect errors. |

How to Make the Most of Professional Servicing?

1. Stick to a Regular Service Schedule36

- Schedule a full tractor check-up at least once a year, or before planting and harvest seasons.

- If notice unusual noises, leaks, or performance drops, book a service appointment immediately.

2. Use Only Genuine Spare Parts37

- Cheap, low-quality parts can cause more harm than good.

- Always ask for manufacturer-approved parts to maintain reliability and performance.

3. Get a Full Hydraulic and Transmission Check38

- Professionals can test hydraulic pressure and detect leaks that you might not see.

- Transmission inspections help prevent slipping gears and ensure smooth shifting.

4. Keep Records of All Maintenance Work

- Track all servicing and repairs to monitor wear patterns over time.

- Keeping records helps plan for part replacements and resale value.

What Happens If Skip Professional Servicing?

A friend of mine once ignored professional servicing, thinking he could handle everything himself. One day, his tractor’s hydraulic system failed while lifting a heavy load. What could have been a simple hydraulic seal replacement turned into a full system overhaul, costing him weeks of downtime and thousands in repairs.

| Problem | Cause | Consequence |

|---|---|---|

| Unexpected Hydraulic Failures | Undetected leaks or pressure loss. | Loss of lifting power and costly repairs. |

| Transmission Breakdown | Worn-out gears or low transmission fluid. | Expensive component replacements. |

| Brake Failure | Worn-out brake pads or hydraulic issues. | Dangerous working conditions. |

Simple Professional Servicing Plan

- Schedule servicing at least once a year to check critical systems.

- Use certified mechanics39 for in-depth inspections and adjustments.

- Always request genuine parts to maintain performance and safety.

- Keep maintenance records40 to track repairs and plan for future servicing.

By scheduling professional servicing, you can avoid costly repairs, improve tractor’s efficiency, and ensure it’s always ready for heavy-duty work.

Regular professional servicing helps prevent major tractor breakdowns and costly repairs.True

Trained mechanics can detect hidden issues, perform hydraulic and transmission checks, and replace worn-out parts before they cause serious damage.

Tractors do not require professional servicing as long as basic maintenance is performed.False

Some issues, like hydraulic leaks and transmission problems, require specialized tools and expertise that regular maintenance may not address, leading to bigger failures if ignored.

Conclusion

Regular tractor maintenance reduces repair costs, extends lifespan, and improves efficiency. Following these tips ensures your tractor performs optimally year-round.

-

Exploring this link will provide insights into the critical role of the manufacturer’s manual in preventing costly repairs and ensuring your tractor operates efficiently. ↩

-

This link will explain how adhering to the maintenance schedules can prevent breakdowns and save on unnecessary repairs, keeping your tractor in top condition. ↩

-

This resource will show how the troubleshooting section can be a valuable tool for diagnosing and fixing tractor performance issues, saving time and money. ↩

-

Learn how to identify and repair hydraulic fluid leaks to prevent costly repairs and downtime, ensuring your tractor operates efficiently. ↩

-

Learn to identify early signs of oil leaks to prevent engine damage and save on expensive repairs. ↩

-

Understanding the importance of fluid maintenance can prevent overheating and mechanical failures, ensuring your tractor runs smoothly. ↩

-

Discover the key fluids necessary for tractor upkeep to ensure optimal performance and longevity of your equipment. ↩

-

Learn the correct techniques for checking tractor fluid levels to prevent damage and ensure optimal performance. ↩

-

Discover the optimal replacement intervals for tractor engine oil to maintain engine health and efficiency. ↩

-

Understand the significance of using the right fluids to avoid damage and ensure your tractor runs smoothly. ↩

-

Understanding the importance of scheduled maintenance can help prevent costly repairs and ensure your tractor operates efficiently. ↩

-

Using the right lubricants and filters is essential to avoid contamination and ensure the longevity of your tractor's engine. ↩

-

Understanding the impact of a clogged air filter can help you maintain your tractor's efficiency and prevent unnecessary fuel consumption. ↩

-

Regular filter replacement ensures your tractor operates at peak efficiency, saving fuel and reducing wear on engine components. ↩

-

Clean filters are crucial for protecting your tractor's engine and hydraulics from dirt and contaminants, ensuring optimal performance. ↩

-

Understanding the impact of airflow restriction can help you maintain optimal engine performance and prevent potential damage. ↩

-

Identifying signs of restricted fuel flow early can save you from costly repairs and ensure your engine runs smoothly. ↩

-

Discover the critical role of proper lubrication in preventing wear and extending the lifespan of tractor components. ↩

-

Explore the advantages of prolonging the life of tractor parts through effective maintenance practices. ↩

-

Understanding the importance of regular maintenance can prevent costly repairs and extend the lifespan of your tractor. ↩

-

Understanding the critical role of lubrication can save you from costly repairs and extend the lifespan of your machinery. ↩

-

High-quality grease can significantly reduce wear and tear, ensuring your machinery operates smoothly for longer periods. ↩

-

Understanding engine strain helps in maintaining tractor health and preventing costly repairs, ensuring long-term efficiency. ↩

-

Preventing transmission failure is crucial for uninterrupted farming operations and avoiding expensive downtime. ↩

-

Knowing the causes of hydraulic system breakdowns can help in implementing preventive measures, saving time and money. ↩

-

Learning about the effects of extreme temperatures on tractor batteries can help you take preventive measures to extend battery life. ↩

-

Understanding the importance of a well-maintained battery can help prevent tractor failures and ensure reliable starts, saving time and money. ↩

-

Learn how a trickle charger can extend your battery's life by maintaining optimal charge levels during inactivity. ↩

-

Learn effective strategies to shield your tractor from winter's harsh conditions, preventing rust and ensuring it's ready for spring. ↩

-

Discover the critical role of seasonal maintenance in ensuring your tractor's reliability and longevity, especially during peak farming seasons. ↩

-

Learn the best practices to protect your tractor's cooling system from winter damage, ensuring longevity and reliability. ↩

-

Explore proven techniques to shield your tractor from rust, preserving its condition and value over time. ↩

-

Discover how regular cleaning can enhance your tractor's performance and prevent common issues like engine overheating. ↩ ↩

-

Find out how a simple cleaning routine can protect your tractor from rust and extend its lifespan. ↩ ↩

-

Regular belt replacements are crucial for maintaining machinery performance and preventing unexpected failures. ↩

-

Understanding the importance of a regular service schedule can help prevent costly repairs and downtime, ensuring your tractor operates efficiently year-round. ↩

-

Using genuine spare parts ensures your tractor maintains its reliability and performance, avoiding the risks associated with low-quality alternatives. ↩

-

A professional hydraulic and transmission check can uncover hidden issues, preventing major failures and ensuring your tractor operates smoothly. ↩

-

Certified mechanics ensure your tractor is inspected and adjusted to the highest standards, preventing future issues. ↩

-

Maintenance records help track repairs and plan future servicing, ensuring your tractor remains in top condition. ↩